LAND ROVER FREELANDER 2001 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 601 of 1007

RESTRAINT SYSTEMS

75-20 REPAIRS

Airbag module - steering wheel -

deployment - off vehicle

$% 76.74.16

These guidelines are written to aid authorised

personnel to carry out the safe disposal of airbag

modules when removed from the vehicle.

Deploy

WARNING: It is imperative that before any

work is undertaken on the SRS system, the

appropriate information is read thoroughly.

1.Make the SRS system safe.

+ GENERAL INFORMATION, SRS

component manual deployment.

2.Remove airbag module from steering wheel.

+ RESTRAINT SYSTEMS, REPAIRS,

Air bag - steering wheel.

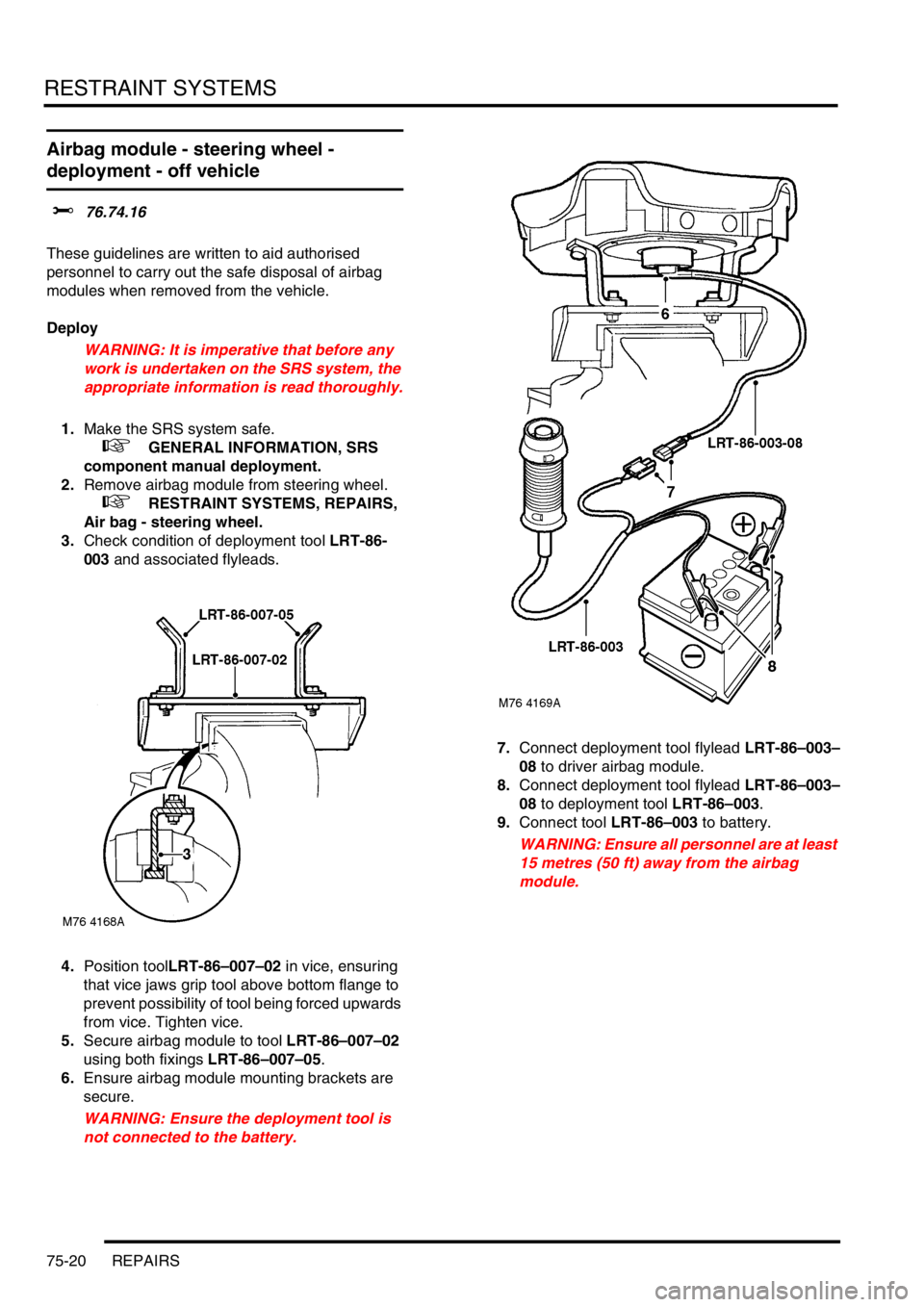

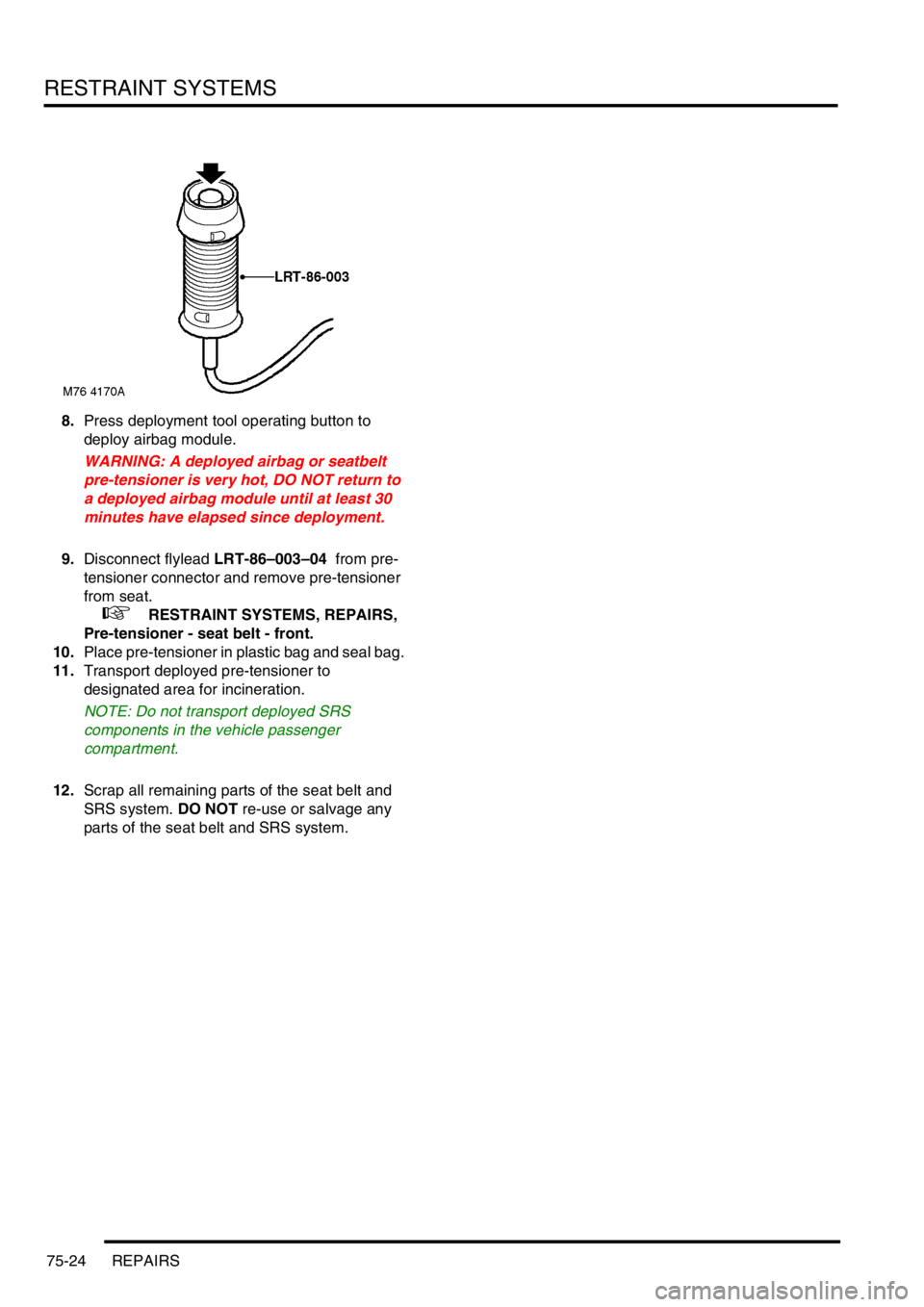

3.Check condition of deployment tool LRT-86-

003 and associated flyleads.

