LAND ROVER DEFENDER 1999 Workshop Manual

DEFENDER 1999

LAND ROVER

LAND ROVER

https://www.carmanualsonline.info/img/64/57244/w960_57244-0.png

LAND ROVER DEFENDER 1999 Workshop Manual

Trending: service indicator, fuel type, mirror, transmission, gas type, set clock, coolant temperature

Page 511 of 667

77PANEL REPAIRS

2

INFORMATION Straightening

Whenever possible, chassis structural members

should be cold straightened under tension. Do not

attempt to straighten with a single pull, but rework the

damaged area using a series of pulls, releasing

tension between each stage and using the opportunity

to check alignment.

Body jig

Unless damage is limited to cosmetic panels, all repair

work to body members must be carried out on a body

jig, to ensure that impact damage has not spread into

more remote parts of the body structure. Mounting on

a jig will also ensure that the straightening and panel

replacement procedures do not cause further

distortion. If original dimensions cannot be

satisfactorily restored by these methods, damaged

structural members should be replaced. Damaged

areas should be cut away using a high speed saw,

NOT an oxy-acetylene torch.

As a rule, body dimensions are symmetrical about the

centre line. A good initial check for distortion is

therefore to measure diagonally and to investigate

apparent differences in dimensions.Inspection

Every accident produces individual differences in

damage. Each repair is influenced by the extent of the

damage and by the facilities and equipment available

for its rectification.

Most accident damage can be visually inspected and

the approximate extent of the damage assessed.

Sometimes deformation will extend beyond the area

of direct damage, and the severity of this must be

accurately established so that steps may be taken to

restore critical body components to their original

dimensions.

An initial check of critical dimensions can be carried

out by means of drop checks or (preferably) trammels.

Gauges are available which will check accurately for

body twist. Where repairs necessitate renewal of a

critical body component it is recommended that a

body jig is used.

ProCarManuals.com

Page 512 of 667

PANEL REPAIRS

3

INFORMATION ELECTRONIC CONTROL UNITS (ECU’s)

The ECU’s fitted to Defender vehicles make it

advisable to follow suitable precautions prior to

carrying out welding repair operations. All ECU’s must

be diconnected before any welding operations take

place. Harsh conditions of heat and vibration may be

generated during these operations which could cause

damage to the units.See ELECTRICAL

PRECAUTIONS section.

