LAND ROVER FREELANDER 2001 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 581 of 1007

BRAKES

70-32 REPAIRS

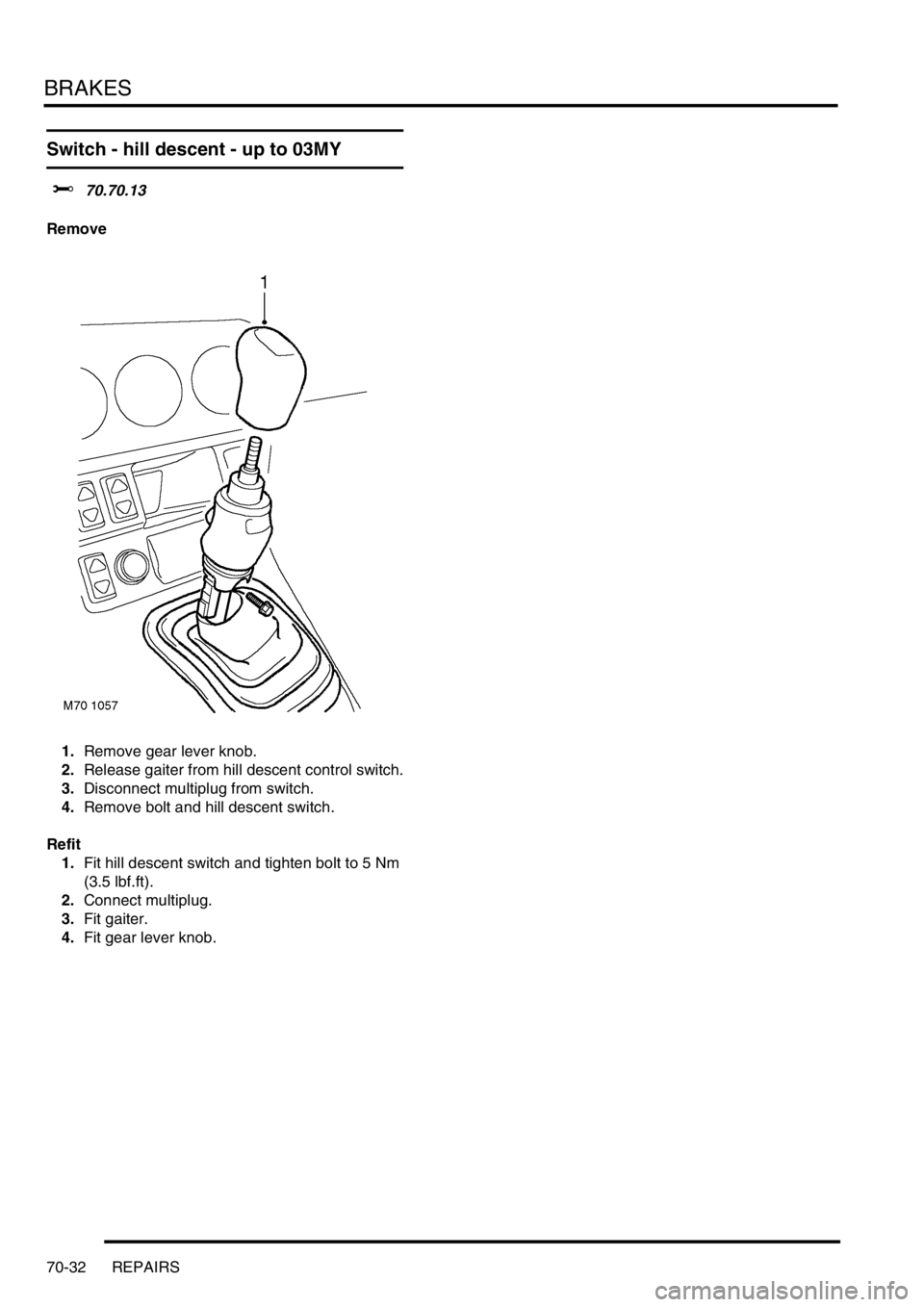

Switch - hill descent - up to 03MY

$% 70.70.13

Remove

1.Remove gear lever knob.

2.Release gaiter from hill descent control switch.

3.Disconnect multiplug from switch.

4.Remove bolt and hill descent switch.

Refit

1.Fit hill descent switch and tighten bolt to 5 Nm

(3.5 lbf.ft).

2.Connect multiplug.

3.Fit gaiter.

4.Fit gear lever knob.

