belt MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 34 of 909

LOCATION INDEX

B2–3

B2

LOCATION INDEXA6E230001002201

.

LOCATION INDEX

7

5

4

3

1

2

6

A6E2500W100

1Drive belt

(See B2–4 DRIVE BELT INSPECTION)

(See B2–4 DRIVE BELT REPLACEMENT)

(See B2–4 DRIVE BELT AUTO TENSIONER

INSPECTION)

2 Rocker arm

(See B2–5 VALVE CLEARANCE INSPECTION)

(See B2–6 VALVE CLEARANCE ADJUSTMENT)

3 Engine

(See B2–8 COMPRESSION INSPECTION)

(See B2–27 ENGINE REMOVAL/INSTALLATION)

(See B2–32 ENGINE DISASSEMBLY/ASSEMBLY)

4 Timing Belt

(See B2–9 TIMING BELT REMOVAL/

INSTALLATION)

5 Cylinder head gasket

(See B2–15 CYLINDER HEAD GASKET

REPLACEMENT)

6 Front oil seal

(See B2–24 FRONT OIL SEAL REPLACEMENT)

7 Rear oil seal

(See B2–26 REAR OIL SEAL REPLACEMENT)

Page 35 of 909

B2–4

DRIVE BELT

End Of Sie

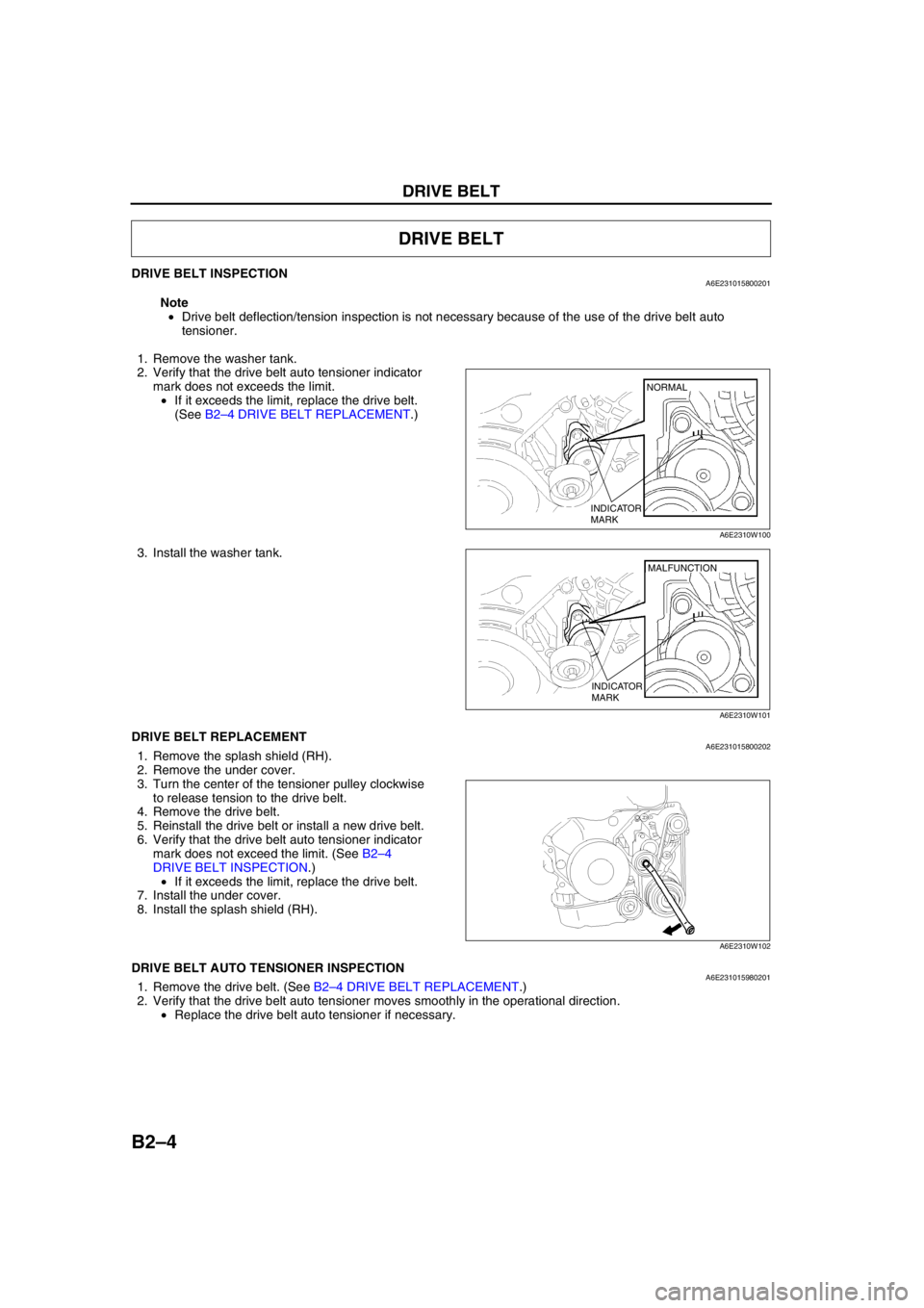

DRIVE BELT INSPECTIONA6E231015800201

Note

•Drive belt deflection/tension inspection is not necessary because of the use of the drive belt auto

tensioner.

1. Remove the washer tank.

2. Verify that the drive belt auto tensioner indicator

mark does not exceeds the limit.

