LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: coolant capacity, navigation, fuel pressure, fuel filter location, checking oil, Absorber suspension, fuel consumption

Page 341 of 4500

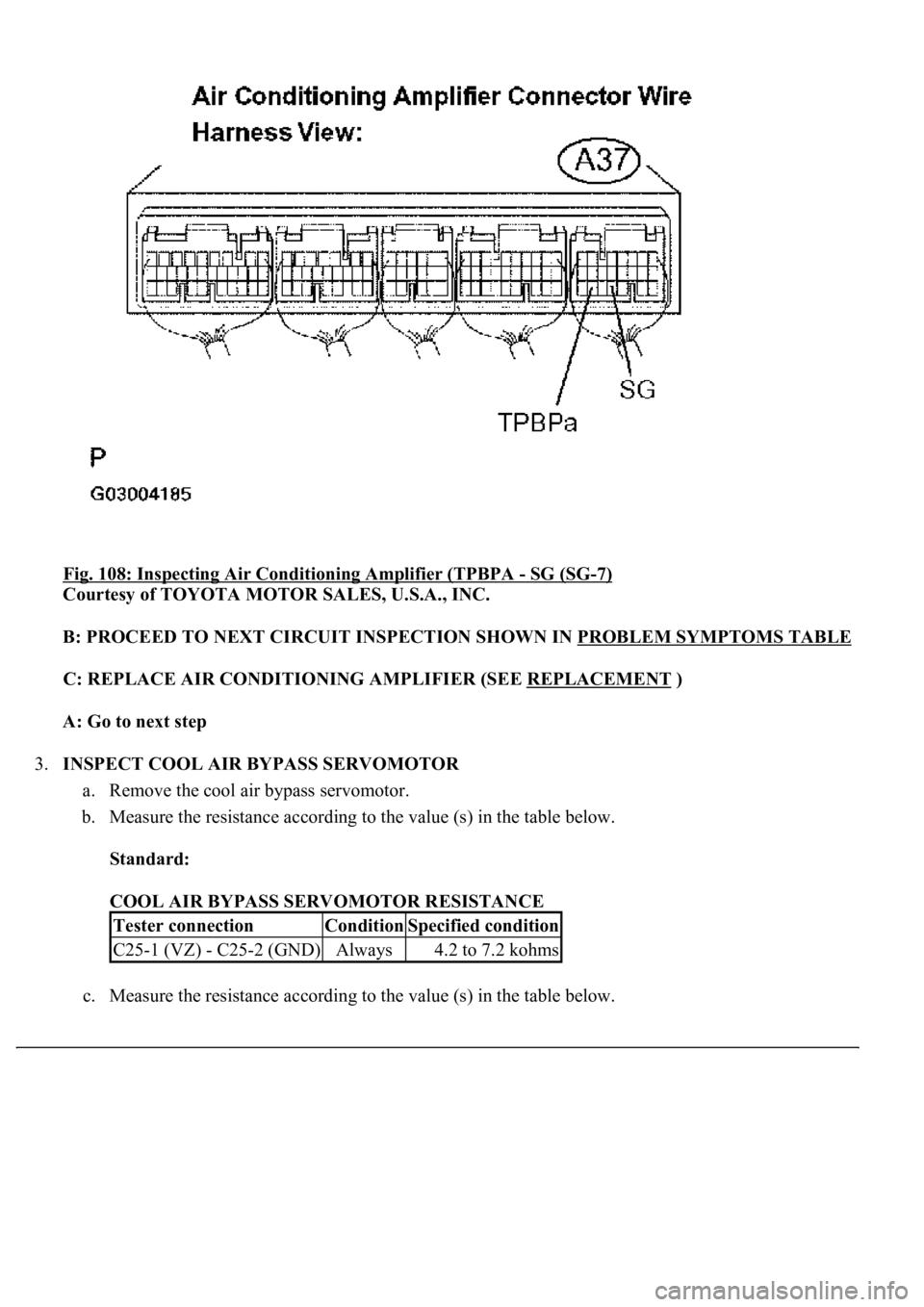

Fig. 108: Inspecting Air Conditioning Amplifier (TPBPA - SG (SG-7)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

B: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

C: REPLACE AIR CONDITIONING AMPLIFIER (SEE REPLACEMENT )

A: Go to next step

3.INSPECT COOL AIR BYPASS SERVOMOTOR

a. Remove the cool air bypass servomotor.

b. Measure the resistance according to the value (s) in the table below.

Standard:

COOL AIR BYPASS SERVOMOTOR RESISTANCE

c. Measure the resistance accordin

g to the value (s) in the table below.

