LAND ROVER FREELANDER 2001 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 571 of 1007

BRAKES

70-22 REPAIRS

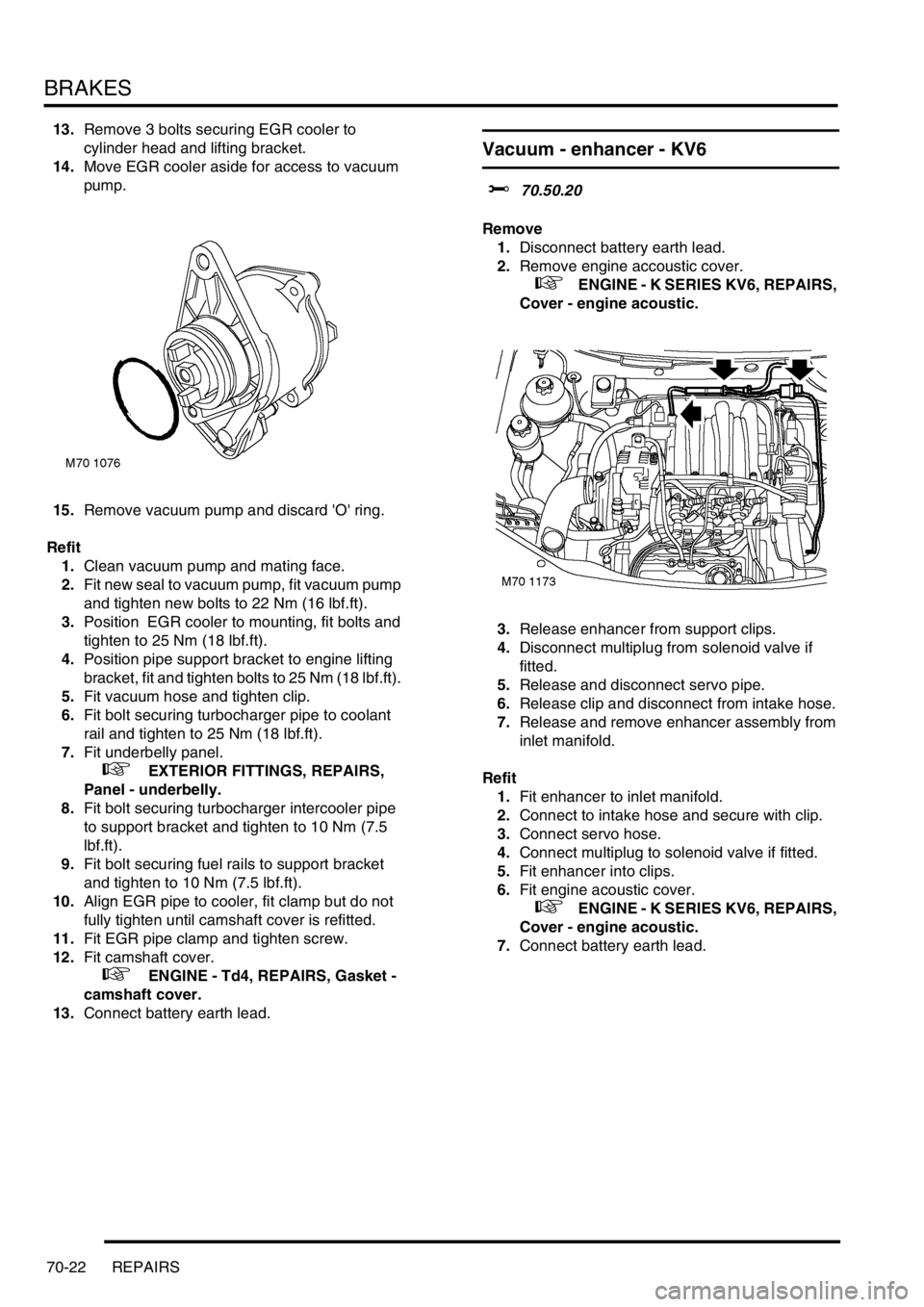

13.Remove 3 bolts securing EGR cooler to

cylinder head and lifting bracket.

