MAZDA 323 1992 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 1992,

Model line: 323,

Model: MAZDA 323 1992

Pages: 279, PDF Size: 24.15 MB

MAZDA 323 1992 Workshop Manual Suplement

323 1992

MAZDA

MAZDA

https://www.carmanualsonline.info/img/28/57055/w960_57055-0.png

MAZDA 323 1992 Workshop Manual Suplement

Trending: remote start, 4WD, brake pads replacement, ESP, fuel pump, wiring diagram, light

Page 141 of 279

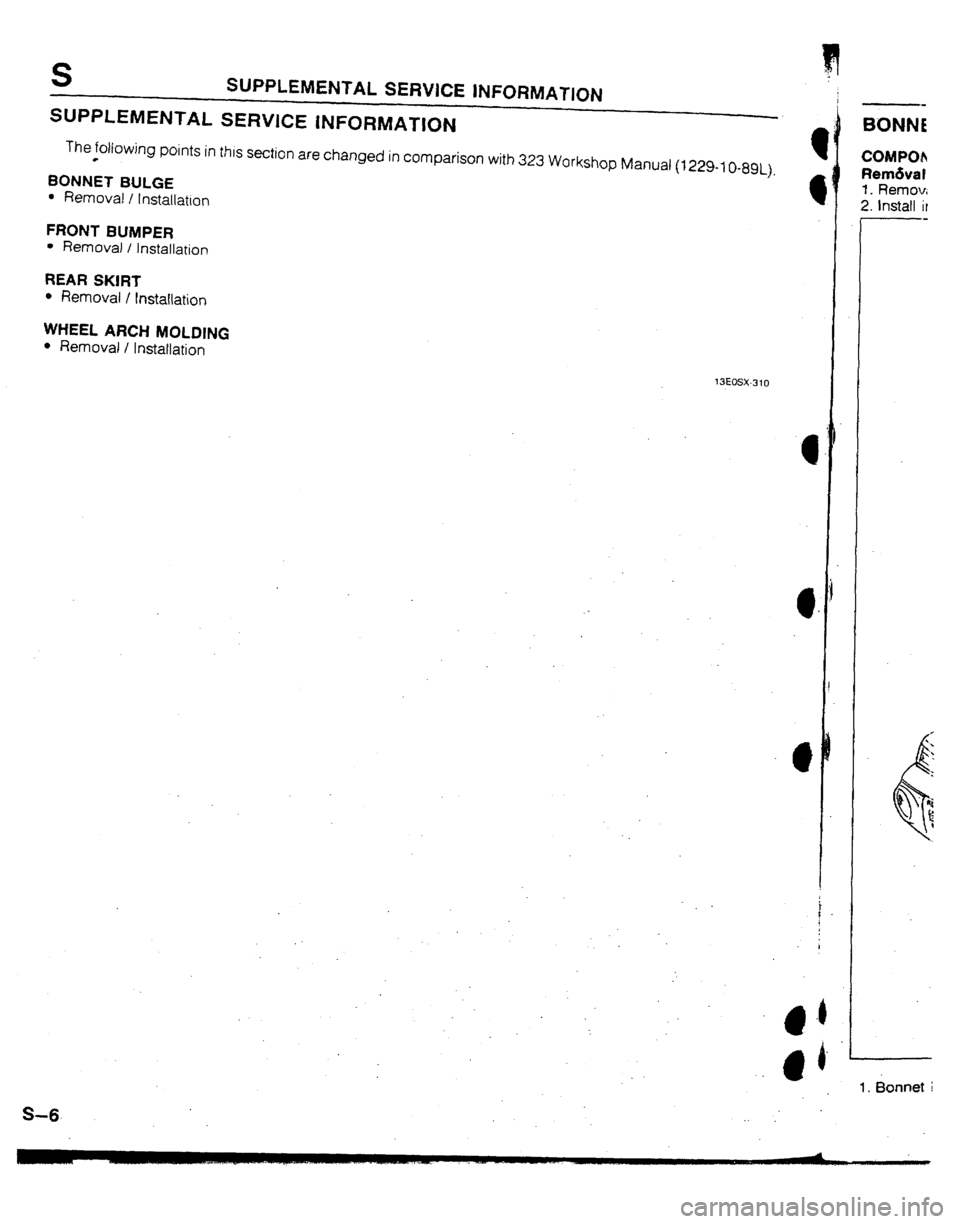

S SUPPLEMENTAL SERVICE INFORMATION

SUPPLEMENTAL SERVICE lNFORMATlON

The following points in this section are changed in comparison with 323 Workshop Manual (1229-~()439~).

