sensor LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 2871 of 4500

relay valve and locks the torque converter clutch.

If the ECM detects no lock-up after lock-up has been requested or if it detects lock-up when it is not requested,

the ECM interprets this as a fault in the shift solenoid valve SLU or lock-up system performance.

The ECM will turn on the MIL and store the DTC.

Example:

When any of the following is met, the system judges it as a malfunction.

a. There is a difference in rotation between before and after torque converters even when the ECM

commands lock-up.

(Engine speed is at least 75 rpm greater than input turbine speed.)

b. There is no difference in rotation between before and after torque converters even when the ECM

commands lock-up off.

(The difference between engine speed and input turbine speed is less than 35 rpm.)

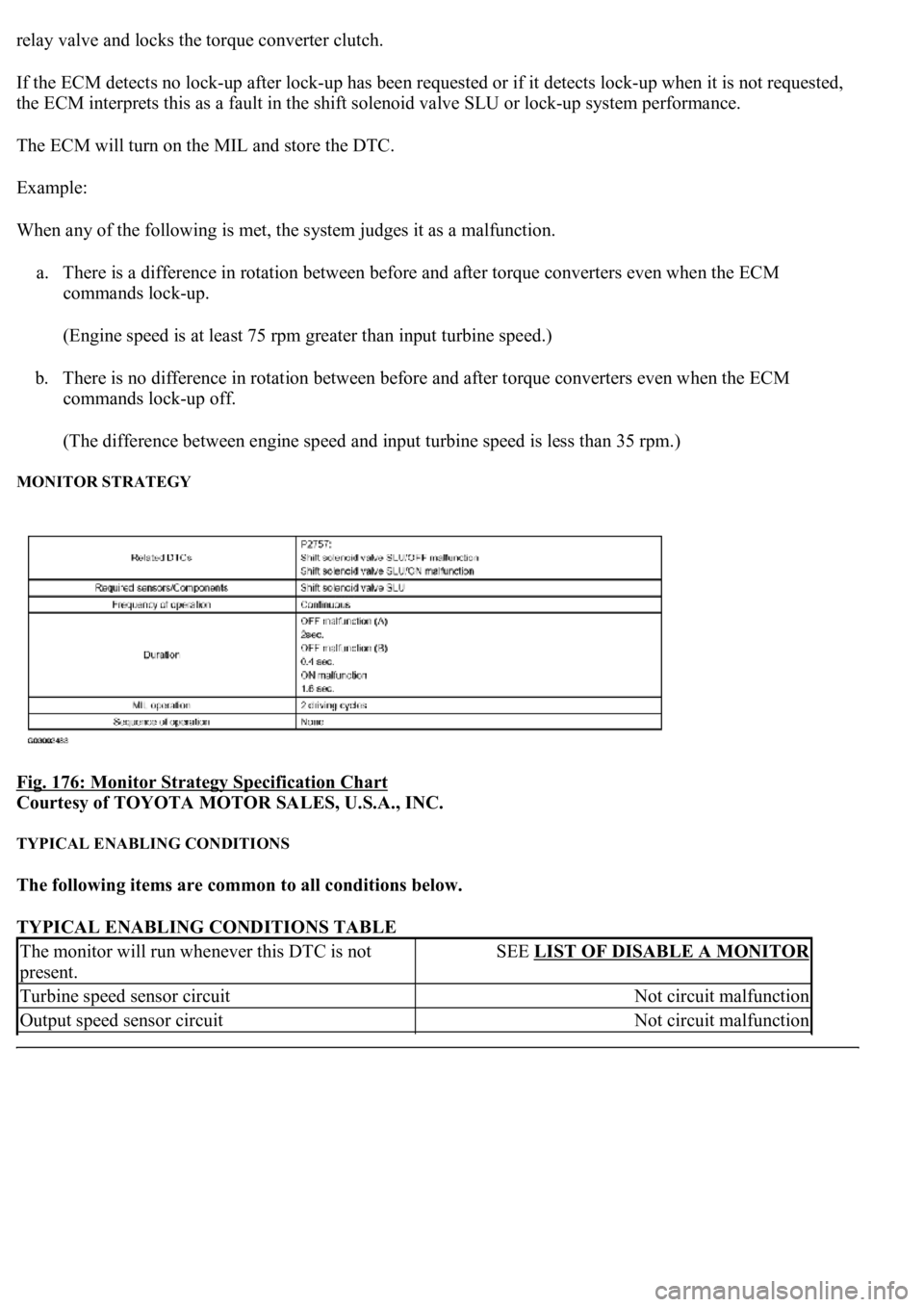

MONITOR STRATEGY

Fig. 176: Monitor Strategy Specification Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

TYPICAL ENABLING CONDITIONS

The following items are common to all conditions below.

TYPICAL ENABLING CONDITIONS TABLE

The monitor will run whenever this DTC is not

present.SEE LIST OF DISABLE A MONITOR

Turbine speed sensor circuitNot circuit malfunction

Output speed sensor circuitNot circuit malfunction

Page 2872 of 4500

OFF malfunction (A)

TYPICAL ENABLING CONDITIONS TABLE - OFF MALFUNCTION A

OFF malfunction (B)

TYPICAL ENABLING CONDITIONS TABLE - OFF MALFUNCTION B

ON malfunction

TYPICAL ENABLING CONDITIONS TABLE - ON MALFUNCTION

Shift solenoid valve S1 circuitNot circuit malfunction

Shift solenoid valve S2 circuitNot circuit malfunction

Shift solenoid valve S3 circuitNot circuit malfunction

Shift solenoid valve S4 circuitNot circuit malfunction

Shift solenoid valve SR circuitNot circuit malfunction

Torque converter clutch pressure control solenoid

circuitNot circuit malfunction

KCS sensor circuitNot circuit malfunction