14.Move EGR cooler aside for access to vacuum

pump.

15.Remove vacuum pump and discard 'O' ring.

Refit

1.Clean vacuum pump and mating face.

2.Fit new seal to vacuum pump, fit vacuum pump

and tighten new bolts to 22 Nm (16 lbf.ft).

3.Position EGR cooler to mounting, fit bolts and

tighten to 25 Nm (18 lbf.ft).

4.Position pipe support bracket to engine lifting

bracket, fit and tighten bolts to 25 Nm (18 lbf.ft).

5.Fit vacuum hose and tighten clip.

6.Fit bolt securing turbocharger pipe to coolant

rail and tighten to 25 Nm (18 lbf.ft).

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Fit bolt securing turbocharger intercooler pipe

to support bracket and tighten to 10 Nm (7.5

lbf.ft).

9.Fit bolt securing fuel rails to support bracket

and tighten to 10 Nm (7.5 lbf.ft).

10.Align EGR pipe to cooler, fit clamp but do not

fully tighten until camshaft cover is refitted.

11.Fit EGR pipe clamp and tighten screw.

12.Fit camshaft cover.

+ ENGINE - Td4, REPAIRS, Gasket -

camshaft cover.

13.Connect battery earth lead.

Vacuum - enhancer - KV6

$% 70.50.20

Remove

1.Disconnect battery earth lead.

2.Remove engine accoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Release enhancer from support clips.

4.Disconnect multiplug from solenoid valve if

fitted.

5.Release and disconnect servo pipe.

6.Release clip and disconnect from intake hose.

7.Release and remove enhancer assembly from

inlet manifold.

Refit

1.Fit enhancer to inlet manifold.

2.Connect to intake hose and secure with clip.

3.Connect servo hose.

4.Connect multiplug to solenoid valve if fitted.

5.Fit enhancer into clips.

6.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

7.Connect battery earth lead.