4.Position toolLRT-86–007–02 in vice, ensuring

that vice jaws grip tool above bottom flange to

prevent possibility of tool being forced upwards

from vice. Tighten vice.

5.Secure airbag module to tool LRT-86–007–02

using both fixings LRT-86–007–05.

6.Ensure airbag module mounting brackets are

secure.

WARNING: Ensure the deployment tool is

not connected to the battery.7.Connect deployment tool flylead LRT-86–003–

08 to driver airbag module.

8.Connect deployment tool flylead LRT-86–003–

08 to deployment tool LRT-86–003.

9.Connect tool LRT-86–003 to battery.

WARNING: Ensure all personnel are at least

15 metres (50 ft) away from the airbag

module.

Page 602 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-21

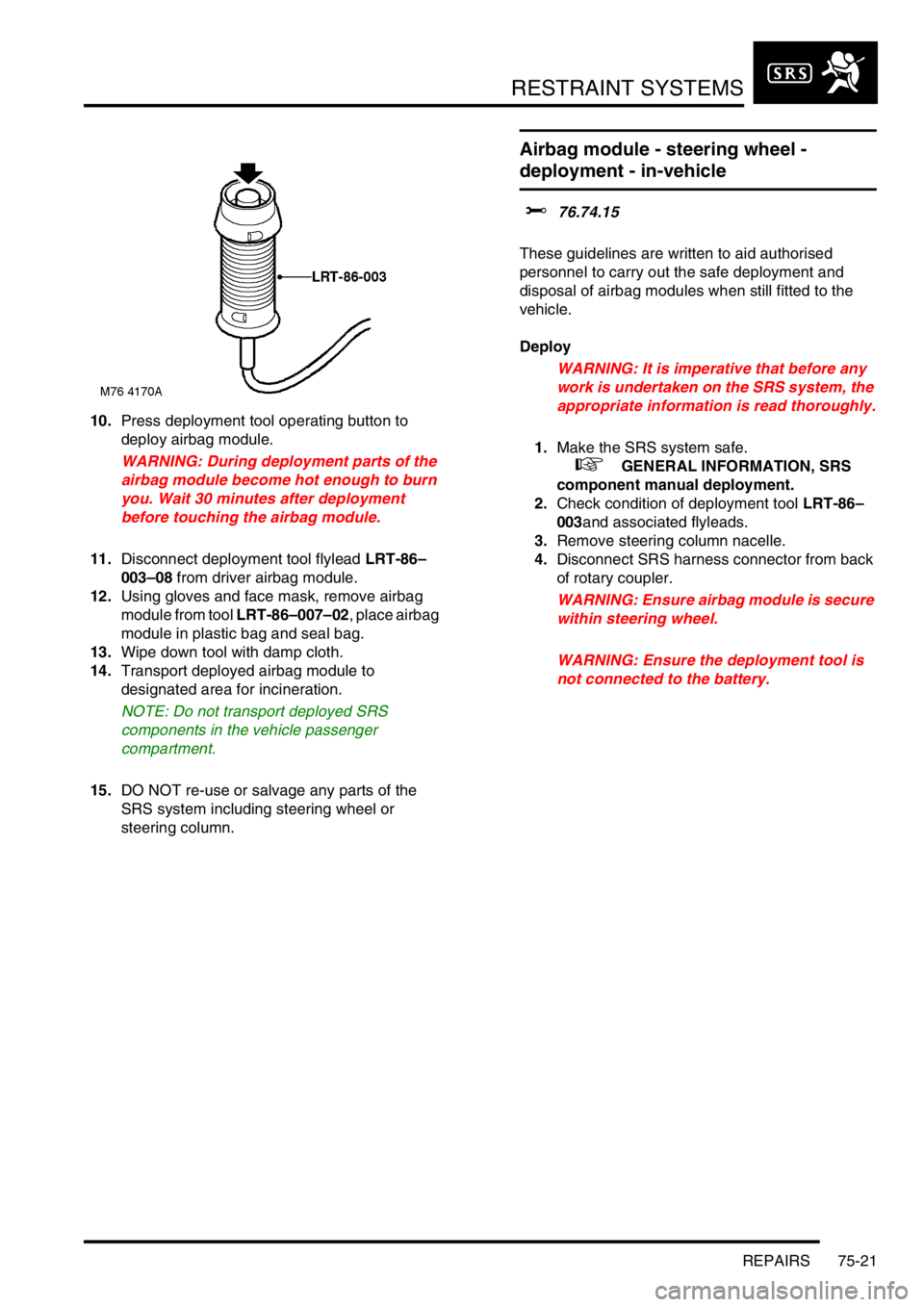

10.Press deployment tool operating button to

deploy airbag module.