Page 582 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-1

RESTRAINT SYSTEMS REPAIRS

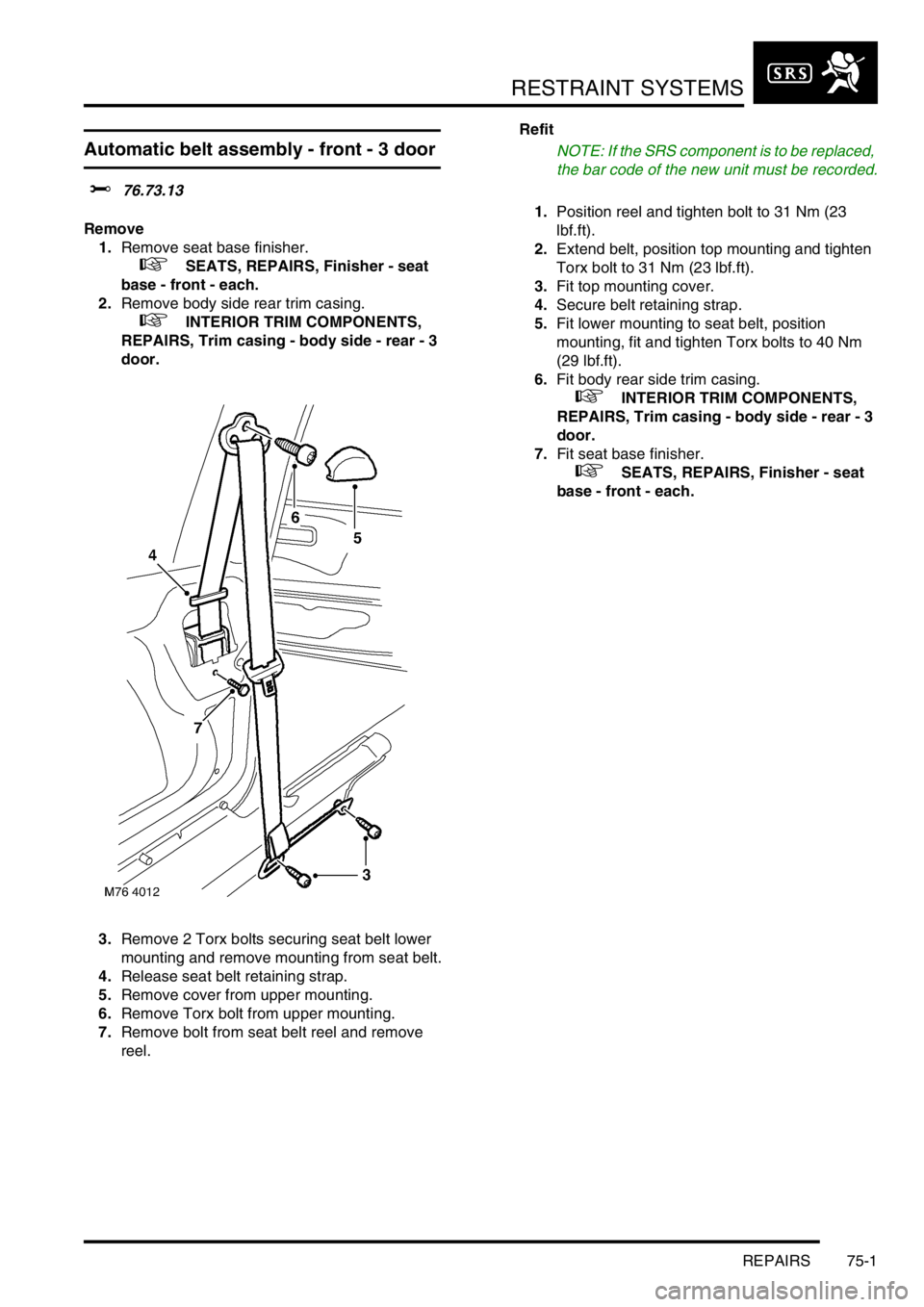

Automatic belt assembly - front - 3 door

$% 76.73.13

Remove

1.Remove seat base finisher.

+ SEATS, REPAIRS, Finisher - seat

base - front - each.

2.Remove body side rear trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - body side - rear - 3

door.

3.Remove 2 Torx bolts securing seat belt lower

mounting and remove mounting from seat belt.

4.Release seat belt retaining strap.

5.Remove cover from upper mounting.

6.Remove Torx bolt from upper mounting.

7.Remove bolt from seat belt reel and remove

reel.Refit

NOTE: If the SRS component is to be replaced,

the bar code of the new unit must be recorded.

1.Position reel and tighten bolt to 31 Nm (23

lbf.ft).

2.Extend belt, position top mounting and tighten

Torx bolt to 31 Nm (23 lbf.ft).

3.Fit top mounting cover.

4.Secure belt retaining strap.

5.Fit lower mounting to seat belt, position

mounting, fit and tighten Torx bolts to 40 Nm

(29 lbf.ft).

6.Fit body rear side trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - body side - rear - 3

door.

7.Fit seat base finisher.

+ SEATS, REPAIRS, Finisher - seat

base - front - each.