Page 572 of 1007

BRAKES

REPAIRS 70-23

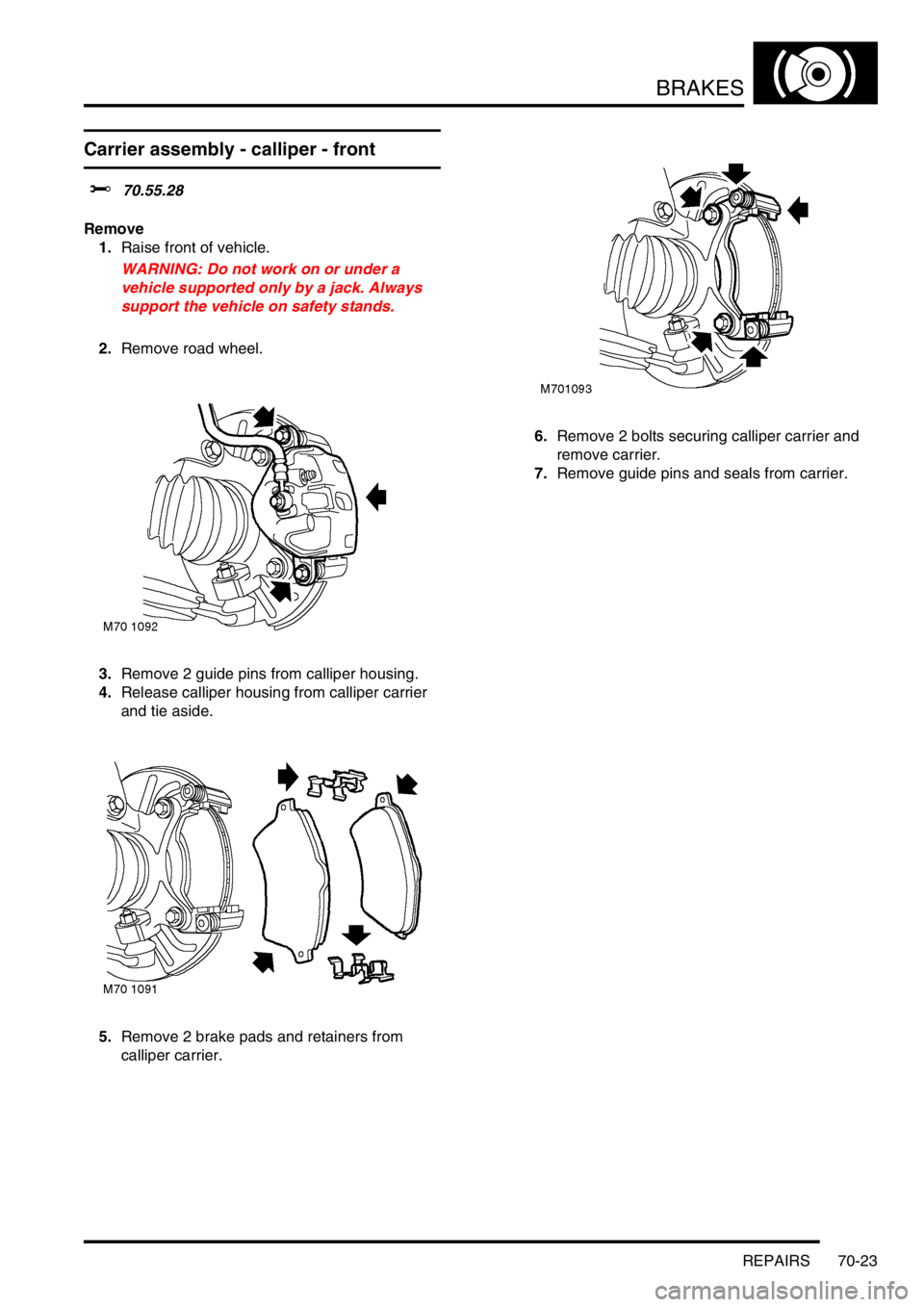

Carrier assembly - calliper - front

$% 70.55.28

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Remove 2 guide pins from calliper housing.

4.Release calliper housing from calliper carrier

and tie aside.

5.Remove 2 brake pads and retainers from

calliper carrier.6.Remove 2 bolts securing calliper carrier and

remove carrier.

7.Remove guide pins and seals from carrier.

Page 573 of 1007

BRAKES

70-24 REPAIRS

Refit

1.Clean guide pins and carrier mating faces.

2.Fit guide pins and seals to carrier.

3.Fit carrier, fit bolts and tighten to 100 Nm (74

lbf.ft).

4.Rotate disc by hand and scrape all scale and

rust from around edge of disc. Clean location

surfaces on calliper bracket.

5.Clean dust from brake parts using brake

cleaning fluid.

WARNING: Do not use an air line to blow

dust from brake assembly. Do not use

petroleum based fluid as damage will occur

to rubber components.

6.Clean mating faces of calliper and hub.

7.Fit pad retainers to calliper bracket.