WARNING: During deployment parts of the

airbag module become hot enough to burn

you. Wait 30 minutes after deployment

before touching the airbag module.

11.Disconnect deployment tool flylead LRT-86–

003–08 from driver airbag module.

12.Using gloves and face mask, remove airbag

module from tool LRT-86–007–02, place airbag

module in plastic bag and seal bag.

13.Wipe down tool with damp cloth.

14.Transport deployed airbag module to

designated area for incineration.

NOTE: Do not transport deployed SRS

components in the vehicle passenger

compartment.

15.DO NOT re-use or salvage any parts of the

SRS system including steering wheel or

steering column.

Airbag module - steering wheel -

deployment - in-vehicle

$% 76.74.15

These guidelines are written to aid authorised

personnel to carry out the safe deployment and

disposal of airbag modules when still fitted to the

vehicle.

Deploy

WARNING: It is imperative that before any

work is undertaken on the SRS system, the

appropriate information is read thoroughly.

1.Make the SRS system safe.

+ GENERAL INFORMATION, SRS

component manual deployment.

2.Check condition of deployment tool LRT-86–

003and associated flyleads.

3.Remove steering column nacelle.

4.Disconnect SRS harness connector from back

of rotary coupler.

WARNING: Ensure airbag module is secure

within steering wheel.

WARNING: Ensure the deployment tool is

not connected to the battery.

Page 603 of 1007

RESTRAINT SYSTEMS

75-22 REPAIRS

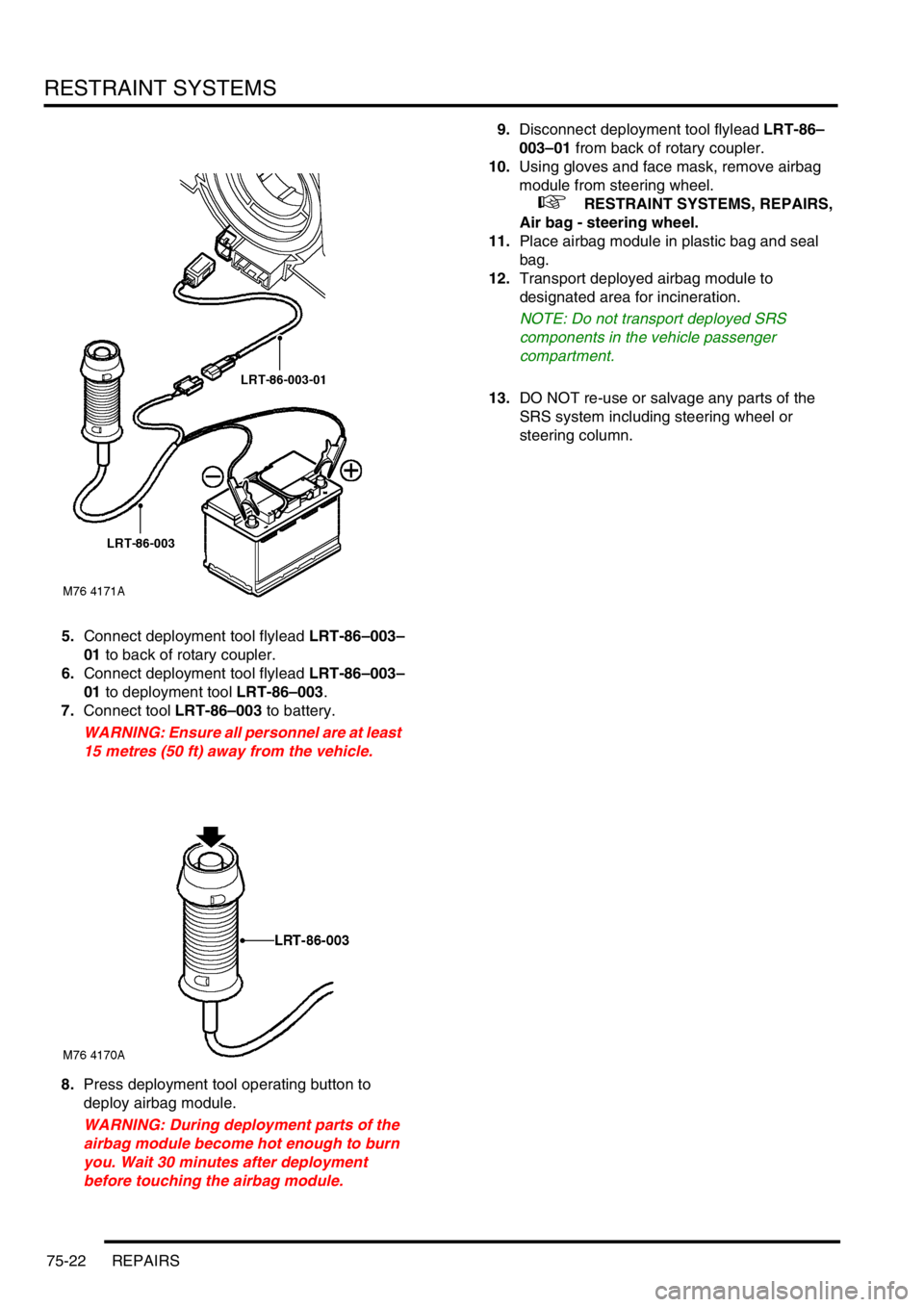

5.Connect deployment tool flylead LRT-86–003–

01 to back of rotary coupler.