•If it exceeds the limit, replace the drive belt.

(See B2–4 DRIVE BELT REPLACEMENT.)

3. Install the washer tank.

End Of SieDRIVE BELT REPLACEMENTA6E2310158002021. Remove the splash shield (RH).

2. Remove the under cover.

3. Turn the center of the tensioner pulley clockwise

to release tension to the drive belt.

4. Remove the drive belt.

5. Reinstall the drive belt or install a new drive belt.

6. Verify that the drive belt auto tensioner indicator

mark does not exceed the limit. (See B2–4

DRIVE BELT INSPECTION.)

•If it exceeds the limit, replace the drive belt.

7. Install the under cover.

8. Install the splash shield (RH).

End Of SieDRIVE BELT AUTO TENSIONER INSPECTIONA6E2310159802011. Remove the drive belt. (See B2–4 DRIVE BELT REPLACEMENT.)

2. Verify that the drive belt auto tensioner moves smoothly in the operational direction.

•Replace the drive belt auto tensioner if necessary.

DRIVE BELT

INDICATOR

MARKNORMAL

A6E2310W100

MALFUNCTION

INDICATOR

MARK

A6E2310W101

A6E2310W102

Page 36 of 909

DRIVE BELT, VALVE CLEARANCE

B2–5

B2

3. Turn the drive belt auto tensioner pulley by hand

and verify that it rotates smoothly.

•Replace the drive belt auto tensioner if

necessary.

4. Install the drive belt.

End Of Sie

VALVE CLEARANCE INSPECTIONA6E2312121112011. Remove the engine cover. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

2. Remove the timing belt cover bolt as shown.

3. Remove the cylinder head cover. (See B2–15

CYLINDER HEAD GASKET REPLACEMENT.)

4. Turn the crankshaft and align the timing mark so

that the piston of the No.1 or No.4 cylinder is at

TDC of compression.

5. Measure valve clearances A with the No.1

cylinder at TDC of compression, and those of B

with the No.4 cylinder at TDC of compression.

•If the valve clearance is not within the

specification, adjust the valves. (See B2–6

VALVE CLEARANCE ADJUSTMENT.)

Standard valve clearance [Engine cold]

IN: 0.12—0.18 mm {0.005—0.007 in}

(0.15±0.03 mm {0.006±0.0011 in})

EX: 0.32—0.38 mm {0.013—0.014 in}

(0.35±0.03 mm {0.014±0.0011 in})

6. Turn the crankshaft one full turn and measure the

remaining valve clearances.

•Adjust if necessary. (See B2–6 VALVE

CLEARANCE ADJUSTMENT.)

7. Install the cylinder head cover. (See B2–21 Cylinder Head Cover Installation Note.)

A6E2310W103

VALVE CLEARANCE

TIMING BELT

COVER BOLT

UPPER TIMING BELT COVER

A6E2312W200

A

A B

B

A6E2312W201

MEASURING

POINT

A6E2312W101

Page 37 of 909

B2–6

VALVE CLEARANCE

8. Install the timing belt cover bolt as shown.

Tightening torque

7.9—10.7 N·m {80—110 kgf·cm, 69.5—95.4

in·lbf}

9. Install the engine cover. (See B2–9 TIMING BELT

REMOVAL/INSTALLATION.)

