brake Lancia Delta 2010 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2010, Model line: Delta, Model: Lancia Delta 2010Pages: 276, PDF Size: 5.31 MB

Page 211 of 276

210IN AN EMERGENCY

38

38

38

–

38

38

38

38

38

38

38

38F42

F43

F44

F45

F46

F47

F48

F49

F50

F51

F52

F535

30

15

–

20

20

20

5

7.5

5/7.5 (*)

15

7.5

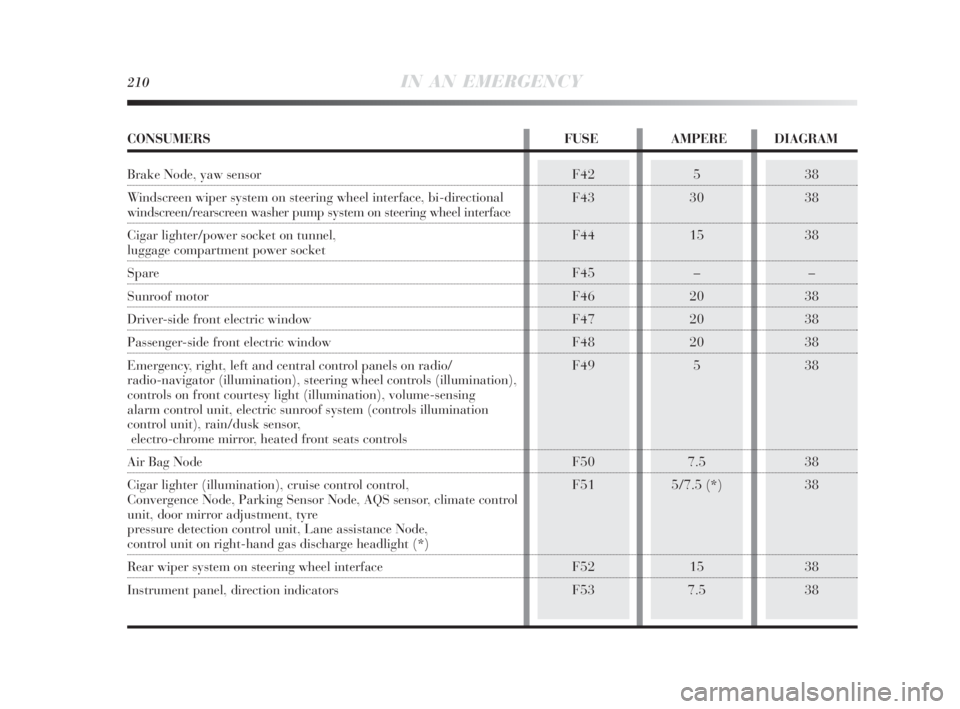

CONSUMERS FUSE AMPERE DIAGRAM

Brake Node, yaw sensor

Windscreen wiper system on steering wheel interface, bi-directional

windscreen/rearscreen washer pump system on steering wheel interface

Cigar lighter/power socket on tunnel,

luggage compartment power socket

Spare

Sunroof motor

Driver-side front electric window

Passenger-side front electric window

Emergency, right, left and central control panels on radio/

radio-navigator (illumination), steering wheel controls (illumination),

controls on front courtesy light (illumination), volume-sensing

alarm control unit, electric sunroof system (controls illumination

control unit), rain/dusk sensor,

electro-chrome mirror, heated front seats controls

Air Bag Node

Cigar lighter (illumination), cruise control control,

Convergence Node, Parking Sensor Node, AQS sensor, climate control

unit, door mirror adjustment, tyre

pressure detection control unit, Lane assistance Node,

control unit on right-hand gas discharge headlight (*)