ProCarManuals.com

Page 513 of 667

Page 514 of 667

PANEL REPAIRS

1

BODY DIMENSIONS CHASSIS AND BODY

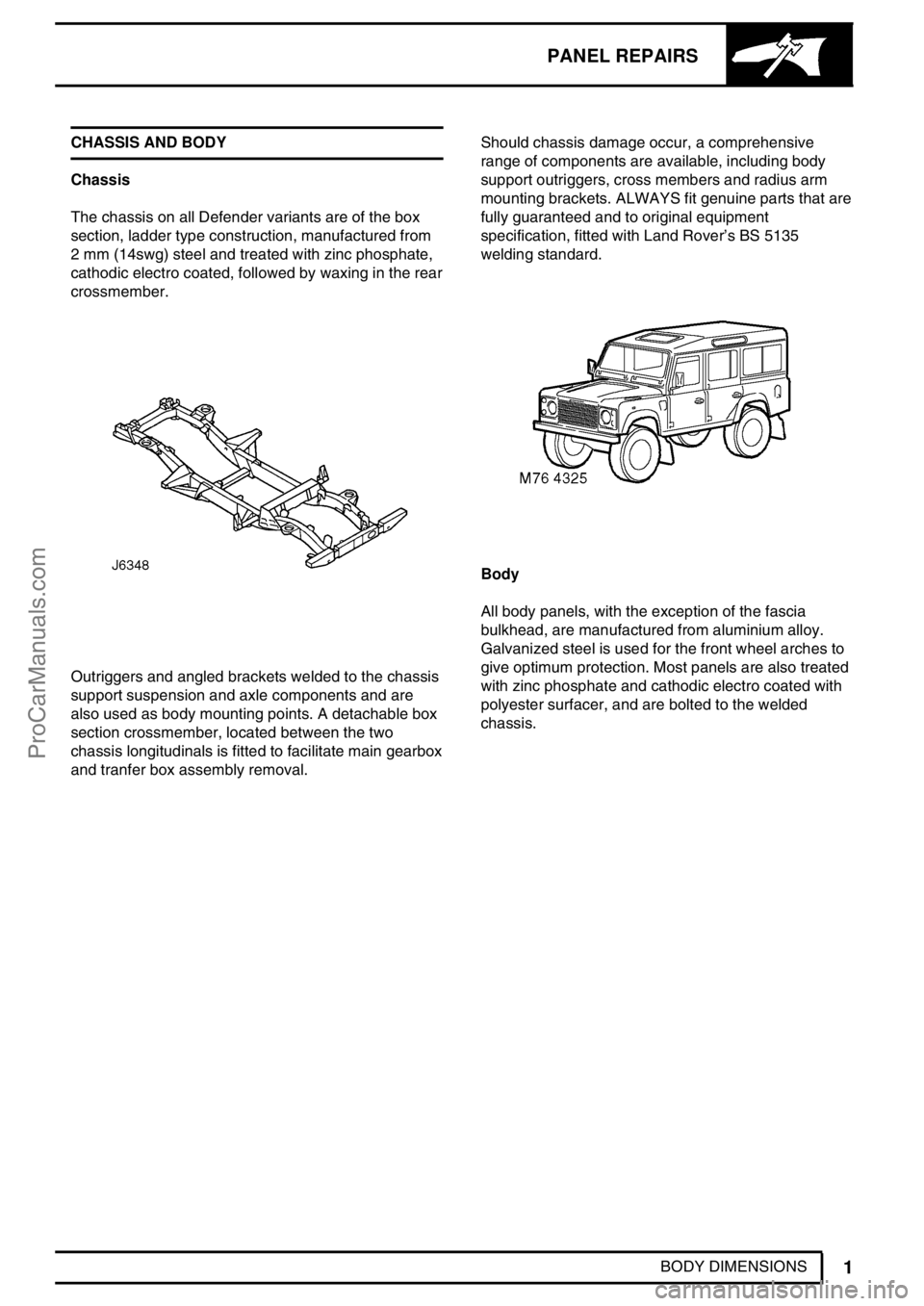

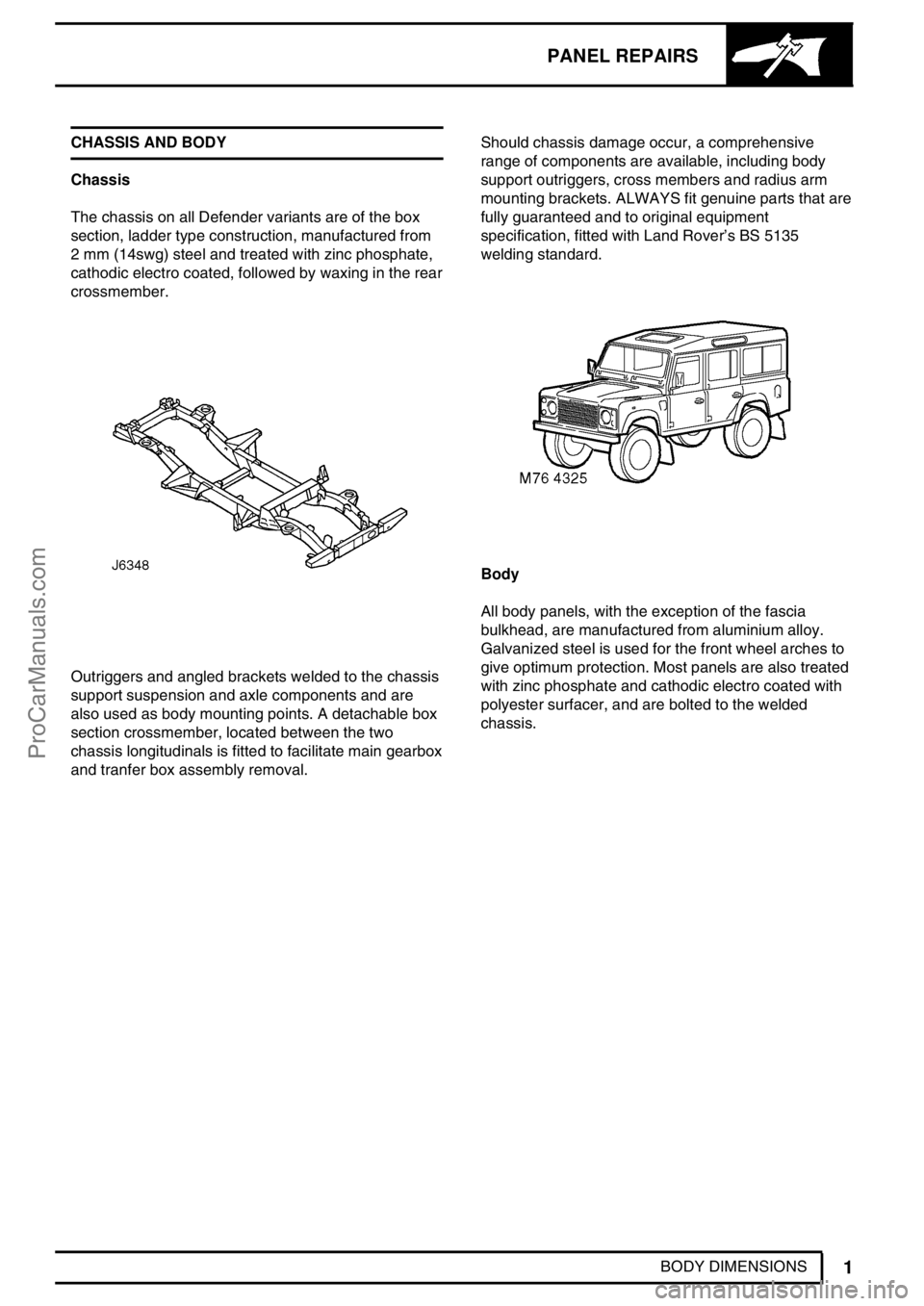

Chassis

The chassis on all Defender variants are of the box

section, ladder type construction, manufactured from

2 mm (14swg) steel and treated with zinc phosphate,

cathodic electro coated, followed by waxing in the rear

crossmember.

Outriggers and angled brackets welded to the chassis

support suspension and axle components and are

also used as body mounting points. A detachable box

section crossmember, located between the two

chassis longitudinals is fitted to facilitate main gearbox

and tranfer box assembly removal.Should chassis damage occur, a comprehensive

range of components are available, including body

support outriggers, cross members and radius arm

mounting brackets. ALWAYS fit genuine parts that are

fully guaranteed and to original equipment

specification, fitted with Land Rover’s BS 5135

welding standard.

Body

All body panels, with the exception of the fascia

bulkhead, are manufactured from aluminium alloy.

Galvanized steel is used for the front wheel arches to

give optimum protection. Most panels are also treated

with zinc phosphate and cathodic electro coated with

polyester surfacer, and are bolted to the welded

chassis.

ProCarManuals.com

Page 515 of 667

77PANEL REPAIRS

2

BODY DIMENSIONS CHASSIS FRAME ALIGNMENT

With the vehicle assembled, a check for chassis

squareness can be made as follows:

1.Place the vehicle on a level floor.

2.Mark measuring points at approximately the

locations shown in LR4412M ensuring that the

marks are exactly opposite on each side of the

chassis frame.3.Hold a plumb line against each of the measuring

points in turn and mark the floor directly beneath

the plumb-bob.

4.Move the vehicle and measure diagonally

between the marks made on the floor, if the

chassis is square the diagonals between the

related measuring points should be within 9,50

mm.

5.Chassis frame dimensional checks can be

made, with the vehicle upper structure removed,

referring to the applicable illustration and

associated key.

