LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 301 of 3229

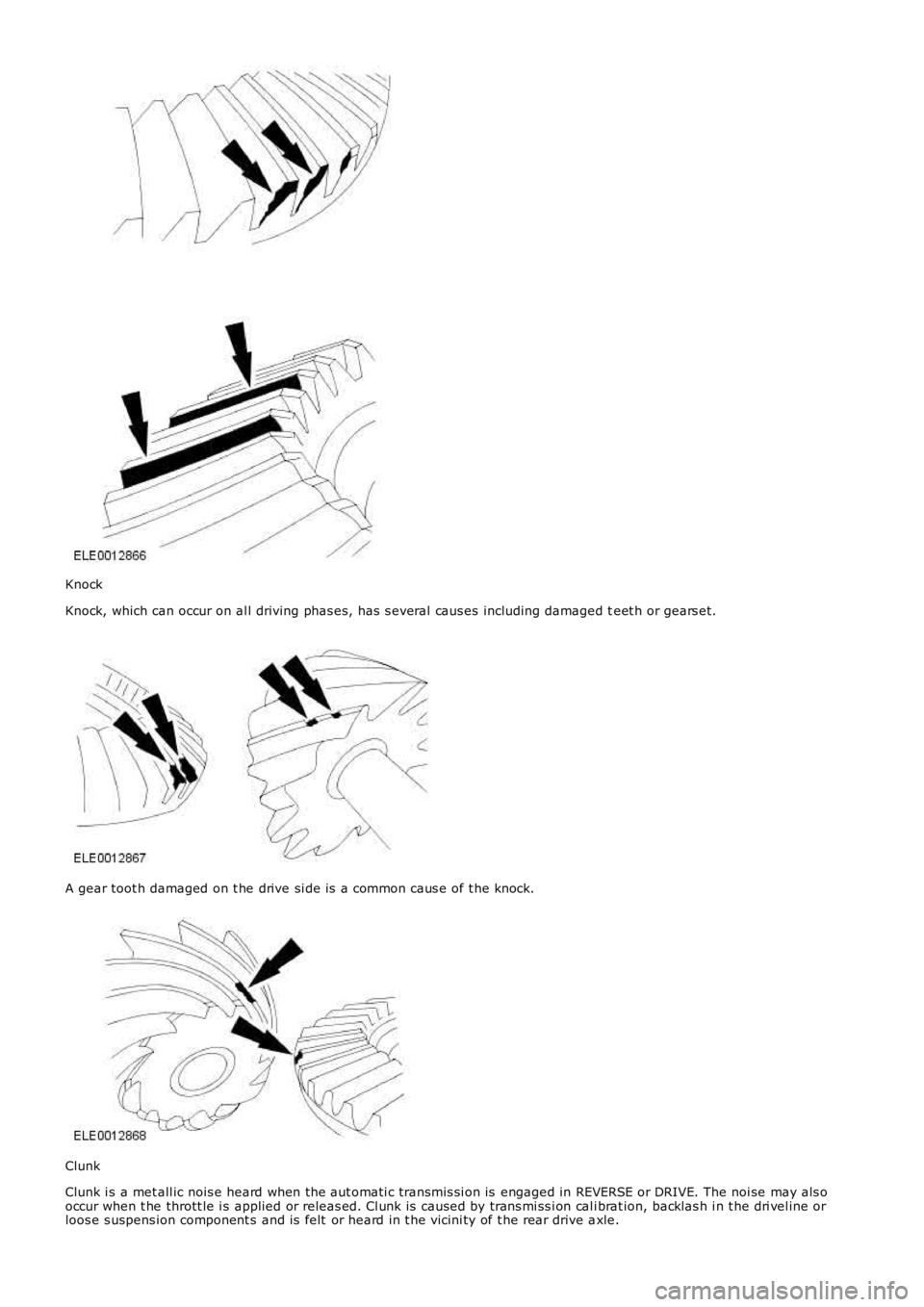

Knock

Knock, which can occur on al l driving phas es, has s everal caus es including damaged teet h or gears et.

A gear toot h damaged on t he drive si de is a common caus e of t he knock.

