LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 321 of 3229

Not s ens it ive to brake tes ti ng on a chas si s dynamomet er.

Generati on 4 Acti ve On-Demand Coupli ng - Vehicles from 2009MY

The generati on 4 coupl ing does not have the di fferenti al s peed dri ven pump used on the previ ous generat ion 3coupl ing, but i s fit ted wi th a bigger capacit y electrically operated axial pump and a hi gh pres s ure accumul ator.The proport ional throt t le valve and press ure s ens or on t he generat ion 3 coupli ng is replaced wit h a proport ionalpres s ure reducing val ve.The t orque li mit er pres sure reducing valve on the generat ion 3 coupli ng is replaced by an electroni c cont rol valveand cont rol ling software.

The generati on 4 acti ve on-demand coupli ng gives t he fol lowing improvements over t he previous generati on 3 coupl ing:

Reduced bas e t orque at high different ial s peedsTorque acti vat ion i s now i ndependent of different ial s peedAccurat e t orque l imi ter cont rolEnergy s tored in hi gh pres s ure accumul ator givi ng a low maximum current consumpt ion of t he electric pump andfas t er res pons e.

Control Module - G eneration 3 and 4 Couplings

The cont rol module, at tached to the cas ing of t he act ive on-demand coupling, forms a s ingle unit wit h t he cont rolvalve/axial s ol enoi d. By anal yzi ng informat ion from other vehi cl e modules and s ensors t he cont rol module regul ates t heaxial sol enoi d t o cont rol t he hydraul ic flui d pres s ure s uppl ied t o t he clut ch pl ates. Some of t he modul es and s ens ors thecont rol module communi cat es wit h are li s ted below:

Hardwi red:- Control valve / axi al s olenoid- Electric hydrauli c pump- Oi l press ure and temperat ure sens orHigh speed CAN (cont rol ler area net work):- Engine cont rol module- Anti -l ock brake s ys t em / t racti on cont rol module- Tracti on res ponse swit ch- Y aw rate sens or- Steering wheel rot at ion sens or

The axial sol enoi d cons t ant ly adjust s t he cont rol valve output us ing a Pul se W i dt h Modulat ion (PW M) s i gnal. The flui dpres s ure deli vered t o t he cl utch plat es determines t he amount of t orque t hat is delivered t o t he rear axl e.

The act ive on-demand coupli ng has int egrated oi l press ure and temperature s ens ors to enable the control modul e t oaccurat ely manage t he t orque t ransfer under all environment al and operat ing condit ions . Usi ng thes e s ignals the controlmodule will us e s t rategi es to protect the coupli ng from overheati ng; in extreme cas es to protect t he coupli ng from damaget he coupli ng wil l dis engage i f the t emperat ure of t he hydraul ic flui d exceeds 105°C. The coupl ing wi ll ret urn to normalfuncti onal it y when t he temperat ure fall s below 101°C.

The cont rol module has an int egrated di agnos ti cs sys tem, whi ch cons tant ly moni tors the act ive on-demand couplings ys t em as wel l as it s input and output s ignals . If t he control modul e detects a fault a Diagnost ic Troubl e Code (DTC) i ss tored. The DTC is acces s ed usi ng t he Land Rover approved di agnos t ic s yst em.

Electric Hydraulic Pump

W hen negoti ati ng very low frict ion s urfaces s uch as wet gras s , snow or i ce; i nit ial wheel -s pin can cut i nt o t he s urface andreduce gri p. W it h a re-act ive on-demand coupl ing, almos t 60 degrees of wheel rotat ion woul d occur before torque could bet ransmit ted t hrough t he coupl ing.

On Generat ion 3 coupli ngs , t o count eract thi s Land Rover devel oped a uni que high-pres s ure pre-charge faci li ty whi chenergizes t he hydraul ic circui t as s oon as the engi ne is s t art ed. Es s ent ial ly an el ect ri cal ly operat ed hydraul ic pump wasdesi gned to maintai n a pot ent ial of 500 Nm (369 l b ft ) of t orque pres s ure wi thi n the coupli ng. (This pre-charge t orquecapacit y has been increas ed to 1500Nm (1106 l b ft ) for t he Generat ion 4 coupli ng.)