*

BONNET BULGE

l Removal / installation

FRONT BUMPER

l Removal / Installation

REAR SKIRT

l Removal / Installation

WHEEL ARCf-f MOLDfNG

l Removal / Installation

13EOSX-310

S-6

BONNE

COMPOh

Rembvaf

1. Removi

2. lnstatl if

Page 142 of 279

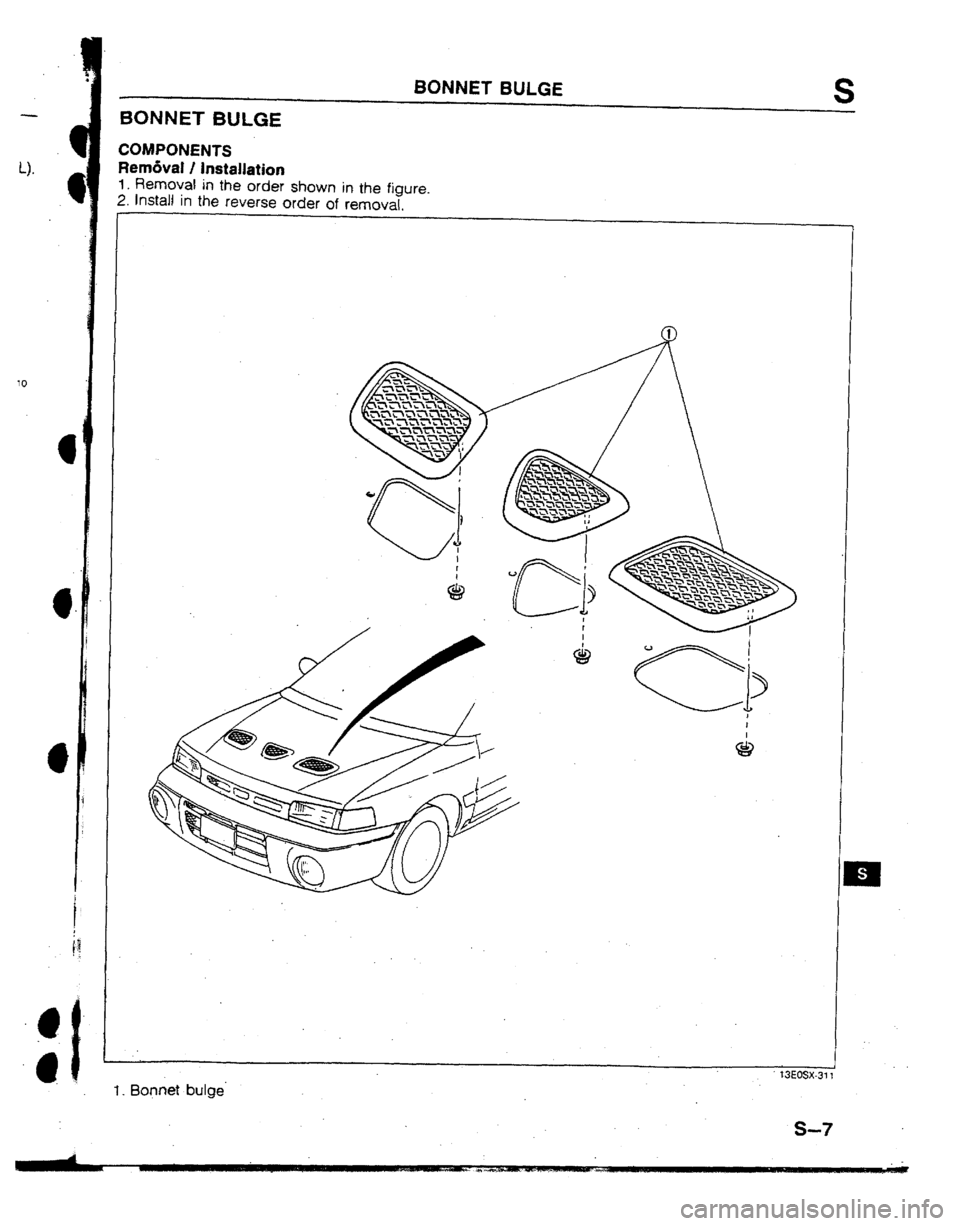

BONNET BULGE S

BONNET BULGE

COMPONENTS

Rem&at ! Installation

1. Removal in the order shown in the

figure.