ETCS (Electric throttle control system)Not system down

Transmission shift position"D"

ECT (Engine coolant temperature)40°C (104°F) or more

Spark advance from Max. retard timing by KCS

control0° CA or more

EngineStarting

ECM selected gear4th, 5th or 6th

Vehicle speed25 km/h (15.5 mph) or more

Shift solenoid valve S1 circuitNot circuit malfunction

Shift solenoid valve S3 circuitNot circuit malfunction

Shift solenoid valve S4 circuitNot circuit malfunction

Shift solenoid valve SL2 circuitNot circuit malfunction

1 - 2 shift valveNot circuit malfunction

ECM lock - up commandON (SLU pressure: 513 kPa or more)

Duration time from lock-up on command3 sec. or more

Vehicle speedLess than 100 km/h (62.2 mph)

ECM selected gear2nd

Vehicle speed2 km/h (1.2 mph) or more

Output speed2nd --> 1st down shift point or more

Throttle valve opening angle6.5% or more (Varies with engine speed)

ECM lock - up commandOFF (SLU pressure: less than 4 kPa)

Duration time from lock-up on command3 sec. or more

Page 2873 of 4500

TYPICAL MALFUNCTION THRESHOLDS

Both of the following conditions are met: OFF malfunction (A) and (B)

OFF malfunction (A)

TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION A

OFF malfunction (B)

TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION B

ON malfunction

2 detections are necessary per driving cycle:

1st detection; temporary flag ON

2md detection; pending fault code ON

Vehicle speed must be under 10 km/h (6.2 mph) once before 2nd detection.

TYPICAL MALFUNCTION THRESHOLDS TABLE - ON MALFUNCTION

COMPONENT OPERATING RANGE

COMPONENT OPERATING RANGE TABLE

INSPECTION PROCEDURE

HINT:

Performing the ACTIVE TEST using the hand-held tester allows the relay, VSV, actuator and so on to operate

without parts removal. Performing the ACTIVE TEST as the first step of troubleshooting is one method to

shorten labor time.

It is possible to display the DATA LIST during the ACTIVE TEST.