ProCarManuals.com

Page 516 of 667

PANEL REPAIRS

3

BODY DIMENSIONS LAND ROVER 90 CHASSIS

ProCarManuals.com

Page 517 of 667

77PANEL REPAIRS

4

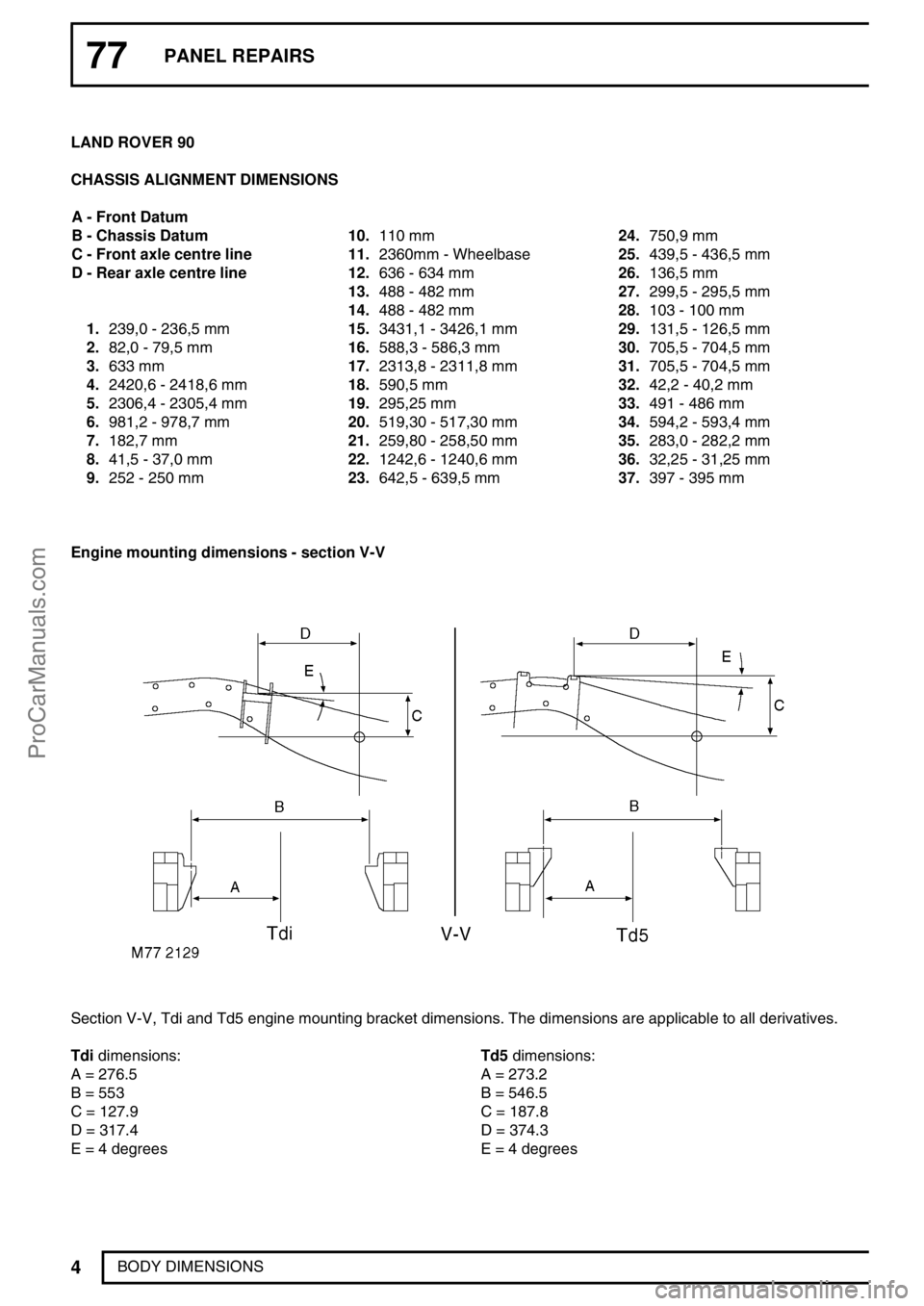

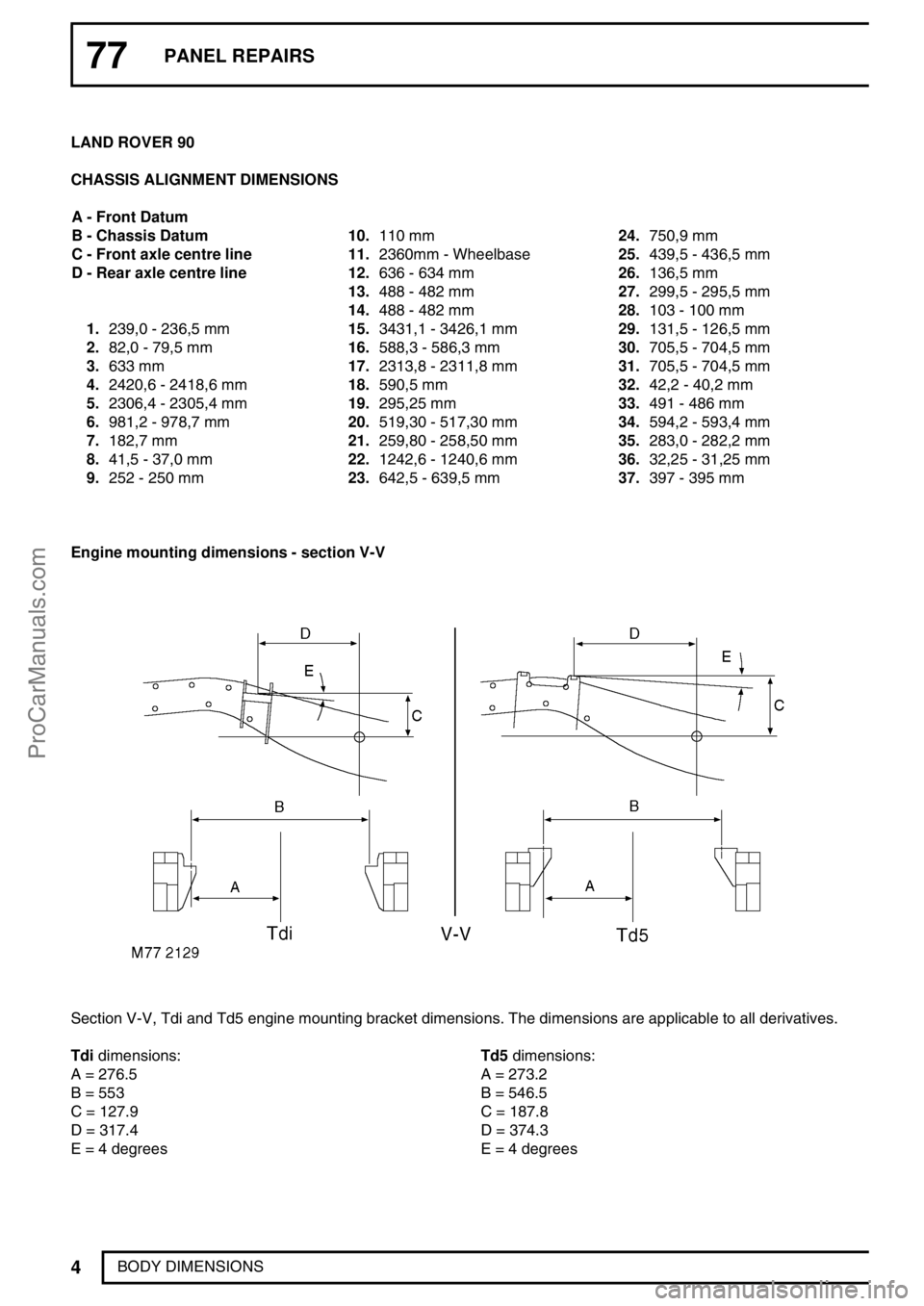

BODY DIMENSIONS LAND ROVER 90

CHASSIS ALIGNMENT DIMENSIONS

A - Front Datum

B - Chassis Datum

C - Front axle centre line

D - Rear axle centre line

1.239,0 - 236,5 mm

2.82,0 - 79,5 mm

3.633 mm

4.2420,6 - 2418,6 mm

5.2306,4 - 2305,4 mm

6.981,2 - 978,7 mm

7.182,7 mm

8.41,5 - 37,0 mm

9.252 - 250 mm10.110 mm

11.2360mm - Wheelbase

12.636 - 634 mm

13.488 - 482 mm

14.488 - 482 mm

15.3431,1 - 3426,1 mm

16.588,3 - 586,3 mm

17.2313,8 - 2311,8 mm

18.590,5 mm

19.295,25 mm

20.519,30 - 517,30 mm

21.259,80 - 258,50 mm

22.1242,6 - 1240,6 mm

23.642,5 - 639,5 mm24.750,9 mm

25.439,5 - 436,5 mm

26.136,5 mm

27.299,5 - 295,5 mm

28.103 - 100 mm

29.131,5 - 126,5 mm

30.705,5 - 704,5 mm