Tester connectionConditionSpecified condition

C25-1 (VZ) - C25-2 (GND)Always4.2 to 7.2 kohms

Page 342 of 4500

HINT:

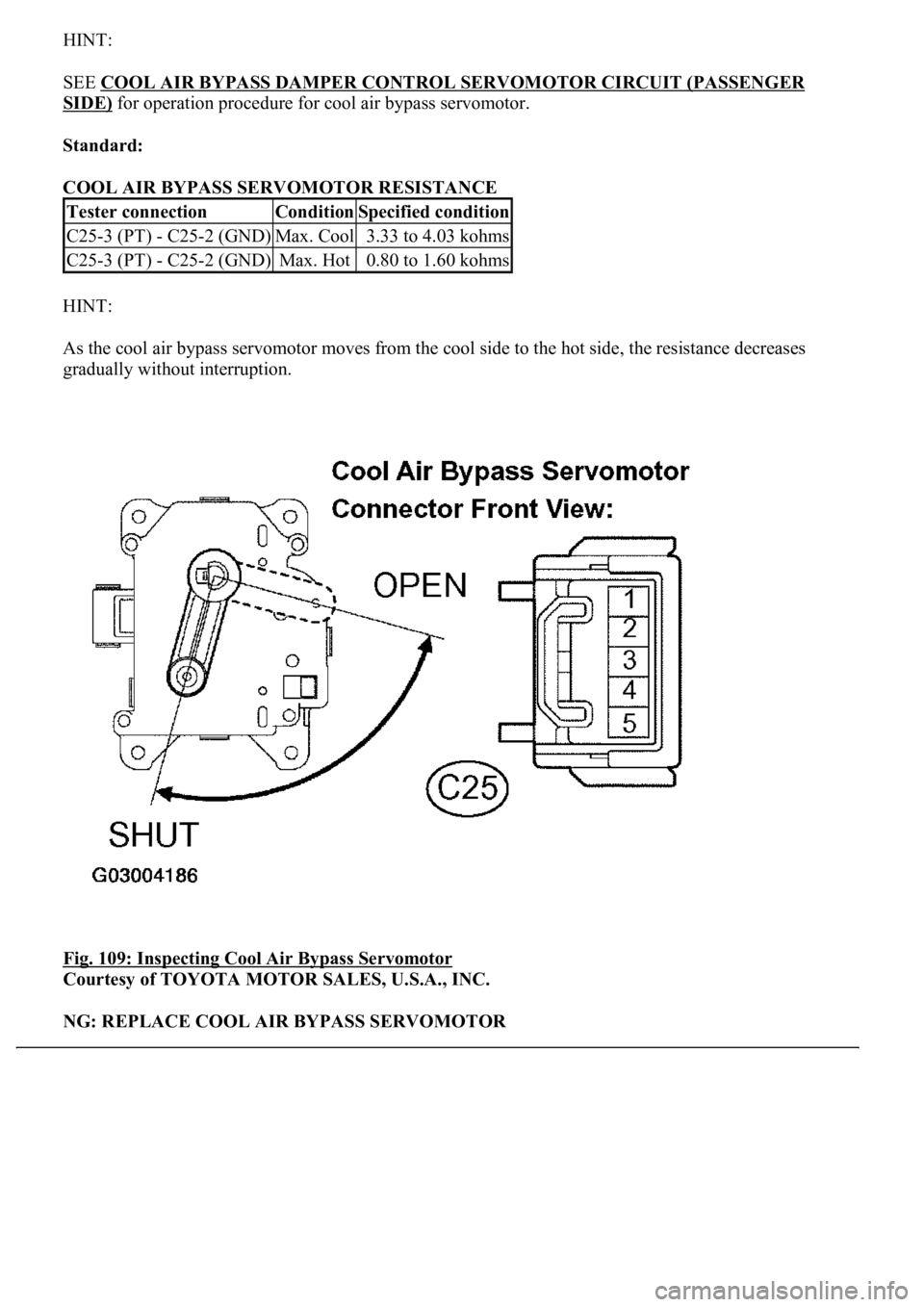

SEE COOL AIR BYPASS DAMPER CONTROL SERVOMOTOR CIRCUIT (PASSENGER

SIDE) for operation procedure for cool air bypass servomotor.

Standard:

COOL AIR BYPASS SERVOMOTOR RESISTANCE

HINT:

As the cool air bypass servomotor moves from the cool side to the hot side, the resistance decreases

gradually without interruption.

