LAND ROVER FREELANDER 2001 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 271 of 1007

ENGINE - K SERIES KV6

12-3-94 OVERHAUL

16.Position injector protection cover - if fitted to RH

fuel rail and secure injector harness to

protection cover or fuel rail with clips.

17.Fit bolts securing fuel rail to inlet manifolds and

tighten to 9 Nm (7 lbf.ft).

18.Connect coolant bleed hose to inlet manifold

and secure with clip.

19. Up to 03MY:Position ignition coils to LH inlet

manifold.

20. Up to 03MY:Position earth lead, fit nuts and

bolts securing ignition coils to LH inlet manifold

and tighten to 9 Nm (7 lbf.ft).

21.Clean camshaft timing belt cover backplate

bolts and apply sealant, Part No. STC 50552 to

the first 3 threads.

22.Position backplate, fit and tighten bolts to 9 Nm

(7 lbf.ft).

23.Fit new camshaft timing belt.

+ ENGINE - K SERIES KV6,

OVERHAUL, Camshaft timing belt.

24.Clean exhaust manifold and mating face on

cylinder head.

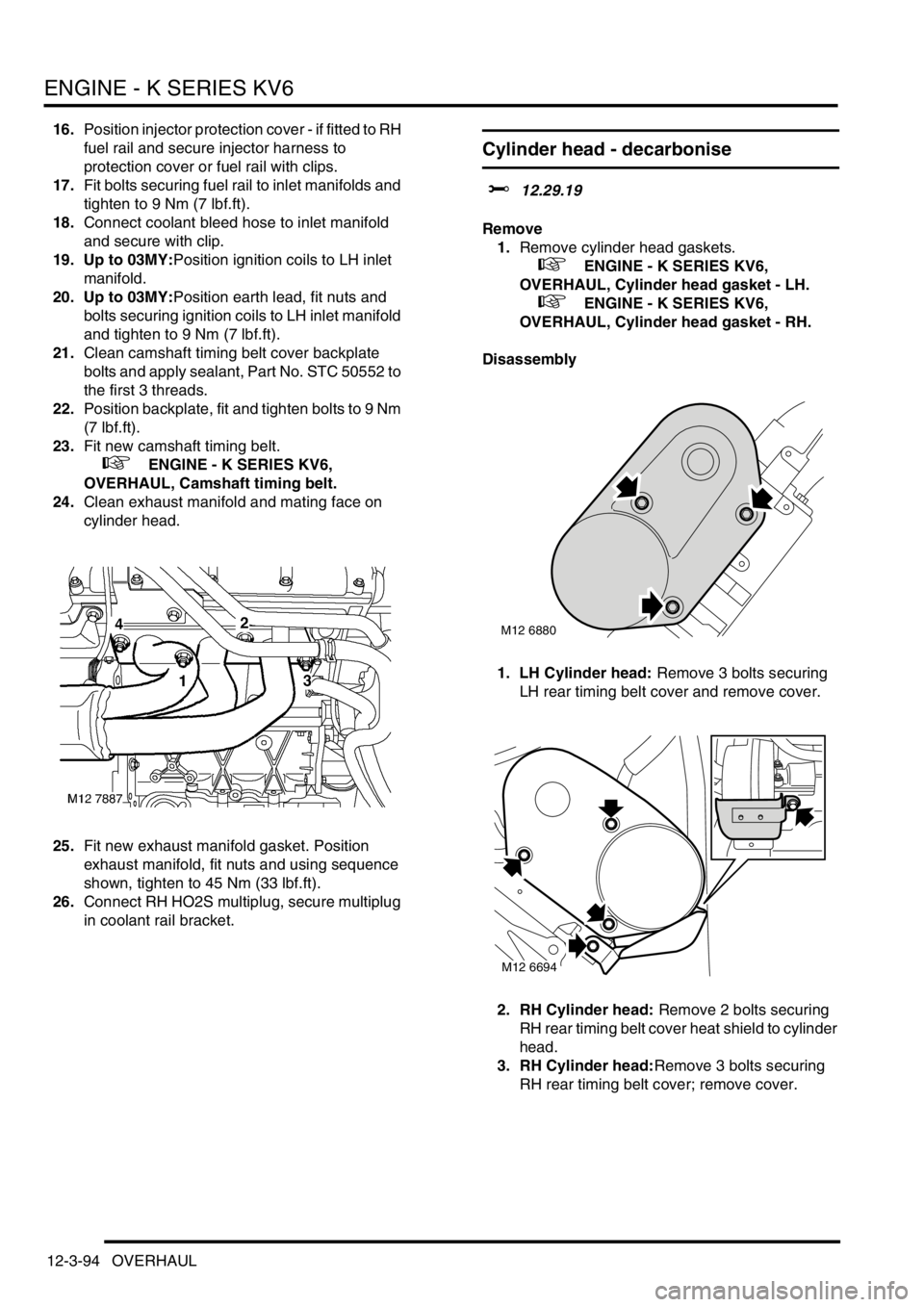

25.Fit new exhaust manifold gasket. Position

exhaust manifold, fit nuts and using sequence

shown, tighten to 45 Nm (33 lbf.ft).

26.Connect RH HO2S multiplug, secure multiplug

in coolant rail bracket.

Cylinder head - decarbonise

$% 12.29.19

Remove

1.Remove cylinder head gaskets.

+ ENGINE - K SERIES KV6,

OVERHAUL, Cylinder head gasket - LH.

+ ENGINE - K SERIES KV6,

OVERHAUL, Cylinder head gasket - RH.

Disassembly

1. LH Cylinder head: Remove 3 bolts securing

LH rear timing belt cover and remove cover.

2. RH Cylinder head: Remove 2 bolts securing

RH rear timing belt cover heat shield to cylinder

head.

3. RH Cylinder head:Remove 3 bolts securing

RH rear timing belt cover; remove cover.