6.Connect deployment tool flylead LRT-86–003–

01 to deployment tool LRT-86–003.

7.Connect tool LRT-86–003 to battery.

WARNING: Ensure all personnel are at least

15 metres (50 ft) away from the vehicle.

8.Press deployment tool operating button to

deploy airbag module.

WARNING: During deployment parts of the

airbag module become hot enough to burn

you. Wait 30 minutes after deployment

before touching the airbag module.9.Disconnect deployment tool flylead LRT-86–

003–01 from back of rotary coupler.

10.Using gloves and face mask, remove airbag

module from steering wheel.

+ RESTRAINT SYSTEMS, REPAIRS,

Air bag - steering wheel.

11.Place airbag module in plastic bag and seal

bag.

12.Transport deployed airbag module to

designated area for incineration.

NOTE: Do not transport deployed SRS

components in the vehicle passenger

compartment.

13.DO NOT re-use or salvage any parts of the

SRS system including steering wheel or

steering column.

Page 604 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-23

Pre-tensioner - front seatbelt -

deployment - in-vehicle

$% 76.73.77

These guidelines are written to aid authorised

personnel to carry out the safe deployment and

disposal of seatbelt pre-tensioners when they are still

fitted in the vehicle.

Deploy

WARNING: It is imperative that before any

work is undertaken on the SRS system, the

appropriate information is read thoroughly.

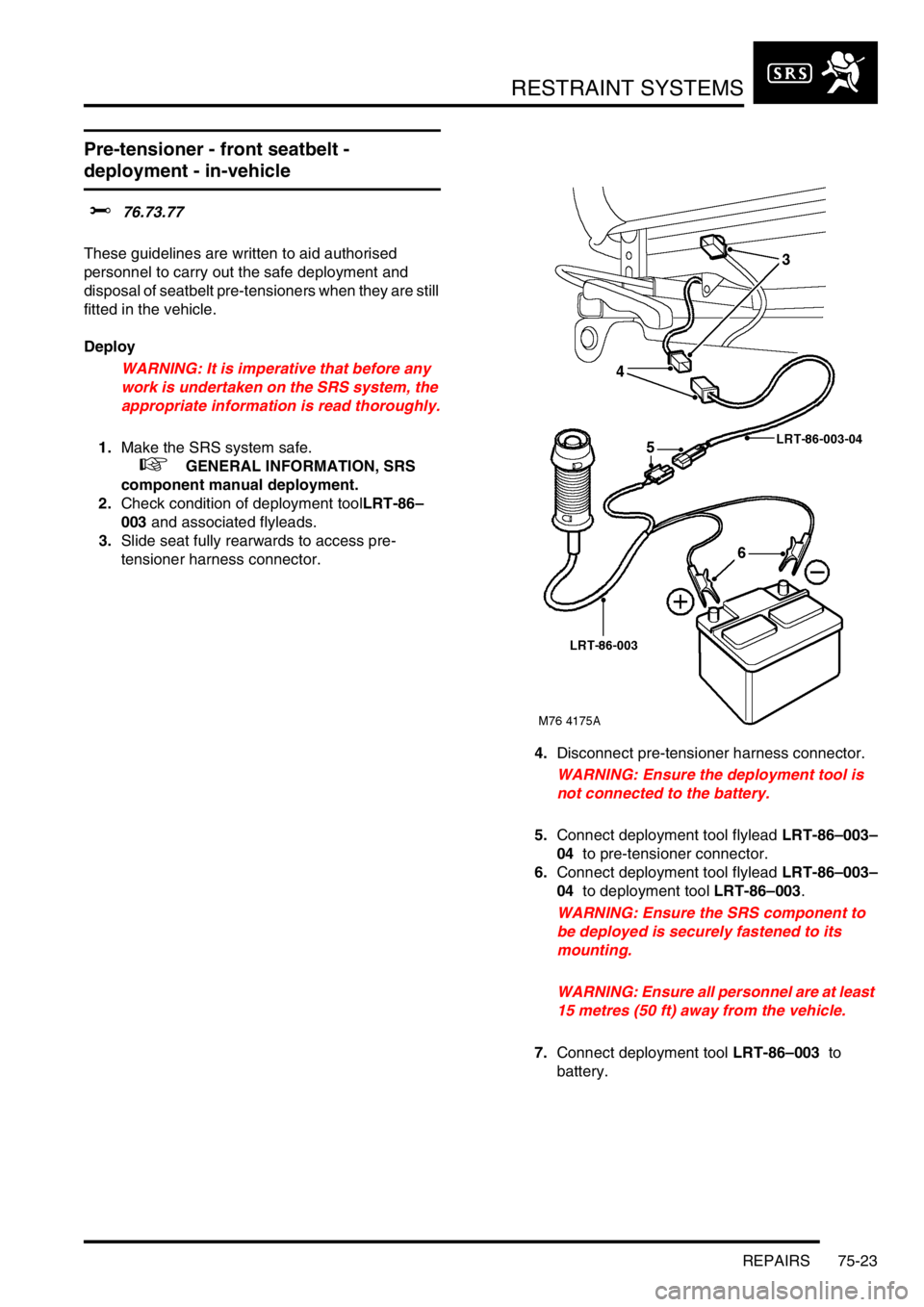

1.Make the SRS system safe.

+ GENERAL INFORMATION, SRS

component manual deployment.

2.Check condition of deployment toolLRT-86–

003 and associated flyleads.

3.Slide seat fully rearwards to access pre-

tensioner harness connector.

4.Disconnect pre-tensioner harness connector.

WARNING: Ensure the deployment tool is

not connected to the battery.

5.Connect deployment tool flylead LRT-86–003–

04 to pre-tensioner connector.

6.Connect deployment tool flylead LRT-86–003–

04 to deployment tool LRT-86–003.

WARNING: Ensure the SRS component to

be deployed is securely fastened to its

mounting.

WARNING: Ensure all personnel are at least

15 metres (50 ft) away from the vehicle.

7.Connect deployment tool LRT-86–003 to

battery.

