ECU LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 895 of 1672

STEERING

57-8 DESCRIPTION AND OPERATION

Steering box

The steering box is located behind the first cross member of the chassis and is secured to the chassis rail with four

bolts. The steering box is of the worm and roller type and has a rotary control valve. The steering box is connected to

the steering knuckles of the front road wheels by the drop arm, drag link and track rod. The steering box is lubricated

by the hydraulic fluid in the housing. The input shaft is attached to the steering wheel via the intermediate shaft and

steering column. The drop arm is secured to the output shaft with a nut and tab washer. A ball joint allows movement

between drop arm and drag link, the ball joint is secured with a locknut. The steering box requries approximately 3.5

turns from lock to lock.

As a maintenance aid, an alignment bolt can be used to lock the drop arm at the steering box centre position. The bolt

fits in a groove in the rear face of the drop arm and screws in to a threaded hole on the bottom of the steering box

housing.

Cross section through steering box

1Relief valve stop 2 off

2Relief valve 2 off

3Piston

4Rack

5Housing

6Output shaft

7Roller

8Valve rotor9Torsion bar

10Input shaft

11Pin

12Valve sleeve

13Course spline

14Worm gear

15Spline (worm gear to torsion bar)

Page 899 of 1672

STEERING

57-12 DESCRIPTION AND OPERATION

PAS pump - V8

1Bolt 2 off

2Nut

3Stud

4Auxiliary housing

5PAS pump6Outlet

7Inlet

8Bolt 3 off

9Drive pulley

The PAS pump is located on the auxiliary housing and is attached by two bolts, the bolts go through flanged bushes

in the auxiliary housing. A stud passes through the PAS pump and through a flanged bush in the auxiliary housing,

the auxiliary housing and PAS pump are secured by a nut. As the two bolts and nut are tightened the bushes move

slightly and the flange of each bush clamps the PAS pump. A drive pulley is attached to the pump drive shaft with

three bolts, and is belt driven at a ratio of 1.4 crankshaft revolutions to 1 of the drive pulley. Fluid is drawn into the

PAS pump inlet from the reservoir through a flexible hose at low (suction) pressure. Fluid at high pressure from the

PAS pump outlet is supplied to the rotary control valve on the steering box.

Page 901 of 1672

STEERING

57-14 DESCRIPTION AND OPERATION

The PAS pump is located on the auxiliary housing, two bolts go through the PAS pump, mounting bracket and into

the auxiliary housing. One bolt also attaches the mounting bracket to the PAS pump, two bolts secure the mounting

bracket to the auxiliary housing. An inlet adaptor pipe with a seal is secured to the bottom of the pump with two bolts.

A drive pulley is attached to the pump drive shaft with three bolts, and is belt driven at a ratio of 1.35 crankshaft

revolutions to 1 of the drive pulley. A coupling on the rear of the PAS pump rotates the water pump impeller located

in the auxiliary housing. Fluid is supplied to the PAS pump inlet from the reservoir through a flexible hose at low

(suction) pressure. Fluid at high pressure from the PAS pump outlet is supplied to the rotary control valve on the

steering box.

The PAS pump is a roller vane type and has an internal pressure regulator and flow control valve. The roller vanes

can move in slots in the pumps rotor and are moved outwards by centrifugal force as the pump rotates. The pump

rotor rotates in the pump housing, the internal shape of the housing forms a 'cam' shape. Due to the 'cam' shape the

volume of the housing decreases between the inlet and outlet ports.

As the pump rotor rotates towards the pump inlet the volume between the roller vanes and the pump housing

increases, this action causes a depression in the chamber between the pump roller vanes and the housing. As the

rotation continues the chamber is opened to the pump inlet, and the depression in the chamber causes fluid to be

drawn in. The roller vanes continue past the inlet port, closing off the inlet port and trapping the fluid in the chamber

between the rollers and the pump housing.