Fig. 109: Inspecting Cool Air Bypass Servomotor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPLACE COOL AIR BYPASS SERVOMOTOR

Tester connectionConditionSpecified condition

C25-3 (PT) - C25-2 (GND)Max. Cool3.33 to 4.03 kohms

C25-3 (PT) - C25-2 (GND)Max. Hot0.80 to 1.60 kohms

Page 343 of 4500

OK: Go to next step

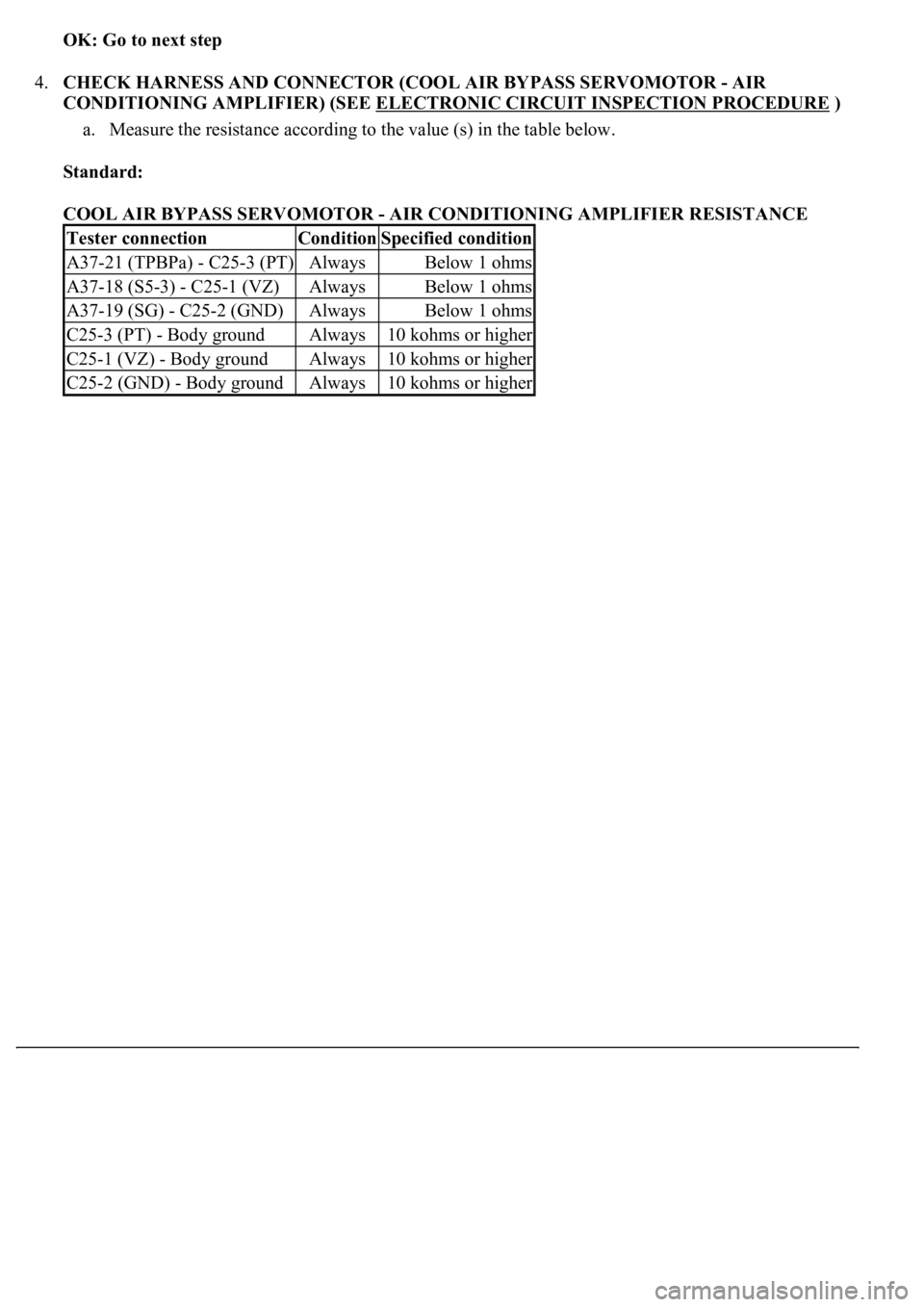

4.CHECK HARNESS AND CONNECTOR (COOL AIR BYPASS SERVOMOTOR - AIR

CONDITIONING AMPLIFIER) (SEE ELECTRONIC CIRCUIT INSPECTION PROCEDURE

)

a. Measure the resistance according to the value (s) in the table below.