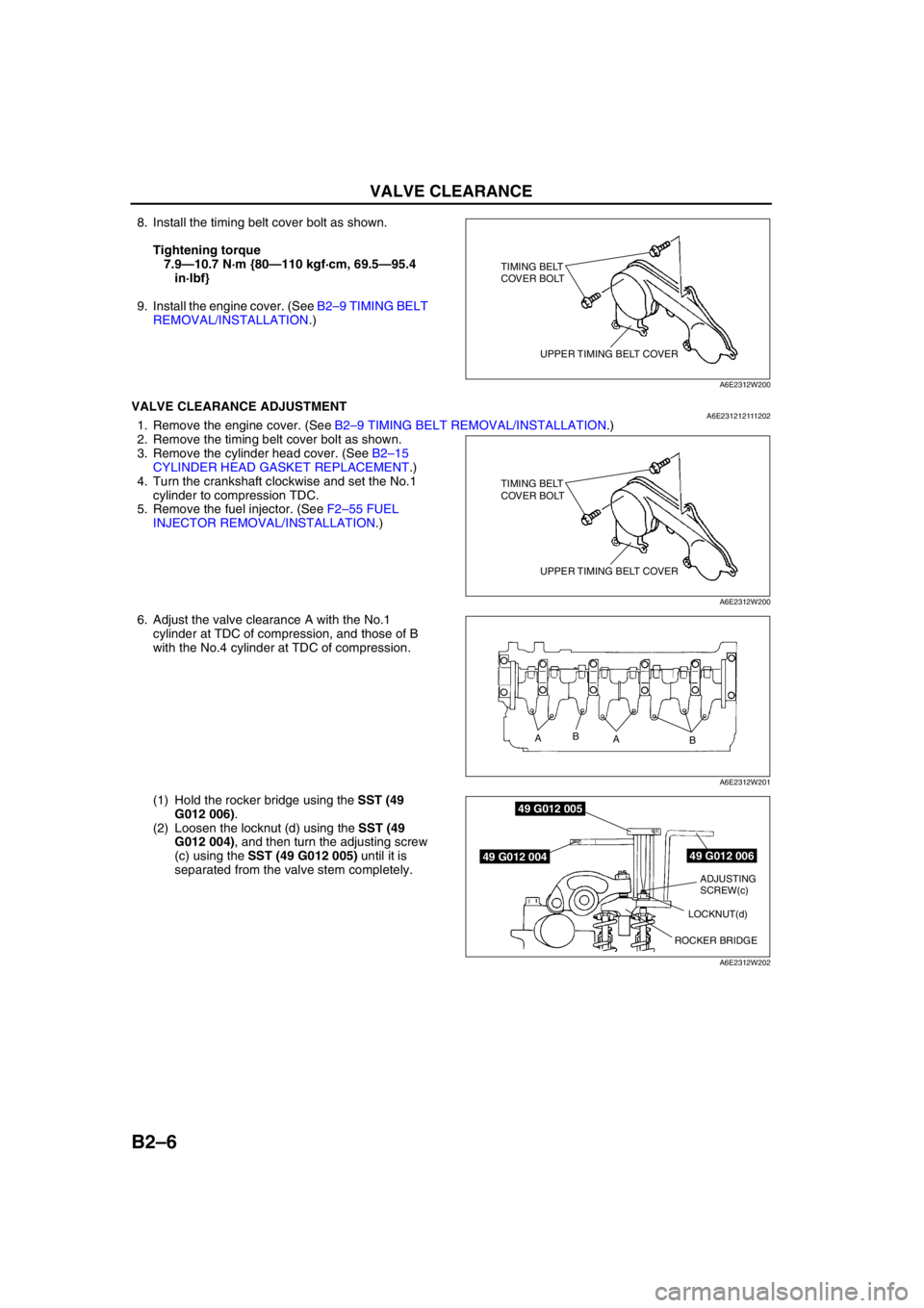

End Of SieVALVE CLEARANCE ADJUSTMENTA6E2312121112021. Remove the engine cover. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

2. Remove the timing belt cover bolt as shown.

3. Remove the cylinder head cover. (See B2–15

CYLINDER HEAD GASKET REPLACEMENT.)

4. Turn the crankshaft clockwise and set the No.1

cylinder to compression TDC.

5. Remove the fuel injector. (See F2–55 FUEL

INJECTOR REMOVAL/INSTALLATION.)

6. Adjust the valve clearance A with the No.1

cylinder at TDC of compression, and those of B

with the No.4 cylinder at TDC of compression.

(1) Hold the rocker bridge using the SST (49

G012 006).

(2) Loosen the locknut (d) using the SST (49

G012 004), and then turn the adjusting screw

(c) using the SST (49 G012 005) until it is

separated from the valve stem completely.

TIMING BELT

COVER BOLT

UPPER TIMING BELT COVER

A6E2312W200

TIMING BELT

COVER BOLT

UPPER TIMING BELT COVER

A6E2312W200

A

A B

B

A6E2312W201

49 G012 006

49 G012 005

49 G012 004

ADJUSTING

SCREW(c)

ROCKER BRIDGELOCKNUT(d)

NORMAL

A6E2312W202

Page 39 of 909

B2–8

VALVE CLEARANCE, COMPRESSION PRESSURE

10. Install the timing belt cover bolt as shown.

Tightening torque

7.9—10.7 N·m {80—110 kgf·cm, 69.5—95.4

in·lbf}

11. Install the engine cover. (See B2–9 TIMING BELT

REMOVAL/INSTALLATION.)

End Of Sie

COMPRESSION INSPECTIONA6E231402000201

Warning

•When the engine and the oil are hot, they can badly burn. Be careful not to burn yourself during

removal/installation of each component.

1. Verify that the battery is fully charged.

•Recharge it if necessary. (See G–6 BATTERY INSPECTION.)

2. Warm up the engine to the normal operating system temperature.

3. Stop the engine and allow it to cool off for about 10 min.

Warning

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent fuel from spurting out of the glow plug

hole, do not ground the fuel injector terminal. (See F2–45 Fuel Line Safety Procedures.)

4. Disconnect the fuel injector connector.

Warning

•If the glow plug harness connector is connected, the glow plug harness and engine component

can come into contact and cause a short when the engine switch is ON. Disconnect the glow plug

harness connector before turning the engine switch on.