Vehicles fit ted wi th Terrai n Res pons e als o add furt her benefi ts by varying t he level of pre-charge t o deli ver opti mumt racti on over a range of di fferent t errai n s urfaces . The level of pre-charge is varied dependi ng on t he part icul ar terrainres ponse mode, for exampl e:

Terrai n respons e in 'Speci al Programs Off' mode as common wit h vehi cl es wit hout terrain res pons e, the coupli ng isprogrammed t o transmit 500 Nm 369 lb ft of t orque on Generat ion 3 couplings and 1500 Nm (1106 l b ft) of t orqueon Generat ion 4 couplings t o t he rear axle when the vehicle moves from res t i n a s t raight l ine. Thi s s trategymi ni mi zes t ract ion l os s from a s t andi ng-s tart regardles s of t he terrain. W hen the vehicle accelerat es the pres surein the coupling is decreas ed to improve fuel economy.The abili ty to sens e t he s teeri ng angl e all ows t he coupli ng t o be programmed t o provide no torque trans fer t hrought he coupli ng. This prevent s t he coupli ng locking when t he vehicle i s maneuvring at low s peeds and acute s teeri ngangl es.In 'Grass / Gravel / Snow' mode t he coupl ing i s programmed to maint ai n i ts pre-charge s t at e unt il much highers peeds are obtained. The s ame applies even i f the vehicle is t raveli ng at low speeds and acut e s t eering angles , ast racti on takes precedence over coupli ng lock-up on l ow-fri ct ion s urfaces .

For addit ional informat ion, refer t o: Ride and Handli ng Opti mizat ion (204-06 Ride and Handli ng Opt imi zat ion, Descripti onand Operat ion).

Mechanical Hydraulic Pump - Generation 3 Couplings - Vehicles up to 2009MY

The dri ves haft i s att ached t o t he coupl ing's front clut ch pl ate as s embly (i nput ), with the rear cl ut ch plat e as sembl yconnected t o t he different ial pini on (out put ). A s was h-pl ate wit h 6 hydrauli c rol lers is al so att ached t o t he different ialpinion. W hen there is no s peed difference bet ween the coupling's input and out put, the rol lers do not funct ion.

Page 322 of 3229

However, when the front and rear axl es st art t o rotat e at different s peeds , t he s wash-pl ate rot at es rel ati ve to the roll erswhich generat es the hydrauli c pres s ure. Thi s pres s ure i s us ed to force the opposi ng clut ch pl ates t oget her, i ncreas ing thet ransmis s ion of t orque t o the rear axl e. As the di fference in axl e s peed i ncreases the hydrauli c pres sure pushes t he clut chplat es further together t o increas e t he t orque to the rear axl e.

A control val ve/axi al s olenoid cont rols the amount of pres s ure appli ed to the clut ch plat es , and hence the amount oft orque transmit ted t o t he rear wheels . Clos e manufact uring t olerances and except ional ly low component wear ens uret orque cont rol remai ns accurat e t hroughout t he vehi cl e's l ife.

Mechanical Hydraulic Pump - Generation 4 Couplings - Vehicles from 2009MY

The Generati on 4 coupl ing does not us e the swas h pl at e t o mechanical ly rais e hydrauli c pres s ure; ins tead, a new hydraul icpump i s used to generat e hydrauli c pres sure and force the cl utch plat es toget her. The removal of t he s was h plat e all ows alarger overal l cl ut ch plat e s urface area, whi ch in t urn reduces t he hydrauli c pres sure requi rement. The press ure required toachi eve 1500Nm (1106 l b ft ) has been reduced from 100 Bar for Generat ion 3 coupli ngs to 40 Bar for Generati on 4coupl ings.

The posi ti oni ng of the Generat ion 4 coupl ing's i nput and output remains t he s ame as t he Generati on 3 coupl ing, asdescribed above.

By-pass Valve

On very low fricti on s urfaces, driveli ne drag t orque can occur, for exampl e:

revers e t orque from engi ne braking, orforced movement of t he dri ves haft by t he front wheel s .

This can i nfluence rear wheel s peed, maki ng it i mpos si ble t o determine the t rue fricti on capabil it y of the rear wheel s, bydis t orti ng t he wheel s peed s ignal. To prevent thi s, t he acti ve on-demand coupli ng is des i gned t o open i mmediat el y inres ponse to a s tabil it y cont rol event . This i s achi eved by a by-pass val ve ins tant ly reducing sys tem pres s ure t o nomi nal .

To balance the 4 bar bas e press ure (s ee below for detai ls ), t he Generati on 3 coupling us es a large Bel levill e s pri ng to forcet he cl utch plat es clear of each ot her t o prevent torque transmis si on t hrough the coupli ng. Even at 0°C, t orque t rans mis s ionis reduced from 300 Nm to Zero wi thi n 10 ms . The Generat ion 4 coupling however, does not require a Bel lvil le s pri ng t os eparate t he plat es as t he coupli ng does not have a si gni fi cant bas e pres s ure pus hi ng t he plates together.

Accumulator

The further t he cl utch pl at es have to move in order to contact each other, t he longer it t akes to di spl ace the hydrauli c fl uidneces s ary t o buil d pres s ure and t rans mit torque. To count er thi s, t he Generati on 3 coupling incorporates an accumulat or.This retains a nominal 4 bar pres sure wi thin the hydraul ic circui t. Al though thi s is not enough pres sure t o caus e s i gni fi cantt orque transmis s ion t hrough the coupli ng, i t forces t he plat es very clos e t oget her so that very l it tl e fluid di s pl acement i srequired t o achi eve full engagement and maxi mum t orque t rans fer. Ful l torque t rans miss i on can be achieved i n 150 ms .