M12 6880

M12 6694

Page 272 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-95

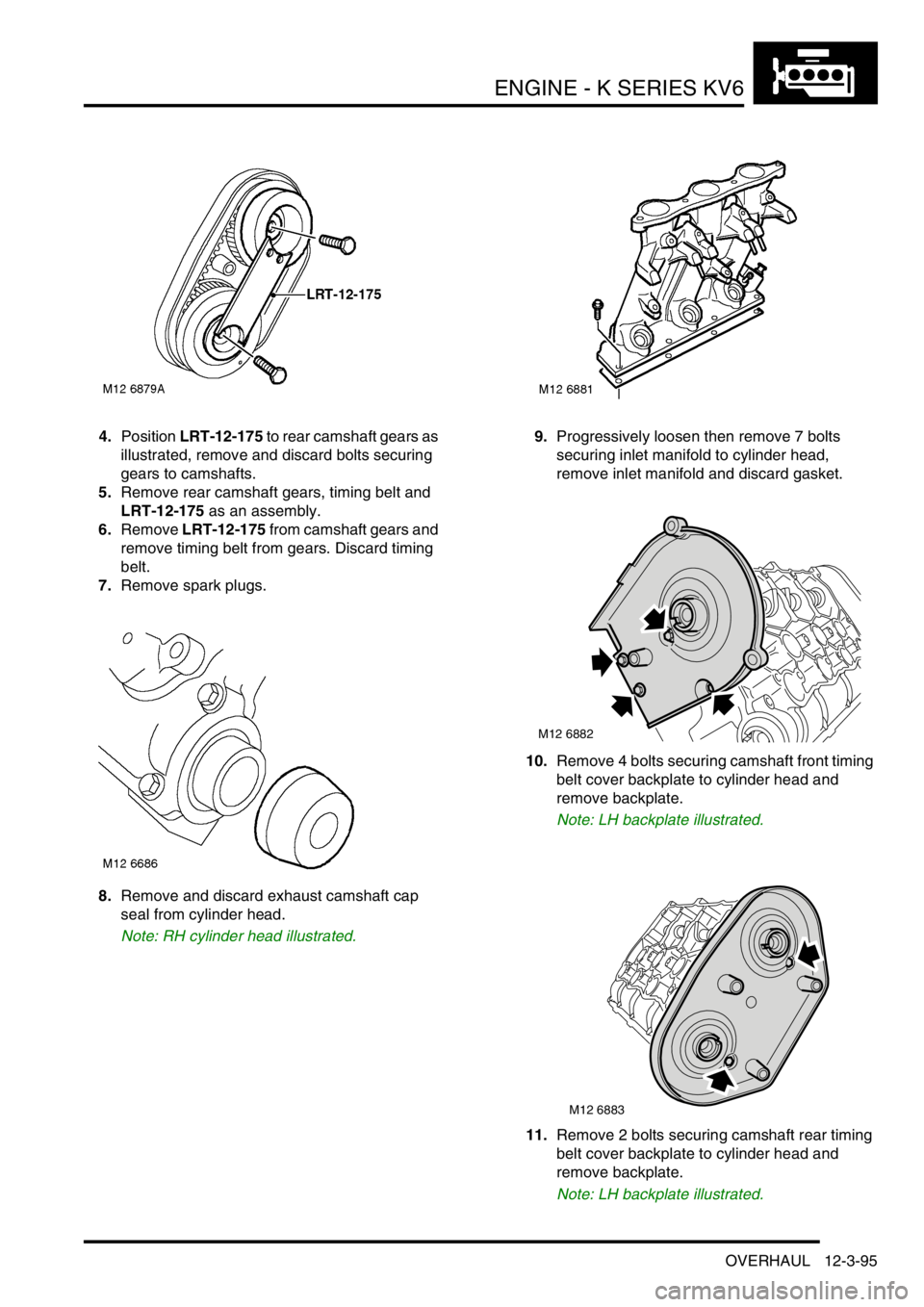

4.Position LRT-12-175 to rear camshaft gears as

illustrated, remove and discard bolts securing

gears to camshafts.

5.Remove rear camshaft gears, timing belt and

LRT-12-175 as an assembly.

6.Remove LRT-12-175 from camshaft gears and

remove timing belt from gears. Discard timing

belt.

7.Remove spark plugs.

8.Remove and discard exhaust camshaft cap

seal from cylinder head.

Note: RH cylinder head illustrated.9.Progressively loosen then remove 7 bolts

securing inlet manifold to cylinder head,

remove inlet manifold and discard gasket.

10.Remove 4 bolts securing camshaft front timing

belt cover backplate to cylinder head and

remove backplate.

Note: LH backplate illustrated.

11.Remove 2 bolts securing camshaft rear timing

belt cover backplate to cylinder head and

remove backplate.

Note: LH backplate illustrated.

M12 6882

M12 6883

Page 273 of 1007

ENGINE - K SERIES KV6

12-3-96 OVERHAUL

12.Check end-float of camshafts using a DTI.

+ GENERAL DATA, Engine - KV6

Petrol.

CAUTION: If camshaft end-float exceeds

limits given, repeat check with new

camshaft(s). If end-float is still excessive,

replace cylinder head and camshaft carrier

as an assembly.