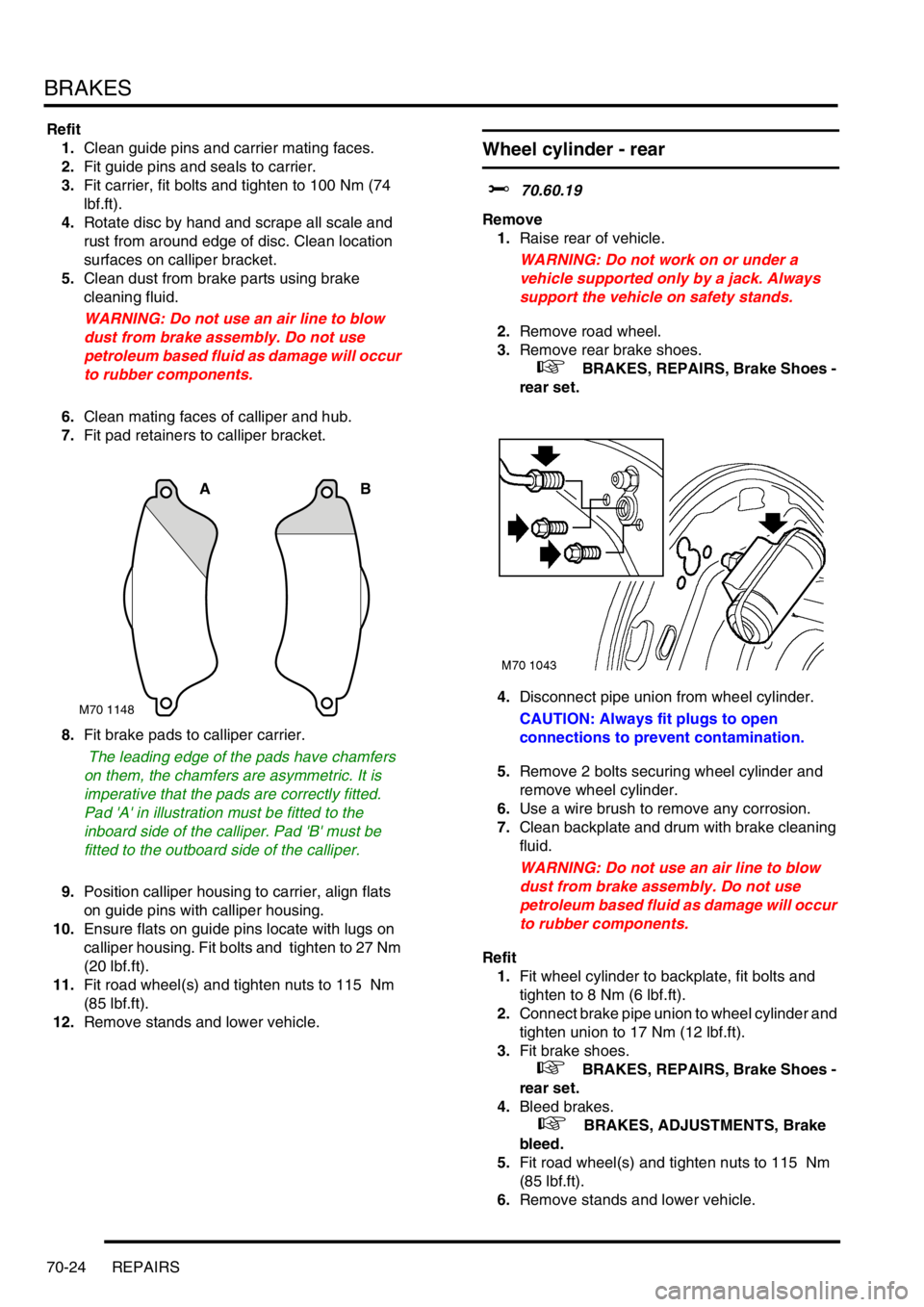

8.Fit brake pads to calliper carrier.

The leading edge of the pads have chamfers

on them, the chamfers are asymmetric. It is

imperative that the pads are correctly fitted.

Pad 'A' in illustration must be fitted to the

inboard side of the calliper. Pad 'B' must be

fitted to the outboard side of the calliper.

9.Position calliper housing to carrier, align flats

on guide pins with calliper housing.

10.Ensure flats on guide pins locate with lugs on

calliper housing. Fit bolts and tighten to 27 Nm

(20 lbf.ft).

11.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

12.Remove stands and lower vehicle.

Wheel cylinder - rear

$% 70.60.19

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Remove rear brake shoes.

+ BRAKES, REPAIRS, Brake Shoes -

rear set.

4.Disconnect pipe union from wheel cylinder.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove 2 bolts securing wheel cylinder and

remove wheel cylinder.

6.Use a wire brush to remove any corrosion.

7.Clean backplate and drum with brake cleaning

fluid.

WARNING: Do not use an air line to blow

dust from brake assembly. Do not use

petroleum based fluid as damage will occur

to rubber components.

Refit

1.Fit wheel cylinder to backplate, fit bolts and

tighten to 8 Nm (6 lbf.ft).