Rear wiper system on steering wheel interface

Instrument panel, direction indicators

175-214 Delta 4ed gb 24-02-2010 14:36 Pagina 210

Page 212 of 276

IN AN EMERGENCY211

4

–

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40F08

F09

F10

F11

F14

F15

F16

F17

F18

F19

F22

F22

F23

F24

F30

F85–

20

10

10

15

30

7.5

10

7.5

7.5

15

20

20

5

15

15

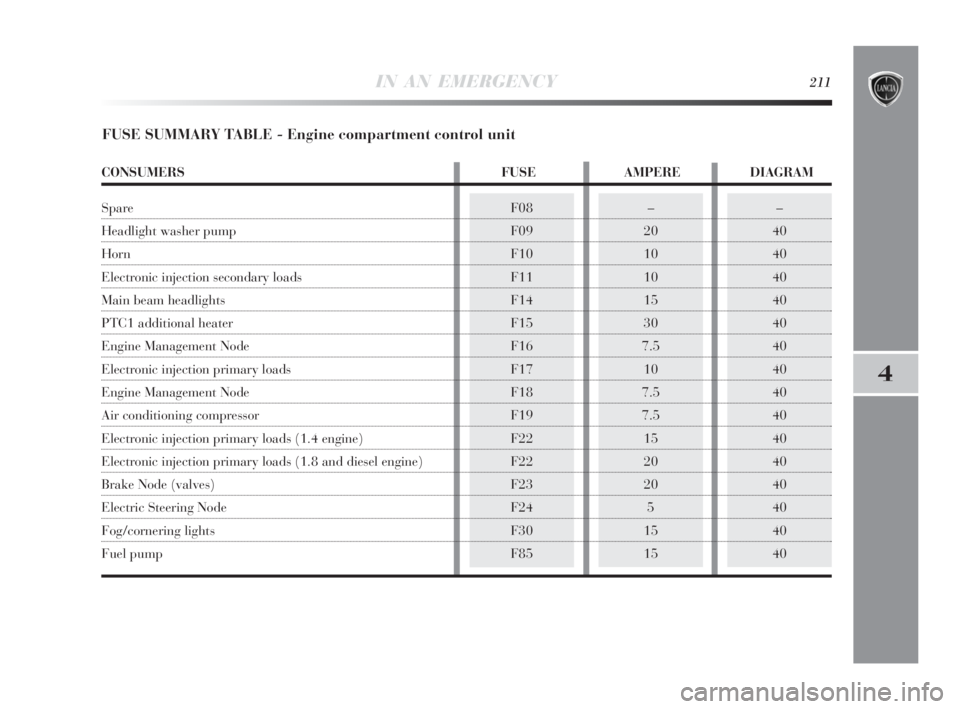

FUSE SUMMARY TABLE - Engine compartment control unit

CONSUMERS FUSE AMPERE DIAGRAM

Spare

Headlight washer pump

Horn

Electronic injection secondary loads

Main beam headlights

PTC1 additional heater

Engine Management Node

Electronic injection primary loads

Engine Management Node

Air conditioning compressor

Electronic injection primary loads (1.4 engine)

Electronic injection primary loads (1.8 and diesel engine)

Brake Node (valves)

Electric Steering Node

Fog/cornering lights

Fuel pump

175-214 Delta 4ed gb 24-02-2010 14:36 Pagina 211

Page 215 of 276

214IN AN EMERGENCY

TOWING THE CAR

The tow ring provided with the car is housed in the tool

box under the luggage compartment mat.

FASTENING THE TOW RING fig. 43-44

Proceed as follows:

❍release cap A;

❍take the tow hook B from its seat in the tool support;

❍tighten the ring on the rear or front threaded pin.

fig. 43L0E0090mfig. 44L0E0091m

Before starting towing operations, turn the ig-

nition key to MAR and then to STOP, without

extracting it. If the key is extracted, the steer-

ing wheel lock will be automatically activated, thus

preventing steering. The power brakes and the elec-

trical power steering will not work while the car is be-

ing towed. More effort on the brake pedal and steer-

ing wheel will therefore be required. Do not use wires

for towing. Do not jerk. Make sure not to damage parts

in contact with the car while towing. Respect the spe-

cific rules of the Highway Code when towing the car

specifically in relation to the towing device and the be-

haviour to maintain on the road. Do not start the en-

gine while towing the car.