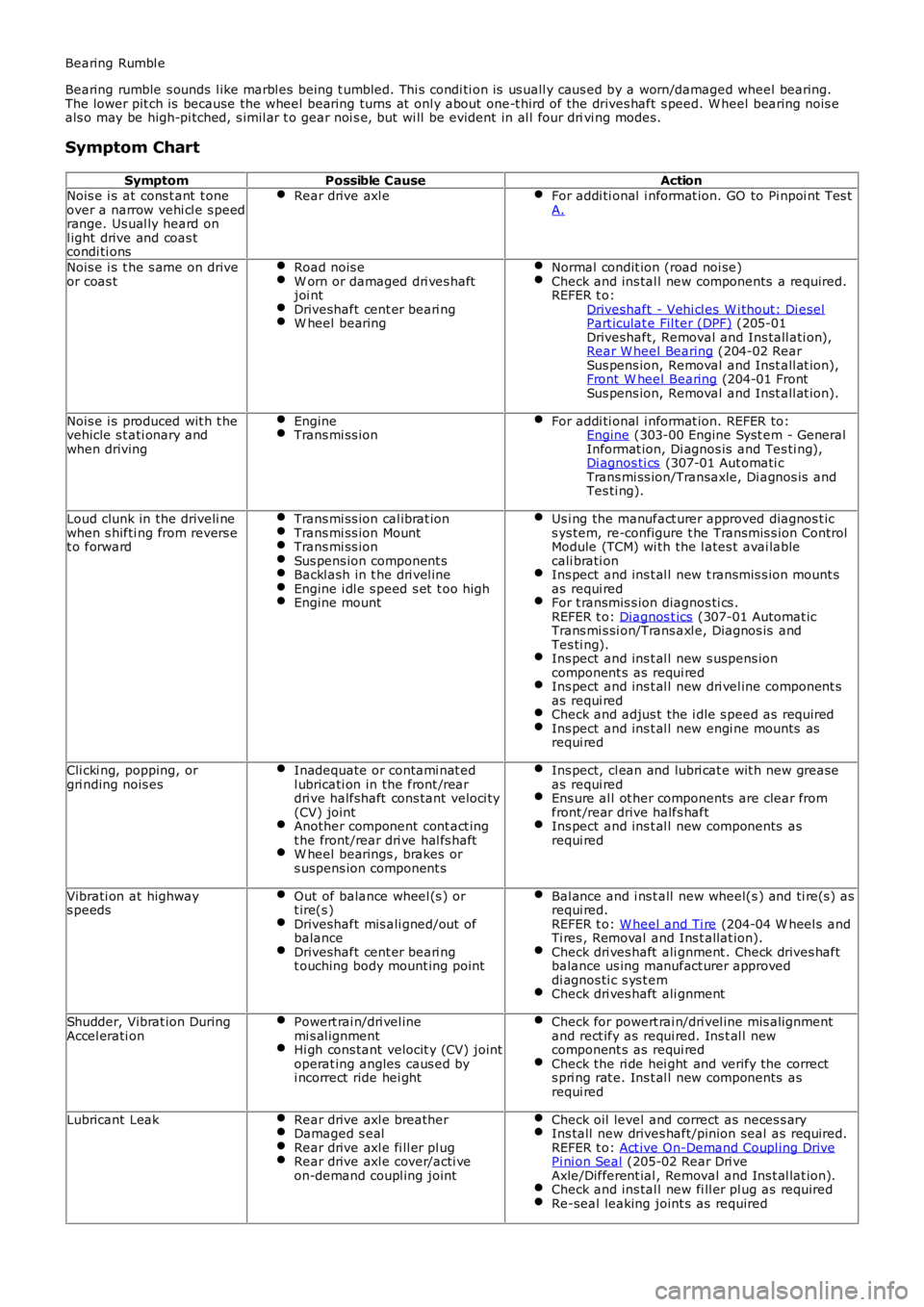

Clunk

Clunk i s a met all ic nois e heard when the aut omati c transmis si on is engaged in REVERSE or DRIVE. The noi se may als ooccur when t he thrott le i s applied or releas ed. Cl unk is caused by trans mi ss i on cal ibrat ion, backlas h i n t he dri vel ine orloos e s uspens ion component s and is felt or heard in t he vicini ty of t he rear drive axle.

Page 302 of 3229

Bearing Rumbl e

Bearing rumble s ounds l ike marbl es being t umbled. Thi s condi ti on is us uall y caus ed by a worn/damaged wheel bearing.The lower pit ch is because the wheel bearing turns at onl y about one-t hird of the drives haft s peed. W heel bearing nois eals o may be high-pi tched, s imil ar t o gear noi s e, but wi ll be evident in al l four drivi ng modes.