Throttle valve opening angle9% or more

Vehicle speedLess than 60 km/h (37.3 mph)

Engine speed - Turbine speed (NE - NT)70 rpm or more

Engine speed - Turbine speed (NE - NT)Not 3.08 to 7.50

Engine speed - Turbine speed| (|NE - NT|)Less than 35 rpm

Speed sensor (NT)Input speed is equal to engine speed when lock-up

ON.

Page 2879 of 4500

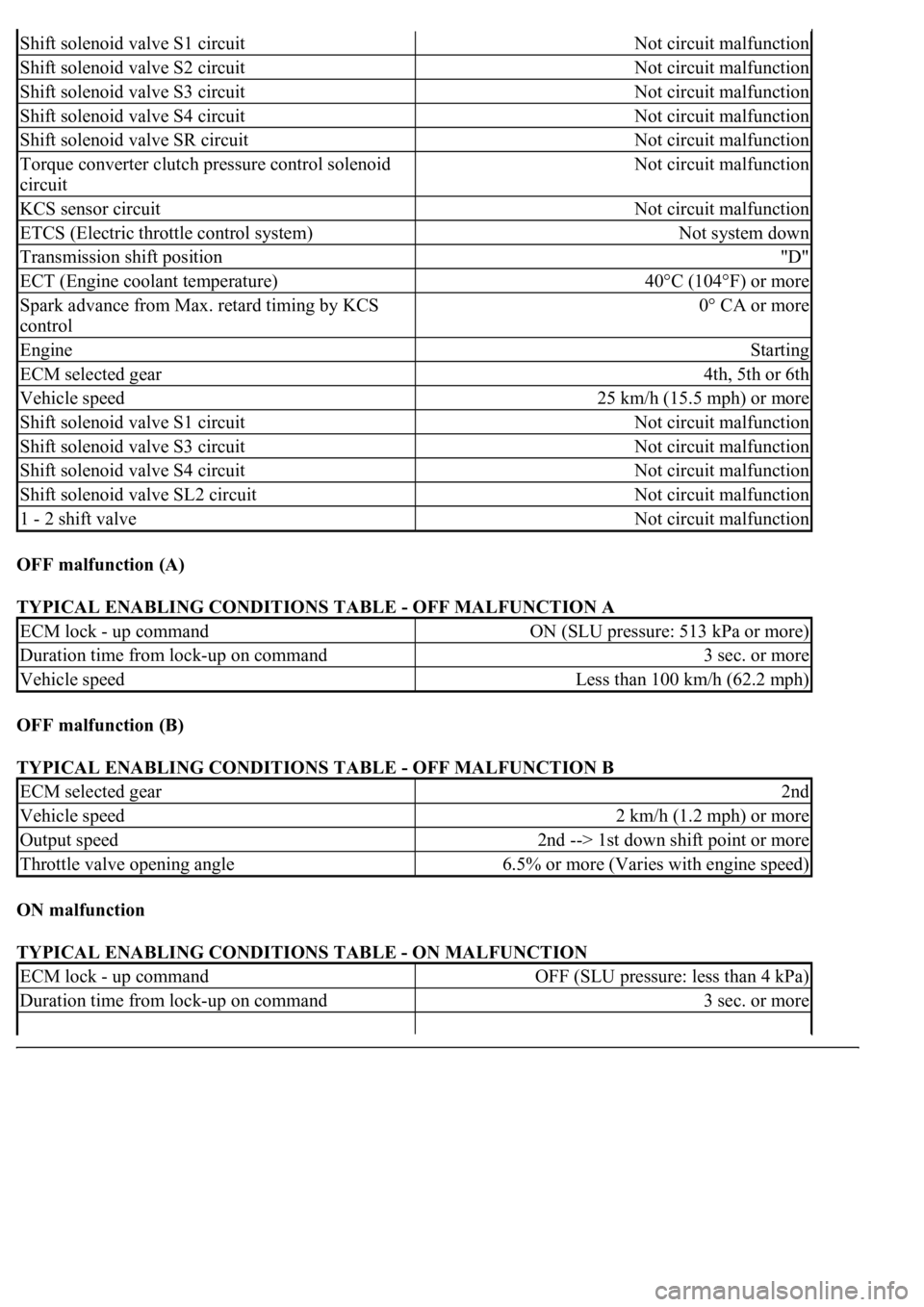

Fig. 181: Identifying Duty Ratio Pattern

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fig. 182: DTC Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

MONITOR DESCRIPTION

When an open or short in a shift solenoid valve (SLU) circuit is detected, the ECM determines there is a

malfunction. The ECM will turn on the MIL and store this DTC.