175-214 Delta 4ed gb 24-02-2010 14:36 Pagina 214

Page 218 of 276

CARE AND MAINTENANCE217

5

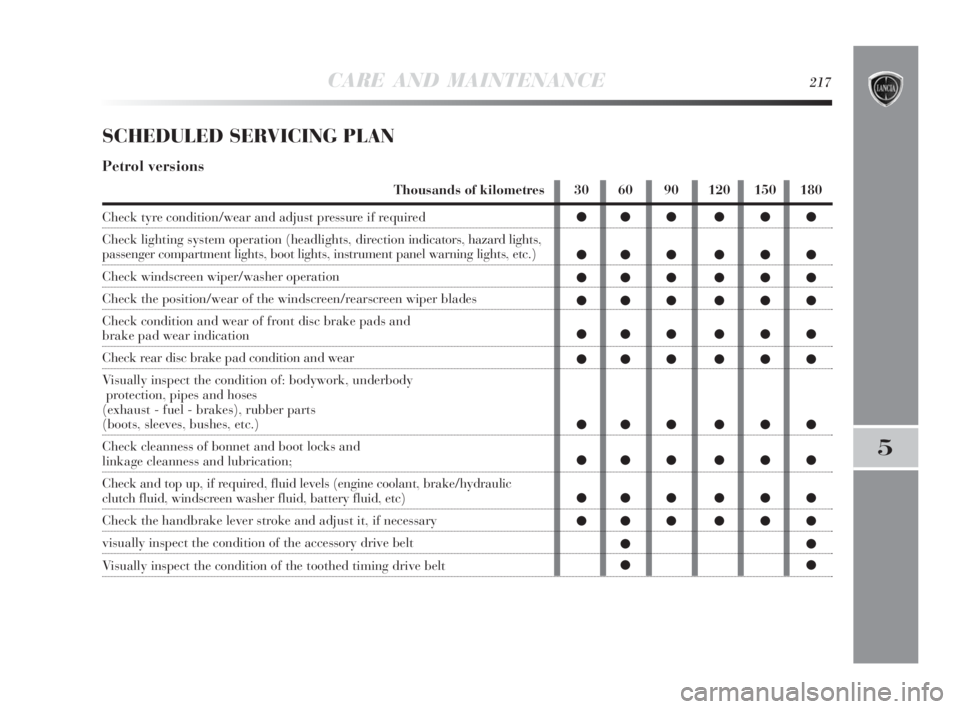

SCHEDULED SERVICING PLAN

Petrol versions

Thousands of kilometres

Check tyre condition/wear and adjust pressure if required

Check lighting system operation (headlights, direction indicators, hazard lights,

passenger compartment lights, boot lights, instrument panel warning lights, etc.)

Check windscreen wiper/washer operation

Check the position/wear of the windscreen/rearscreen wiper blades

Check condition and wear of front disc brake pads and

brake pad wear indication

Check rear disc brake pad condition and wear

Visually inspect the condition of: bodywork, underbody

protection, pipes and hoses

(exhaust - fuel - brakes), rubber parts

(boots, sleeves, bushes, etc.)

Check cleanness of bonnet and boot locks and

linkage cleanness and lubrication;

Check and top up, if required, fluid levels (engine coolant, brake/hydraulic

clutch fluid, windscreen washer fluid, battery fluid, etc)

Check the handbrake lever stroke and adjust it, if necessary

visually inspect the condition of the accessory drive belt

Visually inspect the condition of the toothed timing drive belt30 60 90 120 150 180