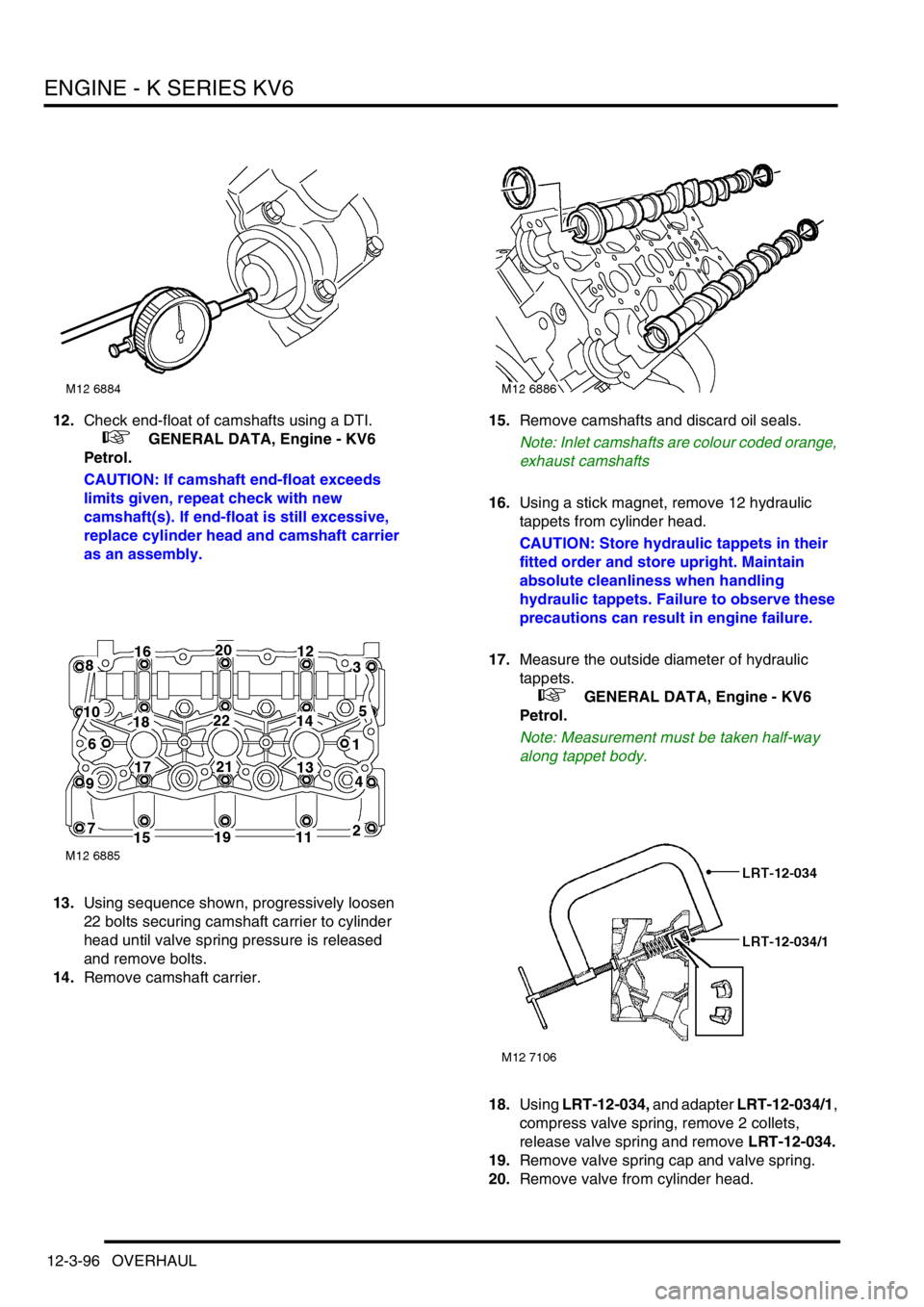

13.Using sequence shown, progressively loosen

22 bolts securing camshaft carrier to cylinder

head until valve spring pressure is released

and remove bolts.

14.Remove camshaft carrier.15.Remove camshafts and discard oil seals.

Note: Inlet camshafts are colour coded orange,

exhaust camshafts

16.Using a stick magnet, remove 12 hydraulic

tappets from cylinder head.

CAUTION: Store hydraulic tappets in their

fitted order and store upright. Maintain

absolute cleanliness when handling

hydraulic tappets. Failure to observe these

precautions can result in engine failure.

17.Measure the outside diameter of hydraulic

tappets.

+ GENERAL DATA, Engine - KV6

Petrol.

Note: Measurement must be taken half-way

along tappet body.

18.Using LRT-12-034, and adapter LRT-12-034/1,

compress valve spring, remove 2 collets,

release valve spring and remove LRT-12-034.

19.Remove valve spring cap and valve spring.

20.Remove valve from cylinder head.

Page 274 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-97

21.Remove valve stem oil seal using LRT-12-071.

Discard stem seal.

22.Repeat procedure for remaining valves,

keeping components in their fitted order.

Inspect

1.Clean camshafts, bearing running surfaces in

carrier and cylinder head, carrier and cylinder

head mating faces.

2.Inspect camshafts and replace camshafts if

scored, pitted or excessively worn.

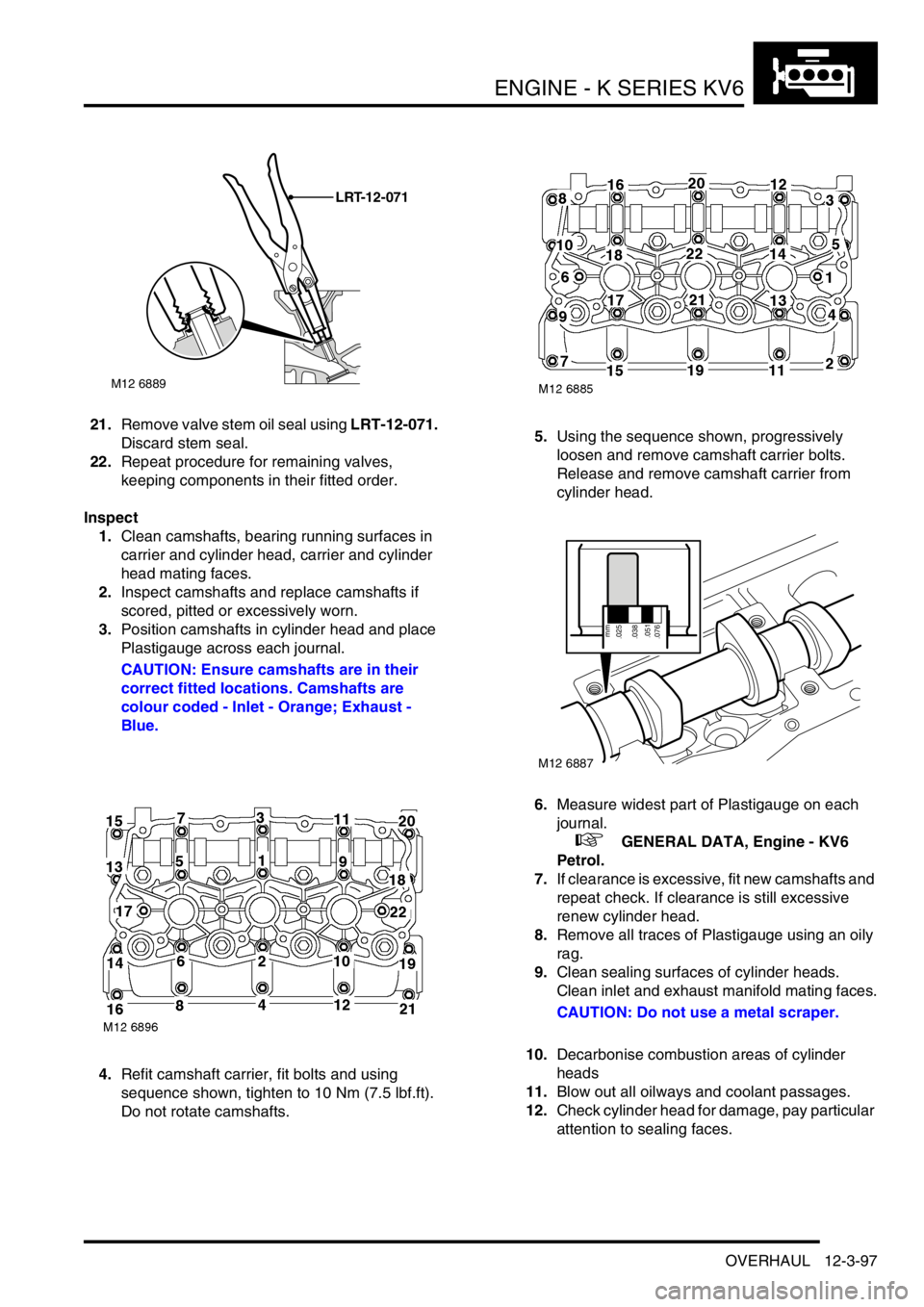

3.Position camshafts in cylinder head and place

Plastigauge across each journal.