Page 583 of 1007

RESTRAINT SYSTEMS

75-2 REPAIRS

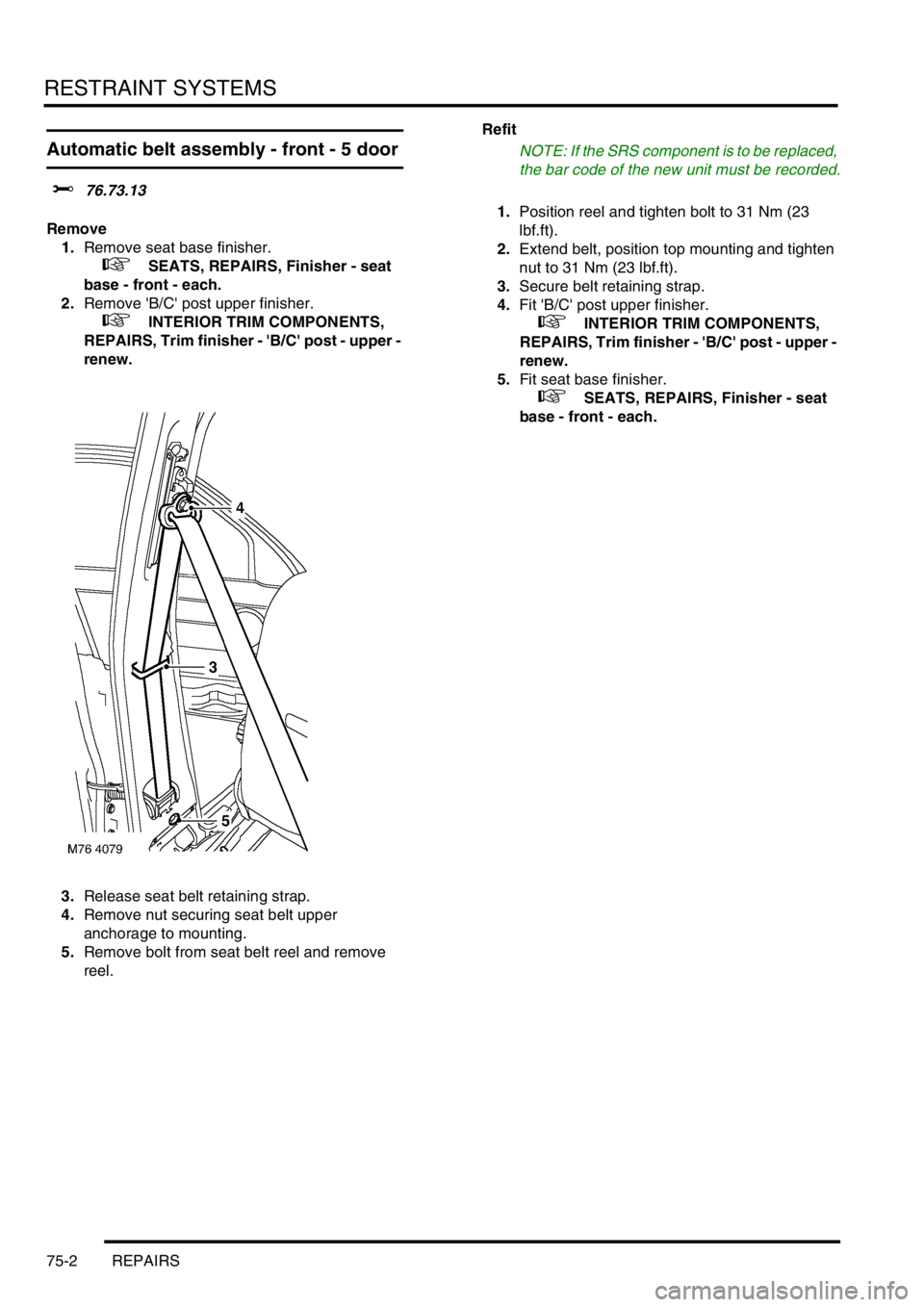

Automatic belt assembly - front - 5 door

$% 76.73.13

Remove

1.Remove seat base finisher.

+ SEATS, REPAIRS, Finisher - seat

base - front - each.

2.Remove 'B/C' post upper finisher.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'B/C' post - upper -

renew.

3.Release seat belt retaining strap.

4.Remove nut securing seat belt upper

anchorage to mounting.

5.Remove bolt from seat belt reel and remove

reel.Refit

NOTE: If the SRS component is to be replaced,

the bar code of the new unit must be recorded.

1.Position reel and tighten bolt to 31 Nm (23

lbf.ft).

2.Extend belt, position top mounting and tighten

nut to 31 Nm (23 lbf.ft).

3.Secure belt retaining strap.

4.Fit 'B/C' post upper finisher.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'B/C' post - upper -

renew.

5.Fit seat base finisher.

+ SEATS, REPAIRS, Finisher - seat

base - front - each.

Page 584 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-3

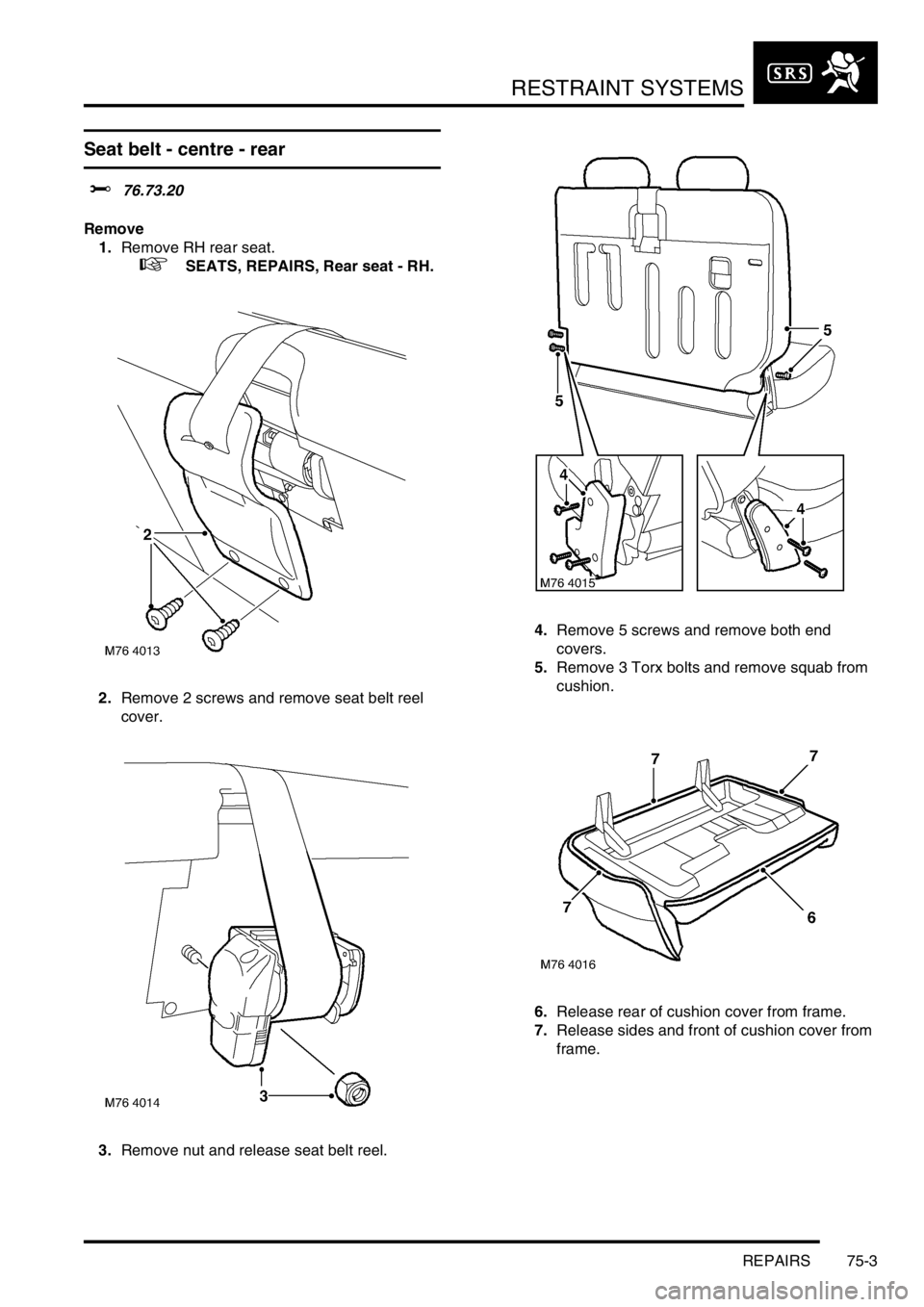

Seat belt - centre - rear

$% 76.73.20

Remove

1.Remove RH rear seat.