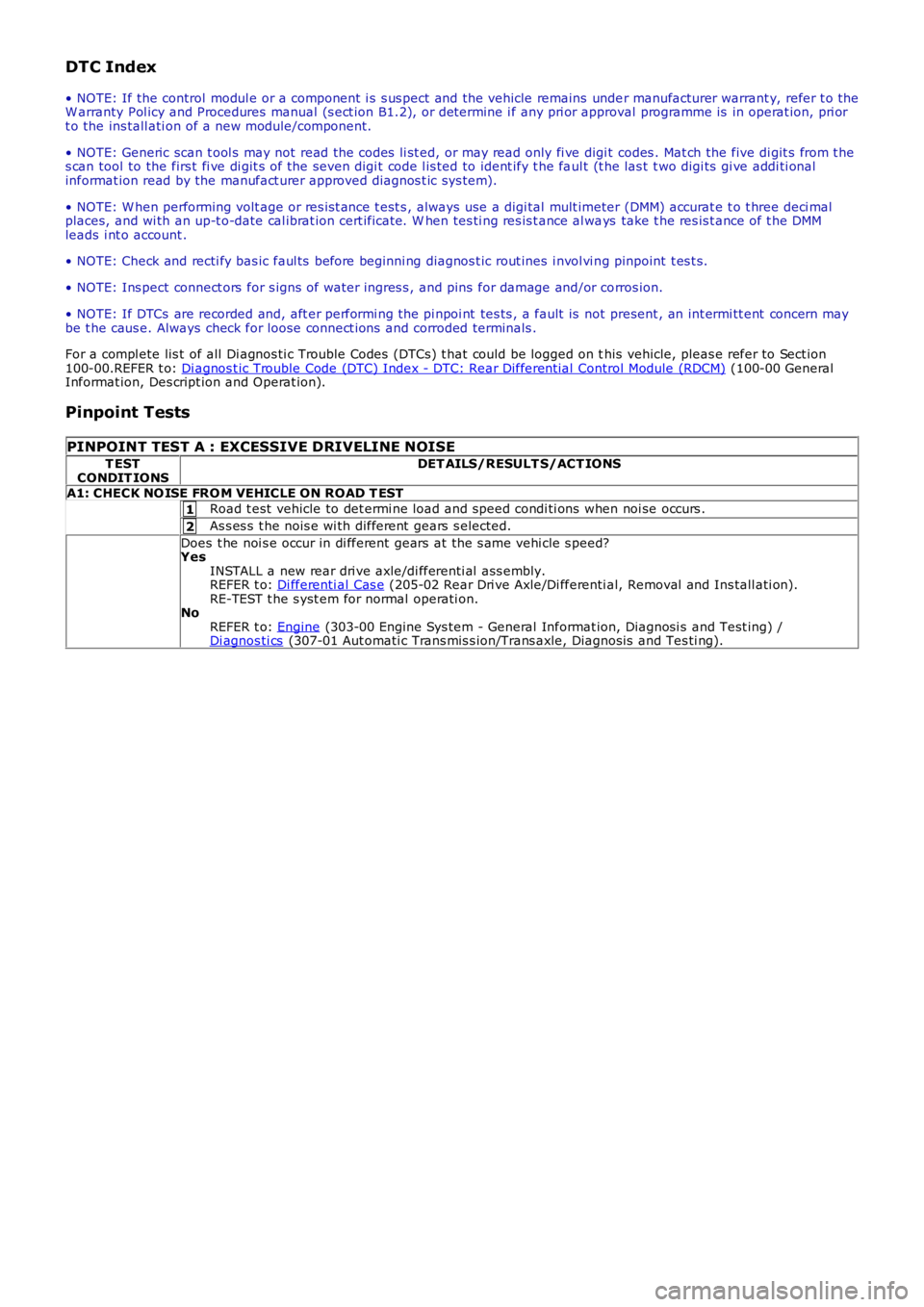

Symptom Chart

SymptomPossible CauseActionNois e i s at cons t ant t oneover a narrow vehi cl e s peedrange. Us ual ly heard onl ight drive and coas tcondi ti ons

Rear drive axl eFor addi ti onal i nformat ion. GO to Pi npoi nt Tes tA.

Nois e i s t he s ame on driveor coas tRoad nois eW orn or damaged dri ves haftjoi ntDriveshaft cent er beari ngW heel bearing

Normal condit ion (road noi se)Check and ins tal l new components a required.REFER t o:Driveshaft - Vehi cl es W i thout: Di eselPart iculat e Fil ter (DPF) (205-01Driveshaft, Removal and Ins tall ati on),Rear W heel Bearing (204-02 RearSus pens ion, Removal and Inst all at ion),Front W heel Bearing (204-01 FrontSus pens ion, Removal and Inst all at ion).

Nois e i s produced wit h t hevehicle s t ati onary andwhen driving

EngineTrans mi ss ionFor addi ti onal i nformat ion. REFER to:Engine (303-00 Engine Syst em - GeneralInformat ion, Di agnos is and Tes ti ng),Di agnos ti cs (307-01 Aut omati cTrans mi ss ion/Transaxle, Di agnos is andTes ti ng).

Loud clunk in the driveli newhen s hifti ng from revers et o forward

Trans mi ss ion cal ibrat ionTrans mi ss ion MountTrans mi ss ionSus pens ion component sBackl ash in t he dri vel ineEngine i dl e s peed s et t oo highEngine mount

Us i ng the manufact urer approved diagnos t ics ys tem, re-configure t he Transmis s ion ControlModule (TCM) wi th the l ates t avai lablecali brati onIns pect and ins t al l new t ransmis s ion mount sas requi redFor t ransmis s ion diagnos ti cs .REFER t o: Diagnos t ics (307-01 Automat icTrans mi s si on/Trans axl e, Diagnos is andTes ti ng).Ins pect and ins t al l new s uspens ioncomponent s as requi redIns pect and ins t al l new dri vel ine component sas requi redCheck and adjus t the i dle s peed as requi redIns pect and ins t al l new engi ne mounts asrequi red

Cli cki ng, popping, orgri nding nois esInadequate or contami nat edl ubricati on in the front /reardri ve halfshaft cons tant veloci ty(CV) jointAnother component cont act ingt he front/rear dri ve hal fs haftW heel bearings , brakes ors uspens ion component s

Ins pect, cl ean and lubri cat e wit h new greaseas requi redEns ure al l ot her components are clear fromfront /rear drive halfs haftIns pect and ins t al l new components asrequi red