Page 605 of 1007

RESTRAINT SYSTEMS

75-24 REPAIRS

8.Press deployment tool operating button to

deploy airbag module.

WARNING: A deployed airbag or seatbelt

pre-tensioner is very hot, DO NOT return to

a deployed airbag module until at least 30

minutes have elapsed since deployment.

9.Disconnect flylead LRT-86–003–04 from pre-

tensioner connector and remove pre-tensioner

from seat.

+ RESTRAINT SYSTEMS, REPAIRS,

Pre-tensioner - seat belt - front.

10.Place pre-tensioner in plastic bag and seal bag.

11.Transport deployed pre-tensioner to

designated area for incineration.

NOTE: Do not transport deployed SRS

components in the vehicle passenger

compartment.

12.Scrap all remaining parts of the seat belt and

SRS system. DO NOT re-use or salvage any

parts of the seat belt and SRS system.

Page 606 of 1007

DOORS

ADJUSTMENTS 76-1-1

DOORS ADJUST ME NTS

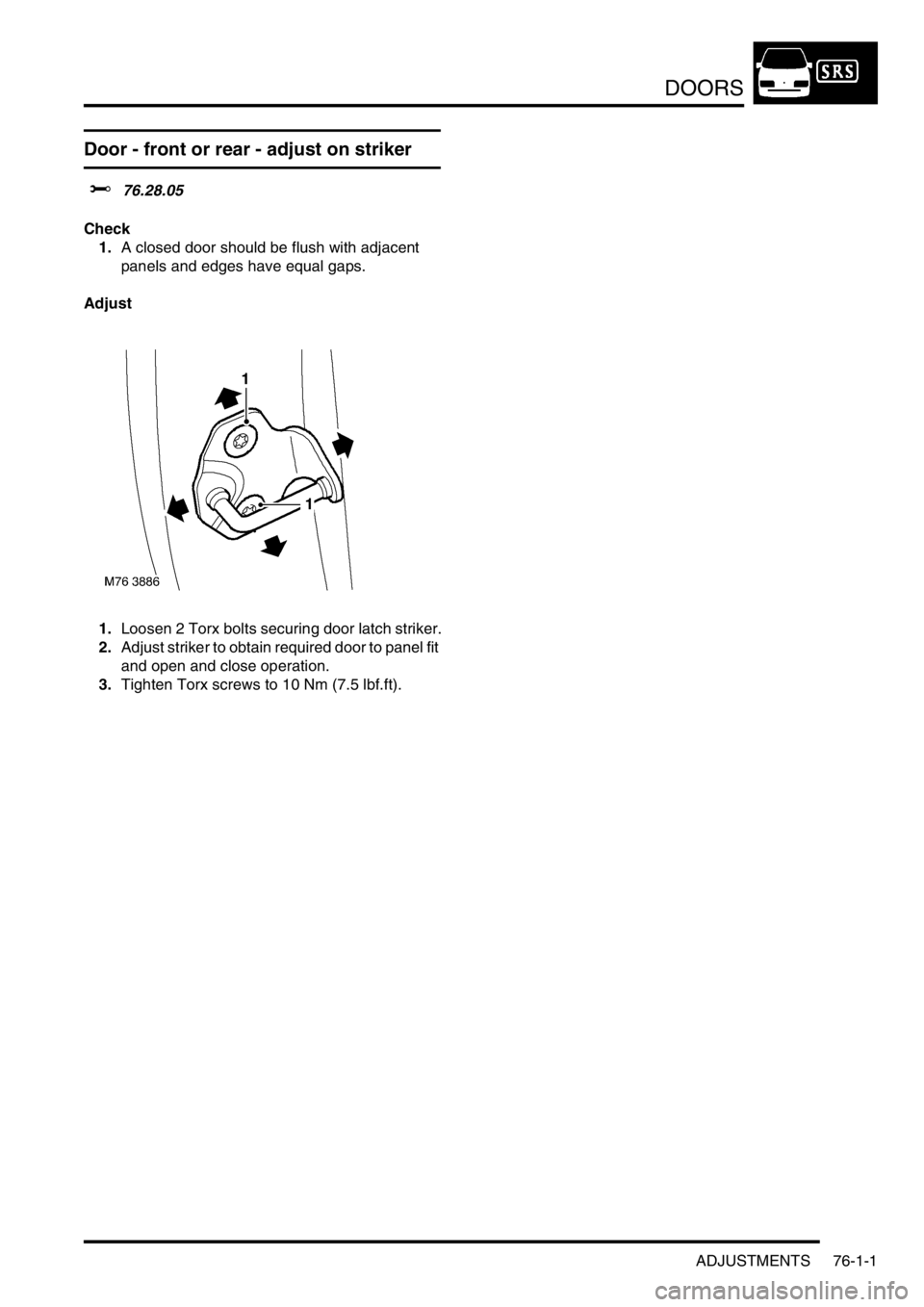

Door - front or rear - adjust on striker

$% 76.28.05

Check

1.A closed door should be flush with adjacent

panels and edges have equal gaps.

Adjust

1.Loosen 2 Torx bolts securing door latch striker.

2.Adjust striker to obtain required door to panel fit

and open and close operation.

3.Tighten Torx screws to 10 Nm (7.5 lbf.ft).

