belt MAZDA 6 2002 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 811 of 909

S–30

SEAT

REAR SEAT DISASSEMBLY/ASSEMBLYA6E775257200202WGN

1. Disassemble in the order indicated in the table.

2. Assemble in the reverse order of disassembly..

End Of Sie

9

1

6

9

8

7

25

4

2

5

4

3

1

6

87

19

18

18

1315

16

171110

11

22

21

20

14

21

2224

24

20

23

3

A

A

12

10

19

23

12

25

25

4WD

4

3

A6E77521015

1 Headrest

2 Hinge cover (2WD)

3 Seat cushion trim

4 Seat cushion pad

5 Seat cushion frame (2WD)

6 Remote button cover

7 Seat back catch cover

8 Child seat anchor cover

9 Retainer bar anchor

10 Seat back board

11 Pole guide

12 Remote button

13 Armrest assembly14 Cup holder

15 Armrest hinge

16 Armrest trim

17 Armrest pad

18 Seat back trim

19 Seat back pad

20 Seat belt guide

21 Retractor cover

22 Rear seat belt

23 Seat back catch

24 Remote wire

25 Seat back frame

Page 812 of 909

T–1

T

TBODY ELECTRICAL SYSTEM

OUTLINE................................................................ T-2

OUTLINE OF CONSTRUCTION ......................... T-2

FEATURES .......................................................... T-2

POWER SYSTEM................................................... T-2

STRUCTURAL VIEW........................................... T-2

MULTIPLEX COMMUNICATION SYSTEM............ T-3

OUTLINE ............................................................. T-3

STRUCTRURAL VIEW ........................................ T-3

SYSTEM WIRING DIAGRAM .............................. T-4

CAN SIGNAL-CHART.......................................... T-4

ON-BOARD DIAGNOSTIC FUNCTION............... T-6

EXTERIOR LIGHTING SYSTEM............................ T-8

OUTLINE ............................................................. T-8

STRUCTURAL VIEW........................................... T-8

INTERIOR LIGHTING SYSTEM............................. T-8

STRUCTURAL VIEW........................................... T-8

WIPER AND WASHER........................................... T-9

OUTLINE ............................................................. T-9

STRUCTURAL VIEW........................................... T-9

WARNING AND INDICATOR SYSTEM............... T-10

OUTLINE ........................................................... T-10

STRUCTURAL VIEW......................................... T-10

SYSTEM WIRING DIAGRAM ............................ T-11

THEFT-DETERRENT SYSTEM............................ T-11

OUTLINE ........................................................... T-11

INTRUDER SENSOR ........................................ T-11

AUDIO AND NAVIGATION SYSTEM.................. T-13

OUTLINE ........................................................... T-13

STRUCTURAL VIEW......................................... T-13

CRUISE CONTROL SYSTEM.............................. T-13

OUTLINE ........................................................... T-13

AIR BAG SYSTEM............................................... T-13

OUTLINE ........................................................... T-13

OUTLINE.............................................................. T-14

SUPPLEMENTAL SERVICE INFORMATION ... T-14

LOCATION INDEX............................................... T-15

POWER SYSTEM.............................................. T-15

EXTERIOR LIGHTING SYSTEM ....................... T-15

INTERIOR LIGHTING SYSTEM ........................ T-16

WIPER AND WASHER SYSTEM ...................... T-16

WARNING AND INDICATOR SYSTEM............. T-17

THEFT-DETERRENT SYSTEM ........................ T-17

AUDIO AND NAVIGATION SYSTEM ................ T-18

AIR BAG SYSTEM............................................. T-18

POWER SYSTEM................................................. T-19

RELAY LOCATION ............................................ T-19

RELAY INSPECTION ........................................ T-19

EXTERIOR LIGHTING SYSTEM.......................... T-20

REAR AUTO LEVELING SENSOR

REMOVAL/INSTALLATION ............................ T-20HIGH-MOUNT BRAKE LIGHT