Vibrati on at highways peedsOut of balance wheel (s ) ort ire(s )Driveshaft mis ali gned/out ofbalanceDriveshaft cent er beari ngt ouching body mount ing point

Bal ance and i ns t all new wheel(s ) and ti re(s) asrequi red.REFER t o: W heel and Ti re (204-04 W heel s andTi res , Removal and Ins t allat ion).Check dri ves haft ali gnment . Check drives haftbalance us ing manufact urer approveddi agnos ti c s ys t emCheck dri ves haft ali gnment

Shudder, Vibrat ion DuringAccel erati onPowert rai n/dri vel inemi s al ignmentHi gh cons tant velocit y (CV) jointoperat ing angles caus ed byi ncorrect ride hei ght

Check for powert rai n/dri vel ine mis alignmentand rect ify as requi red. Ins t al l newcomponent s as requi redCheck the ri de hei ght and verify the corrects pri ng rat e. Ins t al l new components asrequi red

Lubricant LeakRear drive axl e breatherDamaged s ealRear drive axl e fi ll er pl ugRear drive axl e cover/acti veon-demand coupl ing joint

Check oil level and correct as neces s aryIns tall new drives haft/pinion seal as required.REFER t o: Act ive On-Demand Coupl ing DrivePi ni on Seal (205-02 Rear Dri veAxle/Different ial , Removal and Ins t al lat ion).Check and ins tal l new fi ll er pl ug as requiredRe-seal leaking joint s as required

Page 303 of 3229

1

2

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

For a compl ete lis t of all Di agnos ti c Trouble Codes (DTCs) t hat could be logged on this vehicle, pleas e refer to Sect ion100-00.REFER t o: Di agnos t ic Trouble Code (DTC) Index - DTC: Rear Different ial Control Module (RDCM) (100-00 GeneralInformat ion, Des cript ion and Operat ion).

Pinpoint Tests

PINPOINT TEST A : EXCESSIVE DRIVELINE NOISE

T ESTCONDIT IONSDET AILS/RESULT S/ACT IONS

A1: CHECK NO ISE FRO M VEHICLE ON ROAD T EST

Road t est vehicle to det ermi ne load and s peed condi ti ons when noi se occurs .

As s es s t he nois e wi th different gears s elected.

Does t he noi s e occur in di fferent gears at t he s ame vehi cle s peed?YesINSTALL a new rear dri ve axle/di fferenti al as s embly.REFER t o: Di fferenti al Cas e (205-02 Rear Dri ve Axle/Di fferenti al, Removal and Ins tall ati on).RE-TEST t he s yst em for normal operati on.NoREFER t o: Engine (303-00 Engine Sys tem - General Informat ion, Diagnosi s and Test ing) /Di agnos ti cs (307-01 Aut omati c Trans mis s ion/Trans axle, Diagnos is and Tes ti ng).