MONITOR STRATEGY

MONITOR STRATEGY TABLE

Related DTCsP2759: Shift solenoid valve SLU/Range check

Required sensors/ComponentsShift solenoid valve SLU

Frequency of operationContinuous

Page 2894 of 4500

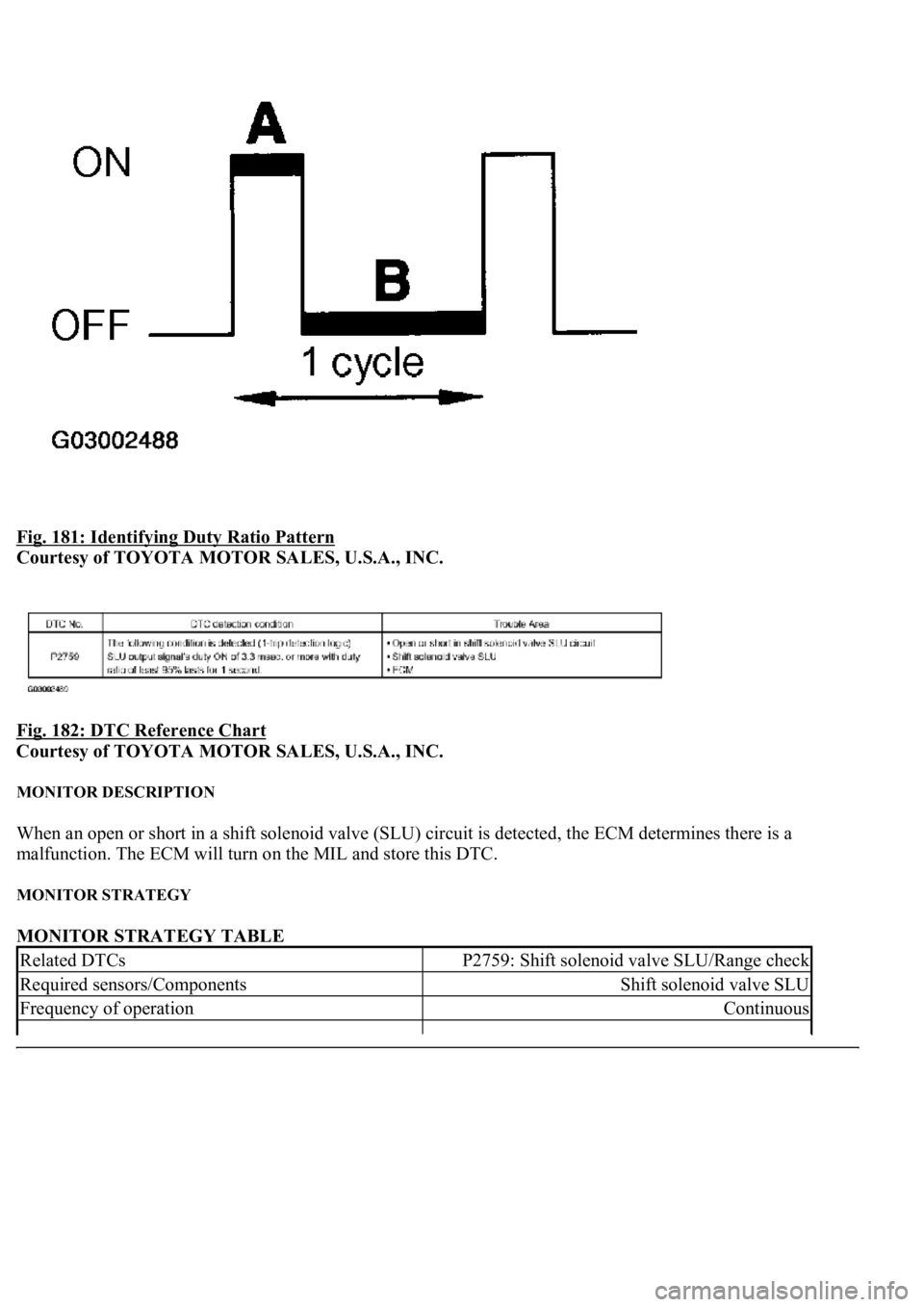

Fig. 198: Transmission Control Switch Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR (See ELECTRONIC CIRCUIT

INSPECTION PROCEDURE )

OK: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE

PATTERN SELECT SWITCH CIRCUIT (PWR)

CIRCUIT DESCRIPTION

Passenger side J/B ECU receives pattern select switch information, and sends it through the multiplex

communication system and CAN system to the ECM.

The ECM memory contains the shift programs for the NORMAL, POWER and SNOW patterns, 2 position, L

position and the loc

k-up patterns. By following the programs corresponding to the signals from the pattern

select switch, the neutral start and other various sensors, the ECM switches the solenoid valves ON and OFF,

and controls the transmission gear change and the lock-up clutch operation.

WIRING DIAGRAM

Page 2905 of 4500

LS 430

CEC

Computerized Engine Controls

EVAP

Fuel Evaporative System

EVAP-CCVVSV

EVAP Canister Closed Valve Vacuum Switching Valve

EVAP-VC

EVAP Vapor Canister

EVAP-VPS

EVAP Vapor Pressure Sensor

EVAP-VPSVSV

Vapor Pressure Sensor Vacuum Switching Valve

Engine & Fuel System(1) Emission Control Systems & Devices

2006

4.3L (261") V8 SFIPCV, EVAP, (2) TWC, FR, SPK, (3) HO2S, CEC,

MIL, EVAP-VSV, EVAP-VC, EVAP-VPS, EVAP-

VPSVSV, EVAP-CCVVSV, ORVR-COV, ORVR-

OCKV

(1)For quick reference, major emission control systems and devices are listed in bold type; components

and other related devices are listed in light type.

(2)Equipped with 3.

(3)Equipped with 4.