CAUTION: Ensure camshafts are in their

correct fitted locations. Camshafts are

colour coded - Inlet - Orange; Exhaust -

Blue.

4.Refit camshaft carrier, fit bolts and using

sequence shown, tighten to 10 Nm (7.5 lbf.ft).

Do not rotate camshafts.5.Using the sequence shown, progressively

loosen and remove camshaft carrier bolts.

Release and remove camshaft carrier from

cylinder head.

6.Measure widest part of Plastigauge on each

journal.

+ GENERAL DATA, Engine - KV6

Petrol.

7.If clearance is excessive, fit new camshafts and

repeat check. If clearance is still excessive

renew cylinder head.

8.Remove all traces of Plastigauge using an oily

rag.

9.Clean sealing surfaces of cylinder heads.

Clean inlet and exhaust manifold mating faces.

CAUTION: Do not use a metal scraper.

10.Decarbonise combustion areas of cylinder

heads

11.Blow out all oilways and coolant passages.

12.Check cylinder head for damage, pay particular

attention to sealing faces.

M12 6889

LRT-12-071

mm.025.038.051.076

M12 6887

Page 275 of 1007

ENGINE - K SERIES KV6

12-3-98 OVERHAUL

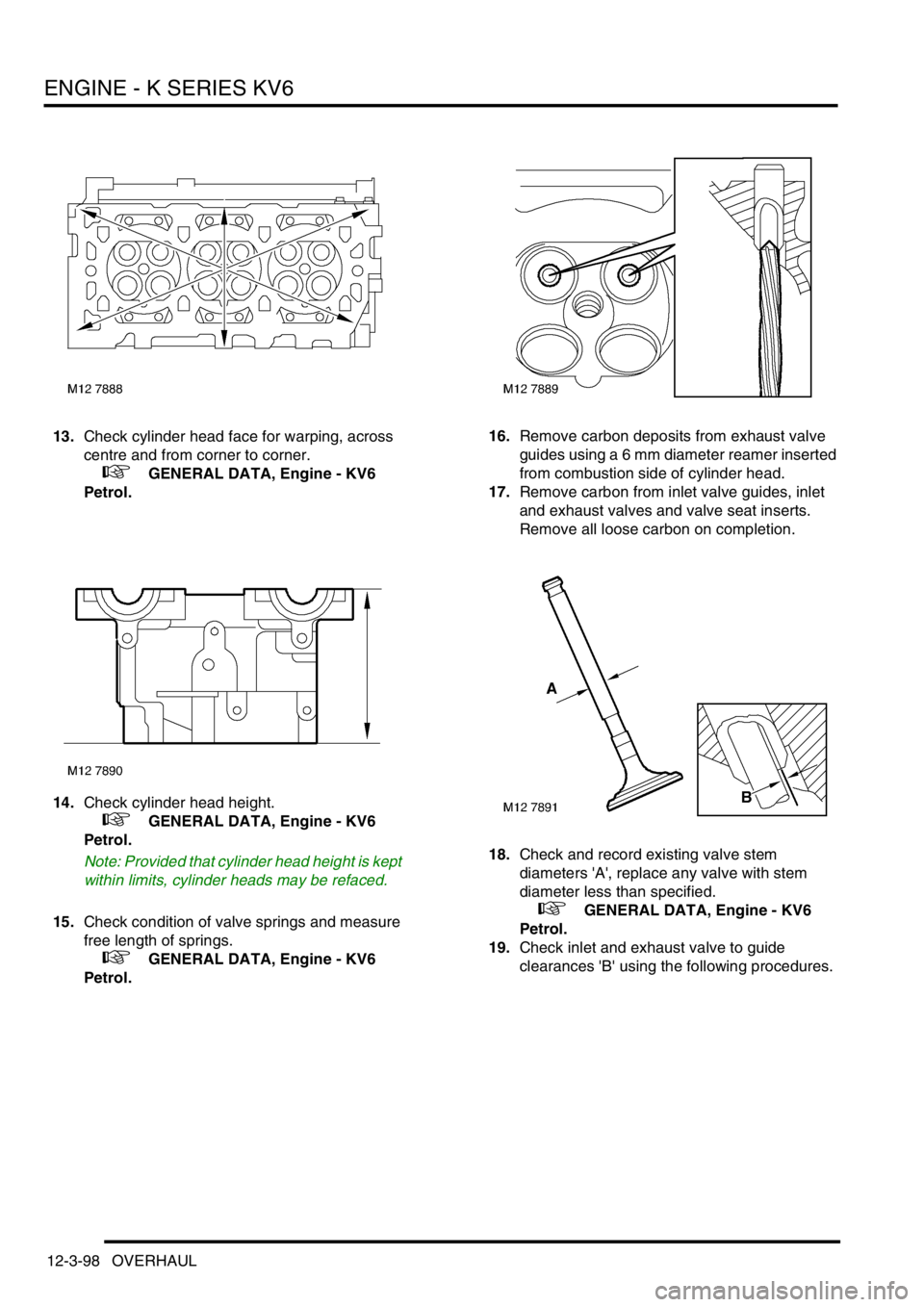

13.Check cylinder head face for warping, across

centre and from corner to corner.

+ GENERAL DATA, Engine - KV6

Petrol.

14.Check cylinder head height.

+ GENERAL DATA, Engine - KV6

Petrol.

Note: Provided that cylinder head height is kept

within limits, cylinder heads may be refaced.

15.Check condition of valve springs and measure

free length of springs.

+ GENERAL DATA, Engine - KV6

Petrol.16.Remove carbon deposits from exhaust valve

guides using a 6 mm diameter reamer inserted

from combustion side of cylinder head.

17.Remove carbon from inlet valve guides, inlet

and exhaust valves and valve seat inserts.

Remove all loose carbon on completion.

18.Check and record existing valve stem

diameters 'A', replace any valve with stem

diameter less than specified.

+ GENERAL DATA, Engine - KV6

Petrol.

19.Check inlet and exhaust valve to guide

clearances 'B' using the following procedures.

Page 276 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-99

20.Insert each valve into its respective guide.

21.Extend valve head 15 mm (0.6 in) out of guide

and position DTI gauge to rear of valve head.

22.Move valve towards front of cylinder head and

zero gauge ensuring that stylus of gauge

remains in contact with valve head.