2. Install in the reverse order of removal.

I . Bonnet butge’

Page 143 of 279

S

FRONT BUMPER FRONT BUMPER

COMPONENTS

Rem’ovat ! Installation

1. Removal in the order shown

2. Install in the reverse order of

1 in the figure.

removal.

-9-9.8 Nm 170-100 kgfem,

U-87 h.lbfJ

f4-m Ikgf-m, ft-lbf J

13EOSX-312

4. Front bumper

Disassembly / Assembly

. . . . . . . . . ..m... page S-9 1. Radiator grille

2. Front conbination light

3. Headlight

5-8

Disassembh

I . Disassemi

2. Assemble

t

1. Fog lights

-

a

-I. 2. Bumper rear

3. Bumper me

Page 144 of 279

FRONT BUMPER S

Disassembly / Assembly

I. Disassemble in the order shown in the figure.

2. Assemble in the reverse order of disassembly.

i

1, Fog lights

2. Bumper reinforcement

3. Bumper mesh 4. Hook cover

5. Bumper fascia

Page 145 of 279

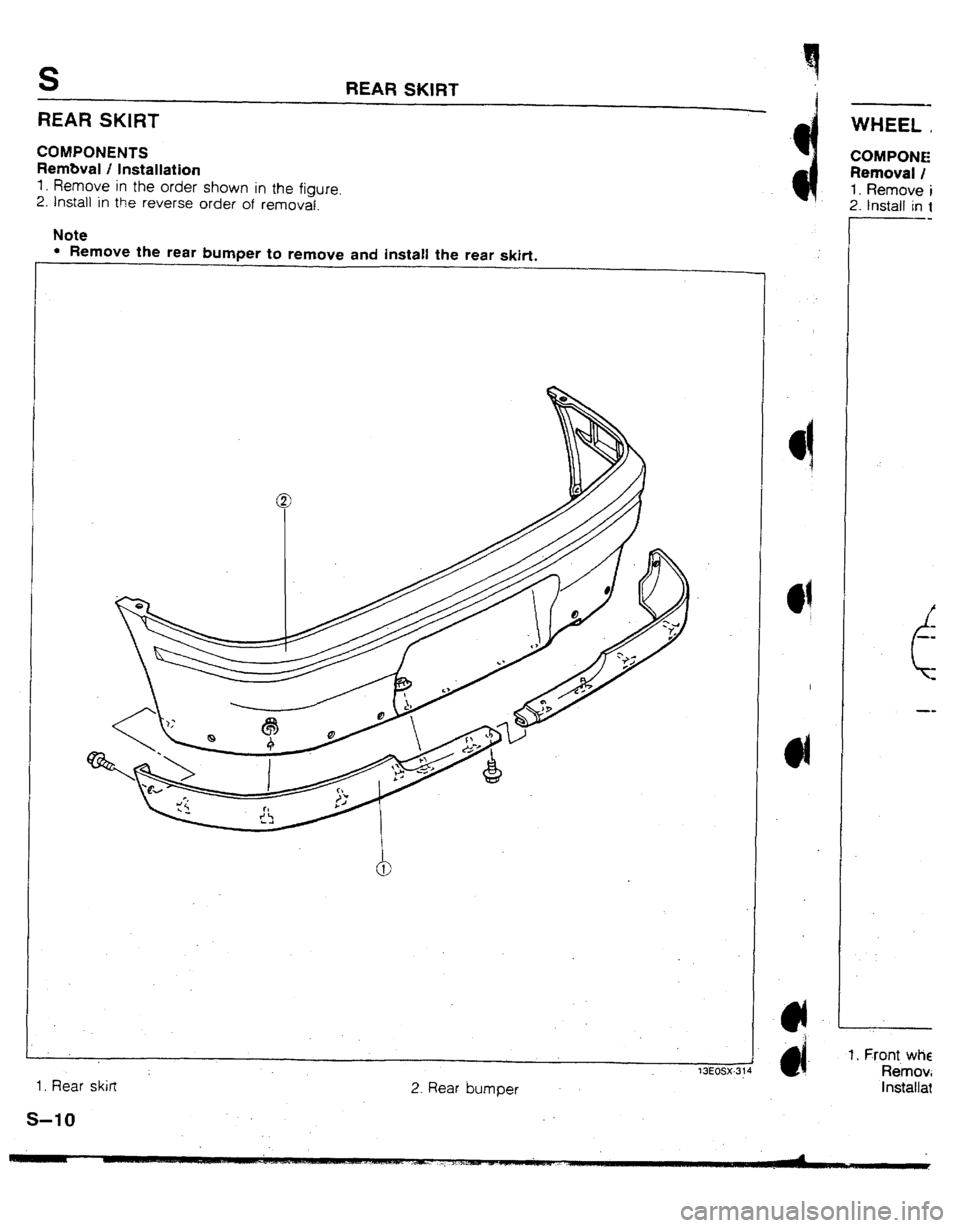

S REAR SKIRT

REAR SKIRT -

COMPONENTS

Rembal / Installation

1. Remove in the order shown in the figure.

2. Install in the reverse order of removal.

Note

l Remove the rear bumper to remove and install the rear skirt.