REMOVAL/INSTALLATION ............................ T-20

INTERIOR LIGHTING SYSTEM........................... T-21

CARGO COMPARTMENT LIGHT

REMOVAL/INSTALLATION ............................ T-21

CARGO COMPARTMENT LIGHT

INSPECTION .................................................. T-22

WIPER AND WASHER......................................... T-22

REAR WIPER MOTOR

REMOVAL/INSTALLATION ............................ T-22

REAR WIPER MOTOR INSPECTION ............... T-22

REAR WIPER ARM AND BLADE

REMOVAL/INSTALLATION ............................ T-23

REAR WIPER ARM AND BLADE

ADJUSTMENT ................................................ T-24

REAR WASHER NOZZLE

REMOVAL/INSTALLATION ............................ T-24

REAR WASHER NOZZLE ADJUSTMENT ........ T-25

REAR WASHER HOSE

REMOVAL/INSTALLATION ............................ T-25

INTERMITTENT REAR WIPER RELAY

REMOVAL/INSTALLATION ............................ T-26

WARNING AND INDICATOR SYSTEM............... T-27

FUEL GAUGE SENDER UNIT

REMOVAL/INSTALLATION ............................ T-27

FUEL GAUGE SENDER UNIT INSPECTION.... T-28

THEFT-DETERRENT SYSTEM............................ T-29

INTRUDER SENSOR

REMOVAL/INSTALLATION ............................ T-29

AUDIO AND NAVIGATION SYSTEM.................. T-30

NOISE FILTER REMOVAL/INSTALLATION ..... T-30

CONDENSER REMOVAL/INSTALLATION ....... T-30

ANTENNA FEEDER LOCATION ....................... T-31

REAR ANTENNA FEEDER INSPECTION ........ T-31

AIR BAG SYSTEM............................................... T-32

SERVICE WARNINGS....................................... T-32

CURTAIN AIR BAG MODULE

REMOVAL/INSTALLATION ............................ T-35

AIR BAG MODULE AND PRE-TENSIONER

SEAT BELT DEPLOYMENT PROCEDURES. T-35

ON-BOARD DIAGNOSTIC

[MULTIPLEX COMMUNICATION SYSTEM].... T-39

MULTIPLEX COMMUNICATION SYSTEM ....... T-39

DTC TABLE ....................................................... T-41

PID/DATA MONITOR TABLE ............................ T-41

PROCEDURES FOR DETERMINING

THE LOCATION OF A MALFUNCTION ......... T-42

DTC U0073, U1900, U2516 ............................... T-45 FEATURES

SERVICE

Page 825 of 909

T–14

OUTLINE

SUPPLEMENTAL SERVICE INFORMATIONA6E810201088203•The following changes and/or additions have been made since publication of the Mazda6 Workshop Manual

(1730-1*-02C).

Relay

•Location has been changed.

•Inspection procedure has been modified.

Rear auto leveling sensor

•Removal/Installation procedure has been modified.

High-mount brake light

•Removal/Installation procedure has been modified.

Cargo compartment light

•Removal/Installation procedure has been modified.

•Inspection procedure has been modified.

Rear wiper motor

•Removal/Installation procedure has been modified.

•Inspection procedure has been modified.

Rear wiper arm and blade

•Removal/Installation procedure has been modified.

•Adjustment procedure has been modified.

Rear washer nozzle

•Removal/Installation procedure has been modified.

•Adjustment procedure has been modified.

Rear washer hose

•Removal/Installation procedure has been modified.

Intermittent rear wiper relay

•Removal/Installation procedure has been modified.

Fuel gauge sender unit

•Removal/Installation procedure has been modified.

•Inspection procedure has been modified.

Intruder sensor

•Removal/Installation procedure has been modified.

Noise filter

•Removal/Installation procedure has been modified.

Condenser

•Removal/Installation procedure has been modified.

Antenna feeder

•Location has been changed.

Rear antenna feeder

•Inspection procedure has been modified.

Curtain air bag module

•Removal/Installation procedure has been added.

Air bag module and pre-tensioner seat belt

•Deployment procedure has been modified.

On-board diagnostic

•Multiplex communication system procedure has been modified.

End Of Sie

OUTLINE

Page 829 of 909

T–18

LOCATION INDEX

AUDIO AND NAVIGATION SYSTEMA6E810001066201

.

End Of SieAIR BAG SYSTEMA6E810001046201

.