The internal 'cam' shape of the pump housing causes the rollers to move closer together as the pump rotor rotates

towards the outlet port. The reduced volume of the chamber between the roller vanes causes the fluid to become

pressurised. When the chamber is opened to the outlet port of the pump the fluid escapes at high pressure. The roller

vanes continue turning and go past the outlet port, closing off the chamber between the two roller vanes.

As rotation continues the inlet sequence begins again. The inlet and pressurisation/outlet sequences continue as the

pump rotates, and is repeated between each two roller vanes. The pump is a positive displacement type and the

potential pump output increases with engine (drive pulley) speed. The pressure relief and flow control valve regulates

flow/pressure by diverting fluid back to the pump inlet through internal recirculation passages in the pump body.

Steering damper

The steering damper is located behind and just below the first cross member of the chassis. The ends of the steering

damper have steel 'eyes' welded on, rubber bushes are installed in each 'eye'. The steering damper is attached

between brackets on the chassis rail and the drag link. Each end of the steering damper is secured by a bolt and

locknut. The hydraulic damper absorbs shocks in the steering, caused by road wheel deflections when operating on

rough terrain.

Page 904 of 1672

STEERING

ADJUSTMENTS 57-17

ADJUST ME NTS

Steering box - check and adjust

$% 57.10.13

Check

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove nut securing drag link to drop arm.

3.Using LRT-57-036, break taper joint and

release drag link.

4.Ensure steering is centralised.

5.With the drop arm held, check for rotational

movement at the intermediate shaft universal

joint. If any movement exists, the steering box

requires adjusting.Adjust

1.Loosen lock nut on steering box adjuster and

tighten adjuster until movement is removed at

universal joint.

CAUTION: Ensure that steering box is

centralised before adjustment. Never over

adjust, free play should just be eliminated.

2.When adjustment is correct, hold the adjuster

and tighten adjuster locknut.

3.Turn steering wheel from lock to lock and check

no tightness exists.

4.Fit drag link to drop arm, and tighten nut to 80

Nm (59 lbf.ft).

5.Remove stands and lower vehicle.

Page 905 of 1672

STEERING

57-18 ADJUSTMENTS

Hydraulic system - bleed

$% 57.15.02

Bleed

1.Clean PAS fluid reservoir around filler cap and

fluid level indicators.

2.Remove filler cap from PAS fluid reservoir. If

necessary, fill PAS fluid reservoir to upper level

indicator with recommended fluid.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Fluids.

CAUTION: Ensure no dirt is allowed to enter

the steering reservoir when the cap is

removed.

3.Start engine and run to normal operating

temperature.

4.Position container to catch fluid spillage from

steering box.

5.With engine at idle speed, and an assistant

turning the steering from lock to lock, loosen

bleed screw on top of steering box. Keep PAS

fluid reservoir topped up and allow all air to

bleed from system. When fluid from bleed

screw is free of air, tighten bleed screw.

CAUTION: Do not hold steering at full lock

for longer than 10 seconds.

6.Stop engine.

7.Clean spilled PAS fluid from steering box and

surrounding area.

CAUTION: Power steering fluid will damage

paint finished surfaces. If spilled,

immediately remove fluid and clean area

with water.

8.Check fluid level in PAS fluid reservoir and fill to

upper level mark. If fluid is aerated, wait until

fluid is free from bubbles.

9.Fit PAS fluid reservoir filler cap.

Steering linkage - centralise

$% 57.35.05

The following procedure assumes that the front

wheel alignment is correctly adjusted.

Adjust

1.Raise front of vehicle, and position the road

wheels at straight ahead.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove nut securing drag link to drop arm.

Using tool LRT-57-036 break taper joint and

release drag link from drop arm.

3.Fit centralising bolt to steering box and ensure

that front road wheels are in the straight ahead

position.

4.Loosen clamp bolts on drag link.

Page 909 of 1672

STEERING

57-22 ADJUSTMENTS

38.Fit new seal, connect PAS cooler pipe and

tighten union nut to 24 Nm (18 lbf ft).