1. Rear skit-! 2. Rear bumper

S-10 WHEEL,

COMPONE

Removal I

1. Remove i

2. Install in t

I, Front why

Removi

I nstallat

Page 146 of 279

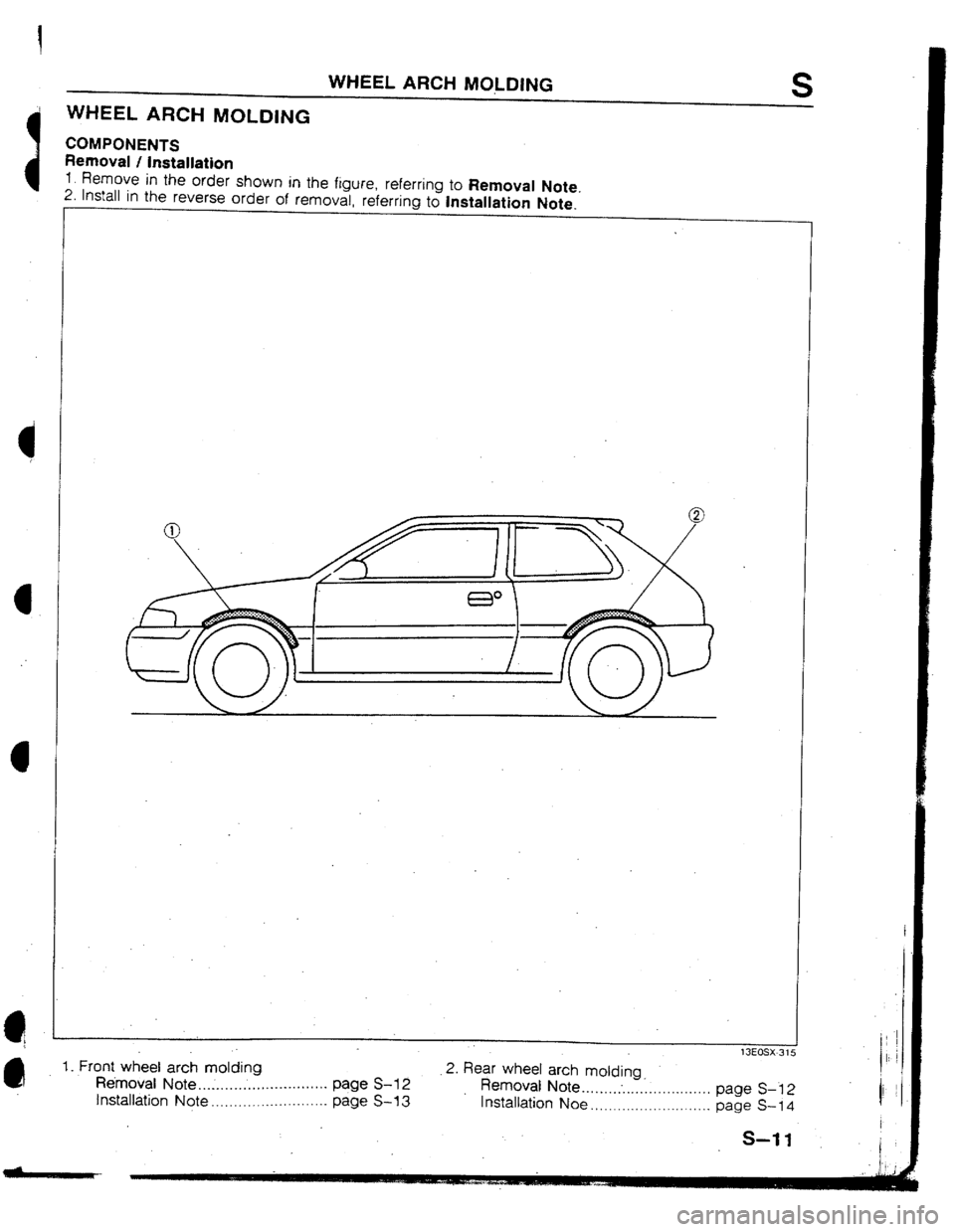

WHEEL ARCH MOLDING S

WHEEL ARCH MOLDING

COMPONENTS

Removal I installation

1 Remove in the order shown in the figure referring to Removal Note

2.