2.Connect brake pipe union to wheel cylinder and

tighten union to 17 Nm (12 lbf.ft).

3.Fit brake shoes.

+ BRAKES, REPAIRS, Brake Shoes -

rear set.

4.Bleed brakes.

+ BRAKES, ADJUSTMENTS, Brake

bleed.

5.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

6.Remove stands and lower vehicle.

M70 1148

AB

Page 574 of 1007

BRAKES

REPAIRS 70-25

Switch - low fluid level

$% 70.65.06

Remove

1.Disconnect brake fluid level multiplug.

2.Release retaining pin and remove fluid level

switch.

Refit

1.Clean brake fluid level switch.

2.Fit brake fluid level switch.

3.Connect multiplug to brake fluid level switch.

Sensor & harness - front wheel - RH

$% 70.65.29

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Remove front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - front wheel arch.

4.Locate ABS sensor harness on inner wing.

5.Release ABS sensor multiplug from body clip

and disconnect multiplug.

6.Release grommet from wing valance and pull

harness through.

Page 575 of 1007

BRAKES

70-26 REPAIRS

7.Release 2 grommets from wing valance and

damper brackets

8.Release harness from brake hose clips.

9.Remove bolt securing ABS sensor to hub, if

fitted.

10.Release ABS sensor from hub.

11.Remove ABS sensor and harness.

12.Remove bush from front hub.Refit

1.Clean ABS sensors and mating faces.

2.Fit new bush to front hub.

3.Apply anti-seize grease to sensor.

4.Fit sensor to hub, ensure sensor is fully seated

in hub.

CAUTION: Ensure ABS sensor is fully

located into hub, so that sensor touches

pole wheel teeth.

5.Fit and tighten bolt securing ABS sensor to hub,

if fitted.

6.Secure harness grommets to brackets.

7.Pass sensor harness through wing valance and

secure grommet.

8.Ensure 'O' ring is in place and connect sensor

multiplug to body harness.

9.Secure multiplug in body clip.

10.Secure harness to brake hose clip.

11.Fit front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - front wheel arch.

12.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

13.Remove stand and lower vehicle.

14.To ensure correct operation, the ABS system

MUST be tested using TestBook/T4.

Page 576 of 1007

BRAKES

REPAIRS 70-27

Sensor & harness - front wheel - LH

$% 70.65.30

Remove

1.Remove battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

2.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove road wheel.

4.Remove front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - front wheel arch.

5.Locate ABS sensor harness on inner wing.

6.Release ABS sensor multiplug from body clip

and disconnect multiplug.

7.Release grommet from wing valance and pull

harness through.8.Release 2 grommets from wing valance and

damper brackets

9.Release harness from brake hose clips.

10.Remove bolt securing ABS sensor to hub, if

fitted.

11.Release ABS sensor from hub.

12.Remove ABS sensor and harness.

13.Remove bush from front hub.

Page 577 of 1007

BRAKES

70-28 REPAIRS

Refit

1.Clean ABS sensors and mating faces.

2.Fit new bush to front hub.

3.Apply anti-seize grease to sensor.

4.Fit sensor to hub, ensure sensor is fully seated

in hub.

CAUTION: Ensure ABS sensor is fully

located into hub, so that sensor touches

pole wheel teeth.

5.Fit bolt securing ABS sensor to hub, if fitted.

6.Secure harness grommets to brackets.

7.Pass sensor harness through wing valance and

secure grommet.

8.Ensure 'O' ring is in place and connect sensor

multiplug to body harness.

9.Secure multiplug in body clip.

10.Secure harness to brake hose clip.

11.Fit front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - front wheel arch.

12.Fit battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

13.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

14.Remove stand and lower vehicle.

15.To ensure correct operation, the ABS system

MUST be tested using TestBook/T4.

Page 578 of 1007

BRAKES

REPAIRS 70-29

Sensor & harness - rear wheel

$% 70.65.31

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Release ABS sensor multiplug from body clip

and disconnect multiplug.