End Of Sie

1

2

3

A6A8124W144

1 Antenna feeder

(See T–31 ANTENNA FEEDER LOCATION)

(See T–31 REAR ANTENNA FEEDER

INSPECTION)2 Noise filter

(See T–30 NOISE FILTER REMOVAL/

INSTALLATION)

3 Condenser

(See T–30 CONDENSER REMOVAL/

INSTALLATION)

1

A6E81301150

1 Curtain air bag module

(See T–35 CURTAIN AIR BAG MODULE

REMOVAL/INSTALLATION)

(See T–35 AIR BAG MODULE AND PRE-

TENSIONER SEAT BELT DEPLOYMENT

PROCEDURES)

Page 843 of 909

T–32

AIR BAG SYSTEM

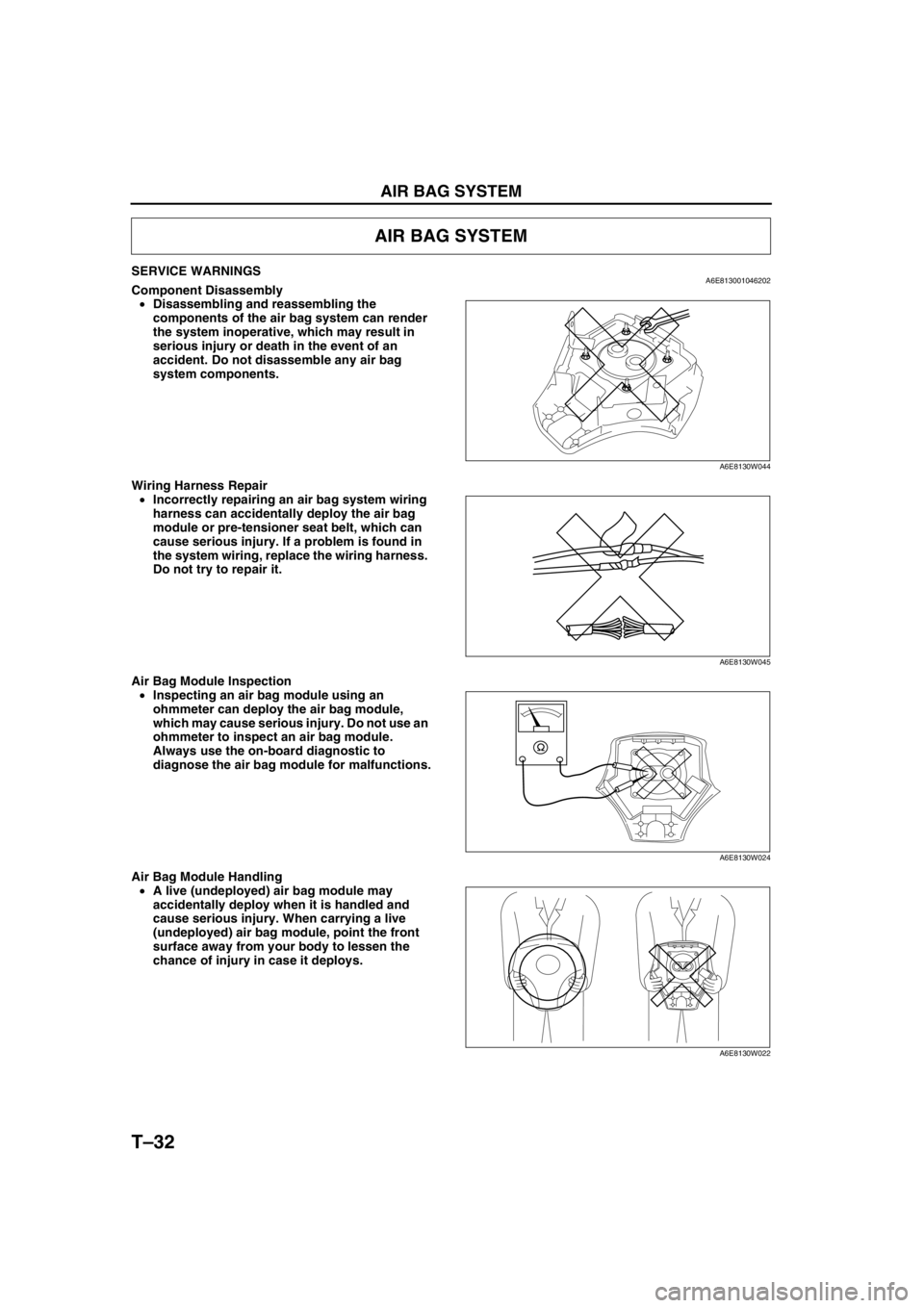

SERVICE WARNINGSA6E813001046202Component Disassembly

•Disassembling and reassembling the

components of the air bag system can render

the system inoperative, which may result in

serious injury or death in the event of an

accident. Do not disassemble any air bag

system components.

Wiring Harness Repair

•Incorrectly repairing an air bag system wiring

harness can accidentally deploy the air bag

module or pre-tensioner seat belt, which can

cause serious injury. If a problem is found in

the system wiring, replace the wiring harness.

Do not try to repair it.

Air Bag Module Inspection

•Inspecting an air bag module using an

ohmmeter can deploy the air bag module,

which may cause serious injury. Do not use an

ohmmeter to inspect an air bag module.

Always use the on-board diagnostic to

diagnose the air bag module for malfunctions.

Air Bag Module Handling

•A live (undeployed) air bag module may

accidentally deploy when it is handled and

cause serious injury. When carrying a live

(undeployed) air bag module, point the front

surface away from your body to lessen the

chance of injury in case it deploys.