Standard:

COOL AIR BYPASS SERVOMOTOR - AIR CONDITIONING AMPLIFIER RESISTANCE

Tester connectionConditionSpecified condition

A37-21 (TPBPa) - C25-3 (PT)AlwaysBelow 1 ohms

A37-18 (S5-3) - C25-1 (VZ)AlwaysBelow 1 ohms

A37-19 (SG) - C25-2 (GND)AlwaysBelow 1 ohms

C25-3 (PT) - Body groundAlways10 kohms or higher

C25-1 (VZ) - Body groundAlways10 kohms or higher

C25-2 (GND) - Body groundAlways10 kohms or higher

Page 344 of 4500

Page 345 of 4500

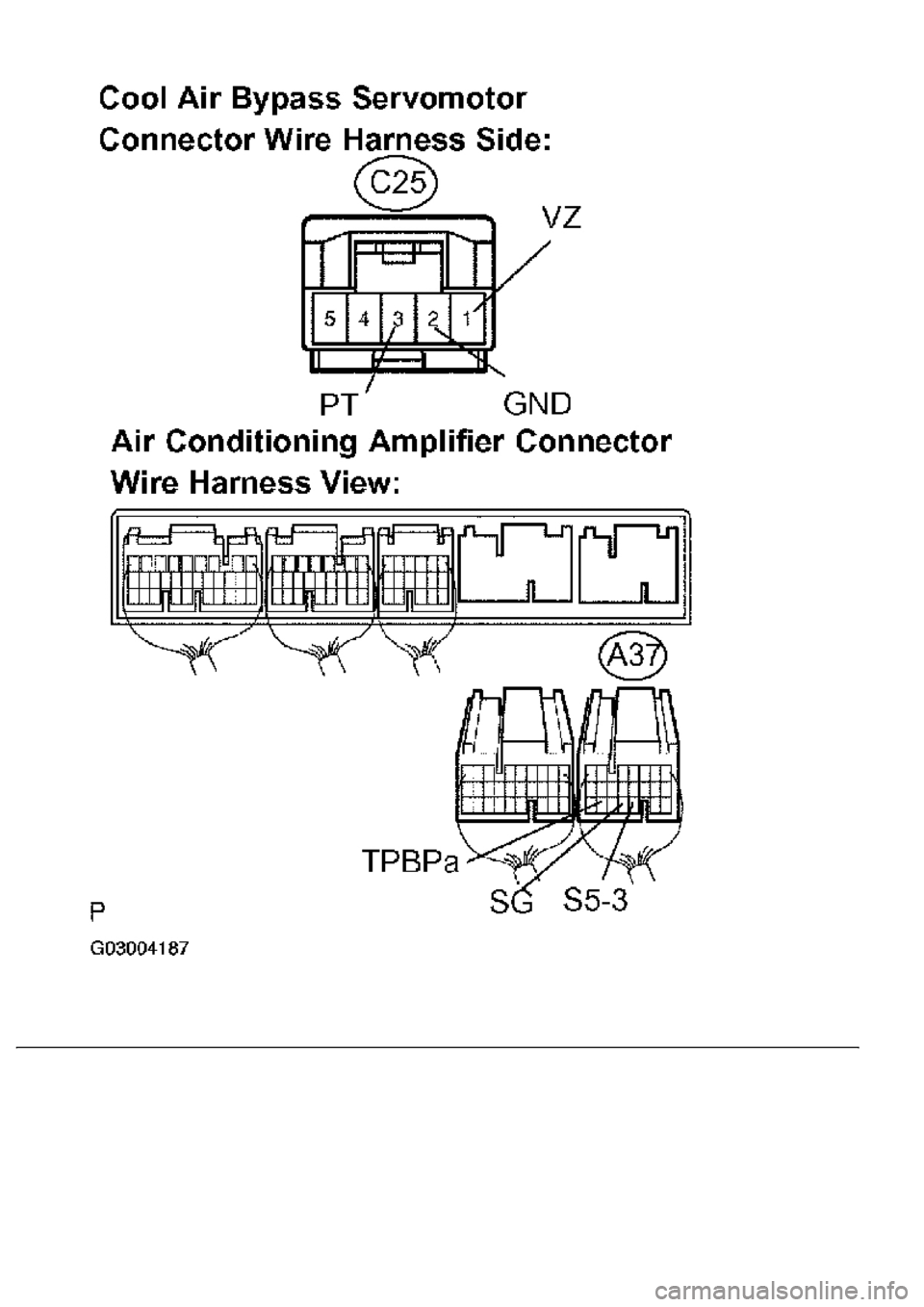

Fig. 110: Checking Harness And Connector (Cool Air Bypass Servomotor - Air Conditioning

Amplifier)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

OK: REPLACE AIR CONDITIONING AMPLIFIER (SEE REPLACEMENT

)

CIRCUIT DESCRIPTION

The air inlet servomotor is controlled by the A/C amplifier and moves the air inlet servomotor to the desired

position.