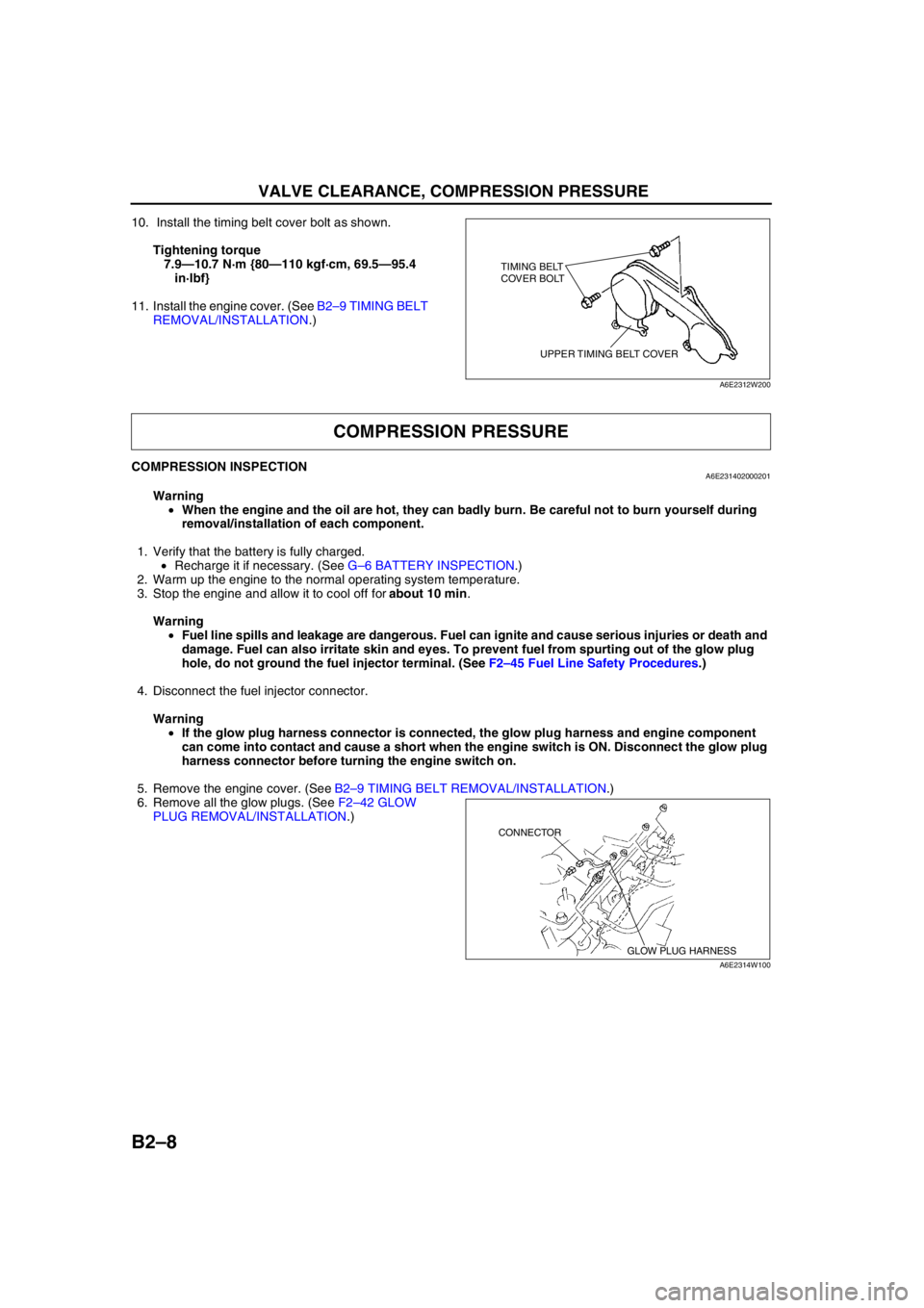

5. Remove the engine cover. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

6. Remove all the glow plugs. (See F2–42 GLOW

PLUG REMOVAL/INSTALLATION.)