AIR BAG SYSTEM

A6E8130W044

A6E8130W045

A6E8130W024

A6E8130W022

Page 844 of 909

AIR BAG SYSTEM

T–33

T

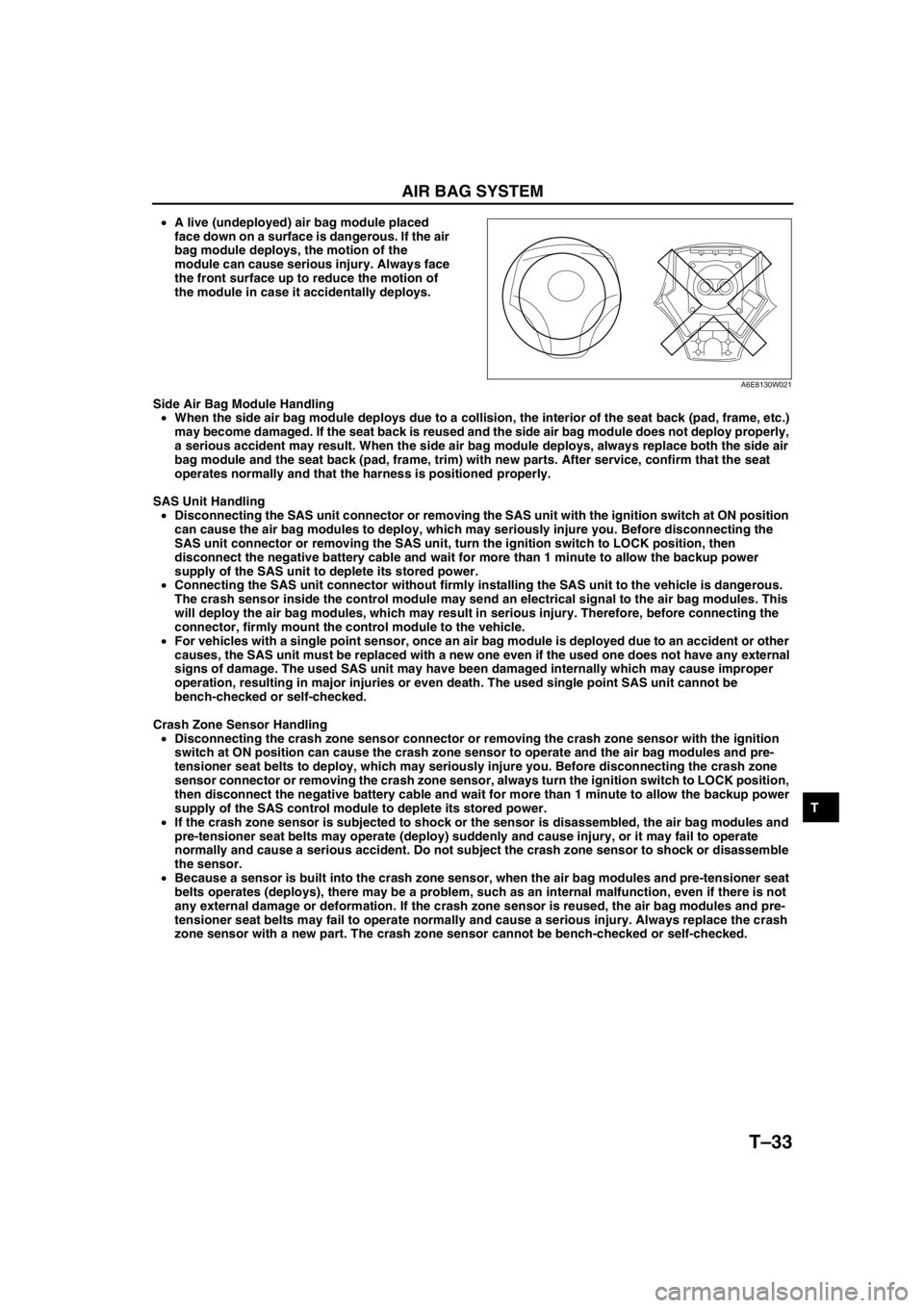

•A live (undeployed) air bag module placed

face down on a surface is dangerous. If the air

bag module deploys, the motion of the

module can cause serious injury. Always face

the front surface up to reduce the motion of

the module in case it accidentally deploys.

Side Air Bag Module Handling

•When the side air bag module deploys due to a collision, the interior of the seat back (pad, frame, etc.)

may become damaged. If the seat back is reused and the side air bag module does not deploy properly,

a serious accident may result. When the side air bag module deploys, always replace both the side air

bag module and the seat back (pad, frame, trim) with new parts. After service, confirm that the seat

operates normally and that the harness is positioned properly.

SAS Unit Handling

•Disconnecting the SAS unit connector or removing the SAS unit with the ignition switch at ON position

can cause the air bag modules to deploy, which may seriously injure you. Before disconnecting the

SAS unit connector or removing the SAS unit, turn the ignition switch to LOCK position, then

disconnect the negative battery cable and wait for more than 1 minute to allow the backup power

supply of the SAS unit to deplete its stored power.

•Connecting the SAS unit connector without firmly installing the SAS unit to the vehicle is dangerous.

The crash sensor inside the control module may send an electrical signal to the air bag modules. This

will deploy the air bag modules, which may result in serious injury. Therefore, before connecting the

connector, firmly mount the control module to the vehicle.