Page 607 of 1007

DOORS

76-1-2 ADJUSTMENTS

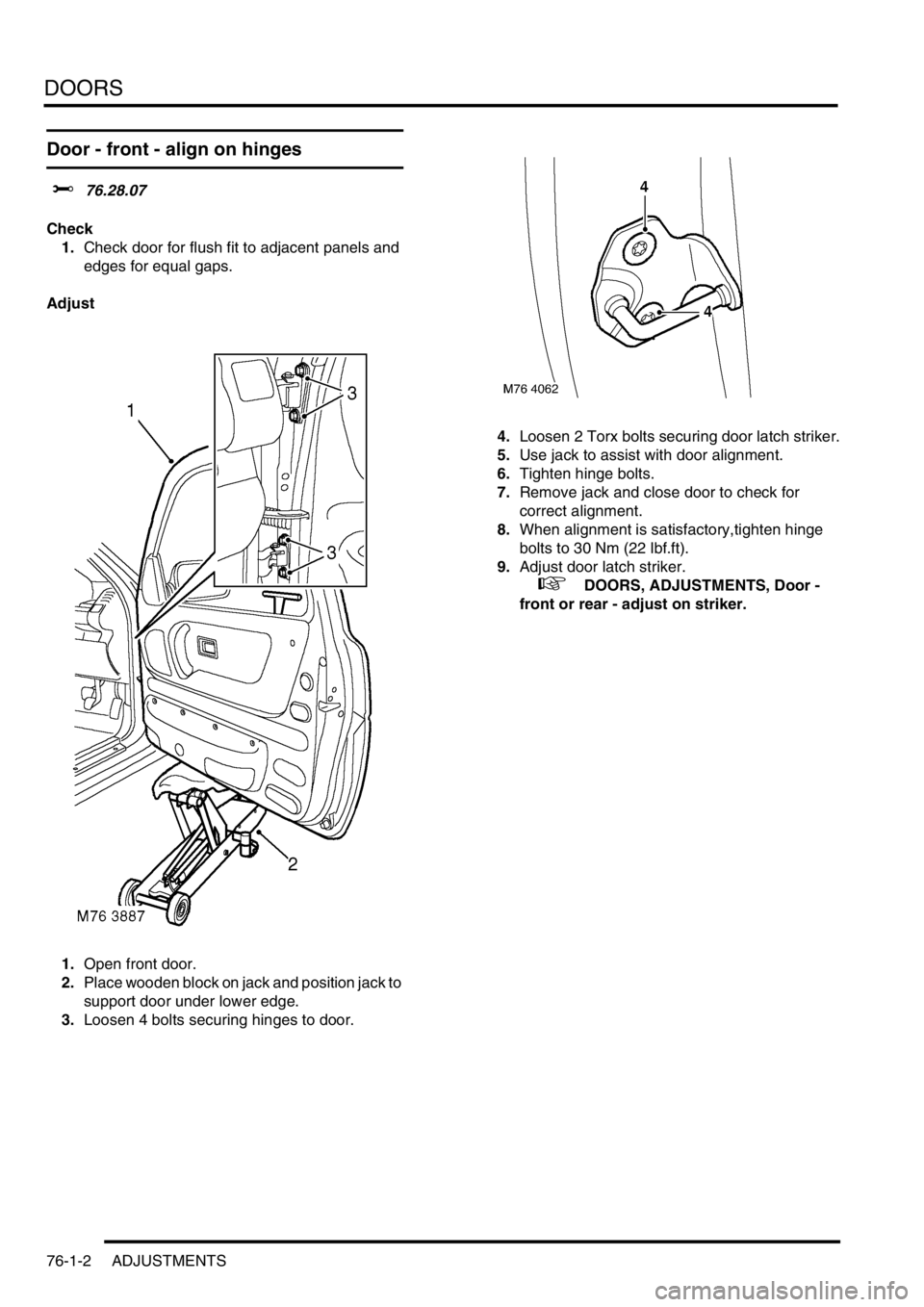

Door - front - align on hinges

$% 76.28.07

Check

1.Check door for flush fit to adjacent panels and

edges for equal gaps.

Adjust

1.Open front door.

2.Place wooden block on jack and position jack to

support door under lower edge.

3.Loosen 4 bolts securing hinges to door.4.Loosen 2 Torx bolts securing door latch striker.

5.Use jack to assist with door alignment.

6.Tighten hinge bolts.

7.Remove jack and close door to check for

correct alignment.

8.When alignment is satisfactory,tighten hinge

bolts to 30 Nm (22 lbf.ft).

9.Adjust door latch striker.

+ DOORS, ADJUSTMENTS, Door -

front or rear - adjust on striker.