4.Release ABS sensor harness from 3 grommets

on suspension and body brackets.

5.Release harness from clip on rear brake hose.6.Remove bolt securing ABS sensor to hub, if

fitted.

7.Release sensor from rear hub and remove

sensor and harness.

8.Remove bush from rear hub.

Refit

1.Clean sensor and rear hub mating faces.

2.Fit new bush to rear hub.

3.Apply anti-seize grease to sensor.

4.Fit sensor to hub, ensure sensor is fully seated

in hub.

CAUTION: Ensure ABS sensor is fully

located into hub, so that sensor touches

pole wheel teeth.

5.Fit bolt securing ABS sensor to hub, if fitted.

6.Ensure 'O' ring is in place and connect sensor

multiplug to body harness.

7.Secure multiplug in body clip.

8.Secure harness grommets to brackets.

9.Secure harness to brake hose clip.

10.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

11.Remove stands and lower vehicle.

12.To ensure correct operation, the ABS system

MUST be tested using TestBook/T4.

Page 579 of 1007

BRAKES

70-30 REPAIRS

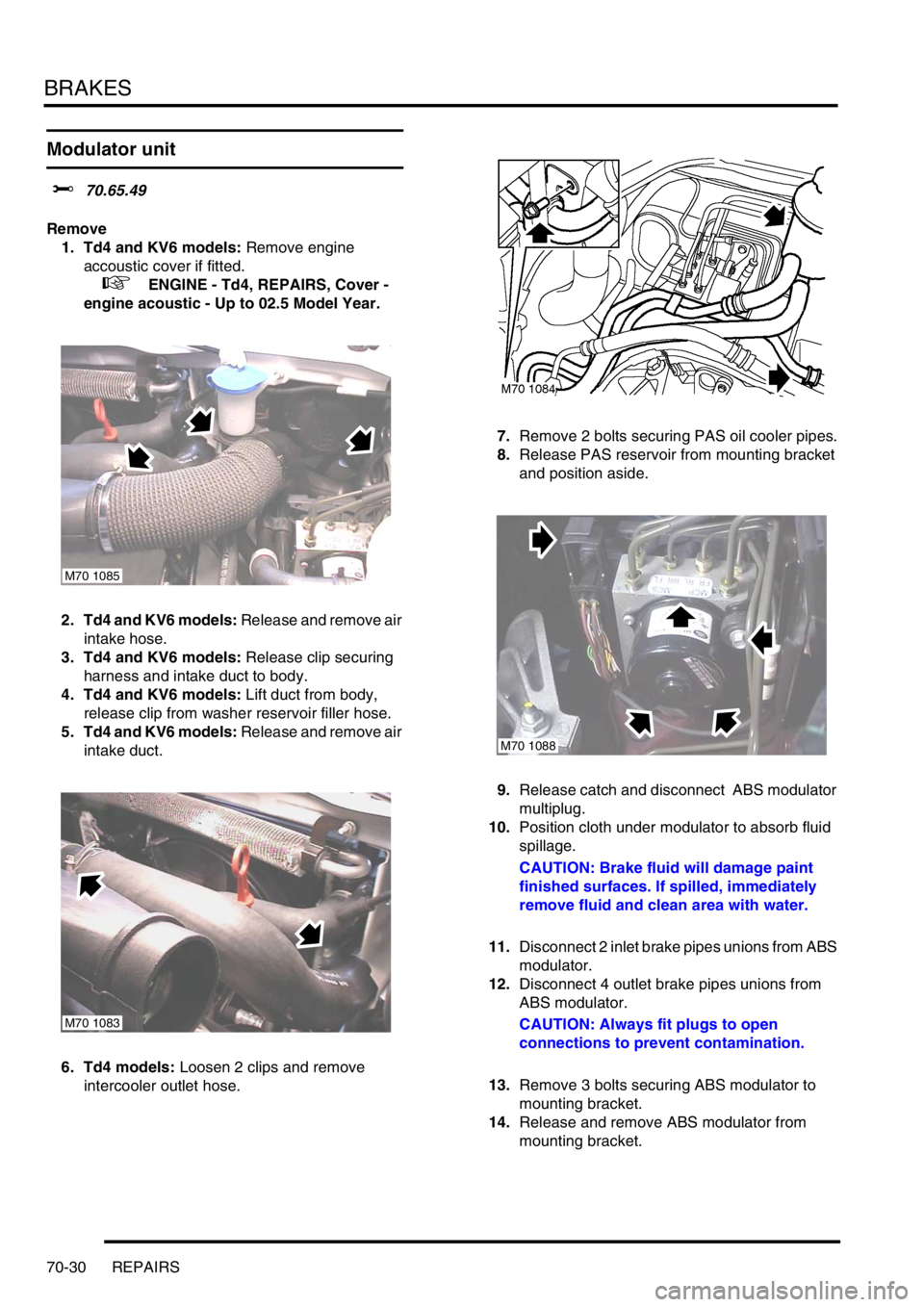

Modulator unit

$% 70.65.49

Remove

1. Td4 and KV6 models: Remove engine

accoustic cover if fitted.

+ ENGINE - Td4, REPAIRS, Cover -

engine acoustic - Up to 02.5 Model Year.

2. Td4 and KV6 models: Release and remove air

intake hose.

3. Td4 and KV6 models: Release clip securing

harness and intake duct to body.

4. Td4 and KV6 models: Lift duct from body,

release clip from washer reservoir filler hose.

5. Td4 and KV6 models: Release and remove air

intake duct.

6. Td4 models: Loosen 2 clips and remove

intercooler outlet hose.7.Remove 2 bolts securing PAS oil cooler pipes.