Install in the reverse order nf rernmtal

rA*rrinh h Inr+dld:nm

&l-r- ’

lXOSX-31

1, Front wheel arch molding

- - 2. Rear wheel arch molding

Hemoval Note .............................. page S-l 2

Removal Note ............. .

Installation Note.. ................

page S-13 installation Noe page S-I 2

I I / ;

........................

........................... page S-14

S-t 1

Page 147 of 279

S

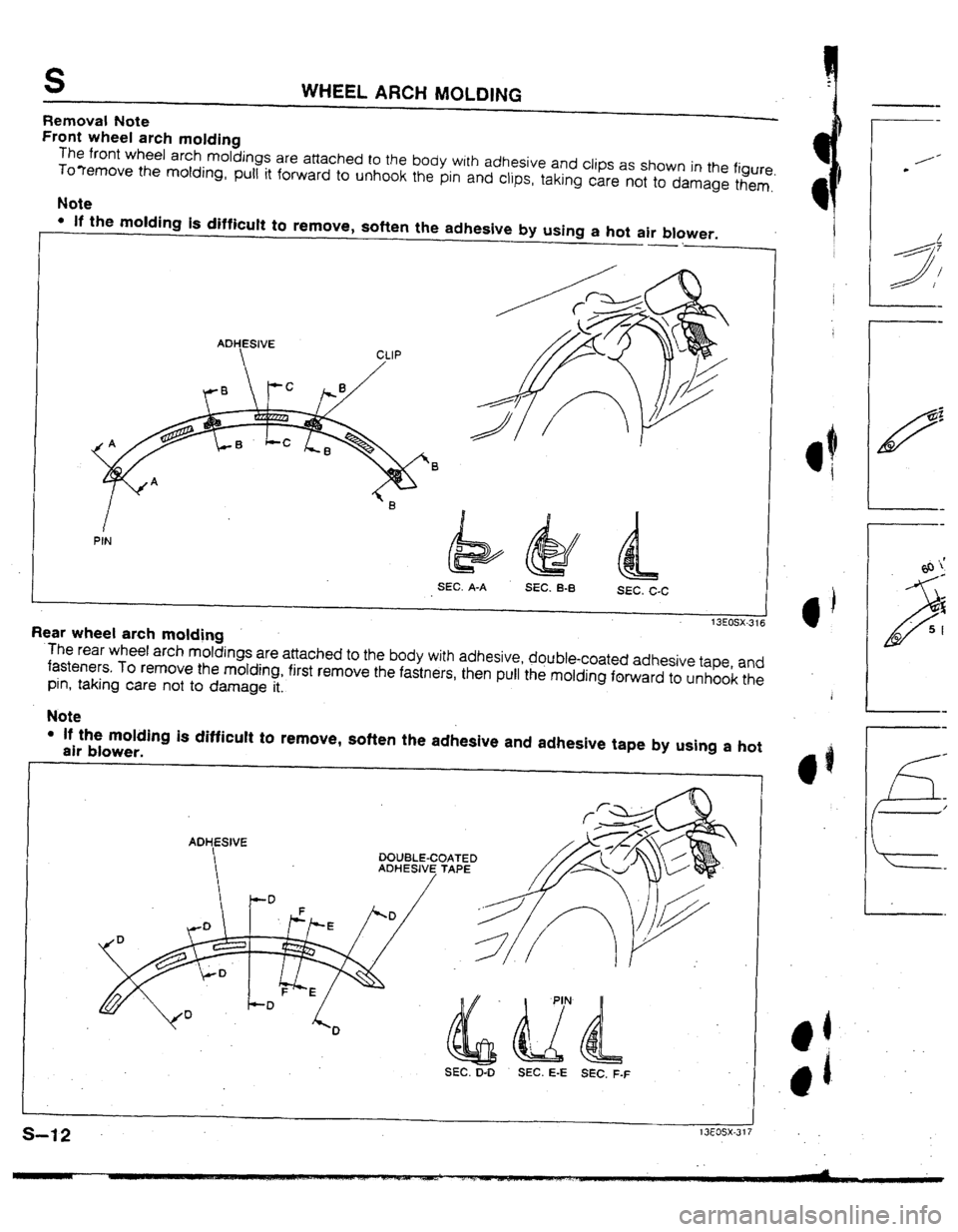

Removal Note

Front wheel arch molding

WHEEL ARCH MOLDING

The front wheel arch moldings are attached to the body with adhesive and clips as shown in the figure

To?emove the molding, puti it forward to unhook the pin and clips, taking care not

to damage them,’

Note

. If the molding is difficult to remove, soften the adhesive by using a hot air blower.