Fig. 111: DTC Detection Item Trouble Area Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

WIRING DIAGRAM

Page 346 of 4500

Fig. 112: Air Inlet Damper Control Servomotor Circuit

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

1.PERFORM ACTUATOR CHECK

a. Remove the glove box to see and check the air inlet servomotor operation.

b. Set the actuator check mode (SEE ACTUATOR CHECK

).

c. Press the DEF switch to set the STEP operation.

d. Press the DEF switch in order and check the operation of the air inlet servomotor.

Page 347 of 4500

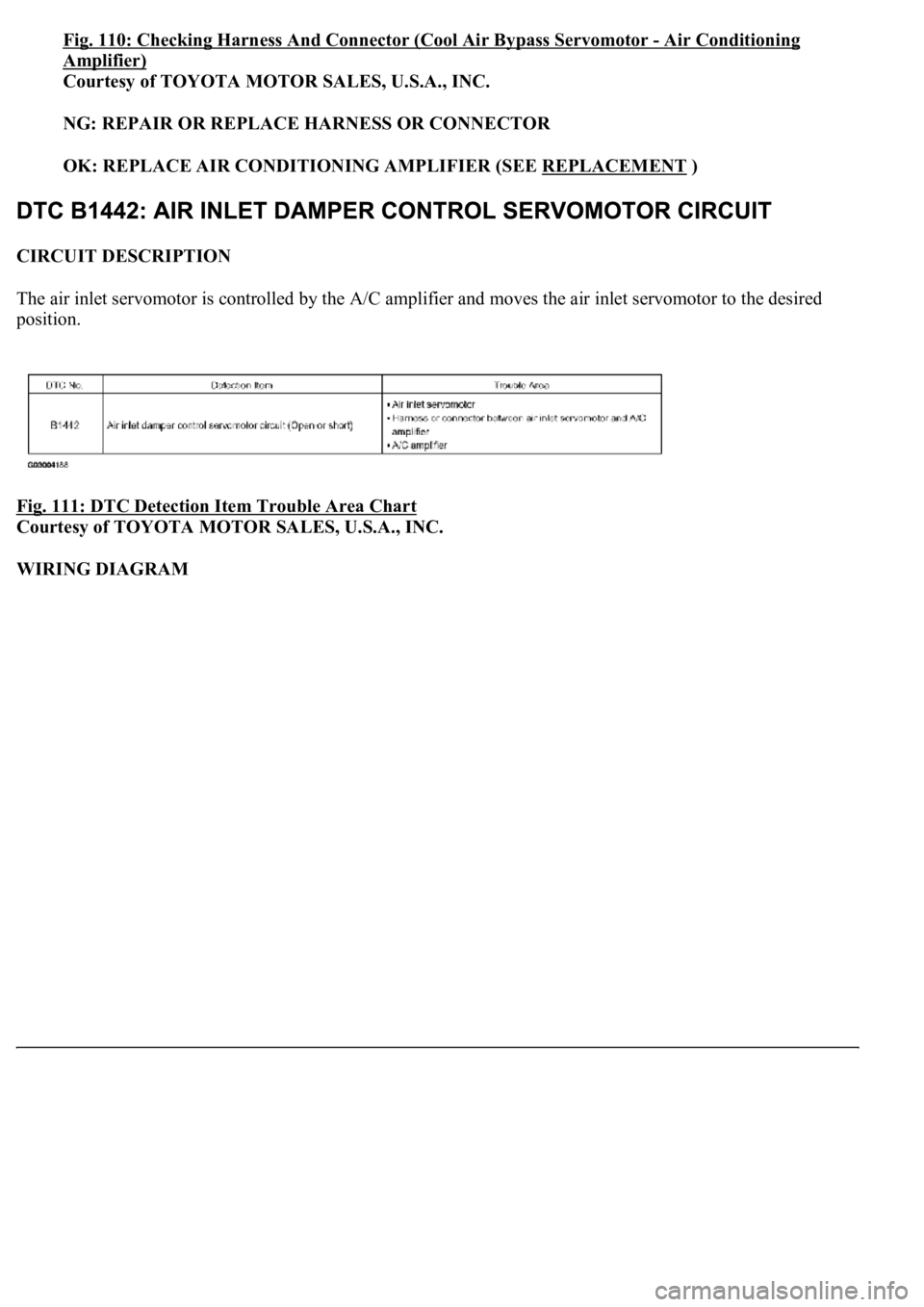

Fig. 113: Checking Actuator

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

DISPLAY CODE - RECIRCULATION DAMPER POSITION

OK:

Recirculation damper changes in accordance with each display code.