On Generat ion 4 coupli ngs , t he 150ms act ivat ion t ime is achieved through the us e of a Bel lvil le s pri ng t hat acts to pus ht he plates t ogether (wi thout caus i ng si gnifi cant t orque t rans mis s ion t hrough t he coupl ing). As t he pump i s notcont inuousl y us ed to create t his bas e pres s ure (as i t was wit h Generat ion 3 coupli ng), improvement s i n fuel economy havebeen achi eved.

Wet Clutch Pack

The clutch pack is made up of 7 pairs of plat es ; t he inner dis cs are produced from hardened st eel wit h t he out er dis csmanufactured from s t eel wi th a s int ered face. The clutch pl ates operat e in trans mi s si on fl uid.

Torque t rans mis s ion acros s t he clutch pack is li mit ed t o 1500 Nm (1106 lb ft ). This ens ures t he l ower gears ret ai n anelement of front-wheel -drive for t ract ion s t abi lit y. W i thin the hi gher gears the coupl ing i s t heoreti call y capabl e oft ransmit ti ng all t he dri ve to the rear axle; al though condit ions woul d have to be ext reme for t his t o occur.

PRINCIPLES OF OPERATION

Generation 3 Couplings - up to 2009MY

An i nt ernal electroni cal ly-controll ed pump provides hydrauli c pre-charge pres sure wit hin the coupling. The pre-chargepres s ure s upplies t he requi red operat ing pres s ure to the clut ch plates to el imi nat e i nit ial wheel -s pin as the vehicleaccelerates from s tandst il l.

In conjunct ion wi th the pre-charge pres s ure a mechanical hydraul ic pump operates wi thi n the cl utch plat es to s upply thecoupl ing's mai n hydraulic operat ing pres sure. The mechanical pump is funct ioned by the 'i nput ' and 'output' of t he coupli ng:

input - dri ves haft connect ion from the front axle,output - different ial connecti on to the rear axl e.

Any s peed di fference bet ween t he front and rear axl es wil l st art t he operat ion of t he mechanical hydraul ic pump. Theamount of hydrauli c pres s ure appli ed to the cl ut ch pack by the pump det ermines the gap bet ween t he cl utch plat es. Forexampl e, the great er the hydraul ic pres s ure, t he s maller t he gap between t he plat es and s ubs equent ly t he great er thet orque transmit ted t hrough t he coupli ng from the front axle t o t he rear axle.

This mai n hydrauli c pres sure is des i gned t o t rans mit the t orque for tract ion demands of off-road drivi ng, and t o provi delock-up as requi red.

Generation 4 Couplings - from 2009MY

The Generati on 4 coupl ing s t il l us es an el ect ri cal ly-controlled pump to provide hydrauli c pre-charge to el imi nat e wheel-s pinfrom st ands t il l; however, the s ame pump is al s o used to provi de t he coupli ng's mai n hydraul ic operat ing press ure.

Page 323 of 3229

The pri nci pl es of transmit ti ng torque through t he clut ch pl ates remains t he s ame, as des cri bed above for the Generat ion 3coupl ing.

Page 324 of 3229

Publi s hed: 11-May-2011

Rear Drive Axle/Differential - Rear Drive Axle and Differential

Diagnosi s and Tes ti ng

For addit ional informat ion.

REFER to: Driveli ne Sys t em (205-00 Driveline Sys tem - General Informat ion, Diagnosi s and Test ing).

Page 325 of 3229

Publi s hed: 11-May-2011

Rear Drive Axle/Differential - Differential Draining and Filling

General Procedures

1. W ARNING: Make sure t o s upport the vehicle wit h axle

s tands . CAUTION: Make s ure the vehicle is on a fl at level s urface.

Rais e and s upport t he vehi cl e.