23.Move valve towards rear of cylinder head,

record gauge reading obtained to give valve

stem to guide clearance 'B'.

+ GENERAL DATA, Engine - KV6

Petrol.

24.Remove valves ensuring they are retained in

their fitted order.

25.Renew valves and/or guides as necessary.

26.To replace valve guides support cylinder head

face down on wooden blocks.

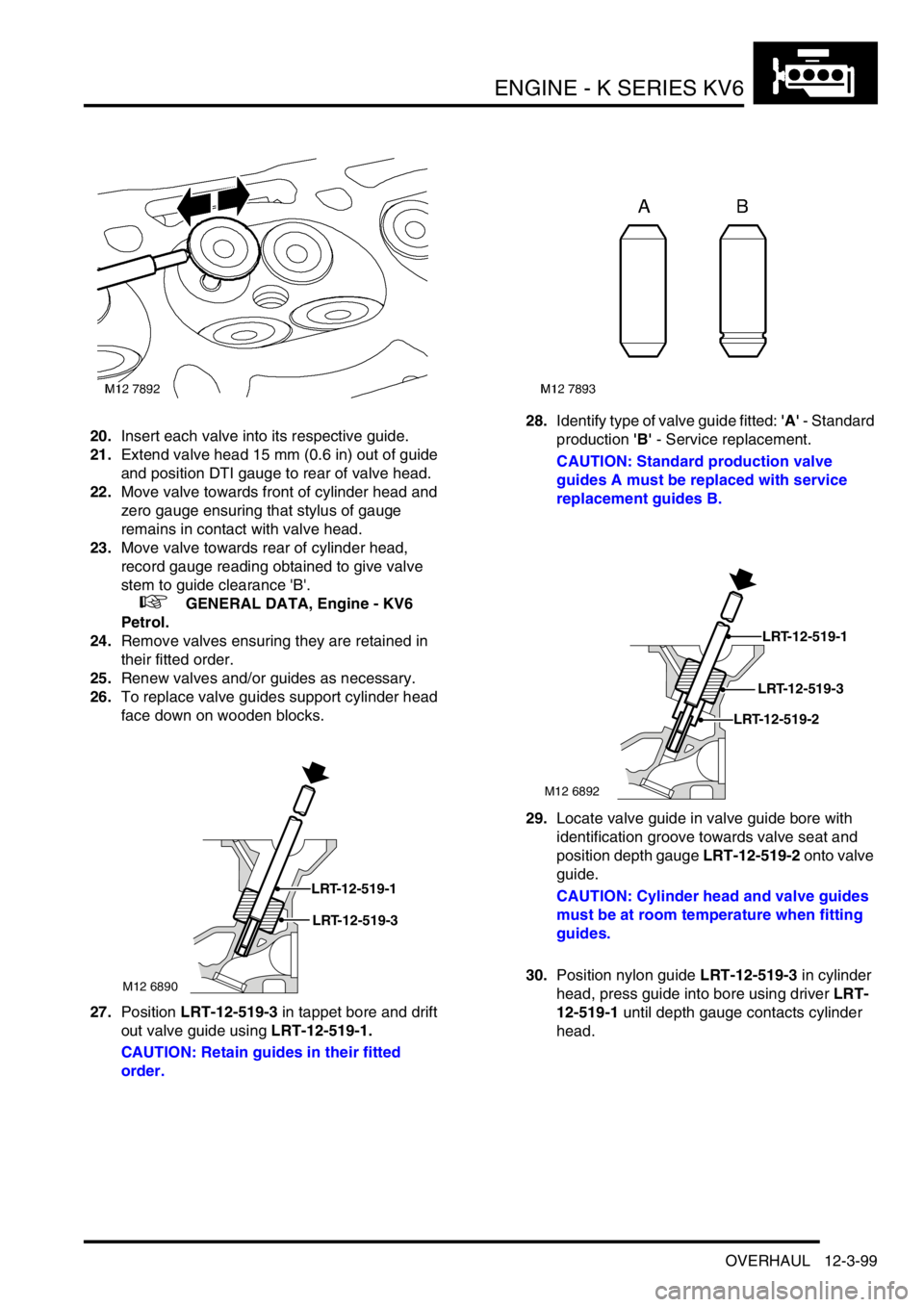

27.Position LRT-12-519-3 in tappet bore and drift

out valve guide using LRT-12-519-1.

CAUTION: Retain guides in their fitted

order.28.Identify type of valve guide fitted: 'A' - Standard

production 'B' - Service replacement.

CAUTION: Standard production valve

guides A must be replaced with service

replacement guides B.

29.Locate valve guide in valve guide bore with

identification groove towards valve seat and

position depth gauge LRT-12-519-2 onto valve

guide.

CAUTION: Cylinder head and valve guides

must be at room temperature when fitting

guides.

30.Position nylon guide LRT-12-519-3 in cylinder

head, press guide into bore using driver LRT-

12-519-1 until depth gauge contacts cylinder

head.