Display codeRecirculation damper position

0FRESH

1FRESH

2RECIRCULATION / FRESH

3RECIRCULATION

4FRESH

5FRESH

6FRESH

7FRESH

8FRESH

9FRESH

Page 348 of 4500

Result:

ACTUATOR TEST RESULT

B: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

C: REPLACE AIR CONDITIONING AMPLIFIER (SEE REPLACEMENT )

A: Go to next step

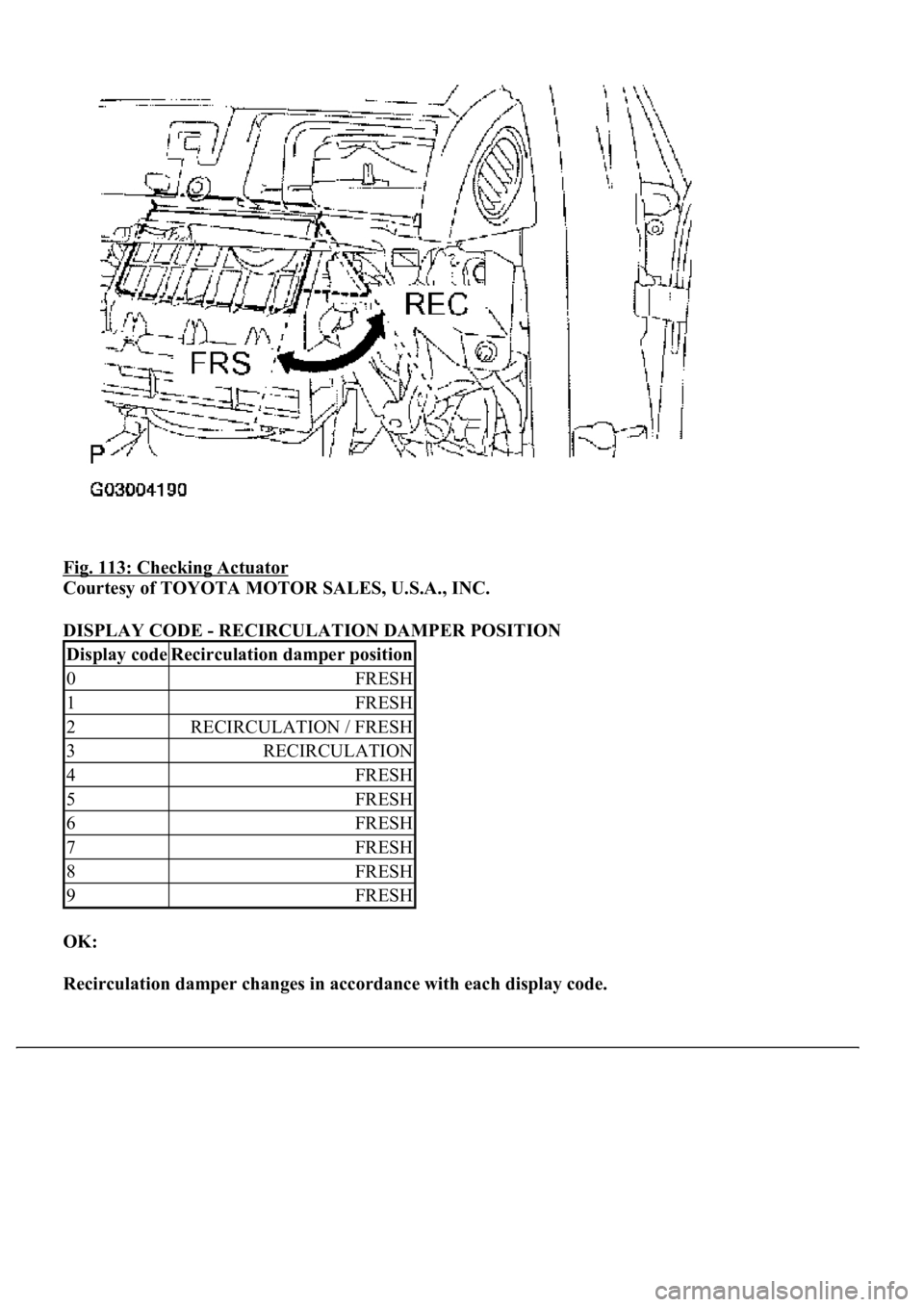

2.INSPECT AIR INLET SERVOMOTOR

a. Remove the air inlet servomotor.

b. Connect the positive (+) lead from the battery to terminal 5 and negative (-) lead to terminal 4, then

check that the lever turns to the "FRESH" position smoothly.

c. Connect the positive (+) lead from the battery to terminal 4 and negative (-) lead to terminal 5, then

check that the lever turns to the "RECIRCULATION" position smoothly.