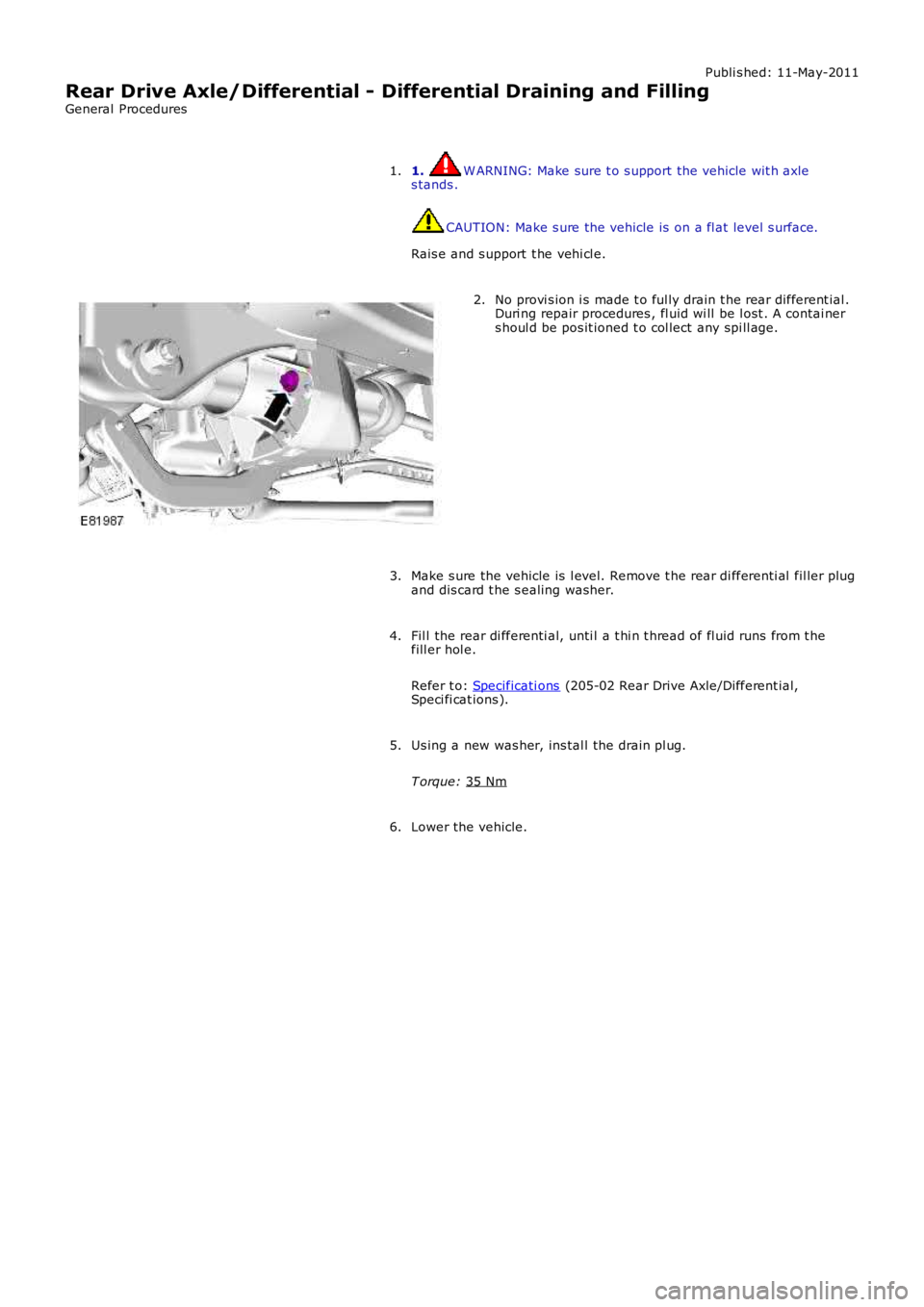

1. No provi s ion i s made t o ful ly drain t he rear different ial .

Duri ng repair procedures , fl uid wi ll be l ost . A contai ner

s houl d be pos it ioned t o col lect any spi ll age.

2.

Make s ure the vehicle is l evel. Remove t he rear di fferenti al fil ler plug

and dis card t he s ealing washer.

3.

Fil l the rear di fferenti al, unti l a t hi n t hread of fl uid runs from t he

fill er hol e.

Refer t o: Specificati ons (205-02 Rear Drive Axle/Different ial,

Speci fi cat ions ).

4.

Us ing a new was her, ins tal l the drain pl ug.

T orque: 35 Nm 5.

Lower the vehicle.

6.

Page 326 of 3229

Publi s hed: 11-May-2011

Rear Drive Axle/Differential - Active On-Demand Coupling Filling

General Procedures

• NOTE: If ins tall ing a new acti ve on-demand coupli ng, fil l wit h 650 ml of fluid. It is not pos si ble t o complet ely drai n t he

act ive on-demand coupli ng fl uid during s ervice. The procedure below MUST be fol lowed for bot h fill ing and t opping up.

1. CAUTION: Make s ure the vehicle is on a fl at level s urface.

Rais e and s upport t he vehi cl e.

1.