Page 2906 of 4500

EVAP-VSV

EVAP Vacuum Switching Valve

FR

Fill Pipe Restrictor

HO2S

Heated Oxygen Sensor

MIL

Malfunction Indicator Light

ORVR-COV

On-Board Refueling Vapor Recovery Cut-Off Valve

ORVR-OCKV

On-Board Refueling Vapor Recovery Overfill Check Valve

PCV

Positive Crankcase Ventilation

SFI

Sequential Multiport Fuel Injection

SPK-CC

SPK Computer Controlled

TWC

Three-Way Catalytic Converter

WU-TWC

Warm-Up Three-Wa

y Catalytic Converter

Page 2912 of 4500

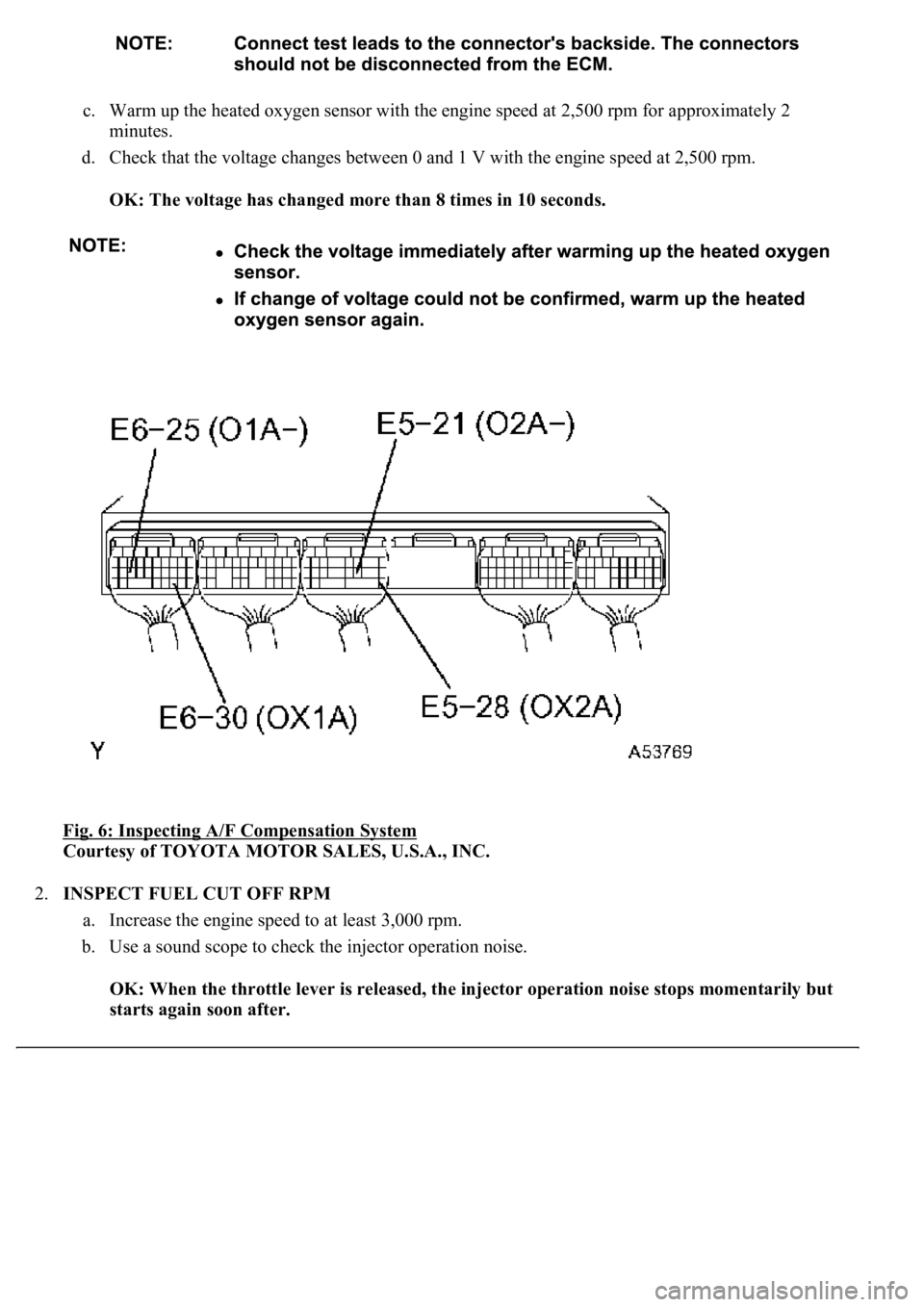

c. Warm up the heated oxygen sensor with the engine speed at 2,500 rpm for approximately 2

minutes.

d. Check that the voltage changes between 0 and 1 V with the engine speed at 2,500 rpm.

OK: The voltage has changed more than 8 times in 10 seconds.

Fig. 6: Inspecting A/F Compensation System

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

2.INSPECT FUEL CUT OFF RPM

a. Increase the engine speed to at least 3,000 rpm.

b. Use a sound scope to check the injector operation noise.

OK: When the throttle lever is released, the injector operation noise stops momentarily but

starts again soon after.