TIMING BELT

COVER BOLT

UPPER TIMING BELT COVER

A6E2312W200

COMPRESSION PRESSURE

GLOW PLUG HARNESS CONNECTOR

A6E2314W100

Page 40 of 909

COMPRESSION PRESSURE, TIMING BELT

B2–9

B2

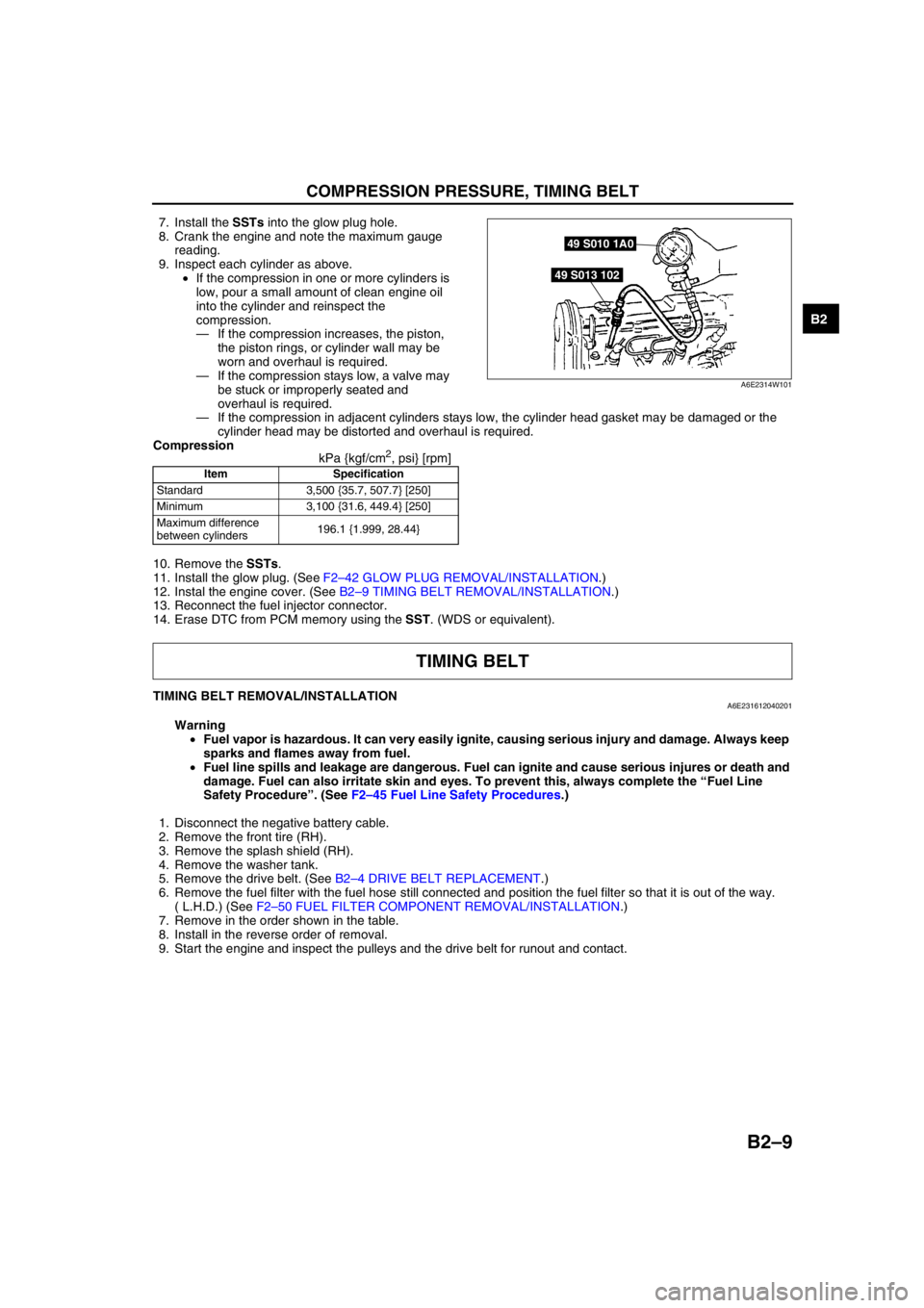

7. Install the SSTs into the glow plug hole.

8. Crank the engine and note the maximum gauge

reading.

9. Inspect each cylinder as above.

•If the compression in one or more cylinders is

low, pour a small amount of clean engine oil

into the cylinder and reinspect the

compression.

—If the compression increases, the piston,

the piston rings, or cylinder wall may be

worn and overhaul is required.

—If the compression stays low, a valve may

be stuck or improperly seated and

overhaul is required.

—If the compression in adjacent cylinders stays low, the cylinder head gasket may be damaged or the

cylinder head may be distorted and overhaul is required.

Compression

kPa {kgf/cm

2, psi} [rpm]

10. Remove the SSTs.

11. Install the glow plug. (See F2–42 GLOW PLUG REMOVAL/INSTALLATION.)

12. Instal the engine cover. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

13. Reconnect the fuel injector connector.

14. Erase DTC from PCM memory using the SST. (WDS or equivalent).

End Of Sie

TIMING BELT REMOVAL/INSTALLATIONA6E231612040201

Warning

•Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injures or death and

damage. Fuel can also irritate skin and eyes. To prevent this, always complete the “Fuel Line

Safety Procedure”. (See F2–45 Fuel Line Safety Procedures.)

1. Disconnect the negative battery cable.

2. Remove the front tire (RH).

3. Remove the splash shield (RH).

4. Remove the washer tank.

5. Remove the drive belt. (See B2–4 DRIVE BELT REPLACEMENT.)

6. Remove the fuel filter with the fuel hose still connected and position the fuel filter so that it is out of the way.

( L.H.D.) (See F2–50 FUEL FILTER COMPONENT REMOVAL/INSTALLATION.)

7. Remove in the order shown in the table.

8. Install in the reverse order of removal.

9. Start the engine and inspect the pulleys and the drive belt for runout and contact.

Item Specification

Standard 3,500 {35.7, 507.7} [250]

Minimum 3,100 {31.6, 449.4} [250]

Maximum difference

between cylinders196.1 {1.999, 28.44}

49 S010 1A0

49 S013 102

A6E2314W101

TIMING BELT

Page 41 of 909

B2–10

TIMING BELT

.