•For vehicles with a single point sensor, once an air bag module is deployed due to an accident or other

causes, the SAS unit must be replaced with a new one even if the used one does not have any external

signs of damage. The used SAS unit may have been damaged internally which may cause improper

operation, resulting in major injuries or even death. The used single point SAS unit cannot be

bench-checked or self-checked.

Crash Zone Sensor Handling

•Disconnecting the crash zone sensor connector or removing the crash zone sensor with the ignition

switch at ON position can cause the crash zone sensor to operate and the air bag modules and pre-

tensioner seat belts to deploy, which may seriously injure you. Before disconnecting the crash zone

sensor connector or removing the crash zone sensor, always turn the ignition switch to LOCK position,

then disconnect the negative battery cable and wait for more than 1 minute to allow the backup power

supply of the SAS control module to deplete its stored power.

•If the crash zone sensor is subjected to shock or the sensor is disassembled, the air bag modules and

pre-tensioner seat belts may operate (deploy) suddenly and cause injury, or it may fail to operate

normally and cause a serious accident. Do not subject the crash zone sensor to shock or disassemble

the sensor.

•Because a sensor is built into the crash zone sensor, when the air bag modules and pre-tensioner seat

belts operates (deploys), there may be a problem, such as an internal malfunction, even if there is not

any external damage or deformation. If the crash zone sensor is reused, the air bag modules and pre-

tensioner seat belts may fail to operate normally and cause a serious injury. Always replace the crash

zone sensor with a new part. The crash zone sensor cannot be bench-checked or self-checked.