Page 608 of 1007

DOORS

REPAIRS 76-1-3

REPAIRS

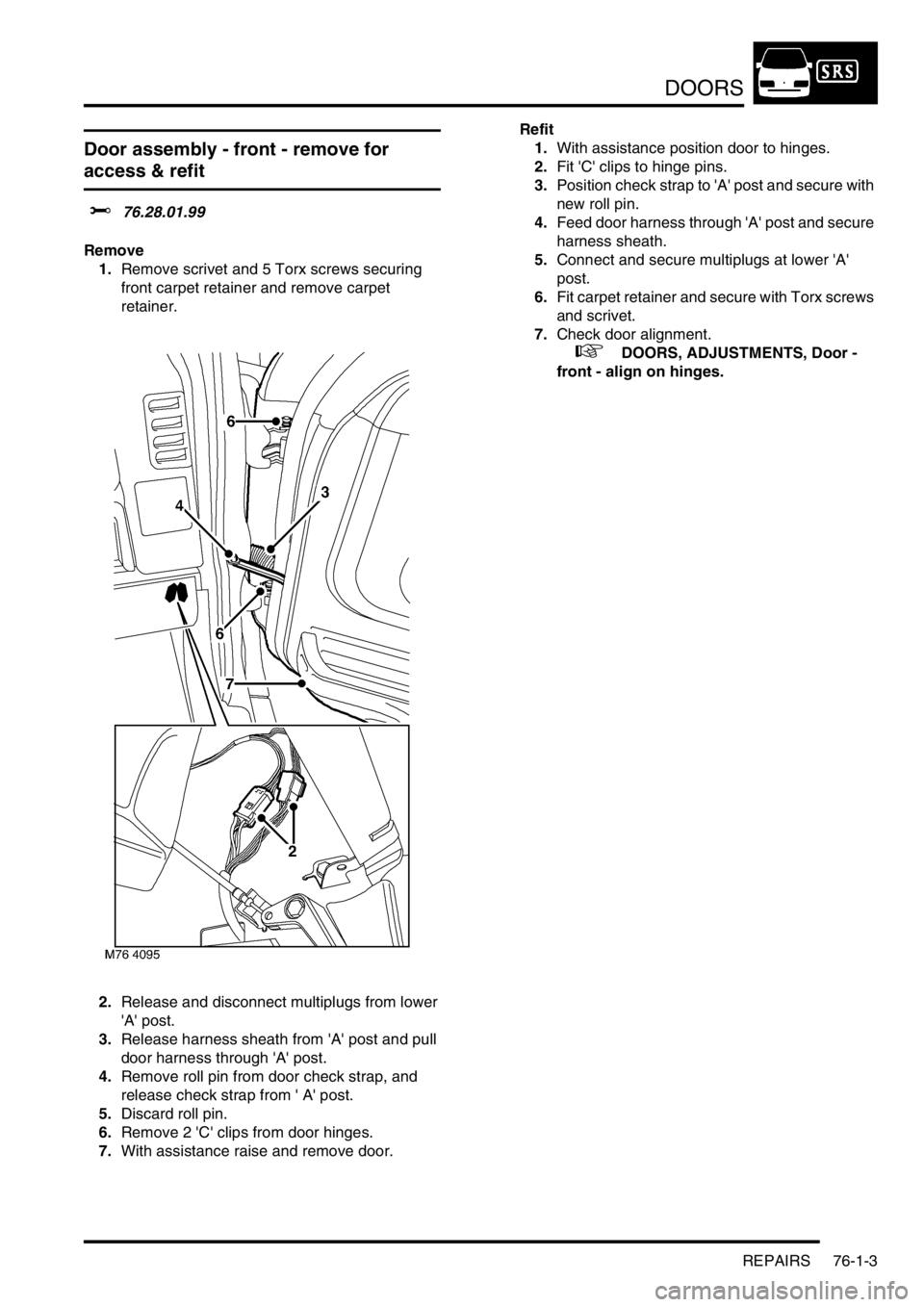

Door assembly - front - remove for

access & refit

$% 76.28.01.99

Remove

1.Remove scrivet and 5 Torx screws securing

front carpet retainer and remove carpet

retainer.

2.Release and disconnect multiplugs from lower

'A' post.

3.Release harness sheath from 'A' post and pull

door harness through 'A' post.

4.Remove roll pin from door check strap, and

release check strap from ' A' post.

5.Discard roll pin.

6.Remove 2 'C' clips from door hinges.

7.With assistance raise and remove door.Refit

1.With assistance position door to hinges.

2.Fit 'C' clips to hinge pins.

3.Position check strap to 'A' post and secure with

new roll pin.

4.Feed door harness through 'A' post and secure

harness sheath.

5.Connect and secure multiplugs at lower 'A'

post.

6.Fit carpet retainer and secure with Torx screws

and scrivet.

7.Check door alignment.

+ DOORS, ADJUSTMENTS, Door -

front - align on hinges.

Page 609 of 1007

DOORS

76-1-4 REPAIRS

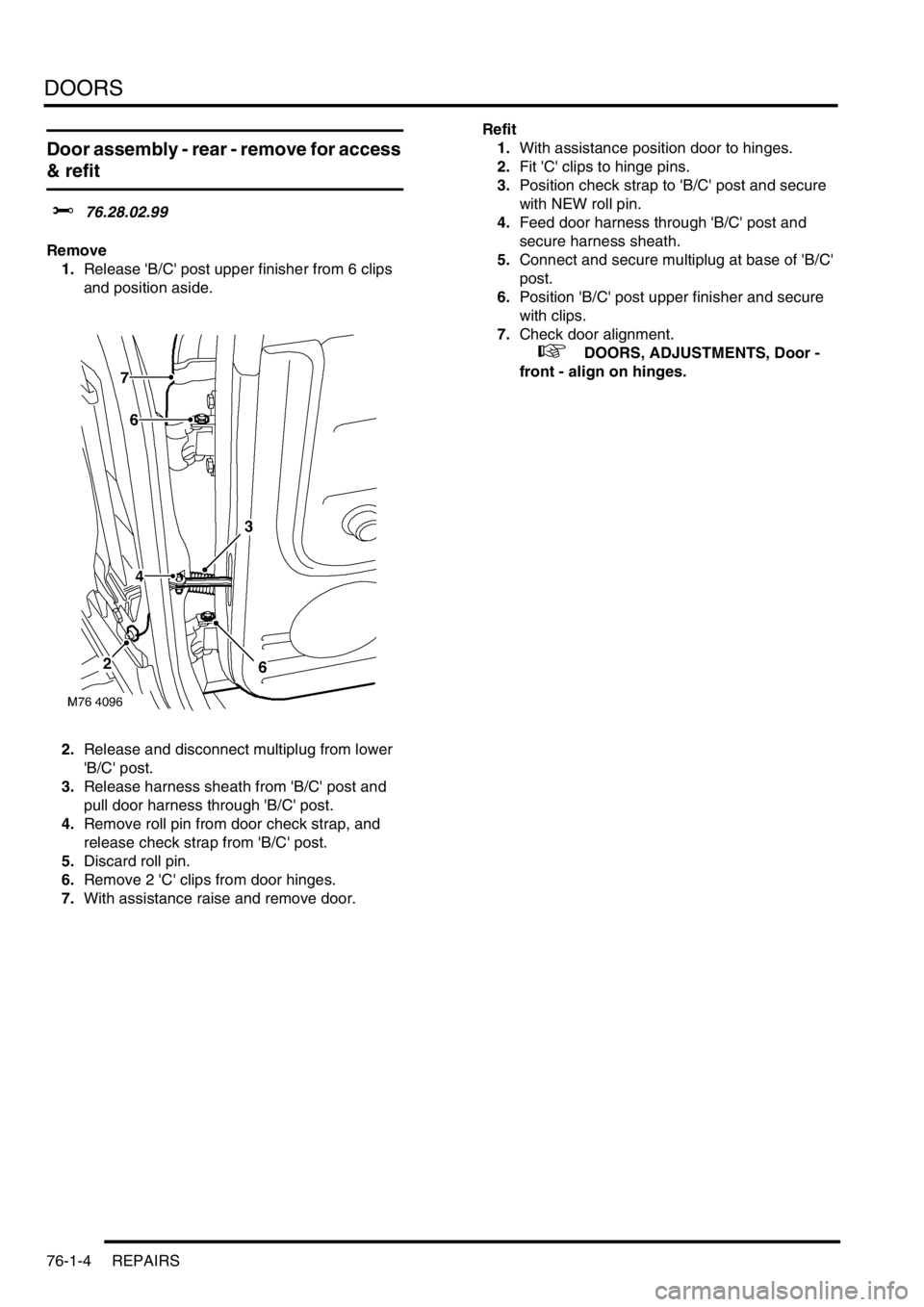

Door assembly - rear - remove for access

& refit

$% 76.28.02.99

Remove

1.Release 'B/C' post upper finisher from 6 clips

and position aside.