+ SEATS, REPAIRS, Rear seat - RH.

2.Remove 2 screws and remove seat belt reel

cover.

3.Remove nut and release seat belt reel.4.Remove 5 screws and remove both end

covers.

5.Remove 3 Torx bolts and remove squab from

cushion.

6.Release rear of cushion cover from frame.

7.Release sides and front of cushion cover from

frame.

Page 585 of 1007

RESTRAINT SYSTEMS

75-4 REPAIRS

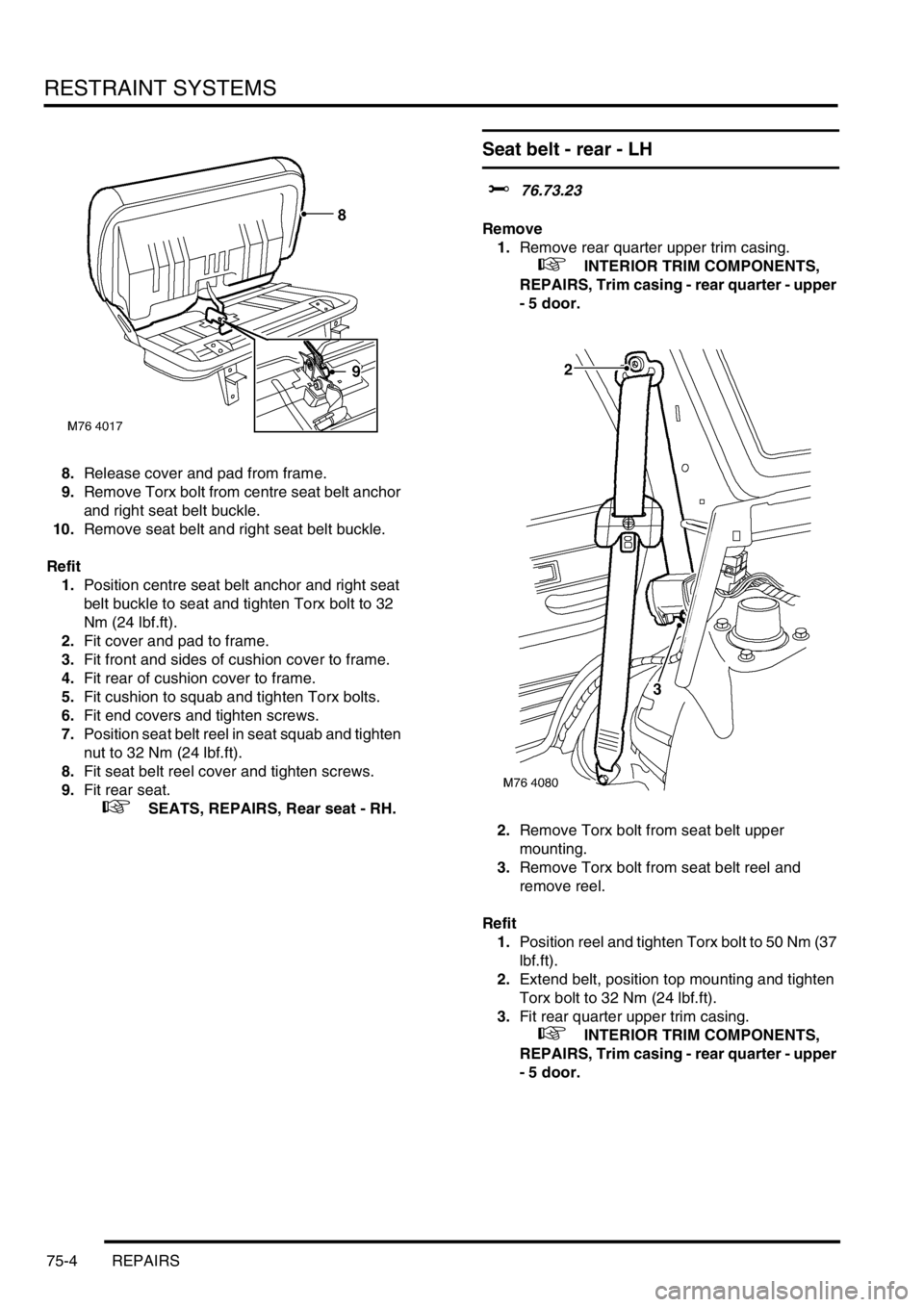

8.Release cover and pad from frame.

9.Remove Torx bolt from centre seat belt anchor

and right seat belt buckle.

10.Remove seat belt and right seat belt buckle.

Refit

1.Position centre seat belt anchor and right seat

belt buckle to seat and tighten Torx bolt to 32

Nm (24 lbf.ft).

2.Fit cover and pad to frame.

3.Fit front and sides of cushion cover to frame.

4.Fit rear of cushion cover to frame.

5.Fit cushion to squab and tighten Torx bolts.

6.Fit end covers and tighten screws.

7.Position seat belt reel in seat squab and tighten

nut to 32 Nm (24 lbf.ft).

8.Fit seat belt reel cover and tighten screws.

9.Fit rear seat.

+ SEATS, REPAIRS, Rear seat - RH.