39. LHD only: Fit turbocharger intercooler feed

pipe and vacuum connection. Fit new seal to air

cleaner. Connect air intake hose and secure

clips. Connect multiplug to MAF sensor.

40.Clean chassis and surrounding area.

41.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

42.Remove adaptor and hose set from tool LRT-

57-041.

43.Check PAS fluid level.

44.Connect battery earth lead.

Power steering pressure check - V8 LHD

models

$% 57.90.10.01

Check

1.Disconnect battery earth lead.

2.Syphon PAS fluid from reservoir.

3.Raise front of vehicle and support on stands.

4.Turn steering on LH lock.

5.Remove 3 screws securing LH splash shield

and remove shield.

6.Release clip securing PAS pipes.

7.Position absorbent cloth to catch spillage.

8.Position container to collect PAS fluid spillage.

Page 910 of 1672

STEERING

ADJUSTMENTS 57-23

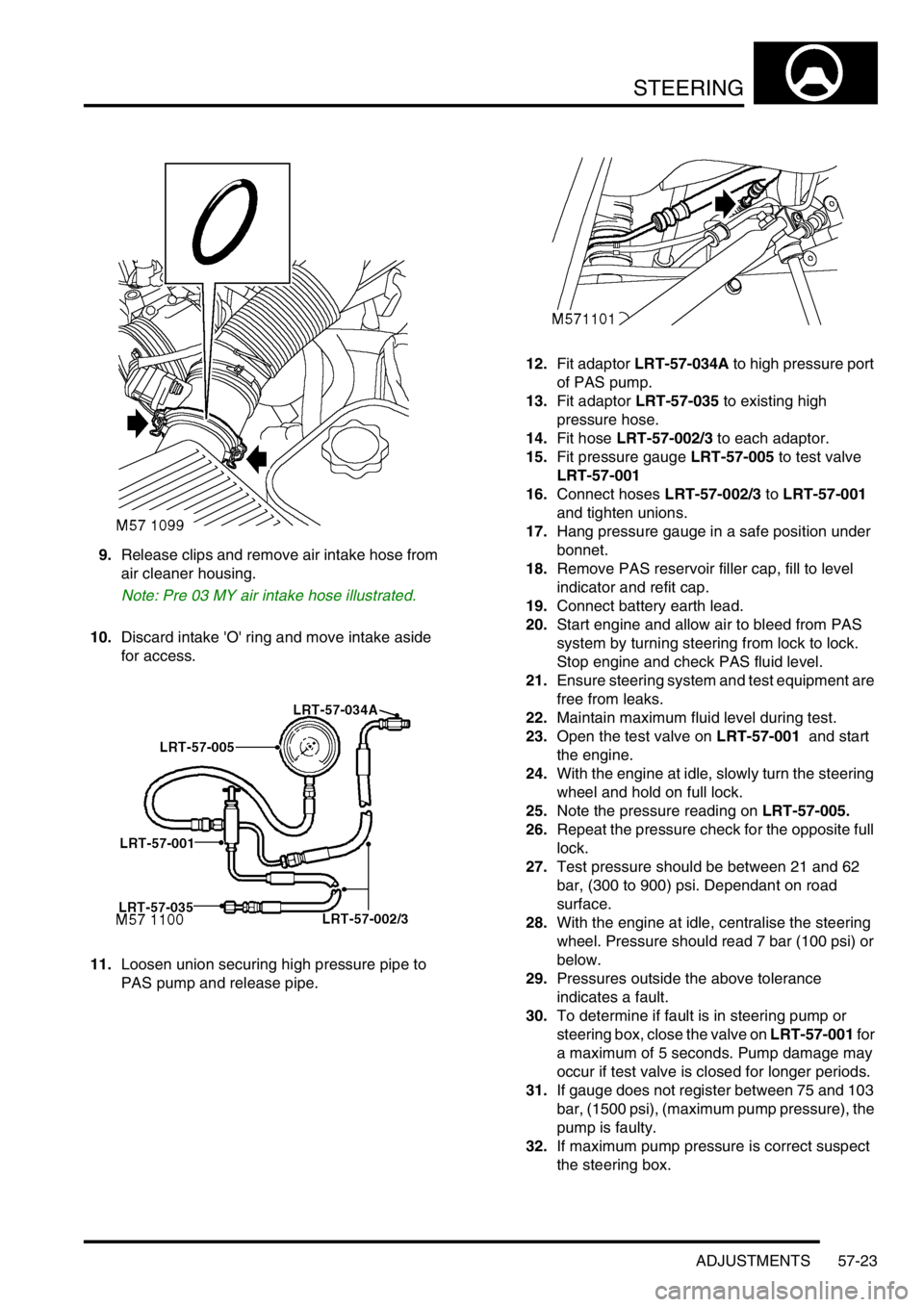

9.Release clips and remove air intake hose from

air cleaner housing.

Note: Pre 03 MY air intake hose illustrated.

10.Discard intake 'O' ring and move intake aside

for access.

11.Loosen union securing high pressure pipe to

PAS pump and release pipe.12.Fit adaptor LRT-57-034A to high pressure port

of PAS pump.

13.Fit adaptor LRT-57-035 to existing high

pressure hose.

14.Fit hose LRT-57-002/3 to each adaptor.

15.Fit pressure gauge LRT-57-005 to test valve

LRT-57-001

16.Connect hoses LRT-57-002/3 to LRT-57-001

and tighten unions.

17.Hang pressure gauge in a safe position under

bonnet.

18.Remove PAS reservoir filler cap, fill to level

indicator and refit cap.

19.Connect battery earth lead.

20.Start engine and allow air to bleed from PAS

system by turning steering from lock to lock.

Stop engine and check PAS fluid level.

21.Ensure steering system and test equipment are

free from leaks.

22.Maintain maximum fluid level during test.

23.Open the test valve on LRT-57-001 and start