8.Release PAS reservoir from mounting bracket

and position aside.

9.Release catch and disconnect ABS modulator

multiplug.

10.Position cloth under modulator to absorb fluid

spillage.

CAUTION: Brake fluid will damage paint

finished surfaces. If spilled, immediately

remove fluid and clean area with water.

11.Disconnect 2 inlet brake pipes unions from ABS

modulator.

12.Disconnect 4 outlet brake pipes unions from

ABS modulator.

CAUTION: Always fit plugs to open

connections to prevent contamination.

13.Remove 3 bolts securing ABS modulator to

mounting bracket.

14.Release and remove ABS modulator from

mounting bracket.

M70 1085

M70 1083

M70 1088

Page 580 of 1007

BRAKES

REPAIRS 70-31

Refit

1.Position modulator to mounting bracket fit bolts

and tighten to 9 Nm (7 lbf.ft).

2.Clean brake pipe unions.

3.Connect brake pipe unions to modulator

ensuring pipes are connected to their correct

ports.

4.Tighten unions to 17 Nm (12 lbf.ft).

5.Connect ABS modulator multiplug and secure

catch.

6. Td4 and KV6 models: Position air intake duct

to body.

7. Td4 and KV6 models: Secure intake duct to

washer bottle filler neck and harness clip.

8. Td4 and KV6 models: Fit air intake hose.

9.Fit PAS reservoir to mounting bracket.

10.Fit bolts securing PAS oil cooler pipes and

tighten to 10 Nm (7.5 lbf.ft).

11. Td4 models: Fit intercooler outlet hose and

tighten clips.

12. Td4 and KV6 models: Fit engine accoustic

cover if fitted.

+ ENGINE - Td4, REPAIRS, Cover -

engine acoustic - Up to 02.5 Model Year.

13.Bleed brakes.

+ BRAKES, ADJUSTMENTS, Brake

bleed.

14.To ensure correct operation, the ABS system

MUST be tested using TestBook/T4.