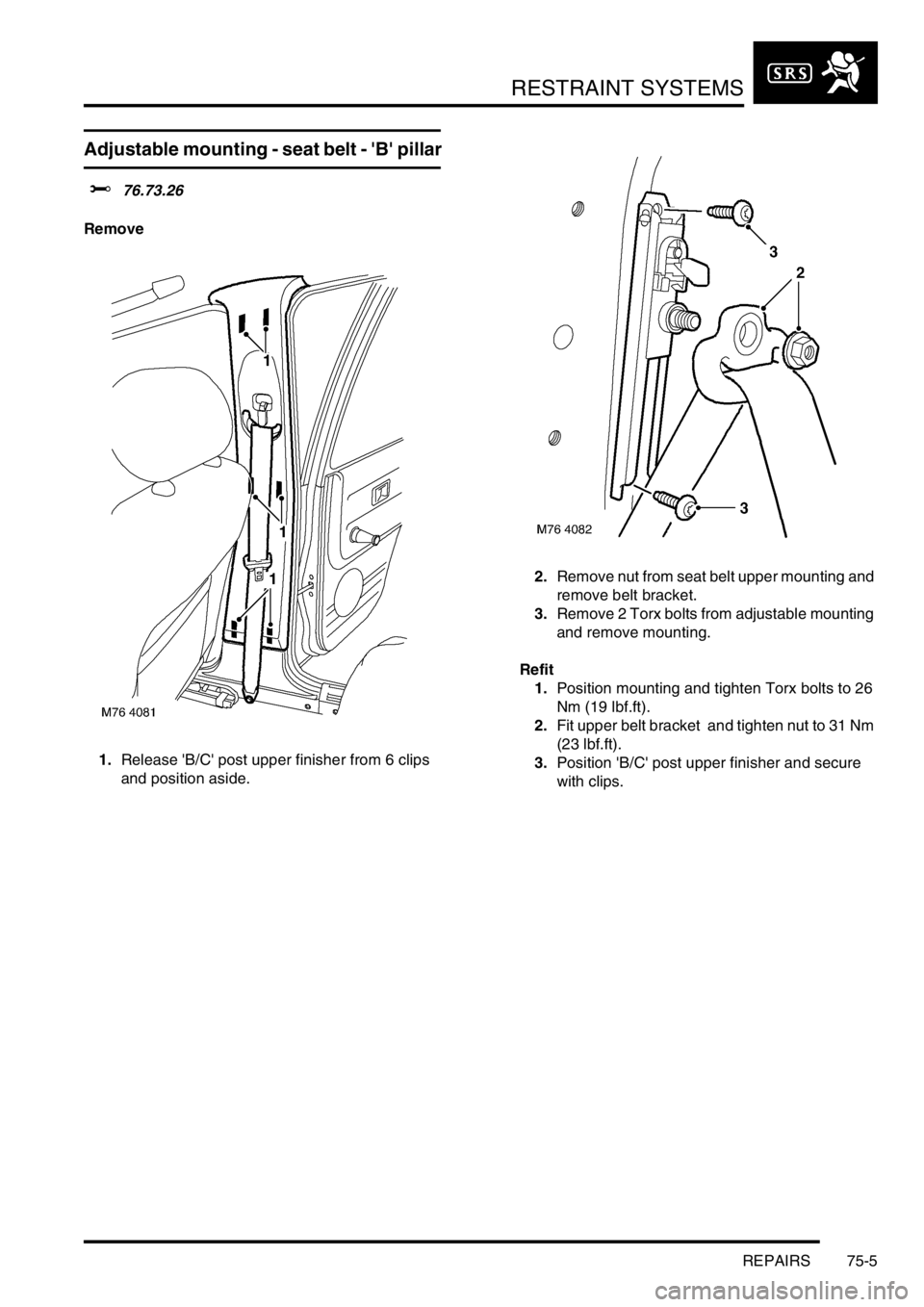

Seat belt - rear - LH

$% 76.73.23

Remove

1.Remove rear quarter upper trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

2.Remove Torx bolt from seat belt upper

mounting.

3.Remove Torx bolt from seat belt reel and

remove reel.

Refit

1.Position reel and tighten Torx bolt to 50 Nm (37

lbf.ft).

2.Extend belt, position top mounting and tighten

Torx bolt to 32 Nm (24 lbf.ft).

3.Fit rear quarter upper trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

Page 586 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-5

Adjustable mounting - seat belt - 'B' pillar

$% 76.73.26

Remove

1.Release 'B/C' post upper finisher from 6 clips

and position aside.2.Remove nut from seat belt upper mounting and

remove belt bracket.

3.Remove 2 Torx bolts from adjustable mounting

and remove mounting.

Refit

1.Position mounting and tighten Torx bolts to 26

Nm (19 lbf.ft).

2.Fit upper belt bracket and tighten nut to 31 Nm

(23 lbf.ft).

3.Position 'B/C' post upper finisher and secure

with clips.