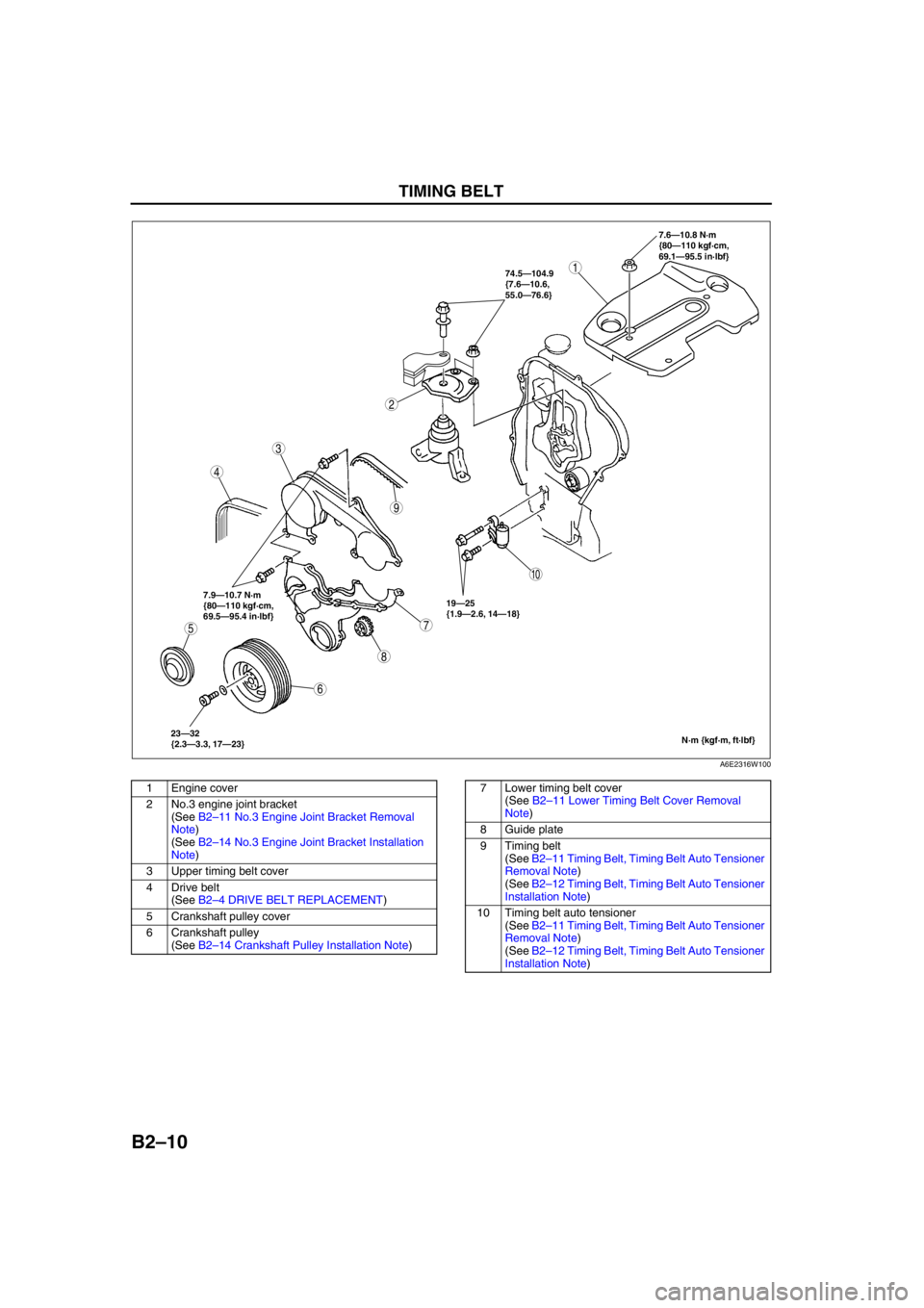

N·m {kgf·m, ft·lbf} 7.6—10.8 N·m

{80—110 kgf·cm,

69.1—95.5 in·lbf}

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}

23—32

{2.3—3.3, 17—23}19—25

{1.9—2.6, 14—18} 74.5—104.9

{7.6—10.6,

55.0—76.6}

9

8

75

4

3

1

2

10

6

A6E2316W100

1 Engine cover

2 No.3 engine joint bracket

(See B2–11 No.3 Engine Joint Bracket Removal

Note)

(See B2–14 No.3 Engine Joint Bracket Installation

Note)

3 Upper timing belt cover

4Drive belt

(See B2–4 DRIVE BELT REPLACEMENT)

5 Crankshaft pulley cover

6 Crankshaft pulley

(See B2–14 Crankshaft Pulley Installation Note)7 Lower timing belt cover

(See B2–11 Lower Timing Belt Cover Removal

Note)

8 Guide plate

9 Timing belt

(See B2–11 Timing Belt, Timing Belt Auto Tensioner

Removal Note)

(See B2–12 Timing Belt, Timing Belt Auto Tensioner

Installation Note)

10 Timing belt auto tensioner

(See B2–11 Timing Belt, Timing Belt Auto Tensioner

Removal Note)

(See B2–12 Timing Belt, Timing Belt Auto Tensioner

Installation Note)