the engine.

24.With the engine at idle, slowly turn the steering

wheel and hold on full lock.

25.Note the pressure reading on LRT-57-005.

26.Repeat the pressure check for the opposite full

lock.

27.Test pressure should be between 21 and 62

bar, (300 to 900) psi. Dependant on road

surface.

28.With the engine at idle, centralise the steering

wheel. Pressure should read 7 bar (100 psi) or

below.

29.Pressures outside the above tolerance

indicates a fault.

30.To determine if fault is in steering pump or

steering box, close the valve on LRT-57-001 for

a maximum of 5 seconds. Pump damage may

occur if test valve is closed for longer periods.

31.If gauge does not register between 75 and 103

bar, (1500 psi), (maximum pump pressure), the

pump is faulty.

32.If maximum pump pressure is correct suspect

the steering box.

Page 911 of 1672

STEERING

57-24 ADJUSTMENTS

33.On completion stop engine, disconnect battery

earth lead and syphon fluid from PAS reservoir.

34.Remove test equipment from LRT-57-002.

35.Clean PAS pump and pipe union.

36.Fit new 'O' ring to high pressure pipe, align to

PAS pump and tighten union to 25 Nm (18

lbf.ft).

37.Secure PAS pipes in clip.

38.Using new 'O' ring fit intake hose to air cleaner

and secure clips.

39.Remove PAS reservoir filler cap, fill to level

indicator and refit cap.

40.Connect battery earth lead.

41.Start engine and allow air to bleed from PAS

system, by turning steering from lock to lock.

42.Visually check PAS system for leaks.

43.Clean chassis member.

44.Check power steering fluid, if aerated, wait until

fluid is free from bubbles then top-up reservoir

to 'UPPER' level mark.

45.Lower vehicle.

46.Dismantle test equipment.

Power steering pressure check - V8 RHD

models

$% 57.90.10.01

Check

1.Fit gauge and hose LRT-57-005 to valve

assembly LRT-57-001, tighten union.