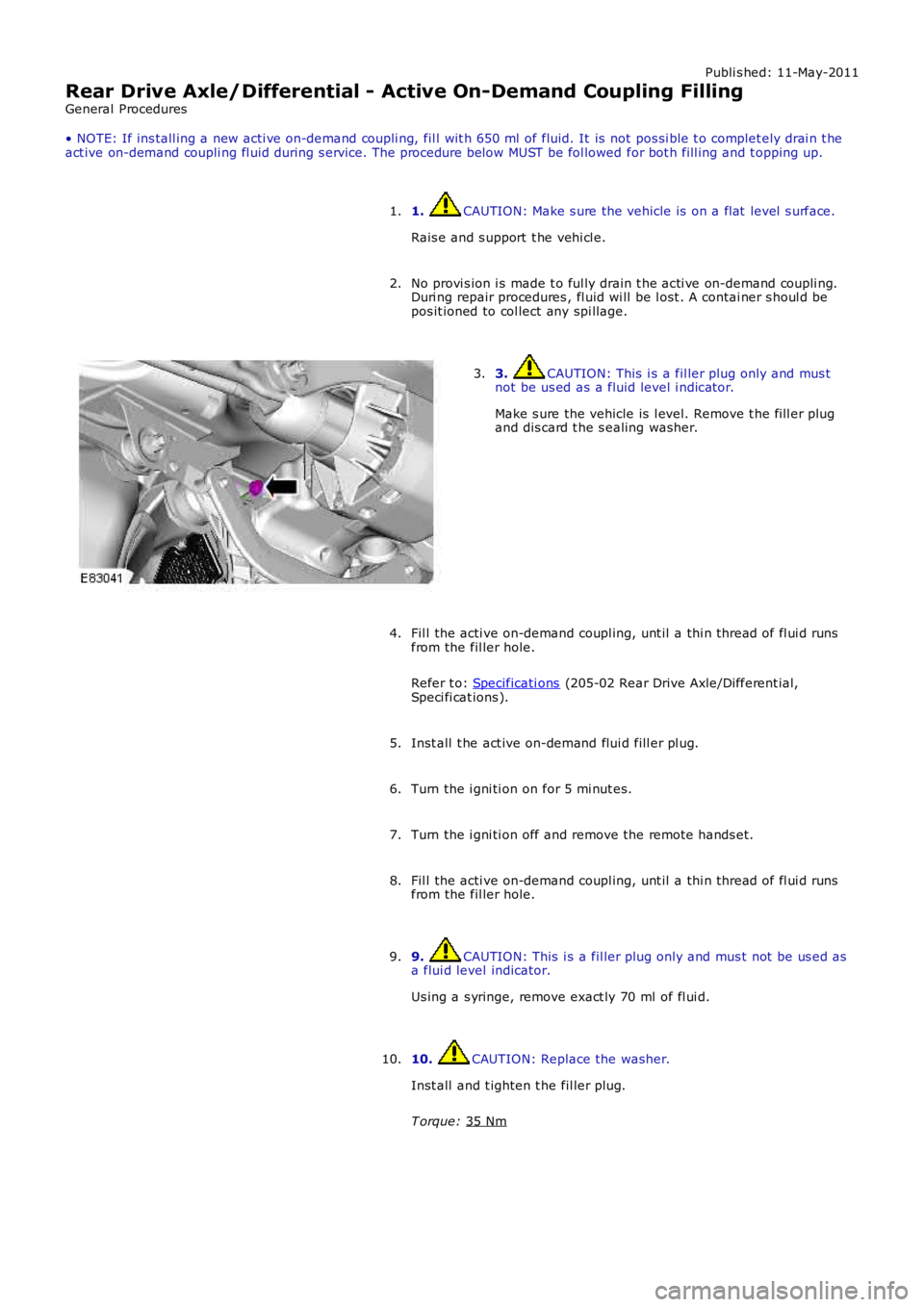

No provi s ion i s made t o ful ly drain t he acti ve on-demand coupli ng.

Duri ng repair procedures , fl uid wi ll be l ost . A contai ner s houl d be

pos it ioned to col lect any spi llage.

2. 3. CAUTION: This i s a fil ler plug onl y and mus t

not be us ed as a fluid level i ndicat or.

Make s ure the vehicle is l evel. Remove t he fill er plug

and dis card t he s ealing washer.

3.

Fil l the acti ve on-demand coupl ing, unt il a thi n thread of fl ui d runs

from the fil ler hole.

Refer t o: Specificati ons (205-02 Rear Drive Axle/Different ial,

Speci fi cat ions ).

4.

Inst all t he act ive on-demand flui d fill er pl ug.

5.

Turn the i gni ti on on for 5 mi nut es.

6.

Turn the i gni ti on off and remove the remot e hands et.

7.

Fil l the acti ve on-demand coupl ing, unt il a thi n thread of fl ui d runs

from the fil ler hole.

8.

9. CAUTION: This i s a fil ler plug onl y and mus t not be us ed as

a flui d level indicator.

Us ing a s yringe, remove exact ly 70 ml of fl ui d.

9.

10. CAUTION: Replace the washer.

Inst all and t ighten t he fil ler plug.

T orque: 35 Nm 10.