M12 6890

LRT-12-519-1

LRT-12-519-3

M12 6892

LRT-12-519-2

LRT-12-519-1

LRT-12-519-3

Page 277 of 1007

ENGINE - K SERIES KV6

12-3-100 OVERHAUL

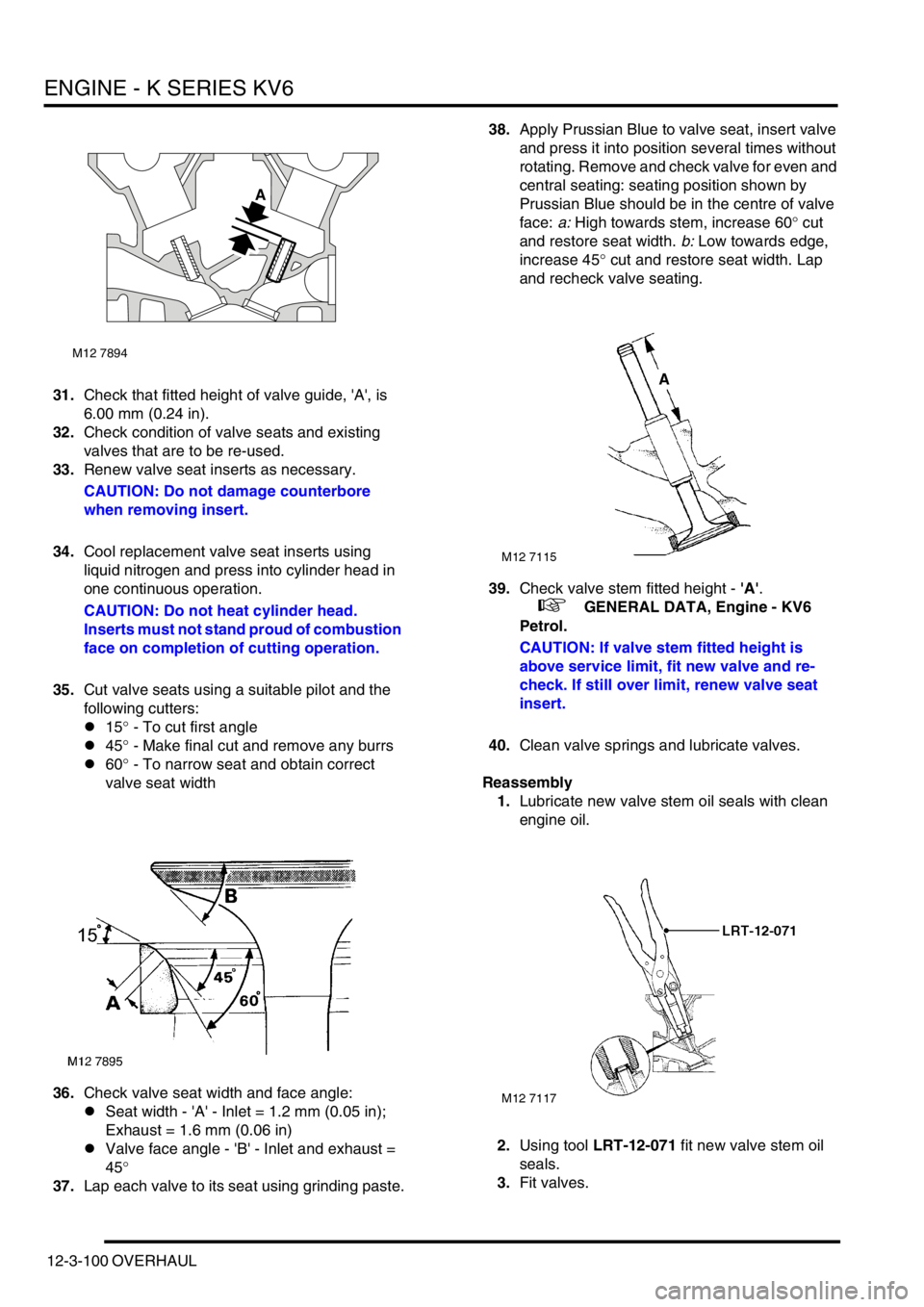

31.Check that fitted height of valve guide, 'A', is

6.00 mm (0.24 in).

32.Check condition of valve seats and existing

valves that are to be re-used.

33.Renew valve seat inserts as necessary.

CAUTION: Do not damage counterbore

when removing insert.

34.Cool replacement valve seat inserts using

liquid nitrogen and press into cylinder head in

one continuous operation.

CAUTION: Do not heat cylinder head.

Inserts must not stand proud of combustion

face on completion of cutting operation.

35.Cut valve seats using a suitable pilot and the

following cutters:

l15° - To cut first angle

l45° - Make final cut and remove any burrs

l60° - To narrow seat and obtain correct

valve seat width

36.Check valve seat width and face angle:

lSeat width - 'A' - Inlet = 1.2 mm (0.05 in);

Exhaust = 1.6 mm (0.06 in)

lValve face angle - 'B' - Inlet and exhaust =

45°

37.Lap each valve to its seat using grinding paste.38.Apply Prussian Blue to valve seat, insert valve

and press it into position several times without

rotating. Remove and check valve for even and

central seating: seating position shown by

Prussian Blue should be in the centre of valve

face: a: High towards stem, increase 60° cut

and restore seat width. b: Low towards edge,

increase 45° cut and restore seat width. Lap

and recheck valve seating.

39.Check valve stem fitted height - 'A'.

+ GENERAL DATA, Engine - KV6

Petrol.

CAUTION: If valve stem fitted height is

above service limit, fit new valve and re-

check. If still over limit, renew valve seat

insert.

40.Clean valve springs and lubricate valves.

Reassembly

1.Lubricate new valve stem oil seals with clean

engine oil.

2.Using tool LRT-12-071 fit new valve stem oil

seals.

3.Fit valves.