●●● ●●●

●●● ●●●

●●● ●●●

●●● ●●●

●●● ●●●

●●● ●●●

●●● ●●●

●●● ●●●

●●● ●●●

●●● ●●●

●●

●●

215-242 Delta 3ed gb 11-11-2009 12:14 Pagina 217

Page 219 of 276

218CARE AND MAINTENANCE

30 60 90 120 150 180

●●● ●●●

●●

●●● ●●●

●

●

●●● ●●●

●●●

●●● ●●●

●●●

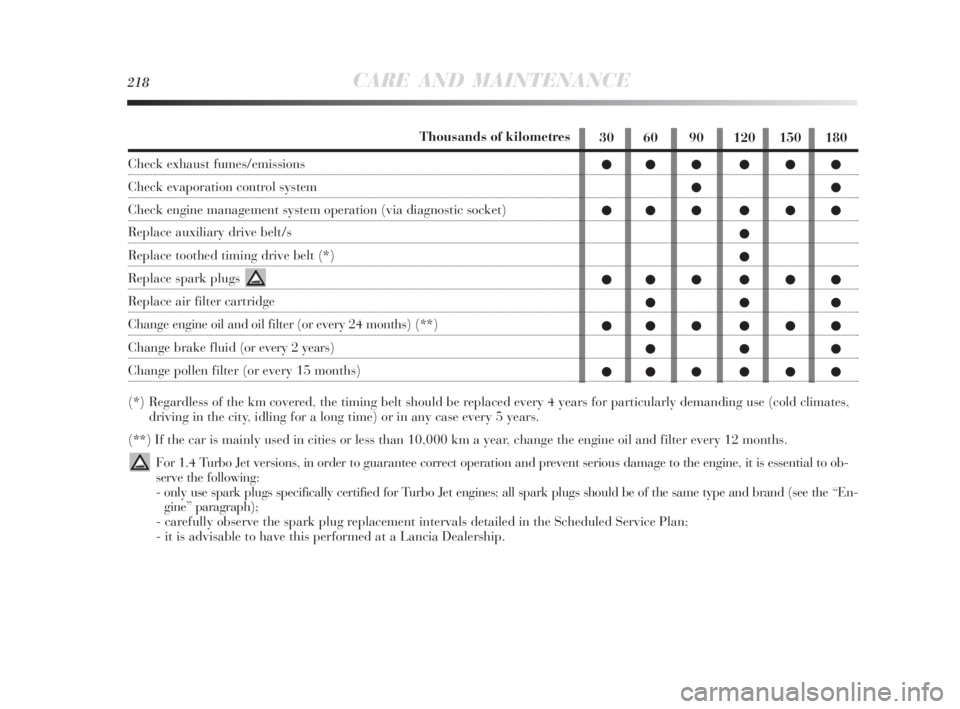

●●● ●●●Thousands of kilometres

Check exhaust fumes/emissions

Check evaporation control system

Check engine management system operation (via diagnostic socket)

Replace auxiliary drive belt/s

Replace toothed timing drive belt (*)

Replace spark plugs

Replace air filter cartridge

Change engine oil and oil filter (or every 24 months) (**)

Change brake fluid (or every 2 years)

Change pollen filter (or every 15 months)

(*) Regardless of the km covered, the timing belt should be replaced every 4 years for particularly demanding use (cold climates,

driving in the city, idling for a long time) or in any case every 5 years.

(**) If the car is mainly used in cities or less than 10,000 km a year, change the engine oil and filter every 12 months.

For 1.4 Turbo Jet versions, in order to guarantee correct operation and prevent serious damage to the engine, it is essential to ob-

serve the following:

- only use spark plugs specifically certified for Turbo Jet engines; all spark plugs should be of the same type and brand (see the “En-

gine” paragraph);

- carefully observe the spark plug replacement intervals detailed in the Scheduled Service Plan;

- it is advisable to have this performed at a Lancia Dealership.