Page 587 of 1007

RESTRAINT SYSTEMS

75-6 REPAIRS

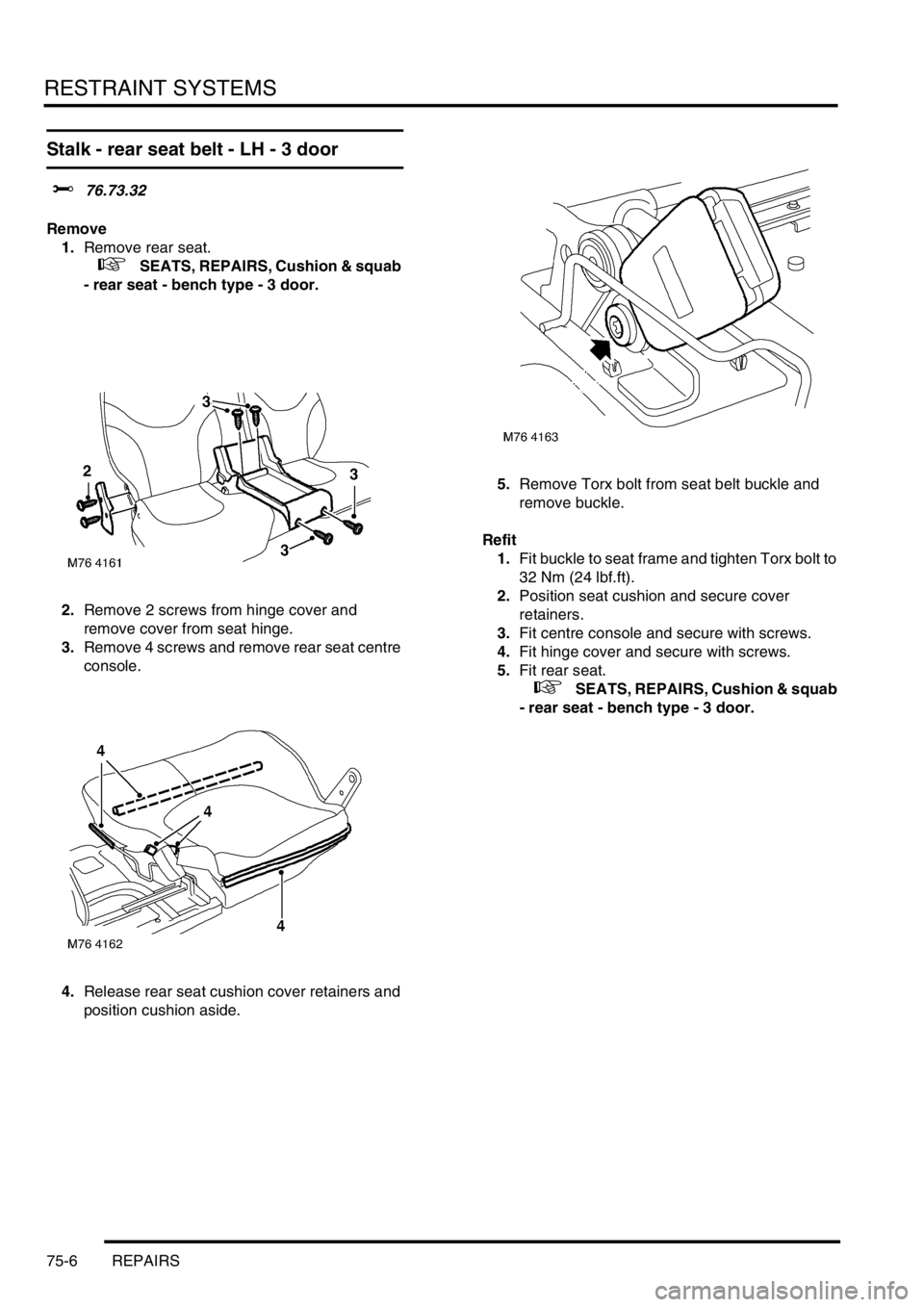

Stalk - rear seat belt - LH - 3 door

$% 76.73.32

Remove

1.Remove rear seat.

+ SEATS, REPAIRS, Cushion & squab

- rear seat - bench type - 3 door.

2.Remove 2 screws from hinge cover and

remove cover from seat hinge.

3.Remove 4 screws and remove rear seat centre

console.

4.Release rear seat cushion cover retainers and

position cushion aside.5.Remove Torx bolt from seat belt buckle and

remove buckle.

Refit

1.Fit buckle to seat frame and tighten Torx bolt to

32 Nm (24 lbf.ft).

2.Position seat cushion and secure cover

retainers.

3.Fit centre console and secure with screws.

4.Fit hinge cover and secure with screws.

5.Fit rear seat.

+ SEATS, REPAIRS, Cushion & squab

- rear seat - bench type - 3 door.