Page 304 of 3229

Publi s hed: 11-May-2011

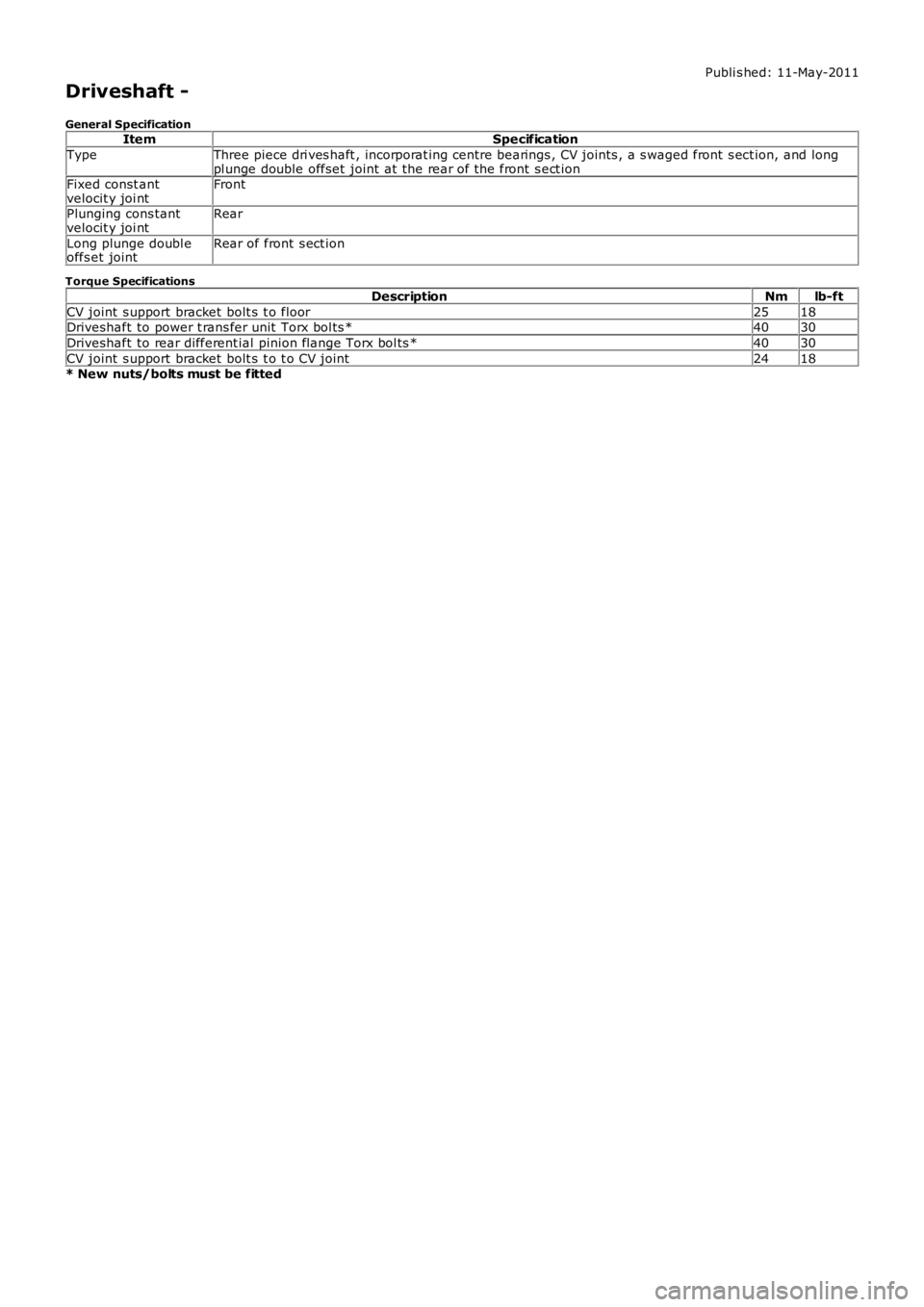

Driveshaft -

General SpecificationItemSpecification

TypeThree piece dri ves haft , incorporat ing centre bearings , CV joints , a s waged front s ect ion, and longpl unge double offset joint at the rear of the front s ect ionFixed const antvelocit y joi ntFront

Plunging cons tantvelocit y joi ntRear

Long plunge doubl eoffs et jointRear of front s ect ion

Torque Specifications

DescriptionNmlb-ft

CV joint s upport bracket bolt s t o floor2518Driveshaft to power t rans fer unit Torx bol ts *4030

Driveshaft to rear different ial pinion flange Torx bol ts *4030

CV joint s upport bracket bolt s t o t o CV joint2418* New nuts/bolts must be fitted