215-242 Delta 3ed gb 11-11-2009 12:14 Pagina 218

Page 220 of 276

CARE AND MAINTENANCE219

5

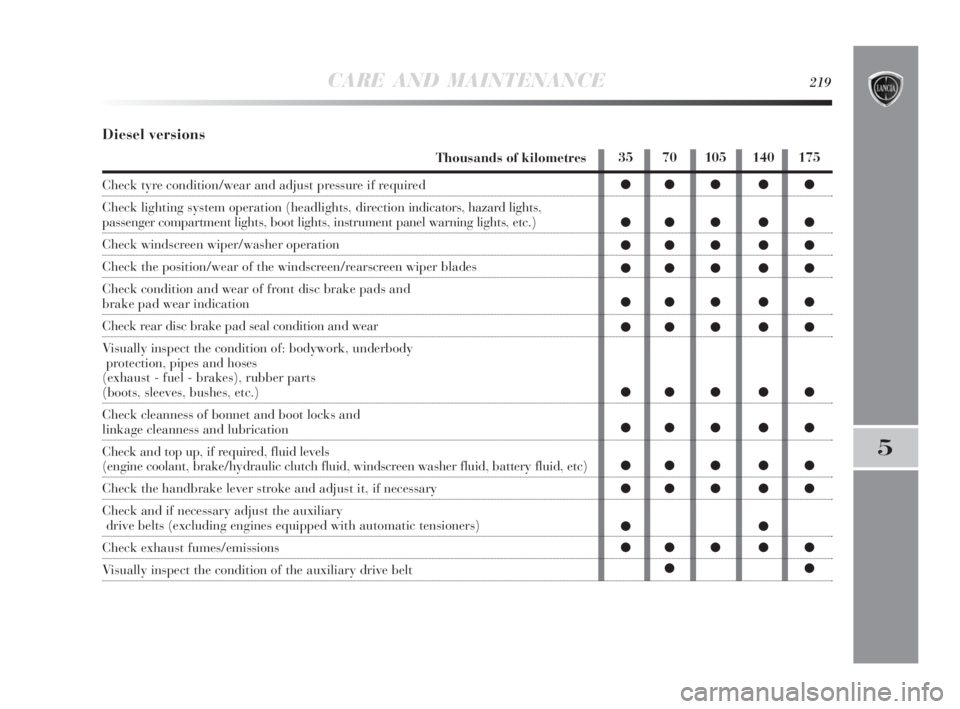

Diesel versions

Thousands of kilometres

Check tyre condition/wear and adjust pressure if required

Check lighting system operation (headlights, direction indicators, hazard lights,

passenger compartment lights, boot lights, instrument panel warning lights, etc.)

Check windscreen wiper/washer operation

Check the position/wear of the windscreen/rearscreen wiper blades

Check condition and wear of front disc brake pads and

brake pad wear indication

Check rear disc brake pad seal condition and wear

Visually inspect the condition of: bodywork, underbody

protection, pipes and hoses

(exhaust - fuel - brakes), rubber parts

(boots, sleeves, bushes, etc.)

Check cleanness of bonnet and boot locks and

linkage cleanness and lubrication

Check and top up, if required, fluid levels

(engine coolant, brake/hydraulic clutch fluid, windscreen washer fluid, battery fluid, etc)

Check the handbrake lever stroke and adjust it, if necessary

Check and if necessary adjust the auxiliary

drive belts (excluding engines equipped with automatic tensioners)

Check exhaust fumes/emissions

Visually inspect the condition of the auxiliary drive belt35 70 105 140 175

●● ● ● ●

●● ● ● ●

●● ● ● ●

●● ● ● ●

●● ● ● ●

●● ● ● ●

●● ● ● ●

●● ● ● ●

●● ● ● ●

●● ● ● ●

●●

●● ● ● ●

●●

215-242 Delta 3ed gb 11-11-2009 12:14 Pagina 219

Page 221 of 276

35 70 105 140 175

●● ● ● ●

●

●

●●

●●

●● ● ● ●

●●

●● ● ● ●

220CARE AND MAINTENANCE

Thousands of kilometres

Check engine management system operation (via diagnostic socket)

Replace auxiliary drive belt

Replace toothed timing drive belt (*)

Replace fuel filter

Replace air filter cartridge

Change engine oil and oil filter (versions without DPF) (or every 24 months)

Change engine oil and oil filter (versions with DPF) (**)

Change brake fluid (or every 24 months)

Change pollen filter (or every 15 months)

(*) Regardless of the km covered, the timing belt should be replaced every 4 years for particularly demanding use (cold climates,

driving in the city, idling for a long time) or in any case every 5 years.

(**) The engine oil and the filter must be changed when the instrument panel warning light comes on (see “Warning lights and

Messages” chapter) and in all cases every 2 years.

If the car is used mainly in towns the engine oil and filter need to be changed every 12 months.