2.Fit 2 hoses LRT-57-002 to valve assembly

LRT-57-001 and tighten unions.

3.Fit adaptor hoses LRT-57-041 to LRT-57-002

and tighten unions.

4.Disconnect battery earth lead.

5.Remove 5 screws securing front splash shield

to chassis. Remove shield.

6.Clean PAS fluid reservoir around filler cap and

fluid level indicators.

Page 912 of 1672

STEERING

ADJUSTMENTS 57-25

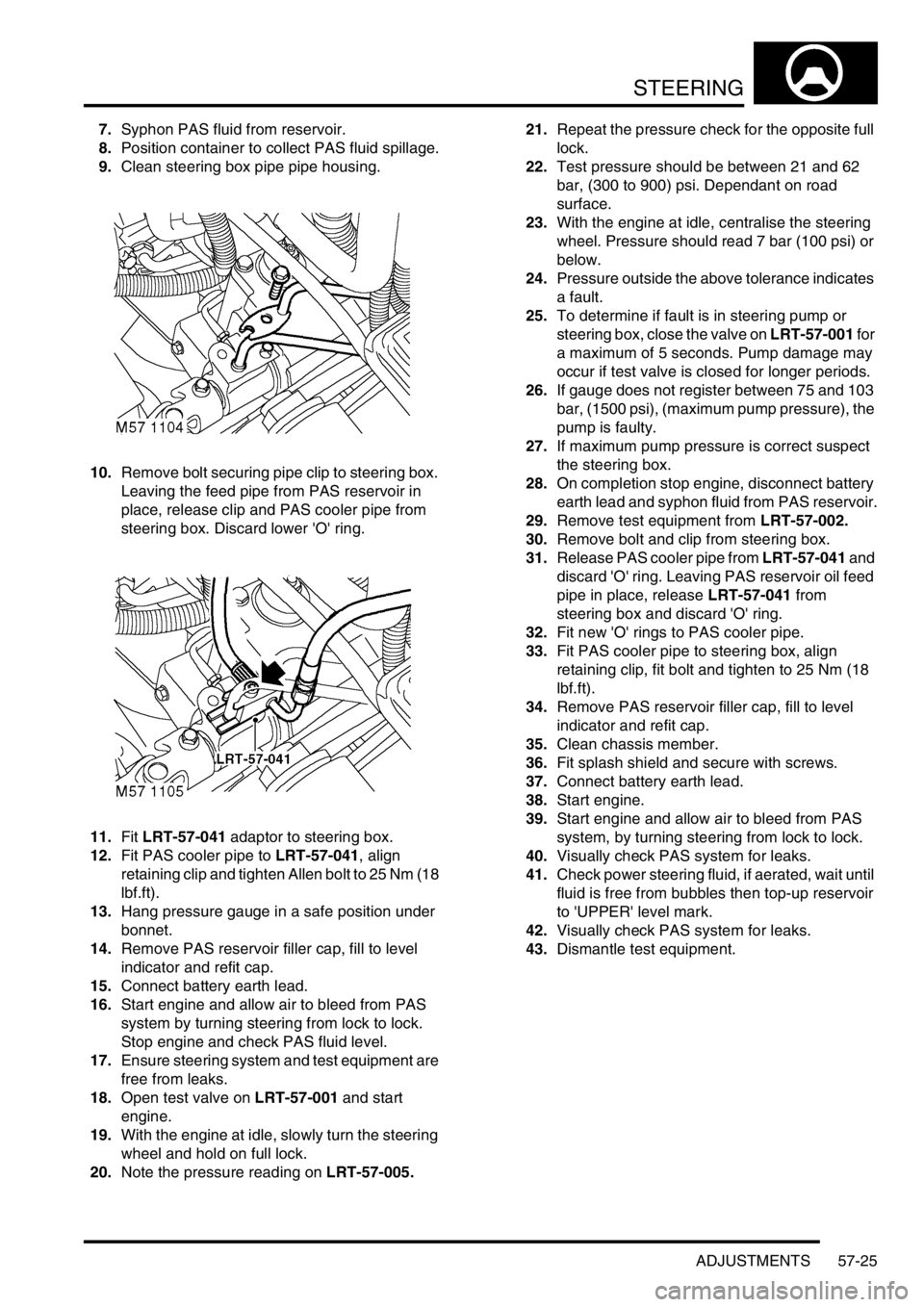

7.Syphon PAS fluid from reservoir.