31.705,5 - 704,5 mm

32.42,2 - 40,2 mm

33.491 - 486 mm

34.594,2 - 593,4 mm

35.283,0 - 282,2 mm

36.32,25 - 31,25 mm

37.397 - 395 mm

Engine mounting dimensions - section V-V

Section V-V, Tdi and Td5 engine mounting bracket dimensions. The dimensions are applicable to all derivatives.

Tdidimensions:

A = 276.5

B = 553

C = 127.9

D = 317.4

E = 4 degreesTd5dimensions:

A = 273.2

B = 546.5

C = 187.8

D = 374.3

E = 4 degrees

ProCarManuals.com

Page 518 of 667

PANEL REPAIRS

5

BODY DIMENSIONS LAND ROVER 110

ProCarManuals.com

Page 519 of 667

77PANEL REPAIRS

6

BODY DIMENSIONS LAND ROVER 110

CHASSIS ALIGNMENT DIMENSIONS

A - Front Datum

B - Chassis Datum

C - Front axle centre line

D - Rear axle centre line

1.4148 - 4143 mm

2.4009,5 - 4005 mm

3.978,7 - 981,2 mm

4.22 - 20 mm

5.252 - 250 mm

6.239 - 236,5 mm

7.3023,3 - 3022,3 mm

8.3030,7 - 3028,7 mm

9.155 - 153 mm

10.871,2 - 869,2 mm

11.2794 mm - Wheelbase