Page 327 of 3229

Publi s hed: 11-May-2011

Rear Drive Axle/Differential - Active On-Demand Coupling

Removal and Inst all ati on

Removal

1. W ARNING: Make sure t o s upport the vehicle wit h axles tands .

Rais e t he vehicle on a li ft .

1.

Remove t he exhaus t sys t em.

Refer t o: Exhaus t Sys t em (309-00B Exhaus t Sys t em - TD4 2.2LDi es el, Removal and Ins tal lat ion).

2.

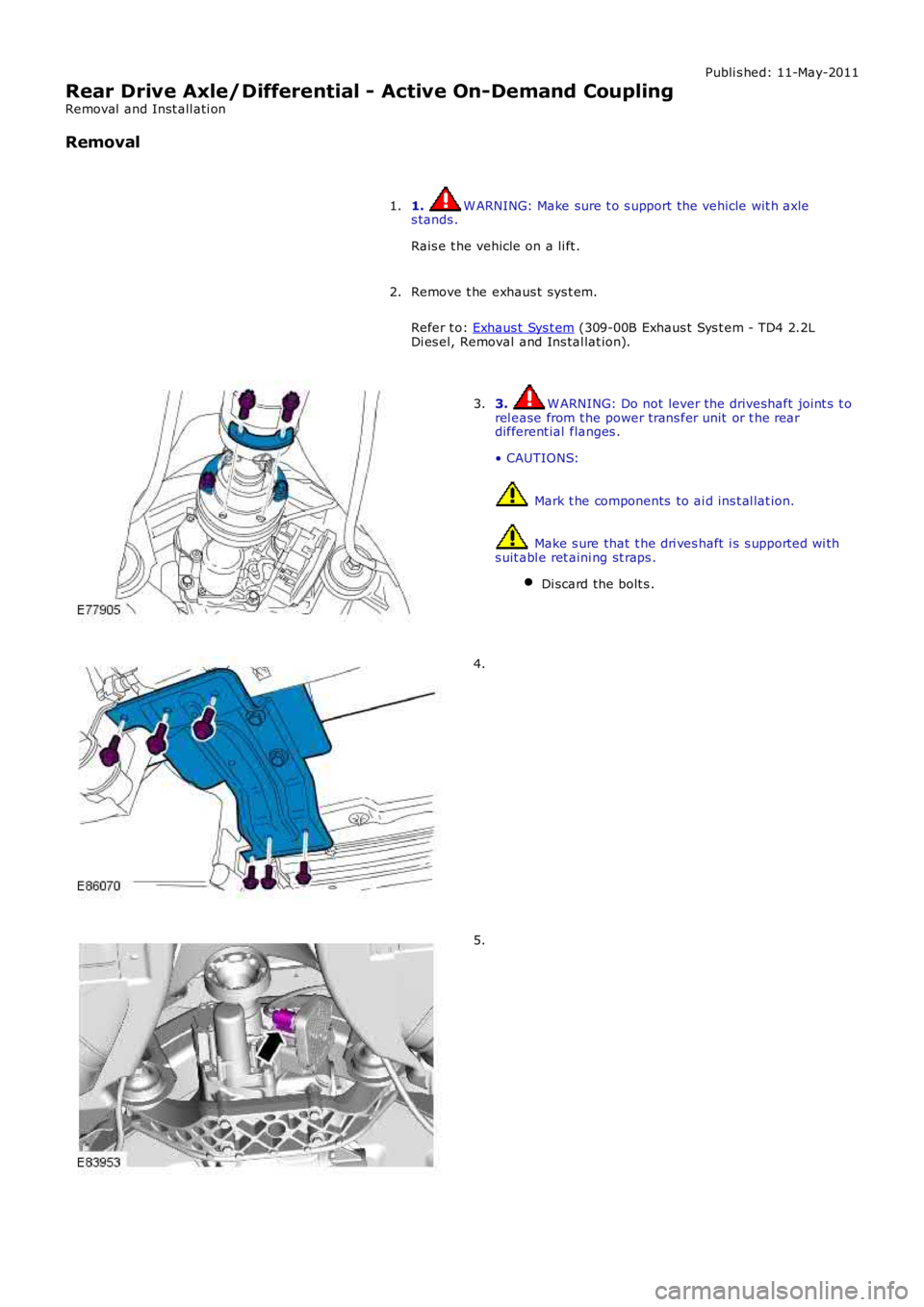

3. W ARNING: Do not lever the driveshaft joint s t orel ease from t he power trans fer unit or t he reardifferent ial flanges .

• CAUTIONS:

Mark t he components to ai d ins t al lat ion.

Make s ure that t he dri ves haft i s s upport ed wi ths uit abl e ret aini ng st raps .

Di scard the bolt s .

3.

4.

5.

Page 328 of 3229

Pos it ion a contai ner t o coll ect t he oil s pill age. Di scard the O-ring s eal.6.

Installation Lubricat e and ins tal l a new O-ri ng s eal .