Page 42 of 909

TIMING BELT

B2–11

B2

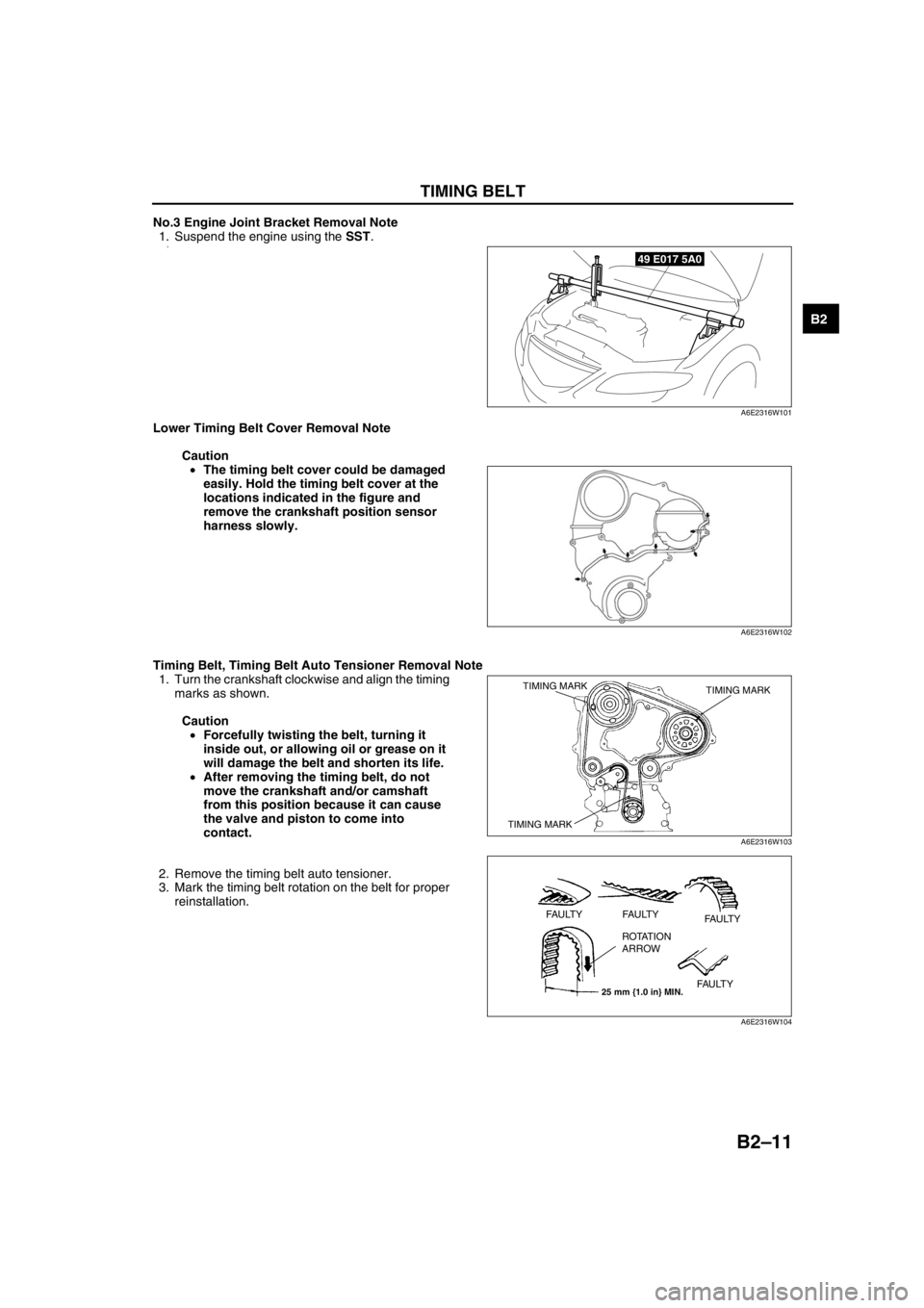

No.3 Engine Joint Bracket Removal Note

1. Suspend the engine using the SST.

2.

Lower Timing Belt Cover Removal Note

Caution

•The timing belt cover could be damaged

easily. Hold the timing belt cover at the

locations indicated in the figure and

remove the crankshaft position sensor

harness slowly.

Timing Belt, Timing Belt Auto Tensioner Removal Note

1. Turn the crankshaft clockwise and align the timing

marks as shown.

Caution

•Forcefully twisting the belt, turning it

inside out, or allowing oil or grease on it

will damage the belt and shorten its life.

•After removing the timing belt, do not

move the crankshaft and/or camshaft

from this position because it can cause

the valve and piston to come into

contact.

2. Remove the timing belt auto tensioner.

3. Mark the timing belt rotation on the belt for proper

reinstallation.

49 E017 5A0

A6E2316W101

A6E2316W102

TIMING MARK TIMING MARK

TIMING MARK

A6E2316W103

25 mm {1.0 in} MIN.

FAULTY FAULTY

FAULTY

FAULTY ROTATION

ARROW

A6E2316W104

Page 43 of 909

B2–12

TIMING BELT

Timing Belt, Timing Belt Auto Tensioner Installation Note

1. Measure the tensioned rod projection length.

•If not as specified, replace the timing belt auto

tensioner.

2. Inspect the timing belt auto tensioner for oil

leakage.

•If not as specified, replace the timing belt auto

tensioner.

Projection (free length)

12.9—14.6 mm {0.508—0.574 in}

Caution

•Placing the timing belt auto tensioner

horizontally can cause oil leakage and

damage the timing belt auto tensioner. Place the timing belt auto tensioner vertically when using a

vise.

3. Verify the thrust of the timing belt auto tensioner

rod in the following order:

•If the timing belt auto tensioner rod is rigid

when it is pushed with a force of

approximately 235 N {24 kgf, 53 Ibf}, push it

down slowly and fix the pin in the hole.

•If there is no resistance on the timing belt auto

tensioner rod and it moves slightly when it is

pushed with a force of approximately 235 N

{24 kgf, 53 Ibf};

(1) Push it down slowly two or three times to the

bottom end of the rod.

(2) If the rod protrudes approximately 8.1 mm

{0.32 in}, verify that there is resistance on the

timing belt auto tensioner rod.

Caution

•To prevent damage to the inside of the

timing belt auto tensioner, do not press

down the timing belt auto tensioner rod

with a force greater than the specified

235 N {24 kgf, 53 lbf}.

Be careful that the rod does not touch the

bottom.

•If the timing belt auto tensioner rod

projection is restored, push it down slowly and fix the pin in the hole.

—If the resistance is not restored, replace the timing belt auto tensoner.