12.488 - 482 mm13.488 - 482 mm

14.82 - 79,5 mm

15.750,9 mm

16.750,9 mm

17.440,5 - 435,5 mm

18.440,5 - 435,5 mm

19.299,5 - 295,5 mm

20.500 - 495 mm

21.500 - 495 mm

22.594,2 - 593,4 mm

23.594,2 - 593,4 mm

24.283 - 282,2 mm

25.283 - 282,2 mm

26.1970 - 1968 mm

27.642,9 - 639,5 mm

28.750,9 mm29.290,5 mm

30.295,5 mm

31.299,5 - 295,5 mm

32.103 - 100 mm

33.1177,5 - 1175,5 mm

34.1692,5 - 1689,5 mm

35.2610 - 2606 mm

36.2040,5 - 2037,5 mm

37.1912,5 - 1909,5 mm

38.1359 - 1357 mm

39.1573 - 1571 mm

40.270 - 268 mm

41.665,5 - 663,5 mm

42.440 - 438 mm

43.32,25 - 31,25 mm

Section V-V is through the engine mountings. Dimensional information for the mountings can be found in Land

Rover’90’engine mounting dimensions.

ProCarManuals.com

Page 520 of 667

PANEL REPAIRS

7

BODY DIMENSIONS LAND ROVER 130

ProCarManuals.com

Trending: reset, half shaft, alternator belt, auxiliary battery, warning light, tire size, length