->7

ADHESIVE

SEC. A-A

SEC. B-B

SEC. C-C

Rear wheel arch molding 13EosX-316

‘The rear wheel arch moldings are attached to the body with adhesive, double-coated adhesive tape and

fasteners. To remove the motding, first remove the fastners, then pull the molding forward to unhook the

pin, taking care not to damage it.

Note

l If the molding is difficuft to remove, soften the adhesive and adhesive tape by using a hot

air blower.

ADHESIVE

DOUBLE-COATED

ADHESIVE TAPE

SEC. D-D

SEC. E-E SEC. F-F

Page 148 of 279

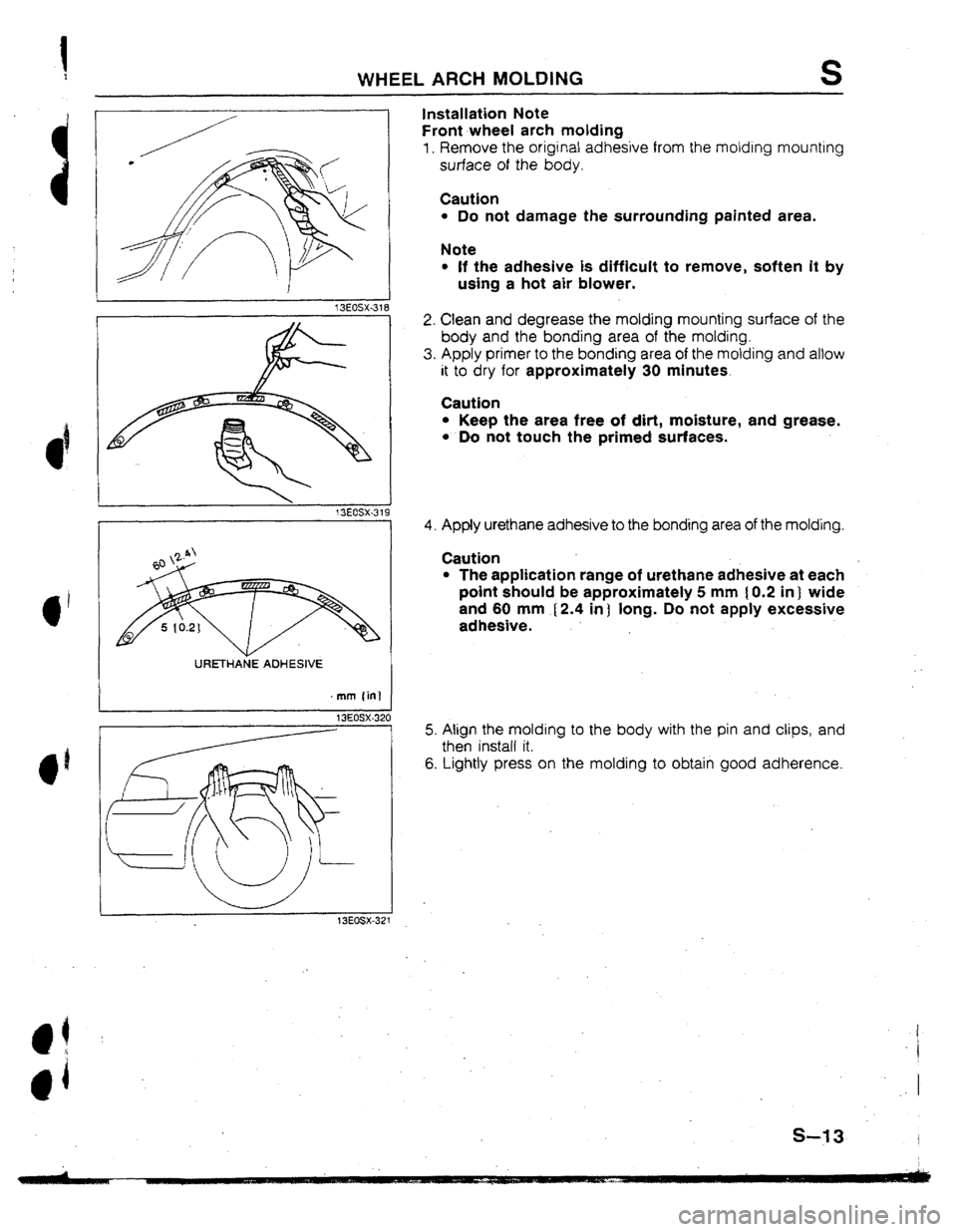

WHEEL ARCH MOLDING

Installation

Note

S

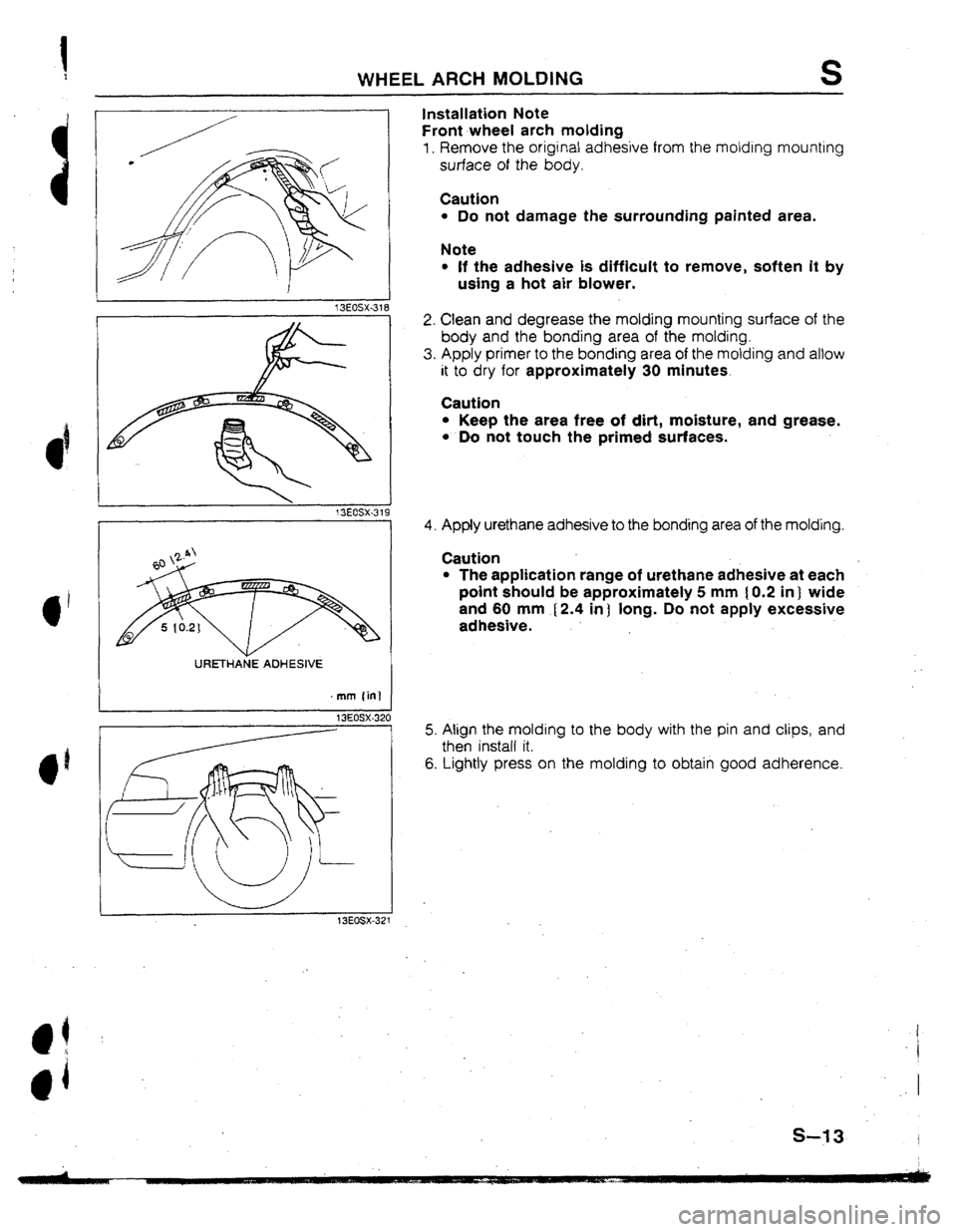

Front wheel arch molding

1. Remove the original adhesive from the molding mounting

surface of the body.

Caution

l Do not damage the surrounding painted area.

Note

l If the adhesive is difficult to remove, soften it by

using a hot air blower.