Switch - hill descent - from 04MY

$% 70.70.11

Remove

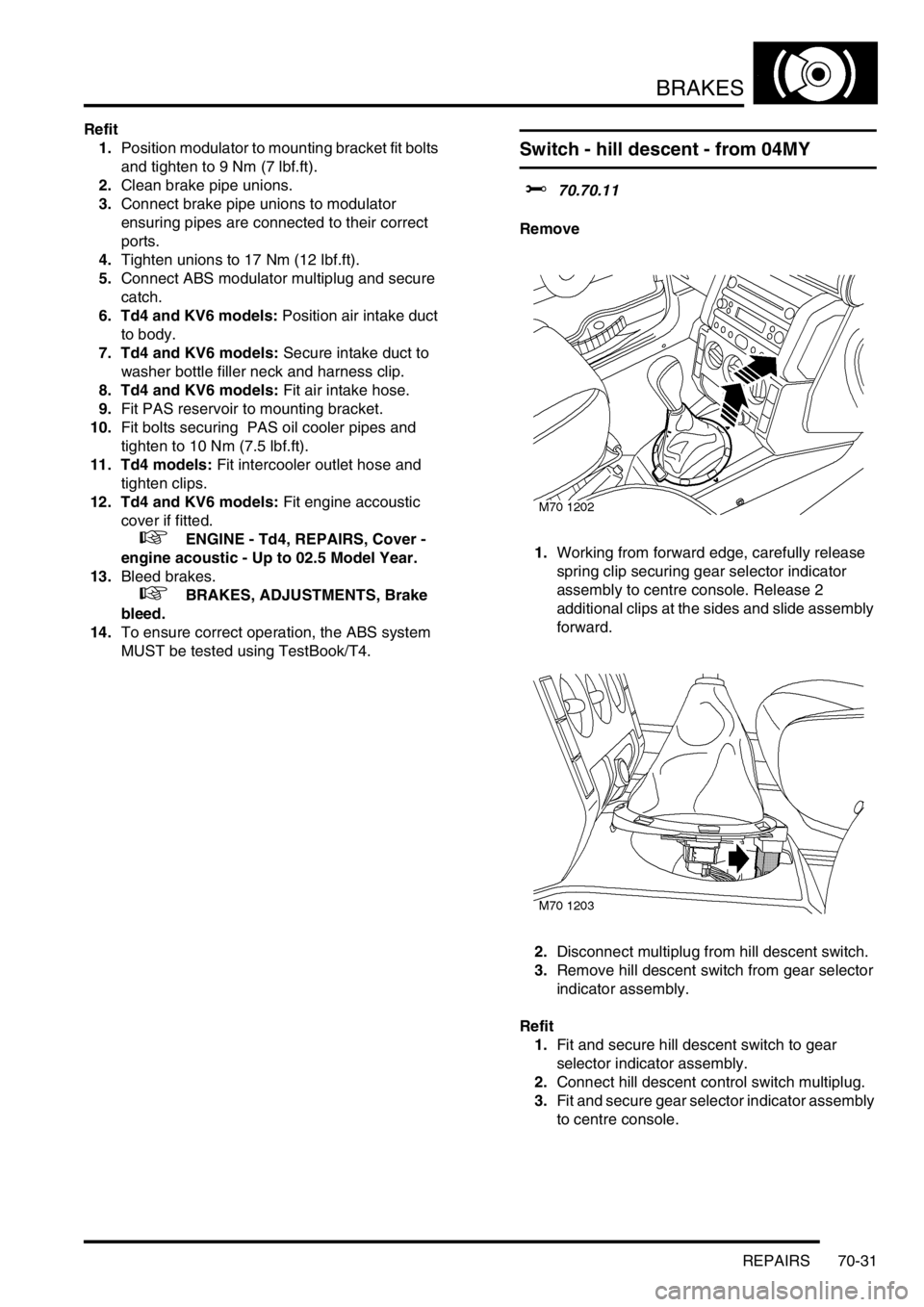

1.Working from forward edge, carefully release

spring clip securing gear selector indicator

assembly to centre console. Release 2

additional clips at the sides and slide assembly

forward.

2.Disconnect multiplug from hill descent switch.

3.Remove hill descent switch from gear selector

indicator assembly.

Refit

1.Fit and secure hill descent switch to gear

selector indicator assembly.

2.Connect hill descent control switch multiplug.

3.Fit and secure gear selector indicator assembly

to centre console.