215-242 Delta 3ed gb 11-11-2009 12:14 Pagina 220

Page 222 of 276

CARE AND MAINTENANCE221

5

REGULAR INSPECTIONS

Every 1,000 km or before long journeys, check and top

up if required:

❍engine coolant fluid level;

❍brake fluid level;

❍windscreen washer fluid level;

❍tyre pressure and condition;

❍operation of lights (headlights, direction indicators,

hazard lights, etc.);

❍operation of the windscreen wiper/washer system, po-

sition and wear of windscreen/rearscreen wiper blades.

Every 3,000 km check the following and top-up, if re-

quired: engine oil level.

You are recommended to use PETRONAS LUBRICANTS

products, designed and produced specifically for Lancia

cars (see table “Capacities” in chapter “6”).

DEMANDING USE OF THE CAR

If you use the vehicle mainly under one of the following

especially heavy conditions:

❍trailer or caravan towing;

❍dusty roads;

❍repetitive short distances (less than 7-8 km) with ex-

ternal temperatures below zero;

❍frequently idling the engine or long distances at low

speed driving (e.g. door-to-door deliveries) or long term

inactivity;

❍urban routes.

215-242 Delta 3ed gb 11-11-2009 12:14 Pagina 221

Page 223 of 276

222CARE AND MAINTENANCE

Perform the following inspections more frequently than

shown on the Scheduled Service Plan:

❍check front disc brake pad condition and wear;

❍check cleanness of bonnet and boot locks and linkage

cleanness and lubrication;

❍visually inspect the condition of: engine, gearbox,

transmission, pipes and hoses (exhaust – fuel supply

- brakes) rubber elements (gaiters – hoses - bushes

etc.);❍check battery charge and fluid level (electrolyte); (see

“Battery - Charge and electrolyte level check” in this

chapter);

❍visually inspect the condition of auxiliary drivebelts;

❍check and if necessary replace the pollen filter; in par-

ticular it should be replaced if a decrease in the air flow

into the passenger compartment is detected;

❍check the air filter and replace, if required.

215-242 Delta 3ed gb 11-11-2009 12:14 Pagina 222

Page 229 of 276

228CARE AND MAINTENANCE

The engine cooling system is pressurized. If

required, replace the cap with an original

spare part so as not to compromise system ef-

ficiency. Do not remove the cap from the vessel when

the engine is hot: risk of burns.

WINDSCREEN/REAR WINDOW

WASHER FLUID C-fig. 1-2-3

To add fluid, remove the cap, pressing the special tab.

Pour a mixture of water and TUTELA PROFESSIONAL

SC35, in the following concentrations:

30% TUTELA PROFESSIONAL SC35 and 70% water in

summer.

50% TUTELA PROFESSIONAL SC35 and 50% water in

winter.

At temperatures below –20°C, use undiluted TUTELA

PROFESSIONAL SC35 fluid.

Check the level through the reservoir.

Close the cap by pressing its central section.

Do not travel with the windscreen washing

reservoir empty: the windscreen washer is

fundamental to improve visibility.

Some commercial windscreen washer additives are

flammable. The engine compartment contains hot

parts which could start a fire if they come into con-

tact.

BRAKE FLUID D-fig. 1-2-3

Undo the cap and check that the liquid contained in the

tank is at the maximum level. Fluid level in the reservoir

must not exceed the MAX mark. Use the brake fluid shown

in the “Fluids and lubricants” table (see chapter “6”).

NOTE Carefully clean the reservoir cap and the sur-

rounding surface.

When opening the cap, make sure that no dirt gets into

the reservoir.

For topping up always use a funnel with built-in filter

(mesh smaller than or equal to 0.12 mm).

IMPORTANT Brake fluid is hygroscopic (i.e. it absorbs

moisture). For this reason, if the car is mainly used in ar-

eas with a high degree of atmospheric humidity, the flu-

id should be replaced at more frequent intervals than spec-

ified in the “Scheduled Service Plan”.

215-242 Delta 3ed gb 11-11-2009 12:14 Pagina 228