Page 2914 of 4500

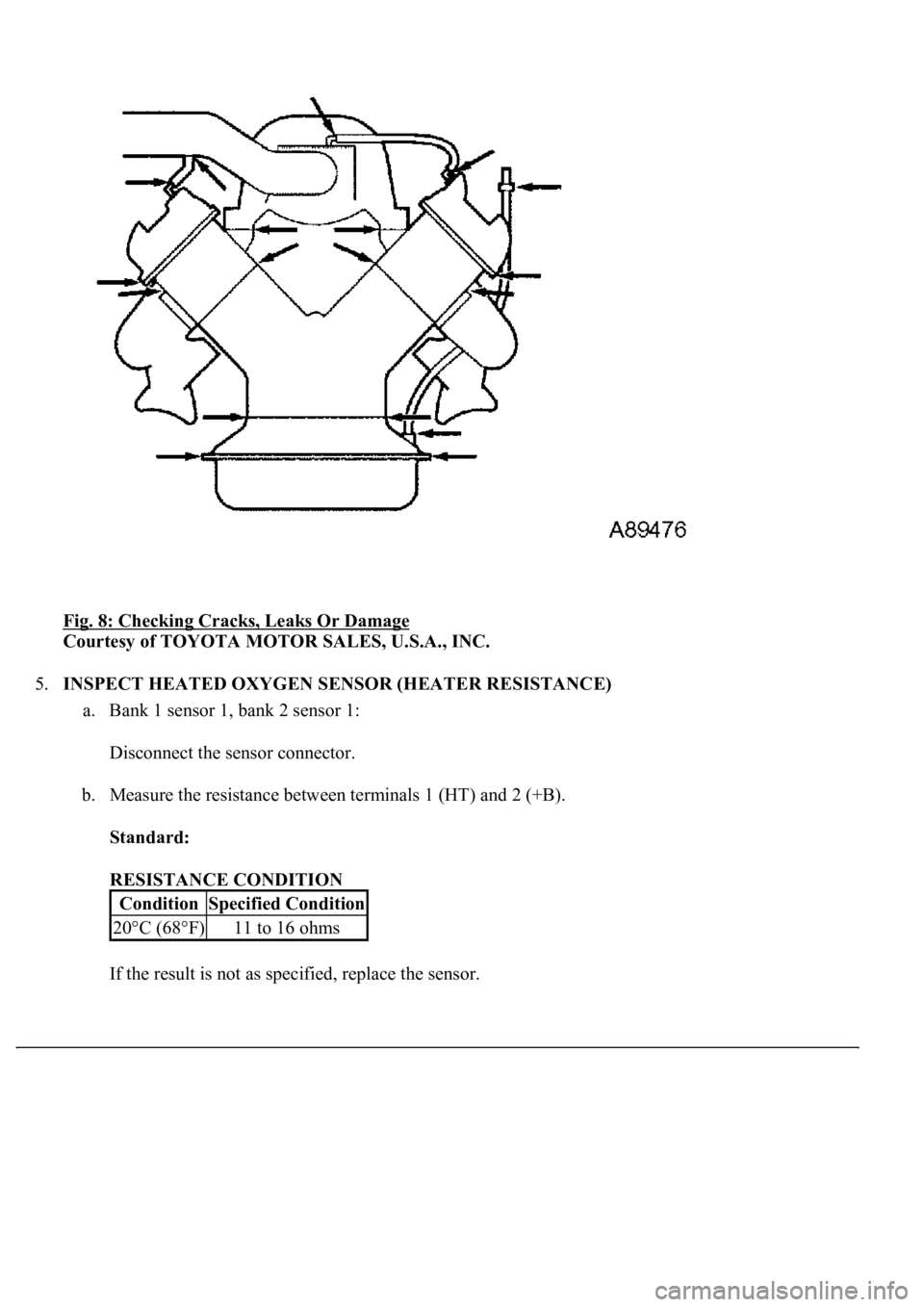

Fig. 8: Checking Cracks, Leaks Or Damage

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

5.INSPECT HEATED OXYGEN SENSOR (HEATER RESISTANCE)

a. Bank 1 sensor 1, bank 2 sensor 1:

Disconnect the sensor connector.

b. Measure the resistance between terminals 1 (HT) and 2 (+B).

Standard:

RESISTANCE CONDITION

If the result is not as specified, replace the sensor.