M12 7894

A

Page 278 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-101

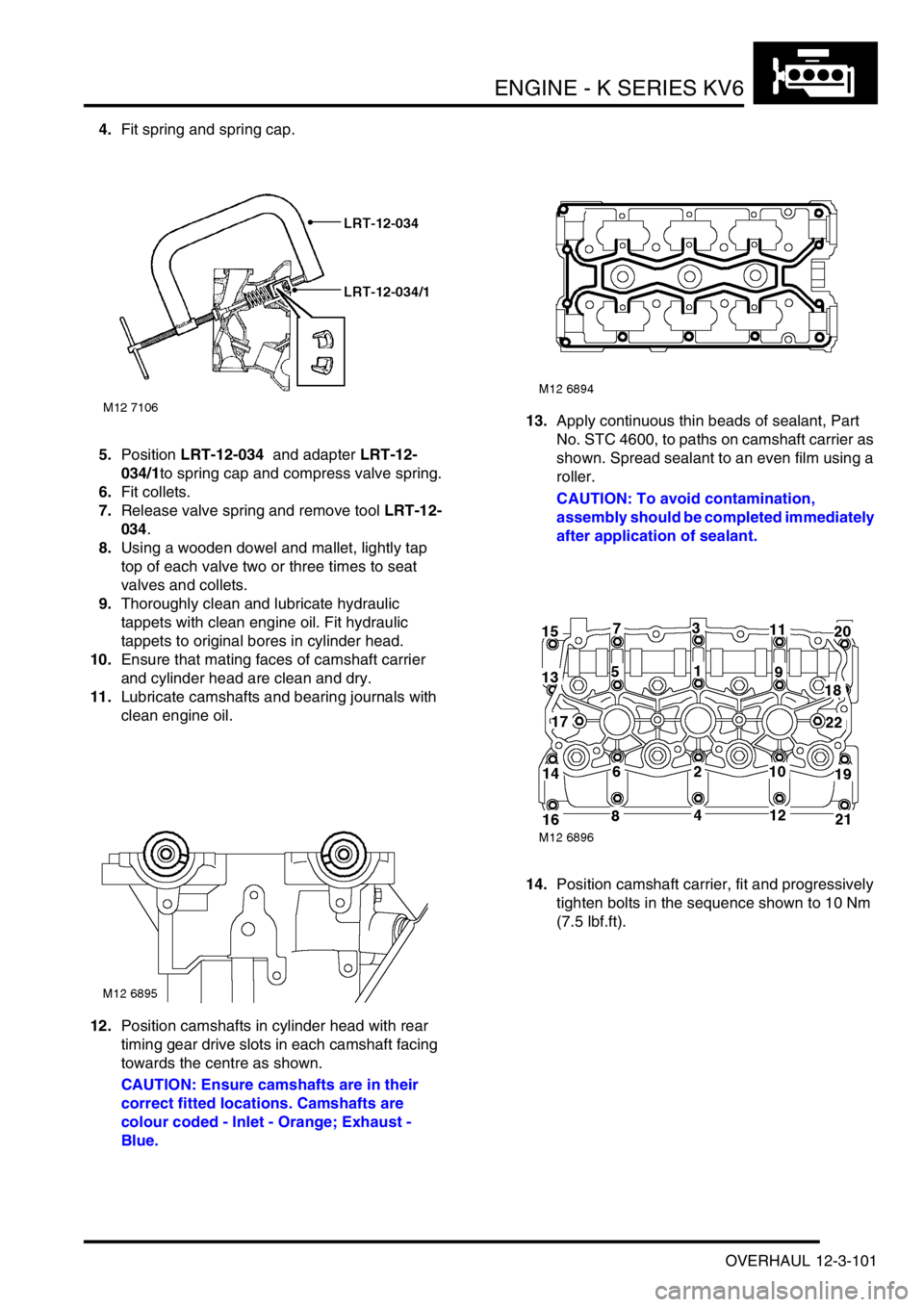

4.Fit spring and spring cap.

5.Position LRT-12-034 and adapter LRT-12-

034/1to spring cap and compress valve spring.

6.Fit collets.

7.Release valve spring and remove tool LRT-12-

034.

8.Using a wooden dowel and mallet, lightly tap

top of each valve two or three times to seat

valves and collets.

9.Thoroughly clean and lubricate hydraulic

tappets with clean engine oil. Fit hydraulic

tappets to original bores in cylinder head.

10.Ensure that mating faces of camshaft carrier

and cylinder head are clean and dry.

11.Lubricate camshafts and bearing journals with

clean engine oil.

12.Position camshafts in cylinder head with rear

timing gear drive slots in each camshaft facing

towards the centre as shown.

CAUTION: Ensure camshafts are in their

correct fitted locations. Camshafts are

colour coded - Inlet - Orange; Exhaust -

Blue.13.Apply continuous thin beads of sealant, Part

No. STC 4600, to paths on camshaft carrier as

shown. Spread sealant to an even film using a

roller.

CAUTION: To avoid contamination,

assembly should be completed immediately

after application of sealant.

14.Position camshaft carrier, fit and progressively

tighten bolts in the sequence shown to 10 Nm

(7.5 lbf.ft).

Page 279 of 1007

ENGINE - K SERIES KV6

12-3-102 OVERHAUL

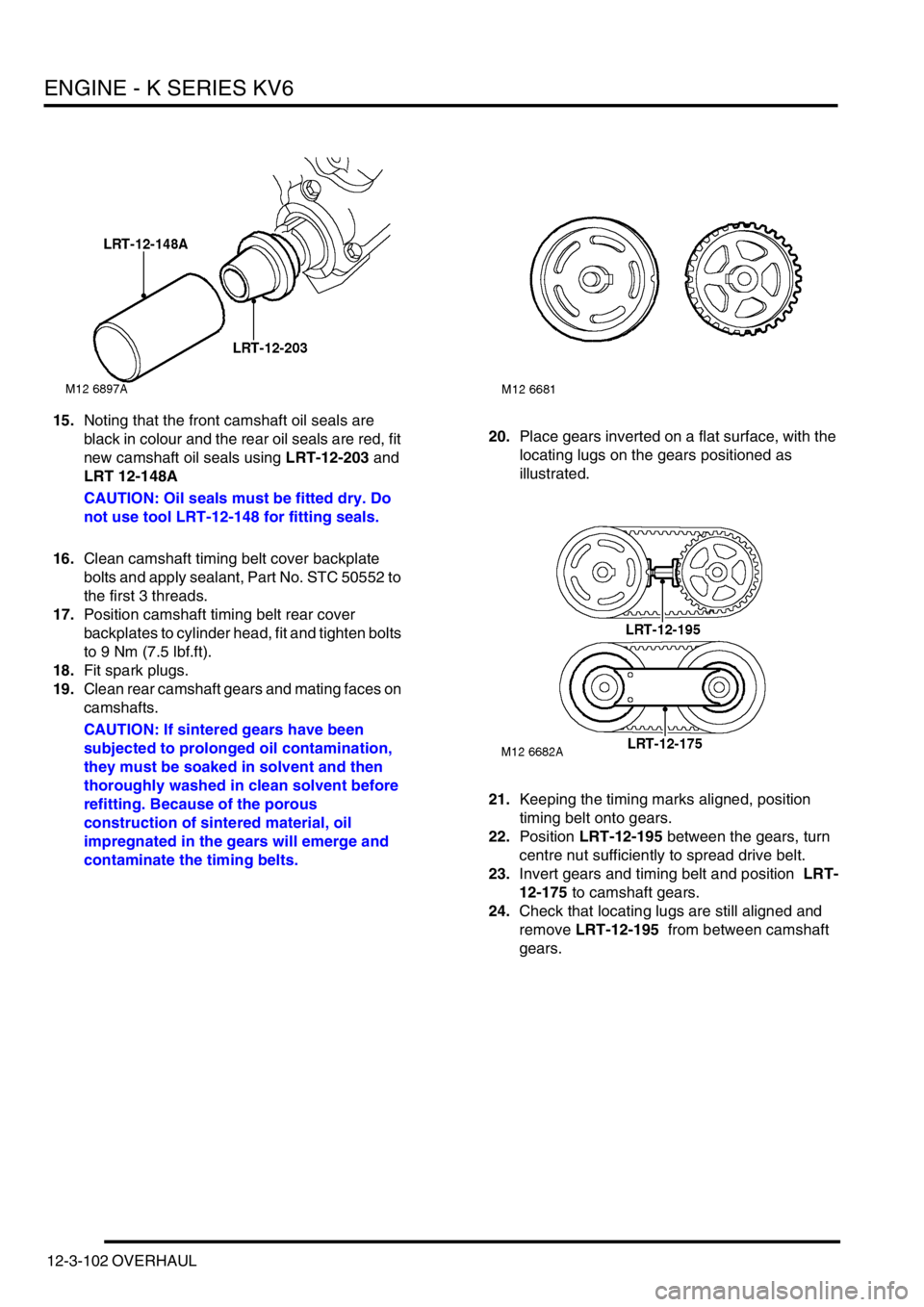

15.Noting that the front camshaft oil seals are

black in colour and the rear oil seals are red, fit

new camshaft oil seals using LRT-12-203 and

LRT 12-148A

CAUTION: Oil seals must be fitted dry. Do

not use tool LRT-12-148 for fitting seals.