A6E8130W021

Page 845 of 909

T–34

AIR BAG SYSTEM

Side Air Bag Sensor Handling

•Disconnecting the side air bag sensor connector or removing the side air bag sensor with the ignition

switch at ON position can cause the side air bag sensor to operate and the side air bag module to

deploy, which may seriously injure you. Before disconnecting the side air bag sensor connector or

removing the side air bag sensor, always turn the ignition switch to LOCK position, then disconnect the

negative battery cable and wait for more than 1 minute to allow the backup power supply of the SAS

control module to deplete its stored power.

•If the side air bag sensor is subjected to shock or the sensor is disassembled, the side air bag module

may operate (deploy) suddenly and cause injury, or it may fail to operate normally and cause a serious

accident. Do not subject the side air bag sensor to shock or disassemble the sensor.

•Because a sensor is built into the side air bag sensor, when the side air bag module operates (deploys),

there may be a problem, such as an internal malfunction, even if there is not any external damage or

deformation. If the side air bag sensor is reused, the side air bag module may fail to operate normally

and cause a serious injury. Always replace the side air bag sensor with a new part. The side air bag

sensor cannot be bench-checked or self-checked.

Pre-tensioner Seat Belt Inspection

•Inspecting a pre-tensioner seat belt using an

ohmmeter can deploy the pre-tensioner seat

belt, which can cause serious injury. Do not

use an ohmmeter to inspect the pre-tensioner

seat belt. Always use the on-board diagnostic

to diagnose the pre-tensioner seat belt for

malfunctions.

Component Handling

•Oil, grease, water, etc on components may cause the air bag modules and pre-tensioner seat belts to

fall to deploy in an accident, which may cause serious injury. Do not allow oil, grease, water, etc., on

components.

•Inserting a screwdriver, etc., into the

connector of an air bag module or a pre-

tensioner seat belt may damage the connector

and cause the air bag module or the pre-

tensioner seat belt to deploy improperly,

which may cause serious injury. Do not insert

any foreign objects into the connector.

Component Reuse

•Even if an air bag module or a pre-tensioner seat belt does not deploy in a collision and does not have

any external signs of damage, it may have been damaged internally, which may cause improper

operation. Improper operation may cause serious injury. Always self-check the undamaged air bag

module or pre-tensioner seat belt to determine whether it can be reused.