Page 588 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-7

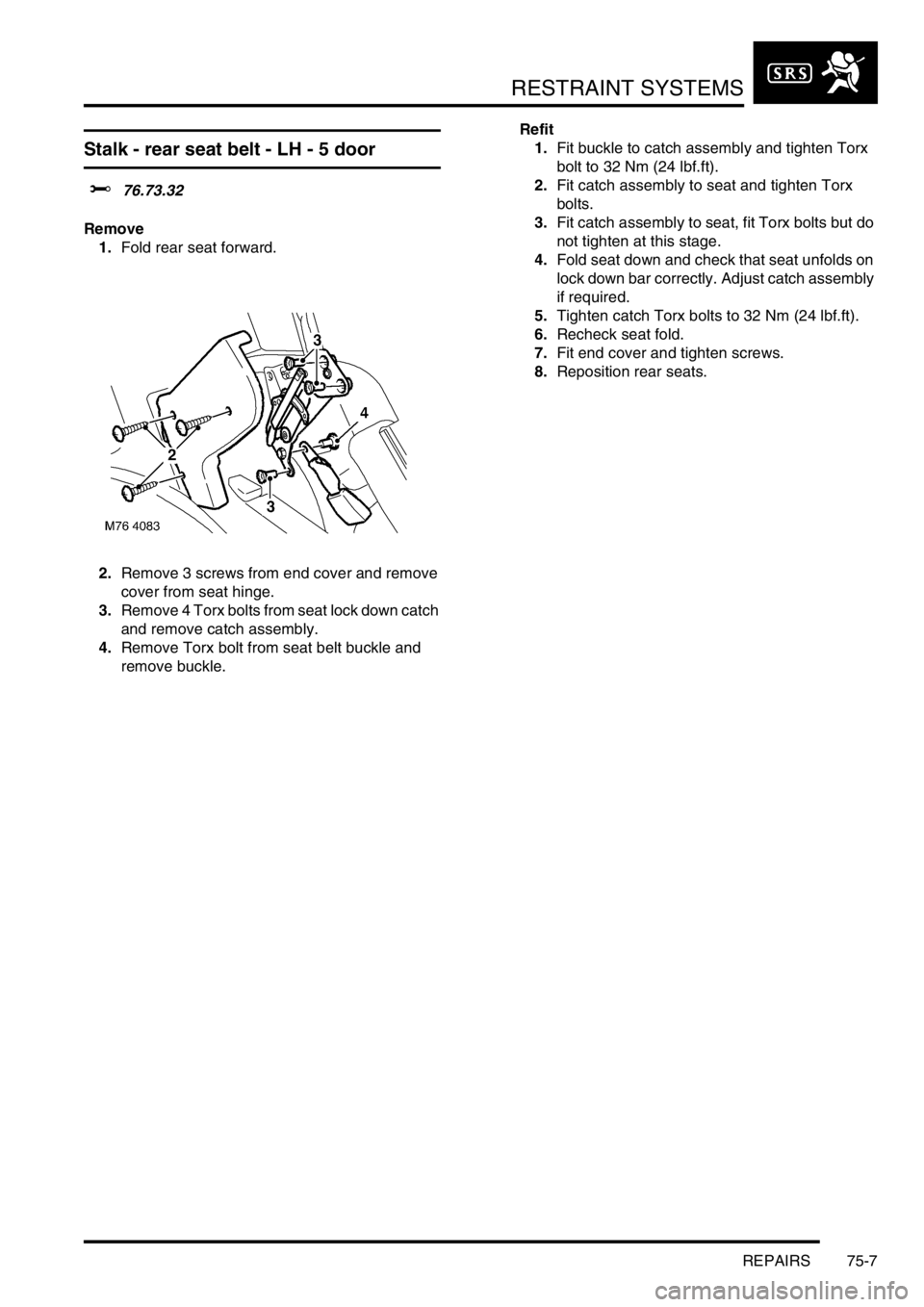

Stalk - rear seat belt - LH - 5 door

$% 76.73.32

Remove

1.Fold rear seat forward.

2.Remove 3 screws from end cover and remove

cover from seat hinge.

3.Remove 4 Torx bolts from seat lock down catch

and remove catch assembly.

4.Remove Torx bolt from seat belt buckle and

remove buckle.Refit

1.Fit buckle to catch assembly and tighten Torx

bolt to 32 Nm (24 lbf.ft).

2.Fit catch assembly to seat and tighten Torx

bolts.

3.Fit catch assembly to seat, fit Torx bolts but do

not tighten at this stage.

4.Fold seat down and check that seat unfolds on

lock down bar correctly. Adjust catch assembly

if required.

5.Tighten catch Torx bolts to 32 Nm (24 lbf.ft).

6.Recheck seat fold.

7.Fit end cover and tighten screws.

8.Reposition rear seats.

Page 589 of 1007

RESTRAINT SYSTEMS

75-8 REPAIRS

Pre-tensioner - seat belt - front

$% 76.73.75

Remove

WARNING: It is imperative that before any

work is undertaken on the SRS system the

appropriate information is read thoroughly.

WARNING: When removing, testing or

installing a seatbelt pre-tensioner, do not

lean directly over it or block the end of the

piston tube.

1.Make the SRS system safe.

+ GENERAL INFORMATION,

Supplementary restraint system

precautions.

2.Remove rear console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - rear.

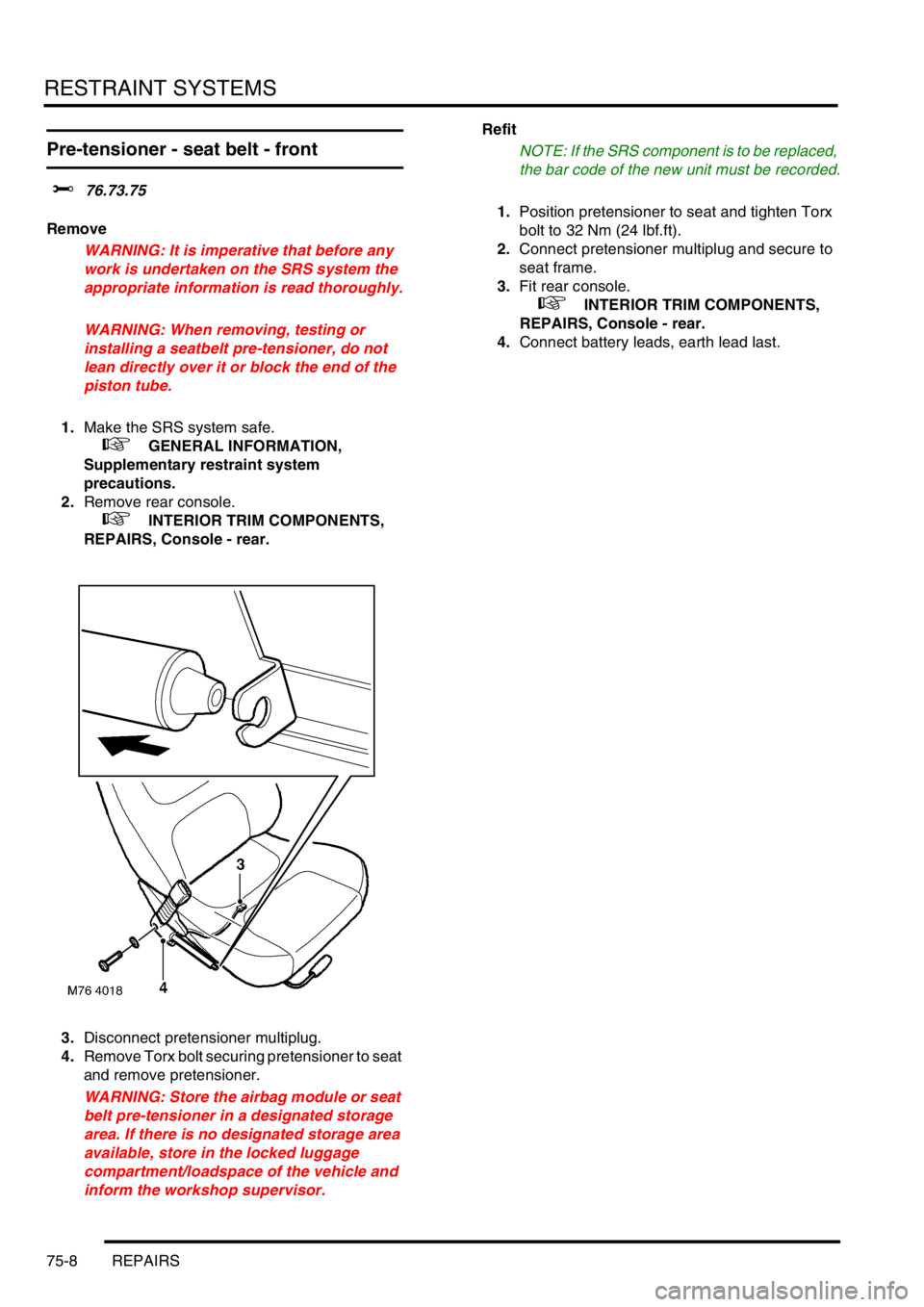

3.Disconnect pretensioner multiplug.