Refer t o: Specificati ons (205-02 Rear Drive Axle/Different ial,

Speci fi cat ions ).

1.

2. CAUTION: Make s ure that the area around t he component is

clean and free of foreign materi al.

Inst all t he act ive on-demand coupli ng.

T orque: 24 Nm 2.

Connect t he electrical connect or.

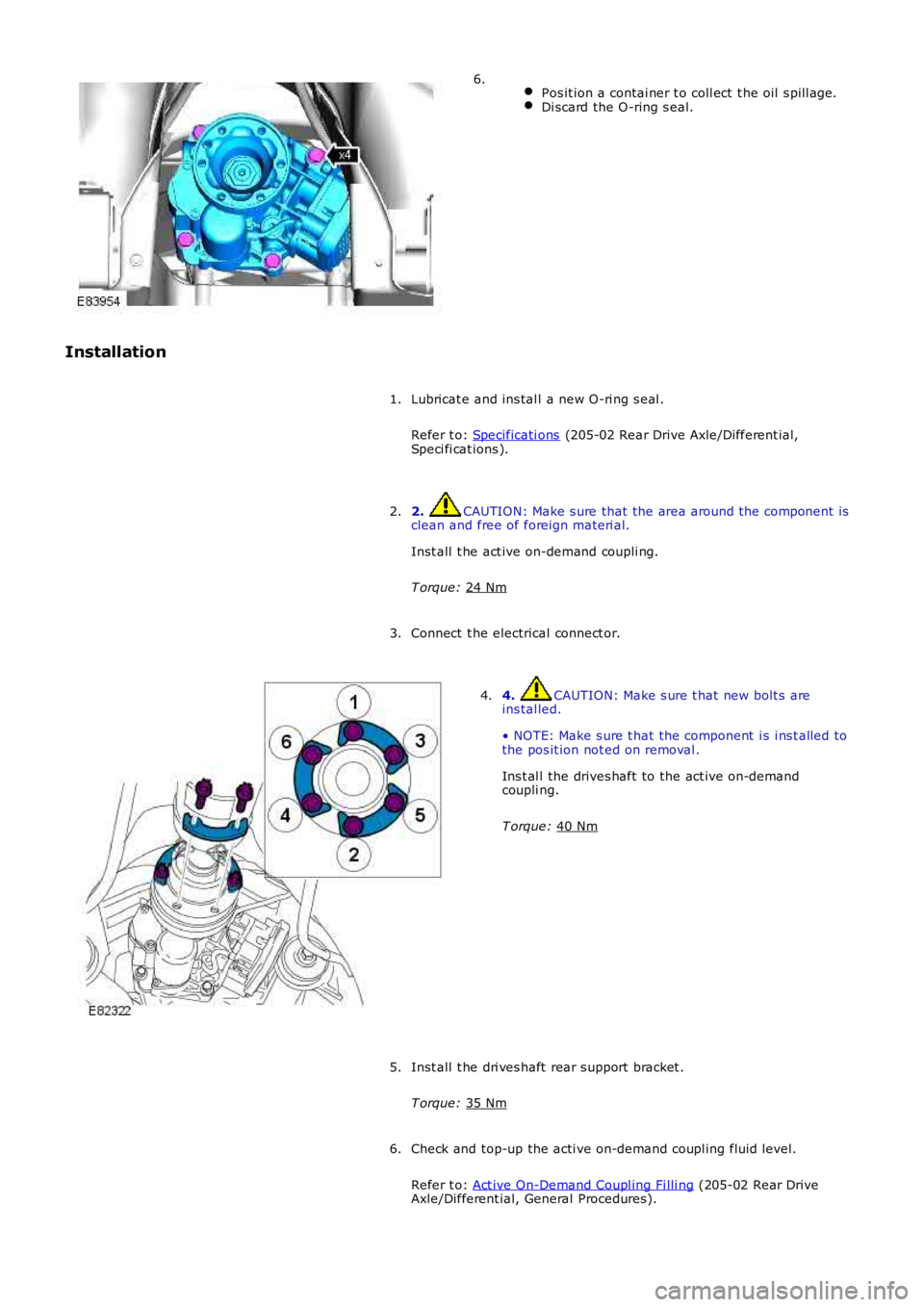

3. 4. CAUTION: Make s ure t hat new bolt s are

ins tal led.

• NOTE: Make s ure t hat the component i s i ns t alled to

the pos it ion not ed on removal .

Ins t al l the drives haft to the act ive on-demand

coupli ng.

T orque: 40 Nm 4.

Inst all t he dri ves haft rear s upport bracket .

T orque: 35 Nm 5.

Check and top-up the acti ve on-demand coupl ing fluid level.

Refer t o: Act ive On-Demand Coupl ing Fi lli ng (205-02 Rear Drive

Axle/Different ial, General Procedures).

6.