End Of Sie

A6E8130W025

A6E8130W023

Page 846 of 909

AIR BAG SYSTEM

T–35

T

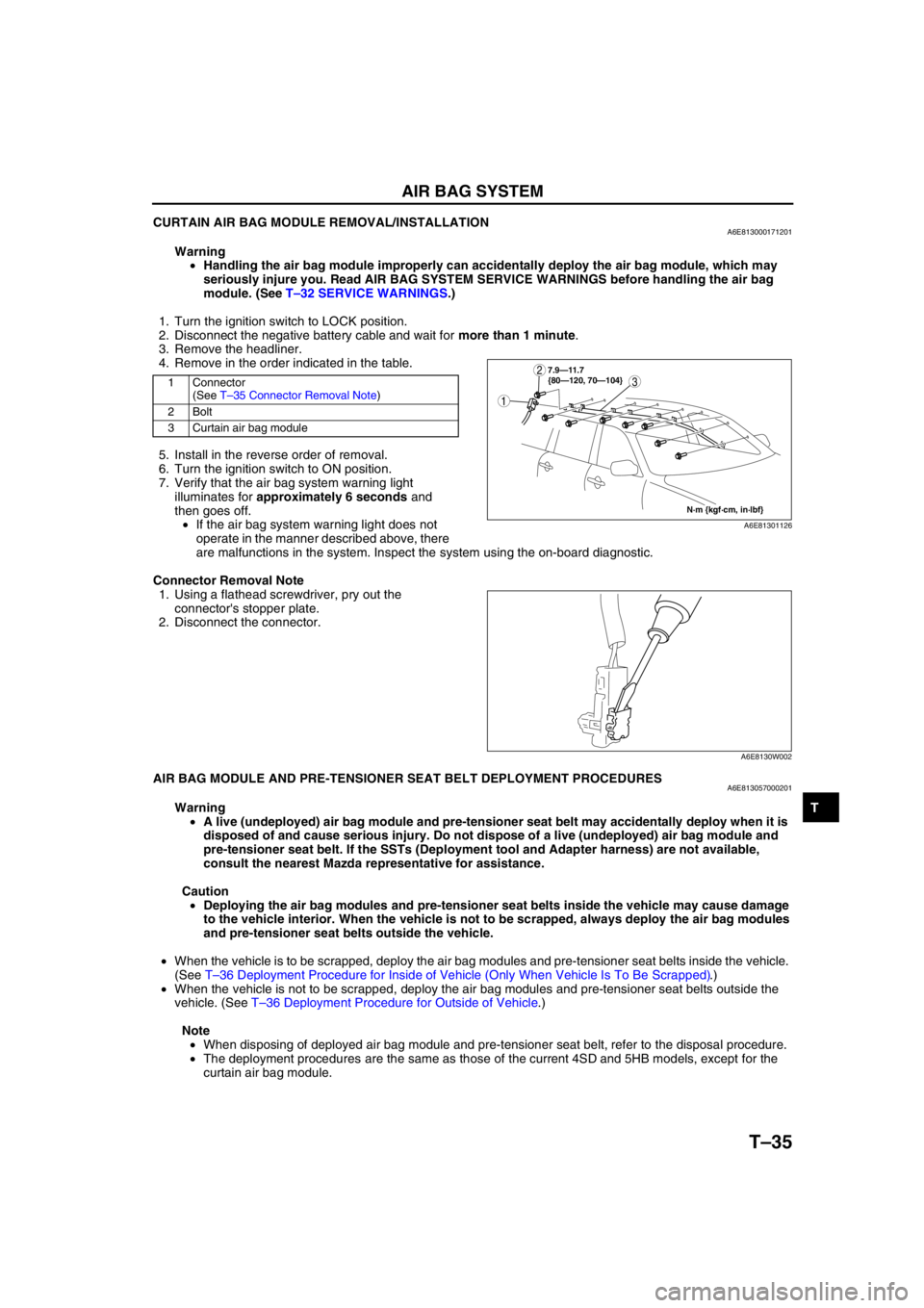

CURTAIN AIR BAG MODULE REMOVAL/INSTALLATIONA6E813000171201

Warning

•Handling the air bag module improperly can accidentally deploy the air bag module, which may

seriously injure you. Read AIR BAG SYSTEM SERVICE WARNINGS before handling the air bag

module. (See T–32 SERVICE WARNINGS.)

1. Turn the ignition switch to LOCK position.

2. Disconnect the negative battery cable and wait for more than 1 minute.

3. Remove the headliner.

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

6. Turn the ignition switch to ON position.

7. Verify that the air bag system warning light

illuminates for approximately 6 seconds and

then goes off.

•If the air bag system warning light does not

operate in the manner described above, there

are malfunctions in the system. Inspect the system using the on-board diagnostic.

Connector Removal Note

1. Using a flathead screwdriver, pry out the

connector's stopper plate.

2. Disconnect the connector.

End Of SieAIR BAG MODULE AND PRE-TENSIONER SEAT BELT DEPLOYMENT PROCEDURESA6E813057000201

Warning

•A live (undeployed) air bag module and pre-tensioner seat belt may accidentally deploy when it is

disposed of and cause serious injury. Do not dispose of a live (undeployed) air bag module and

pre-tensioner seat belt. If the SSTs (Deployment tool and Adapter harness) are not available,

consult the nearest Mazda representative for assistance.

Caution

•Deploying the air bag modules and pre-tensioner seat belts inside the vehicle may cause damage

to the vehicle interior. When the vehicle is not to be scrapped, always deploy the air bag modules

and pre-tensioner seat belts outside the vehicle.

•When the vehicle is to be scrapped, deploy the air bag modules and pre-tensioner seat belts inside the vehicle.

(See T–36 Deployment Procedure for Inside of Vehicle (Only When Vehicle Is To Be Scrapped).)

•When the vehicle is not to be scrapped, deploy the air bag modules and pre-tensioner seat belts outside the

vehicle. (See T–36 Deployment Procedure for Outside of Vehicle.)