16.Clean camshaft timing belt cover backplate

bolts and apply sealant, Part No. STC 50552 to

the first 3 threads.

17.Position camshaft timing belt rear cover

backplates to cylinder head, fit and tighten bolts

to 9 Nm (7.5 lbf.ft).

18.Fit spark plugs.

19.Clean rear camshaft gears and mating faces on

camshafts.

CAUTION: If sintered gears have been

subjected to prolonged oil contamination,

they must be soaked in solvent and then

thoroughly washed in clean solvent before

refitting. Because of the porous

construction of sintered material, oil

impregnated in the gears will emerge and

contaminate the timing belts.20.Place gears inverted on a flat surface, with the

locating lugs on the gears positioned as

illustrated.

21.Keeping the timing marks aligned, position

timing belt onto gears.

22.Position LRT-12-195 between the gears, turn

centre nut sufficiently to spread drive belt.

23.Invert gears and timing belt and position LRT-

12-175 to camshaft gears.

24.Check that locating lugs are still aligned and

remove LRT-12-195 from between camshaft

gears.

Page 280 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-103

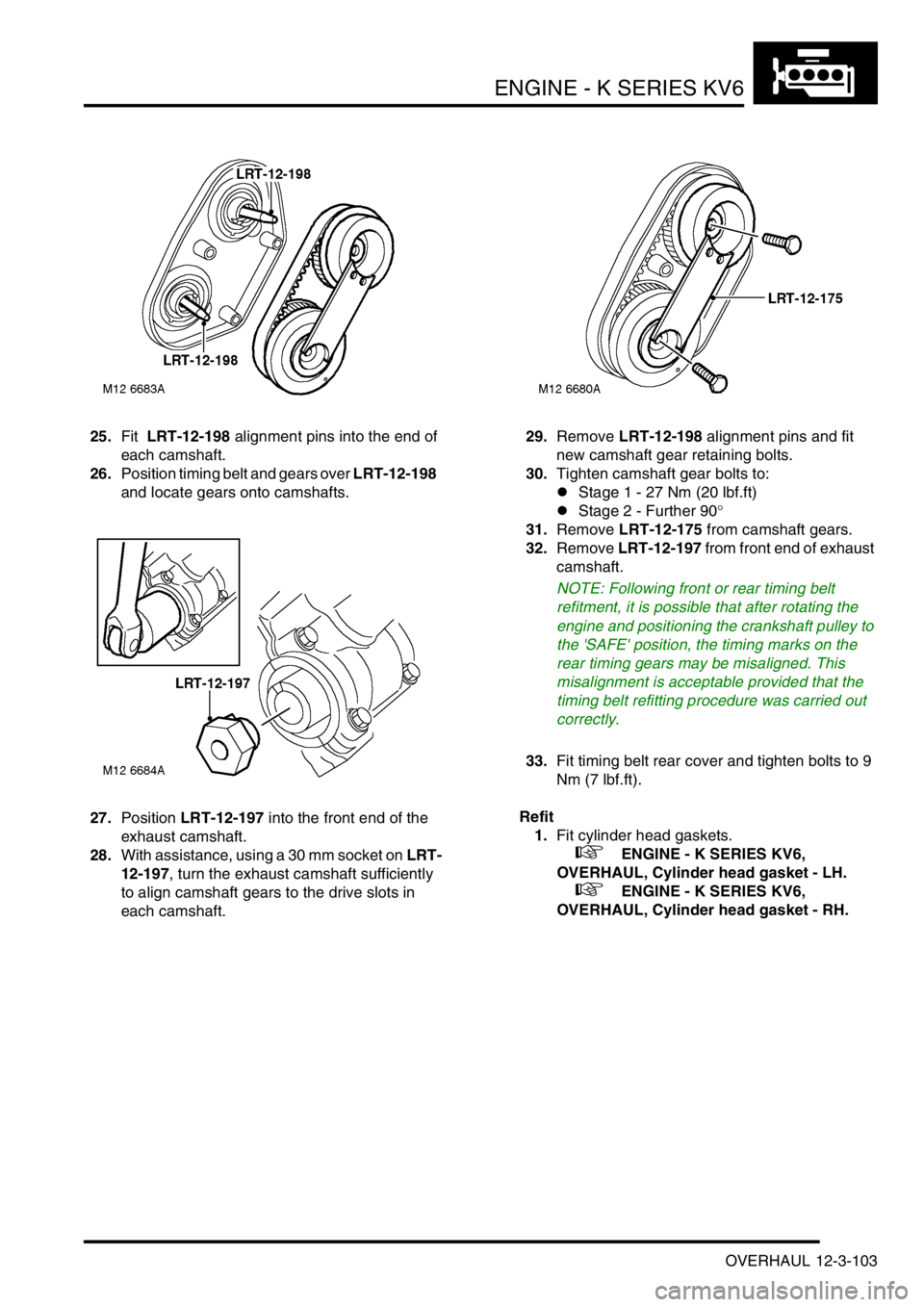

25.Fit LRT-12-198 alignment pins into the end of

each camshaft.

26.Position timing belt and gears over LRT-12-198

and locate gears onto camshafts.

27.Position LRT-12-197 into the front end of the

exhaust camshaft.

28.With assistance, using a 30 mm socket on LRT-

12-197, turn the exhaust camshaft sufficiently

to align camshaft gears to the drive slots in

each camshaft.29.Remove LRT-12-198 alignment pins and fit

new camshaft gear retaining bolts.

30.Tighten camshaft gear bolts to:

lStage 1 - 27 Nm (20 lbf.ft)

lStage 2 - Further 90°

31.Remove LRT-12-175 from camshaft gears.

32.Remove LRT-12-197 from front end of exhaust

camshaft.

NOTE: Following front or rear timing belt

refitment, it is possible that after rotating the

engine and positioning the crankshaft pulley to

the 'SAFE' position, the timing marks on the

rear timing gears may be misaligned. This

misalignment is acceptable provided that the

timing belt refitting procedure was carried out

correctly.

33.Fit timing belt rear cover and tighten bolts to 9

Nm (7 lbf.ft).

Refit

1.Fit cylinder head gaskets.

+ ENGINE - K SERIES KV6,

OVERHAUL, Cylinder head gasket - LH.

+ ENGINE - K SERIES KV6,

OVERHAUL, Cylinder head gasket - RH.