2.Release and disconnect multiplug from lower

'B/C' post.

3.Release harness sheath from 'B/C' post and

pull door harness through 'B/C' post.

4.Remove roll pin from door check strap, and

release check strap from 'B/C' post.

5.Discard roll pin.

6.Remove 2 'C' clips from door hinges.

7.With assistance raise and remove door.Refit

1.With assistance position door to hinges.

2.Fit 'C' clips to hinge pins.

3.Position check strap to 'B/C' post and secure

with NEW roll pin.

4.Feed door harness through 'B/C' post and

secure harness sheath.

5.Connect and secure multiplug at base of 'B/C'

post.

6.Position 'B/C' post upper finisher and secure

with clips.

7.Check door alignment.

+ DOORS, ADJUSTMENTS, Door -

front - align on hinges.

Page 610 of 1007

DOORS

REPAIRS 76-1-5

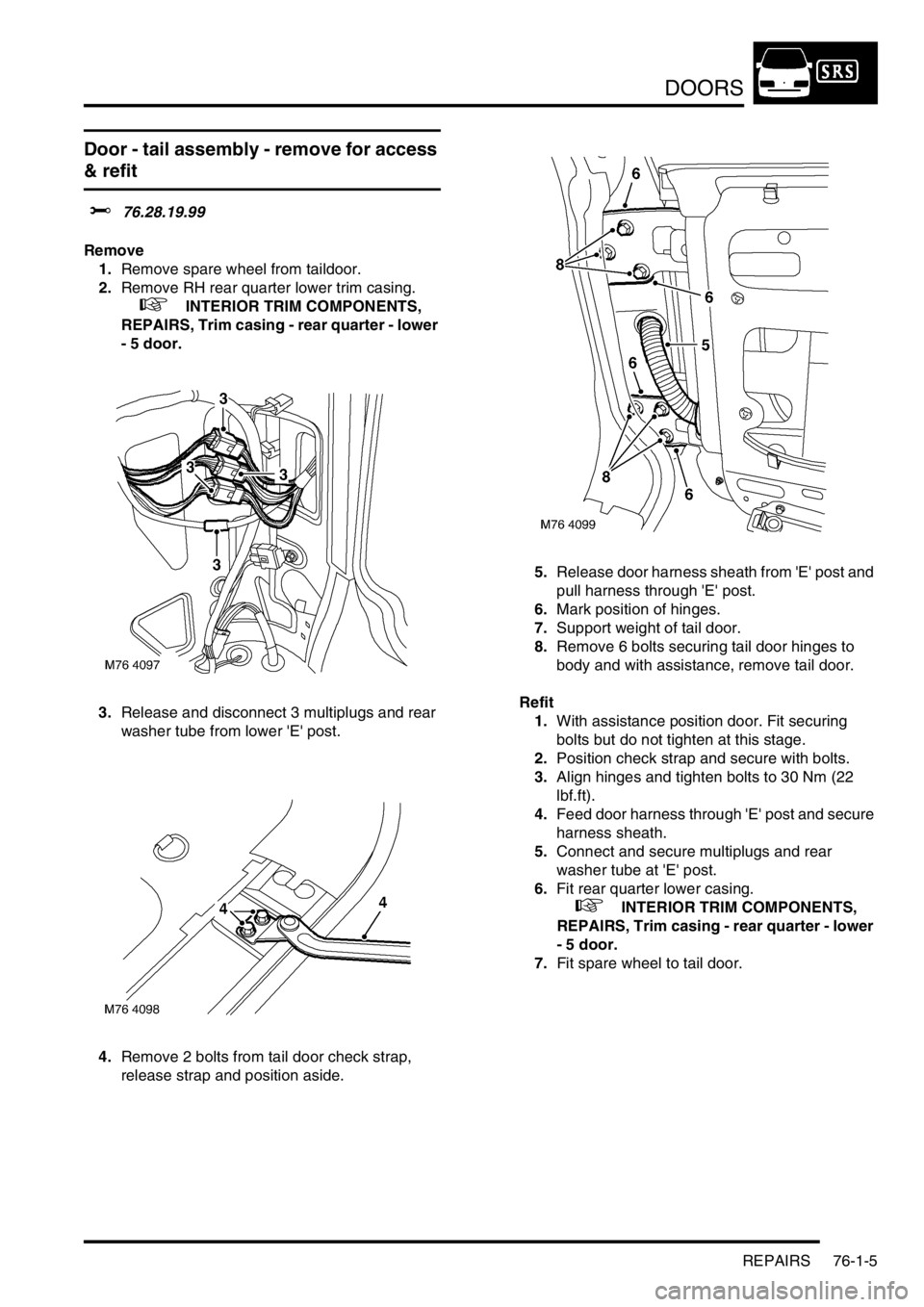

Door - tail assembly - remove for access

& refit

$% 76.28.19.99

Remove

1.Remove spare wheel from taildoor.

2.Remove RH rear quarter lower trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 5 door.

3.Release and disconnect 3 multiplugs and rear

washer tube from lower 'E' post.

4.Remove 2 bolts from tail door check strap,

release strap and position aside.5.Release door harness sheath from 'E' post and

pull harness through 'E' post.

6.Mark position of hinges.

7.Support weight of tail door.

8.Remove 6 bolts securing tail door hinges to

body and with assistance, remove tail door.

Refit

1.With assistance position door. Fit securing

bolts but do not tighten at this stage.

2.Position check strap and secure with bolts.

3.Align hinges and tighten bolts to 30 Nm (22

lbf.ft).

4.Feed door harness through 'E' post and secure

harness sheath.

5.Connect and secure multiplugs and rear

washer tube at 'E' post.

6.Fit rear quarter lower casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 5 door.

7.Fit spare wheel to tail door.