ConditionSpecified Condition

20°C (68°F)11 to 16 ohms

Page 2915 of 4500

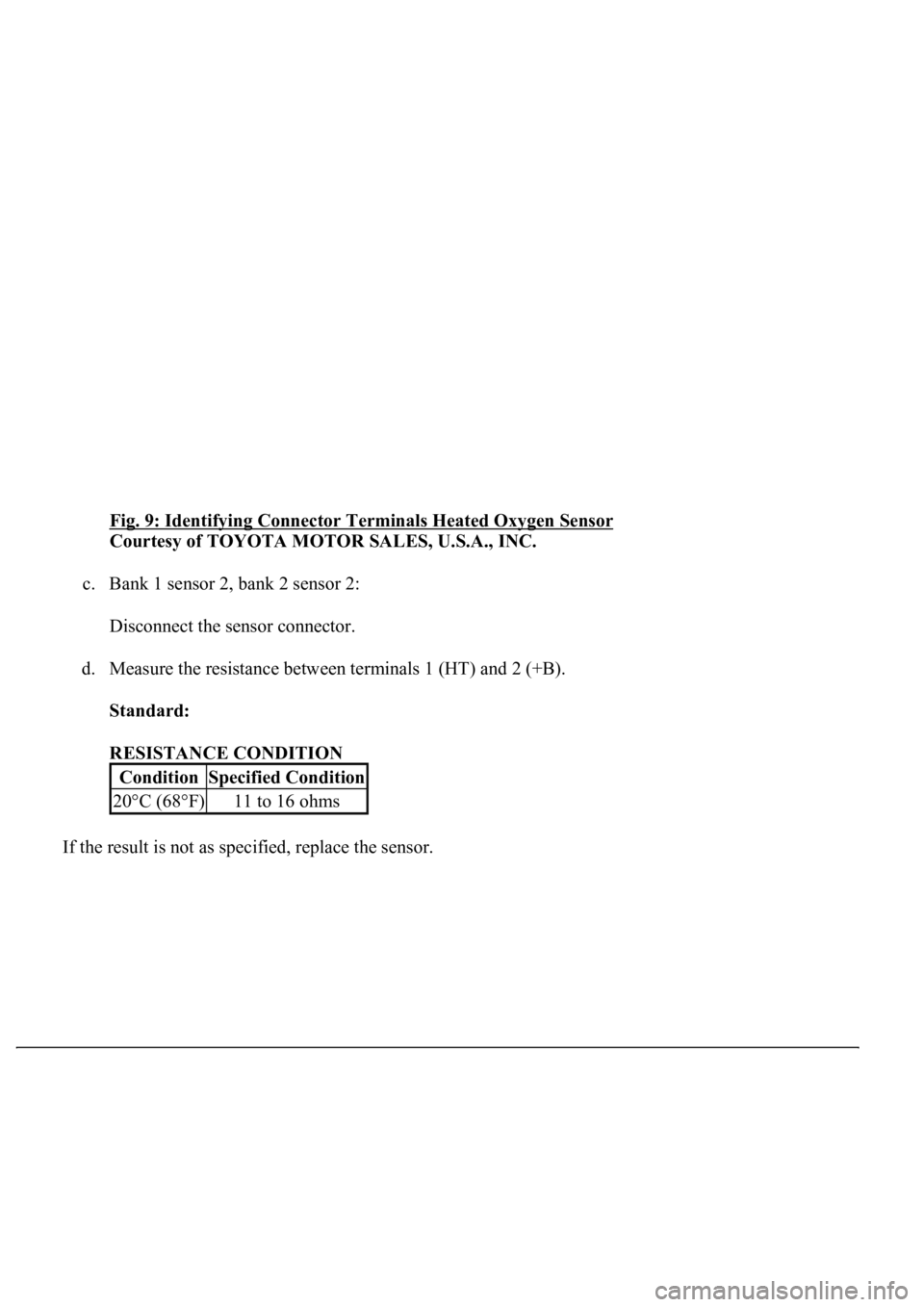

Fig. 9: Identifying Connector Terminals Heated Oxygen Sensor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

c. Bank 1 sensor 2, bank 2 sensor 2:

Disconnect the sensor connector.

d. Measure the resistance between terminals 1 (HT) and 2 (+B).

Standard:

RESISTANCE CONDITION

If the result is not as specified, replace the sensor.

ConditionSpecified Condition

20°C (68°F)11 to 16 ohms