Page 305 of 3229

Publi s hed: 11-May-2011

Driveshaft - Driveshaft

Des cript ion and Operat ion

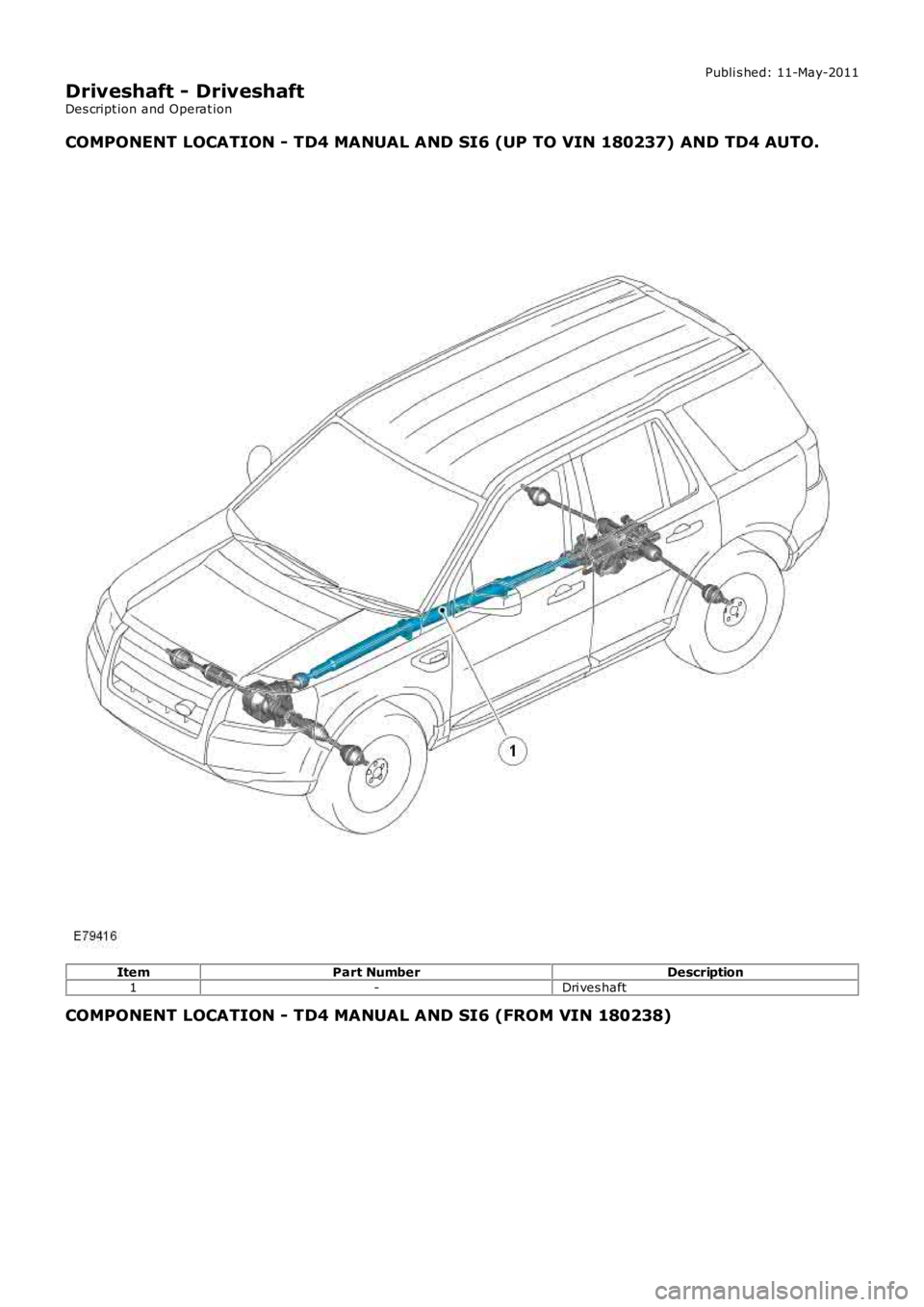

COMPONENT LOCATION - TD4 MANUAL AND SI6 (UP TO VIN 180237) AND TD4 AUTO.

ItemPart NumberDescription1-Dri ves haft

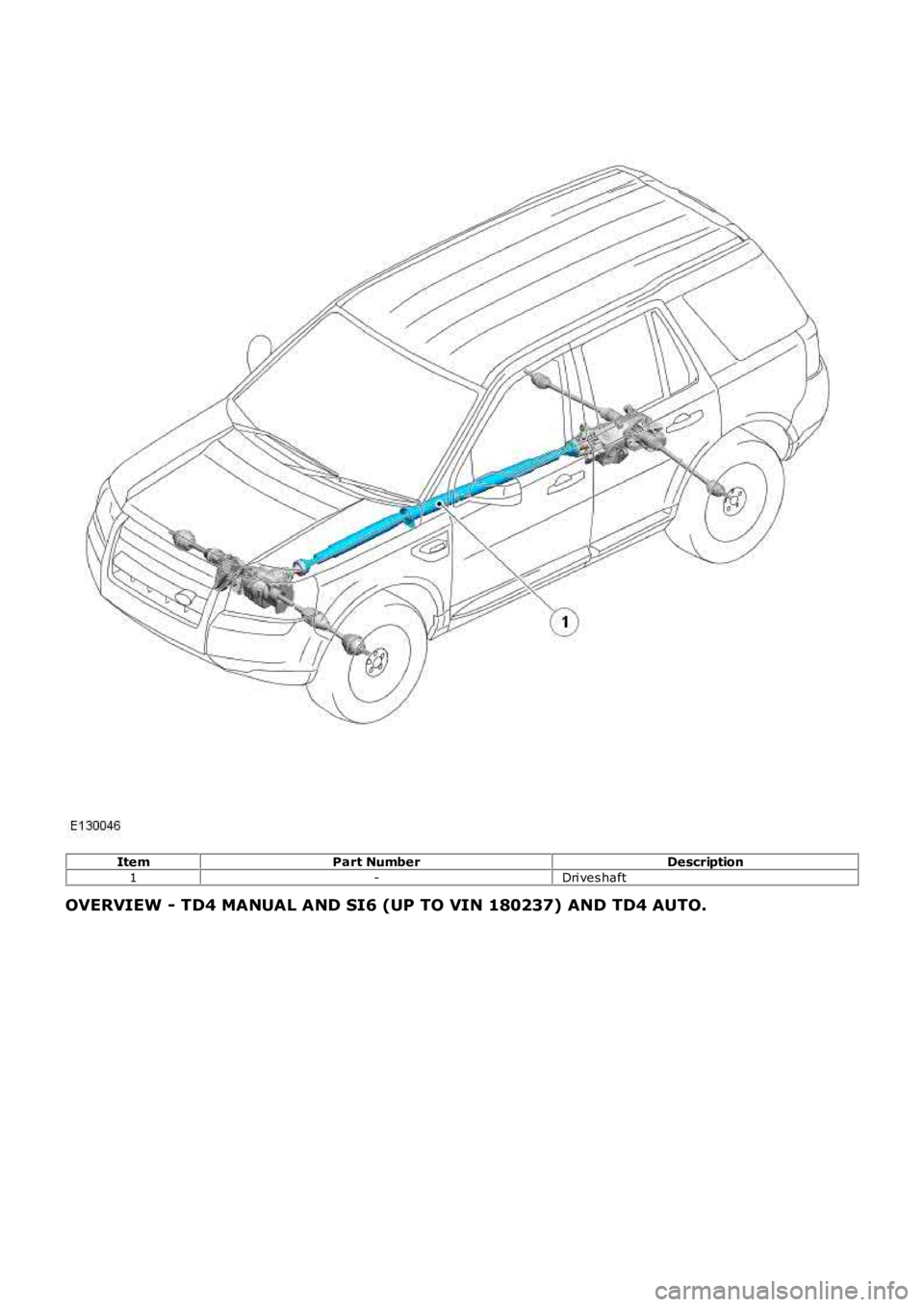

COMPONENT LOCATION - TD4 MANUAL AND SI6 (FROM VIN 180238)

Page 306 of 3229

ItemPart NumberDescription

1-Dri ves haft

OVERVIEW - TD4 MANUAL AND SI6 (UP TO VIN 180237) AND TD4 AUTO.