8.Position container to collect PAS fluid spillage.

9.Clean steering box pipe pipe housing.

10.Remove bolt securing pipe clip to steering box.

Leaving the feed pipe from PAS reservoir in

place, release clip and PAS cooler pipe from

steering box. Discard lower 'O' ring.

11.Fit LRT-57-041 adaptor to steering box.

12.Fit PAS cooler pipe to LRT-57-041, align

retaining clip and tighten Allen bolt to 25 Nm (18

lbf.ft).

13.Hang pressure gauge in a safe position under

bonnet.

14.Remove PAS reservoir filler cap, fill to level

indicator and refit cap.

15.Connect battery earth lead.

16.Start engine and allow air to bleed from PAS

system by turning steering from lock to lock.

Stop engine and check PAS fluid level.

17.Ensure steering system and test equipment are

free from leaks.

18.Open test valve on LRT-57-001 and start

engine.

19.With the engine at idle, slowly turn the steering

wheel and hold on full lock.

20.Note the pressure reading on LRT-57-005.21.Repeat the pressure check for the opposite full

lock.

22.Test pressure should be between 21 and 62

bar, (300 to 900) psi. Dependant on road

surface.

23.With the engine at idle, centralise the steering

wheel. Pressure should read 7 bar (100 psi) or

below.

24.Pressure outside the above tolerance indicates

a fault.

25.To determine if fault is in steering pump or

steering box, close the valve on LRT-57-001 for

a maximum of 5 seconds. Pump damage may

occur if test valve is closed for longer periods.

26.If gauge does not register between 75 and 103

bar, (1500 psi), (maximum pump pressure), the

pump is faulty.

27.If maximum pump pressure is correct suspect

the steering box.

28.On completion stop engine, disconnect battery

earth lead and syphon fluid from PAS reservoir.

29.Remove test equipment from LRT-57-002.

30.Remove bolt and clip from steering box.

31.Release PAS cooler pipe from LRT-57-041 and

discard 'O' ring. Leaving PAS reservoir oil feed

pipe in place, release LRT-57-041 from

steering box and discard 'O' ring.

32.Fit new 'O' rings to PAS cooler pipe.

33.Fit PAS cooler pipe to steering box, align

retaining clip, fit bolt and tighten to 25 Nm (18

lbf.ft).

34.Remove PAS reservoir filler cap, fill to level

indicator and refit cap.

35.Clean chassis member.

36.Fit splash shield and secure with screws.

37.Connect battery earth lead.

38.Start engine.

39.Start engine and allow air to bleed from PAS

system, by turning steering from lock to lock.

40.Visually check PAS system for leaks.

41.Check power steering fluid, if aerated, wait until

fluid is free from bubbles then top-up reservoir

to 'UPPER' level mark.

42.Visually check PAS system for leaks.

43.Dismantle test equipment.

Page 914 of 1672

STEERING

REPAIRS 57-27

REPAIRS

Power steering box - V8

$% 57.10.01

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove front road wheel.

3.Ensure steering wheel is centralised and fit

centralising bolt to steering box. Remove key

from steering lock and engage column lock.

4.Remove 3 bolts securing intermediate shaft

and universal joint.

5.Push intermediate shaft upwards, release and

remove universal joint.

CAUTION: Do not turn the steering wheel

with the intermediate shaft or universal joint

disconnected as damage to the rotary

coupler and the steering wheel switches

may occur.

6.Position container to catch oil spillage.