4.Remove Torx bolt securing pretensioner to seat

and remove pretensioner.

WARNING: Store the airbag module or seat

belt pre-tensioner in a designated storage

area. If there is no designated storage area

available, store in the locked luggage

compartment/loadspace of the vehicle and

inform the workshop supervisor.Refit

NOTE: If the SRS component is to be replaced,

the bar code of the new unit must be recorded.

1.Position pretensioner to seat and tighten Torx

bolt to 32 Nm (24 lbf.ft).

2.Connect pretensioner multiplug and secure to

seat frame.

3.Fit rear console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - rear.

4.Connect battery leads, earth lead last.

Page 590 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-9

Pre-tensioner - seat belt - front -

deployment - off vehicle

$% 76.73.78

These guidelines are written to aid authorised

personnel to carry out the safe disposal of airbag

modules when removed from the vehicle.

Deploy

It is imperative that before any work is

undertaken on the SRS system, the

appropriate information is read thoroughly.

1.Make the SRS system safe.

+ GENERAL INFORMATION, SRS

component manual deployment.

2.Remove seat belt pre-tensioner from vehicle.

+ RESTRAINT SYSTEMS, REPAIRS,

Pre-tensioner - seat belt - front.

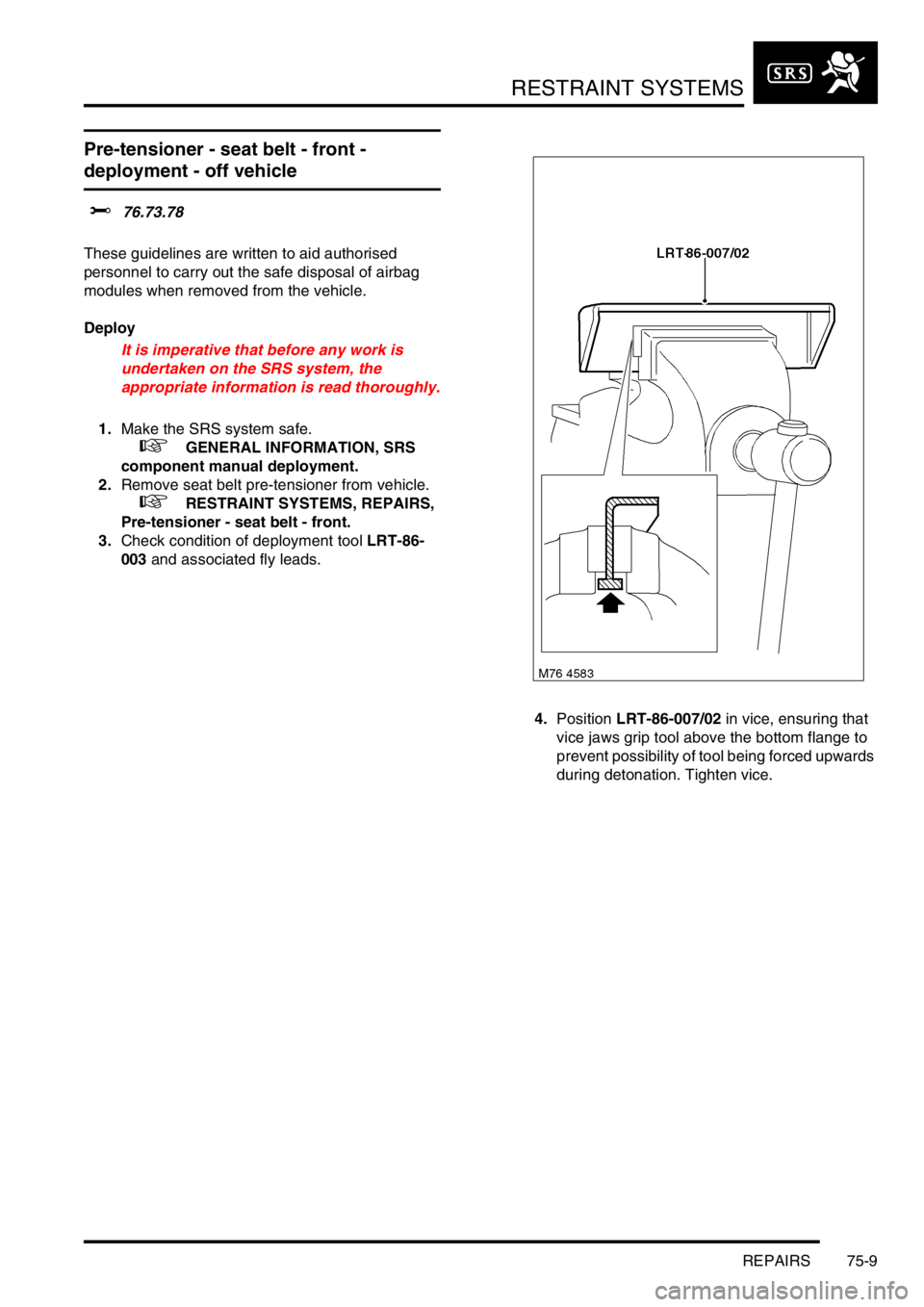

3.Check condition of deployment tool LRT-86-

003 and associated fly leads.

4.Position LRT-86-007/02 in vice, ensuring that

vice jaws grip tool above the bottom flange to

prevent possibility of tool being forced upwards

during detonation. Tighten vice.