Page 307 of 3229

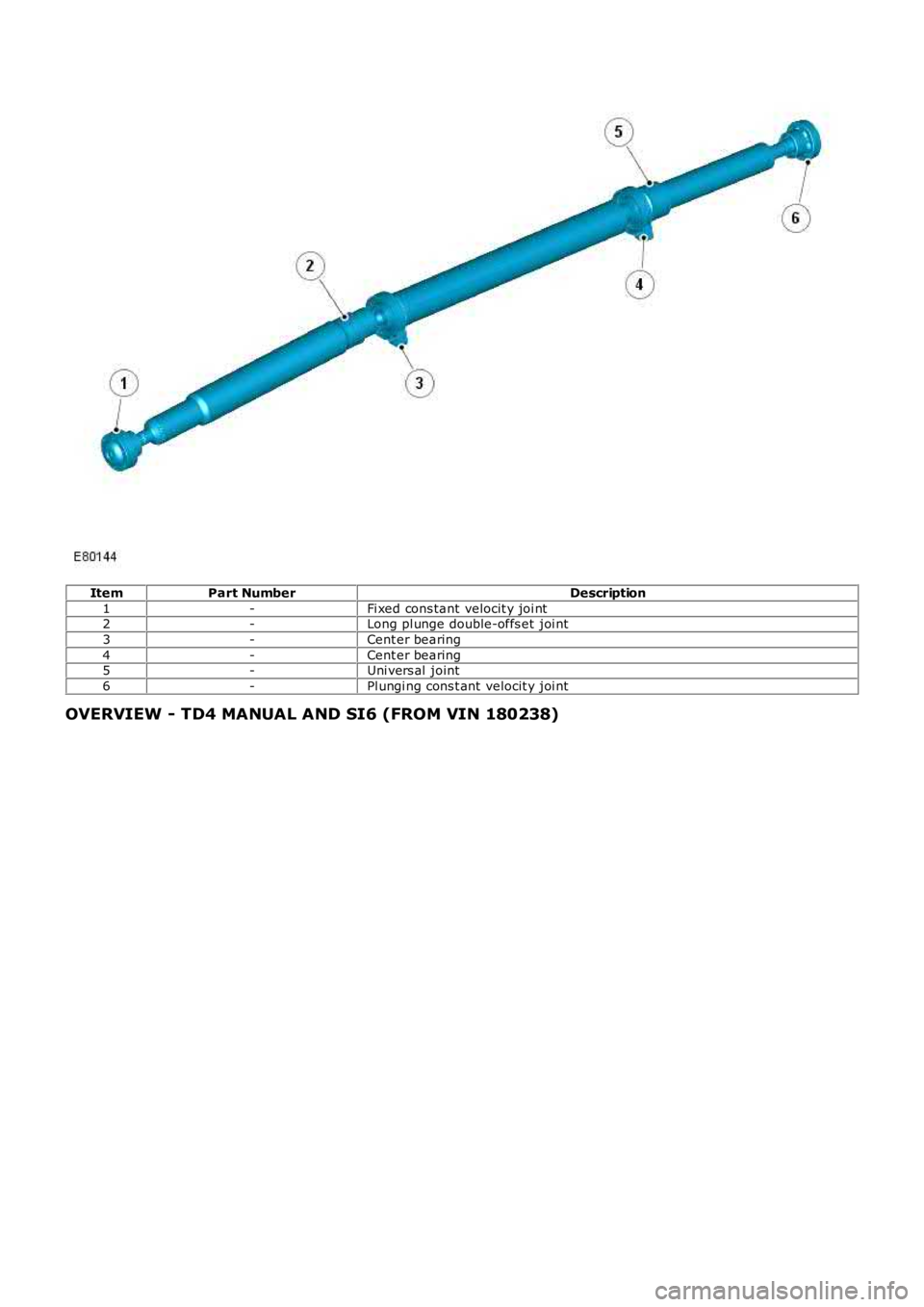

ItemPart NumberDescription

1-Fi xed cons tant velocit y joi nt2-Long pl unge double-offs et joi nt

3-Cent er bearing

4-Cent er bearing5-Uni vers al joint

6-Pl ungi ng cons t ant velocit y joi nt

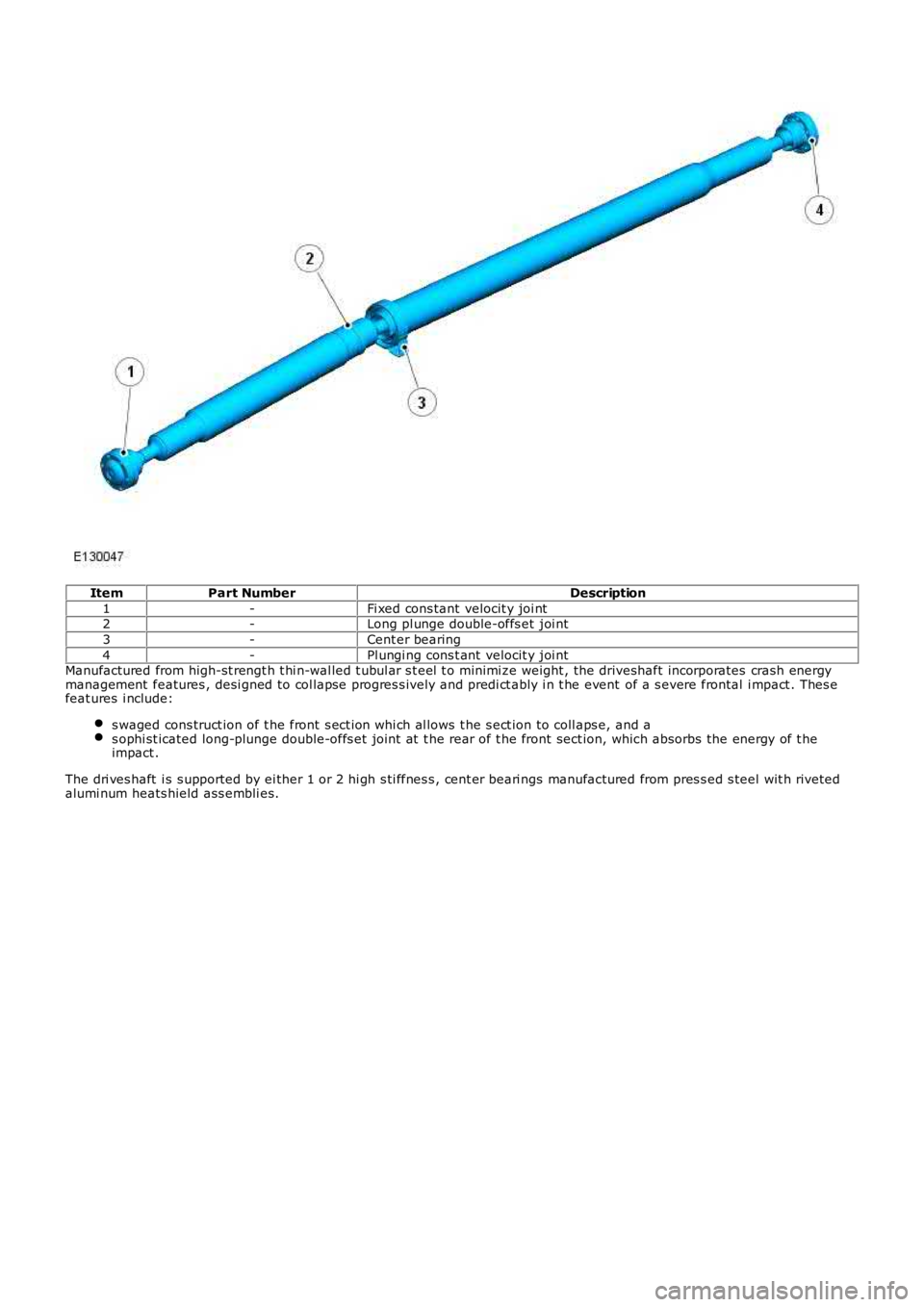

OVERVIEW - TD4 MANUAL AND SI6 (FROM VIN 180238)

Page 308 of 3229

ItemPart NumberDescription

1-Fi xed cons tant velocit y joi nt2-Long pl unge double-offs et joi nt

3-Cent er bearing

4-Pl ungi ng cons t ant velocit y joi ntManufactured from high-st rengt h t hi n-wal led t ubul ar s t eel t o minimi ze weight , the driveshaft incorporates crash energymanagement features , desi gned to col lapse progres s ively and predi ct ably i n t he event of a s evere frontal i mpact . Thes efeat ures i nclude:

s waged cons truct ion of t he front s ect ion whi ch al lows t he s ect ion to coll aps e, and as ophi st icated long-plunge double-offs et joi nt at t he rear of t he front sect ion, which absorbs the energy of t heimpact .

The dri ves haft i s s upported by ei ther 1 or 2 hi gh s ti ffnes s , cent er beari ngs manufactured from pres s ed s teel wit h rivetedalumi num heats hield ass embli es.

Page 309 of 3229

Publi s hed: 11-May-2011

Driveshaft - Universal Joints

Des cript ion and Operat ion

For addit ional informat ion, refer t o: Dri ves haft (205-01 Driveshaft, Des cript ion and Operat ion).

Page 310 of 3229

Publi s hed: 11-May-2011

Driveshaft - Driveshaft

Diagnosi s and Tes ti ng

For addit ional informat ion.REFER to: Driveli ne Sys t em (205-00 Driveline Sys tem - General Informat ion, Diagnosi s and Test ing).