Note

•When disposing of deployed air bag module and pre-tensioner seat belt, refer to the disposal procedure.

•The deployment procedures are the same as those of the current 4SD and 5HB models, except for the

curtain air bag module.

1 Connector

(See T–35 Connector Removal Note)

2Bolt

3 Curtain air bag module3

1

2

N·m {kgf·cm, in·lbf} 7.9—11.7

{80—120, 70—104}

A6E81301126

A6E8130W002

Page 847 of 909

T–36

AIR BAG SYSTEM

Deployment Procedure for Inside of Vehicle (Only When Vehicle Is To Be Scrapped)

1. Inspect the SST (Deployment tool).

2. Move the vehicle to an open space, away from strong winds, and close all the doors and windows.

3. Turn the ignition switch to LOCK position.

4. Disconnect the negative battery cable and wait for more than 1 minute.

5. Follow the appropriate procedure for deploying the driver-side air bag module, passenger-side air bag module,

side air bag module, curtain air bag module, or pre-tensioner seat belt.

Curtain air bag module (WGN)

1. Remove the headliner.

2. Disconnect the curtain air bag module connector.

3. Connect the SST (Adapter harness) to the curtain

air bag module.

4. Connect the SST (Deployment tool) to the SST

(Adapter harness).

5. Connect the red clip of the SST (Deployment tool)

to the positive battery terminal and the black clip

to the negative battery terminal.

6. Verify that the red light on the SST (Deployment

tool) is illuminated.

7. Make sure all persons are standing at least 6 m

{20 ft} from the vehicle.

8. Press the activation switch on the SST

(Deployment tool) to deploy the curtain air bag

module.

Deployment Procedure for Outside of Vehicle

1. Inspect the SST (Deployment tool).

2. Turn the ignition switch to LOCK position.

3. Disconnect the negative battery cable and wait for more than 1 minute.

4. Follow the appropriate procedure for deploying the driver-side air bag module, passenger-side air bag module,

side air bag module, curtain air bag module, or pre-tensioner seat belt.

49 L066 002

CURTAIN

AIR BAG MODULE

CONNECTOR

A6E81301112

49 L066 002

49 H066 002

A6E8130W151

49 H066 002

ACTIVATION

SWITCH

A6E8130W028

Page 874 of 909

BASIC SYSTEM

U–11

U

7. Install in the reverse order of removal.

8. Perform the refrigerant system performance test.

A/C Unit Installation Note

1. When installing a new A/C unit or evaporator, add a supplemental amount of ATMOS GU10 compressor oil into

the refrigerant cycle.

Supplemental amount (approximate quantity)

40 ml {40 cc, 1.4 fl oz}

End Of Sie

A/C COMPRESSOR REMOVAL/INSTALLATIONA6E8516614502011. Disconnect the negative battery cable.

2. Discharge the refrigerant from the system.

3. Remove the right side splash shield.

4. Loosen the drive belt and remove it.

Caution

•If moisture or foreign material enters the refrigeration cycle, cooling ability will be lowered and

abnormal noise will occur. Always immediately plug open fittings after removing any refrigeration

cycle parts to keep moisture or foreign material out of the cycle.

5. Remove in the order indicated in the table. Do not

allow compressor oil to spill.

.

6. Install in the reverse order of removal.

7. Adjust the drive belt.

8. Perform the refrigerant system performance test.

A/C Compressor Installation Note

1. Remove the following amount of compressor oil from the new A/C compressor when replacing the A/C

compressor.

Compressor oil to be removed (approximate quantity)

150 ml {150 cc, 5.07 fl oz} – [compressor oil from old A/C compressor + 15 ml {15 cc, 0.5 fl oz}]

End Of Sie

1 Cooler hose (HI)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)

2 Cooler hose (LO)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)

3 Magnetic clutch connector

4A/C compressor

(See U–11 A/C Compressor Installation Note)

4

3

1

2

N·m {kgf·cm, in·lbf} 6.86—9.80

{70.0—99.9,

60.8—86.7}

R

R

6.86—9.80

{70.0—99.9,

60.8—86.7}

17.6—26.5 N·m

{1.80—2.70 kgf·m,

13.0—19.5 ft·lbf}

A6E85162005