I URETHAtiE ADHESIVE

I

13EOSX-320

13EOSX-321

2. Clean and degrease the molding mounting surface of the

body and the bonding area of the molding.

3. Apply primer to the bonding area of the molding and allow

it to dry for approximately 30 minutes.

Caution

l Keep the area free of dirt, moisture, and grease.

l Do not touch the primed surfaces.

4. Apply urethane adhesive to the bonding area of the molding.

Caution

l The application range of urethane adhesive at each

point should be approximately 5 mm [ 0.2 in 1 wide

and 60 mm [ 2.4 in 1 long. Do not apply excessive

adhesive.

5. Align the molding to the body with the pin and clips, and

then install it.

6. Lightly press on the molding to obtain good adherence.

1

i

1

S-f 3 I

Page 149 of 279

![MAZDA 323 1992 Workshop Manual Suplement S WHEEL ARCH MOLDING

13EOSX-323

r

ADHESIVE TAPE

mm fin]

f 3EOSX-324

13EOSX.325

s-14.

Rear wheel arch molding

1. Remove the original adhesive from the molding mounting

surface of the body.

C MAZDA 323 1992 Workshop Manual Suplement S WHEEL ARCH MOLDING

13EOSX-323

r

ADHESIVE TAPE

mm fin]

f 3EOSX-324

13EOSX.325

s-14.

Rear wheel arch molding

1. Remove the original adhesive from the molding mounting

surface of the body.

C](/img/28/57055/w960_57055-148.png)

S WHEEL ARCH MOLDING

13EOSX-323

r

ADHESIVE TAPE

mm fin]

f 3EOSX-324

13EOSX.325

s-14.

Rear wheel arch molding

1. Remove the original adhesive from the molding mounting

surface of the body.

Caution

l Do not damage the surrounding painted area.

Note

l tf the adhesive is difficult to remove, soften it by

using a hot air blower.

2. Clean and degrease the molding mounting surface of the

body and the bonding area of the molding.

3. Apply primer to the bonding area of the molding and allow

it to dry for approximately 30 minutes.

Caution

l Keep the area free of dirt, moisture, and grease.

l Do not touch the primed surfaces.

4. Apply strips of double-coated adhesive tape to the bond-

ing area of the molding.

Note

l Use 40 mm I-1.6 in) lengths of tape.

5. Apply urethane adhesive to the bonding area of the molding.

Caution

l The application range of urethane adhesive should

be approximately 5 mm f 0.2 iii ) wide and 60 mm

(2.4 in) long. Do not apply excessive adhesive.

6. Peel the protection paper from the double-coated adhesive

tape.

7. Align the molding to the body with the pin, and then install it,

8. Lightly press on the molding to obtain good adherence.

9. tnstall the fasteners.

Page 150 of 279

T

BODY ELECTRICAL SYSTEM

INDEX .*,........,..............*....*...*.........*....*.*.

T- 2

jFEATURESl

OUTLINE . . . . . . ..*.....*..*...~.=.........*.*........*~...~

T- 3

FEATURES .e . . . . . *..* . . . . . . * . . . . . . * . . . . . . . *..I . . . . . . . . .

T- 3

LIGHTING SYSTEM .,....*.*..m...*..,...,a*..*.*..,..

T- 3

SPECIFICATDNS .I..*.*...*....*....*.............,.

T- 3

SUPPLEMENTAL SERVICE

INFORMATlON I . . . . . . . . . . . . . . . . . *.*.a=..* . . . . . . . *..*.s

T- ,4

EXTERlOR LlGHTlNG SYSTEM . . . . .

l . . ..e.am..a.. T-

4

FRONT FOG LIGHT

. . . . . . n .* . . . . . l ...* . . . . . s* .,..I..

T- 4

f3EOTX-301

H .

Trending: display, tire pressure, wiper fluid, wheel, open bonnet, fuel, dimensions

![MAZDA 323 1992 Workshop Manual Suplement S WHEEL ARCH MOLDING

13EOSX-323

r

ADHESIVE TAPE

mm fin]

f 3EOSX-324

13EOSX.325

s-14.

Rear wheel arch molding

1. Remove the original adhesive from the molding mounting

surface of the body.

C MAZDA 323 1992 Workshop Manual Suplement S WHEEL ARCH MOLDING

13EOSX-323

r

ADHESIVE TAPE

mm fin]

f 3EOSX-324

13EOSX.325

s-14.

Rear wheel arch molding

1. Remove the original adhesive from the molding mounting

surface of the body.

C](/img/28/57055/w960_57055-148.png)