NGA

OK (Checking from the PROBLEM SYMPTOMS TABLE)B

OK (Checking from the DTC)C

Page 349 of 4500

Fig. 114: Inspecting Air Inlet Servomotor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPLACE AIR INLET SERVOMOTOR

OK: Go to next step

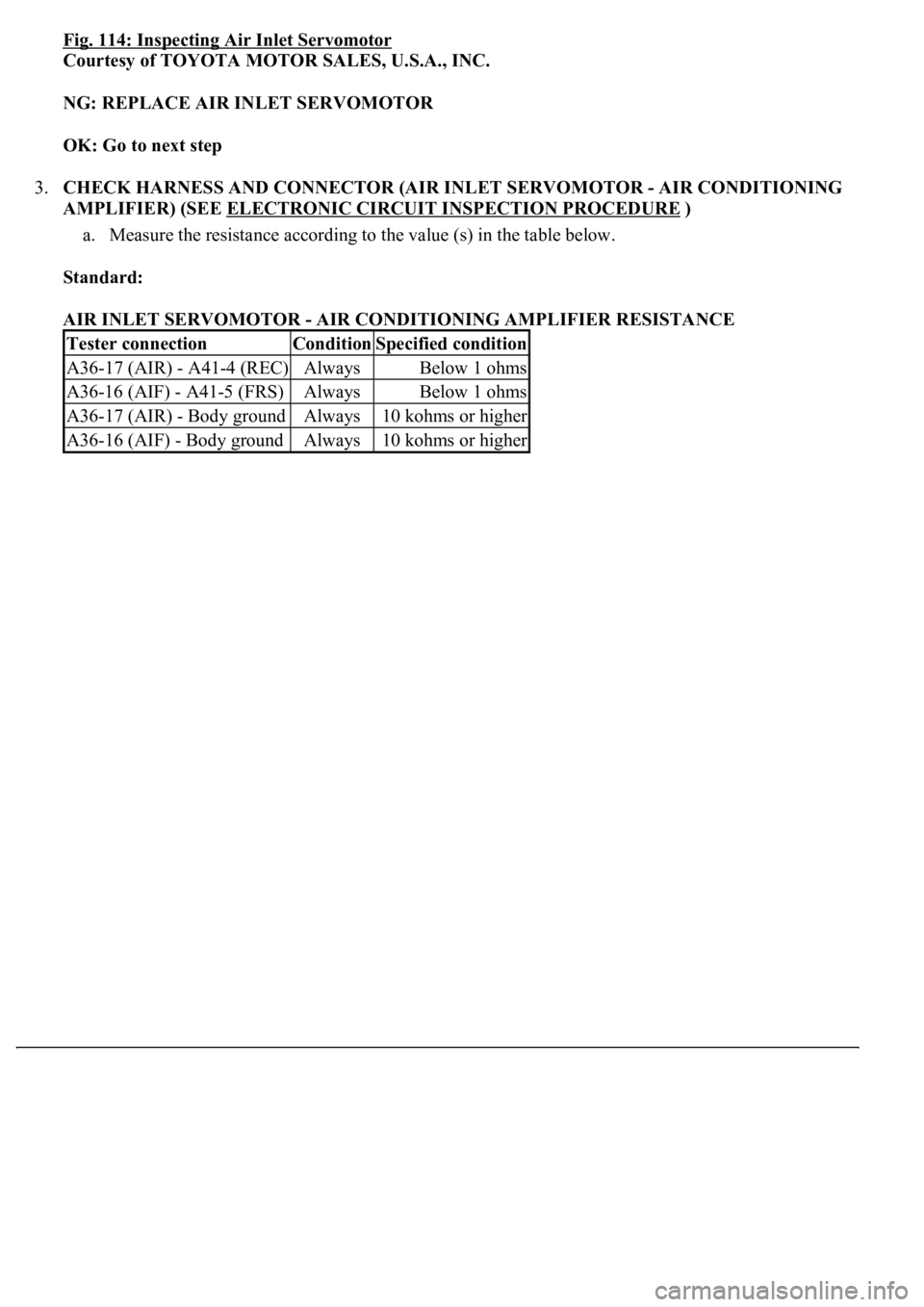

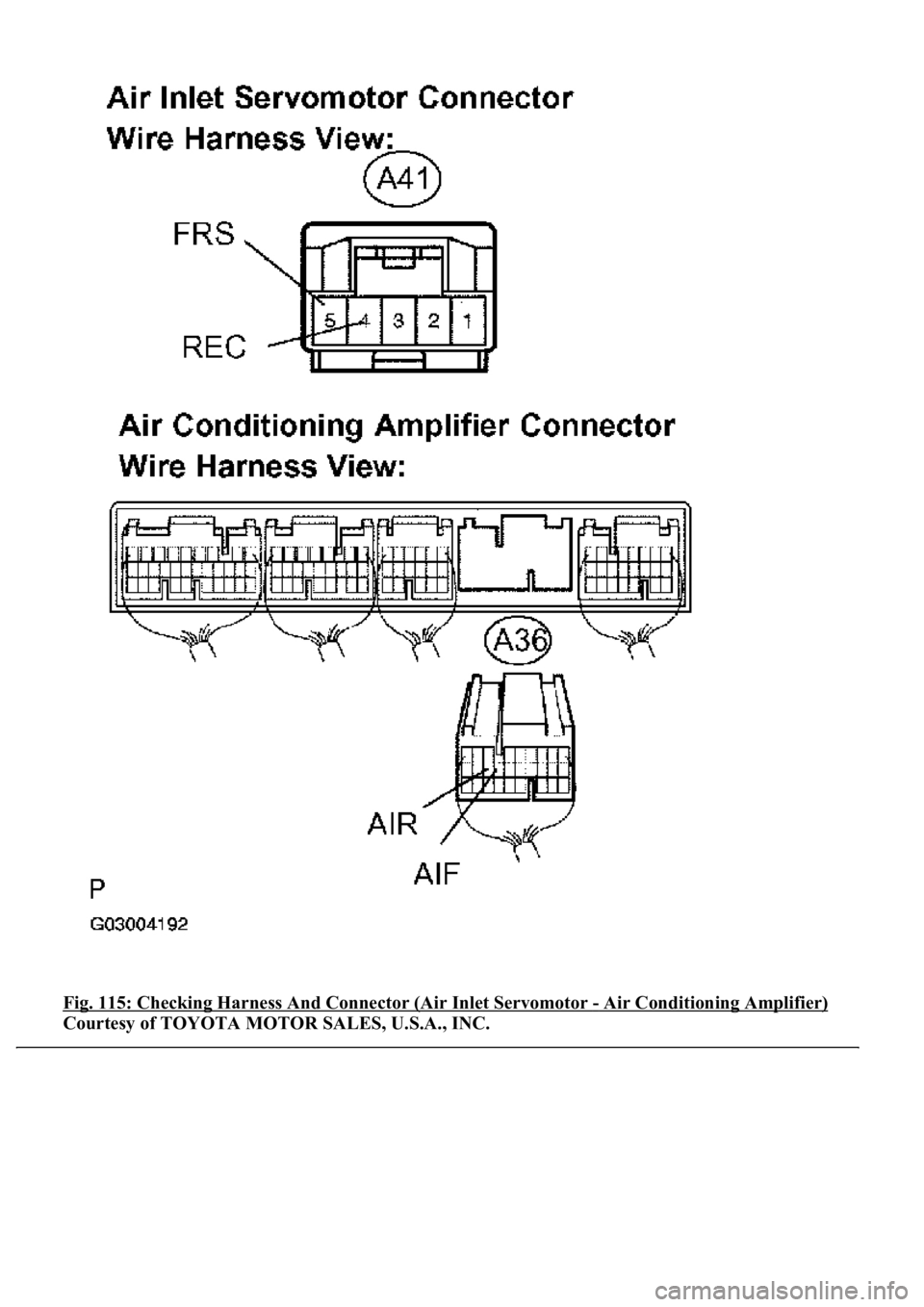

3.CHECK HARNESS AND CONNECTOR (AIR INLET SERVOMOTOR - AIR CONDITIONING

AMPLIFIER) (SEE ELECTRONIC CIRCUIT INSPECTION PROCEDURE

)

a. Measure the resistance according to the value (s) in the table below.

Standard:

AIR INLET SERVOMOTOR - AIR CONDITIONING AMPLIFIER RESISTANCE

Tester connectionConditionSpecified condition

A36-17 (AIR) - A41-4 (REC)AlwaysBelow 1 ohms

A36-16 (AIF) - A41-5 (FRS)AlwaysBelow 1 ohms

A36-17 (AIR) - Body groundAlways10 kohms or higher

A36-16 (AIF) - Body groundAlways10 kohms or higher

Page 350 of 4500

Fig. 115: Checking Harness And Connector (Air Inlet Servomotor - Air Conditioning Amplifier)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Trending: vacuum switching valve, wheel alignment, coolant capacity, sport mode, B2419 bean, ignition, differential