Page 329 of 3229

Inst all t he exhaus t sys t em.

Refer t o: Exhaus t Sys t em (309-00B Exhaus t Sys t em - TD4 2.2LDi es el, Removal and Ins tal lat ion).

7.

Page 330 of 3229

Publi s hed: 11-May-2011

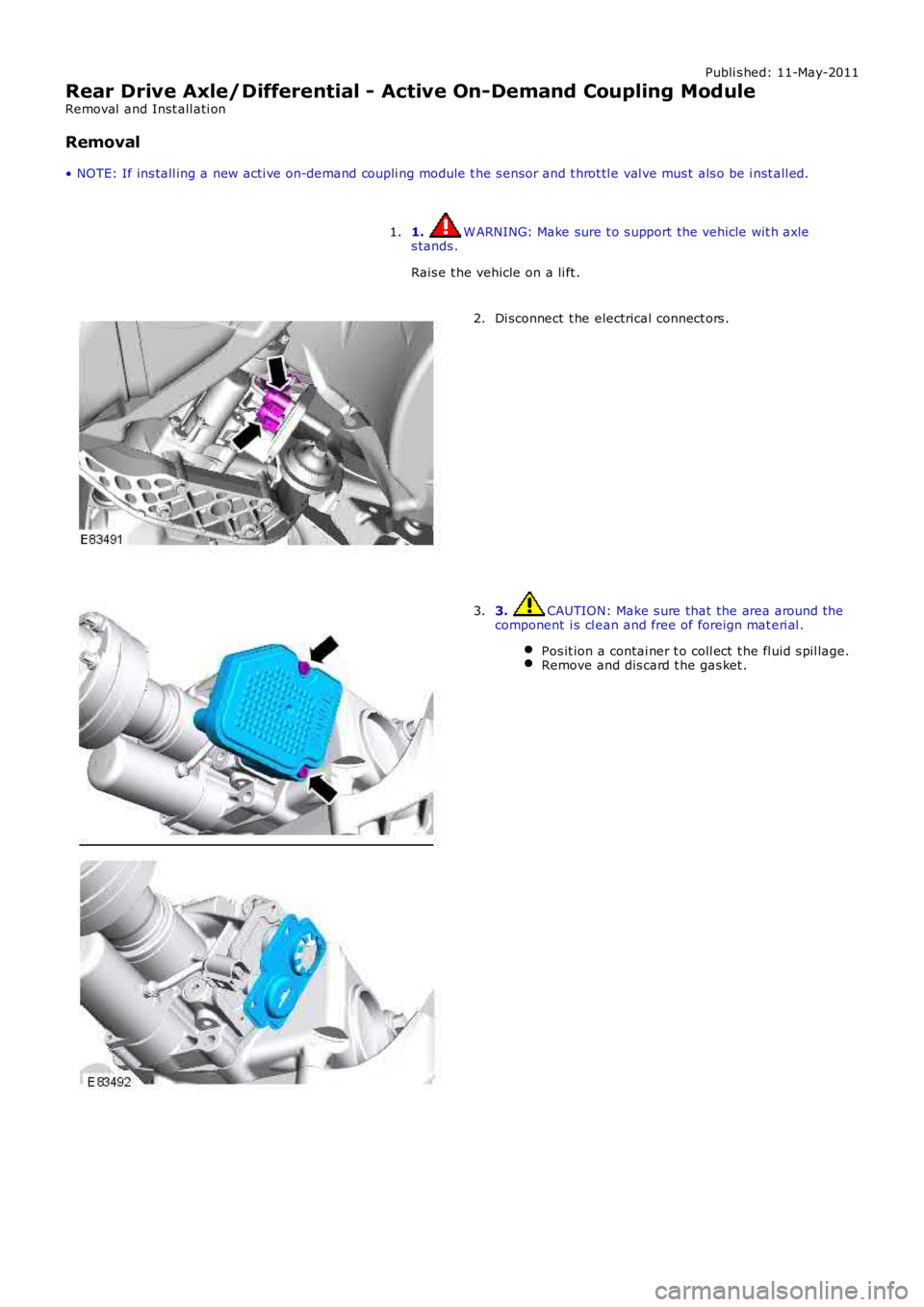

Rear Drive Axle/Differential - Active On-Demand Coupling Module

Removal and Inst all ati on

Removal

• NOTE: If ins tall ing a new acti ve on-demand coupli ng module t he s ensor and t hrot tl e val ve mus t als o be i nst all ed.

1. W ARNING: Make sure t o s upport the vehicle wit h axles tands .

Rais e t he vehicle on a li ft .

1.

Di sconnect t he electrical connect ors .2.

3. CAUTION: Make s ure that the area around t hecomponent i s cl ean and free of foreign mat eri al .

Pos it ion a contai ner t o coll ect t he fl uid s pil lage.Remove and dis card t he gas ket .

3.