A6E2316W105

PIN

A6E2316W106

Page 44 of 909

TIMING BELT

B2–13

B2

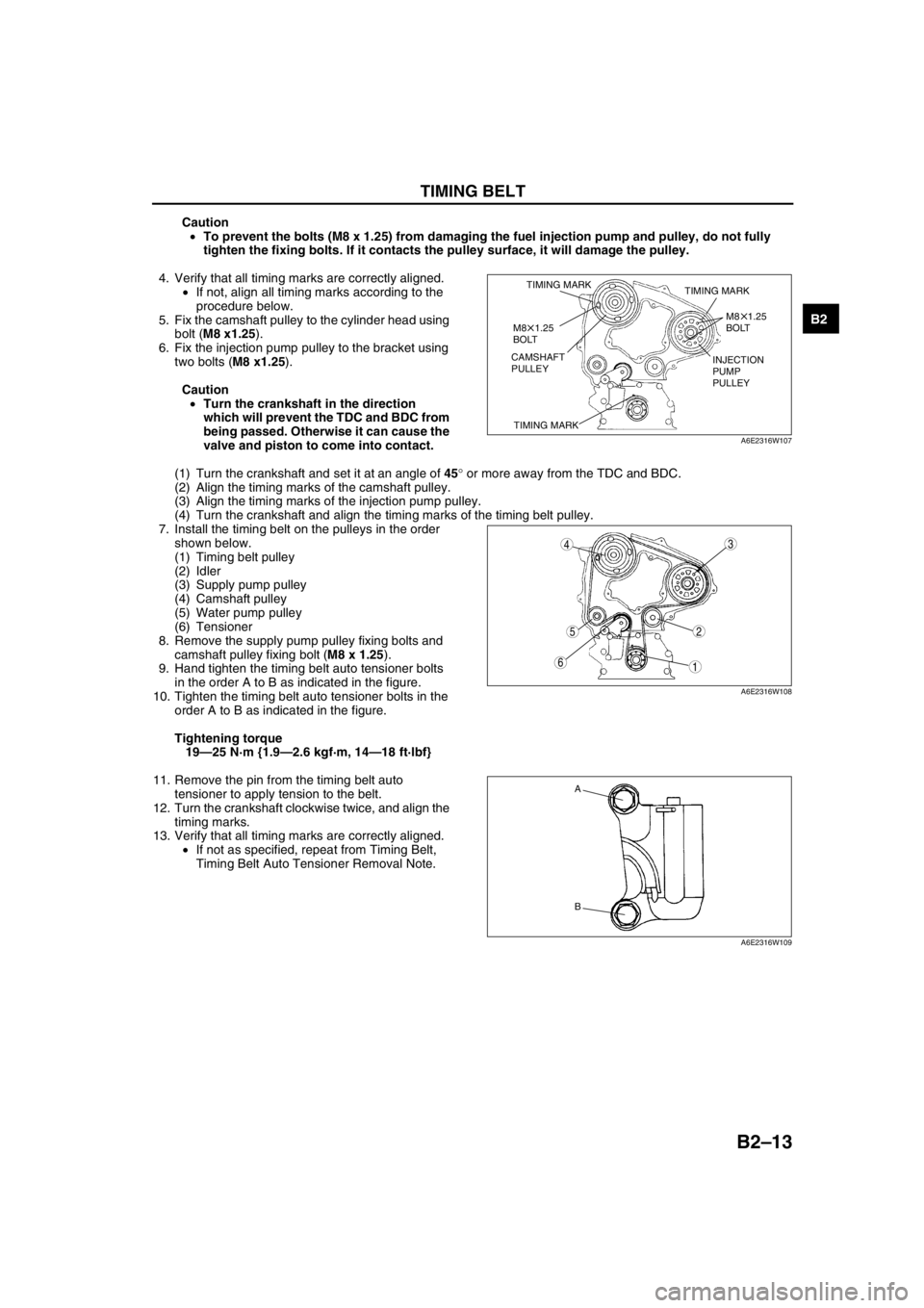

Caution

•To prevent the bolts (M8 x 1.25) from damaging the fuel injection pump and pulley, do not fully

tighten the fixing bolts. If it contacts the pulley surface, it will damage the pulley.

4. Verify that all timing marks are correctly aligned.

•If not, align all timing marks according to the

procedure below.

5. Fix the camshaft pulley to the cylinder head using

bolt (M8 x1.25).

6. Fix the injection pump pulley to the bracket using

two bolts (M8 x1.25).

Caution

•Turn the crankshaft in the direction

which will prevent the TDC and BDC from

being passed. Otherwise it can cause the

valve and piston to come into contact.

(1) Turn the crankshaft and set it at an angle of 45° or more away from the TDC and BDC.

(2) Align the timing marks of the camshaft pulley.

(3) Align the timing marks of the injection pump pulley.

(4) Turn the crankshaft and align the timing marks of the timing belt pulley.

7. Install the timing belt on the pulleys in the order

shown below.

(1) Timing belt pulley

(2) Idler

(3) Supply pump pulley

(4) Camshaft pulley

(5) Water pump pulley

(6) Tensioner

8. Remove the supply pump pulley fixing bolts and

camshaft pulley fixing bolt (M8 x 1.25).

9. Hand tighten the timing belt auto tensioner bolts

in the order A to B as indicated in the figure.

10. Tighten the timing belt auto tensioner bolts in the

order A to B as indicated in the figure.

Tightening torque

19—25 N·m {1.9—2.6 kgf·m, 14—18 ft·lbf}

11. Remove the pin from the timing belt auto

tensioner to apply tension to the belt.

12. Turn the crankshaft clockwise twice, and align the

timing marks.

13. Verify that all timing marks are correctly aligned.

•If not as specified, repeat from Timing Belt,

Timing Belt Auto Tensioner Removal Note.

TIMING MARK

TIMING MARKTIMING MARK

M8 1.25

BOLT

M8 1.25

BOLT

CAMSHAFT

PULLEYINJECTION

PUMP

PULLEY

A6E2316W107

5

43

1

2

6

A6E2316W108

A

B

A6E2316W109