belt MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 45 of 909

B2–14

TIMING BELT

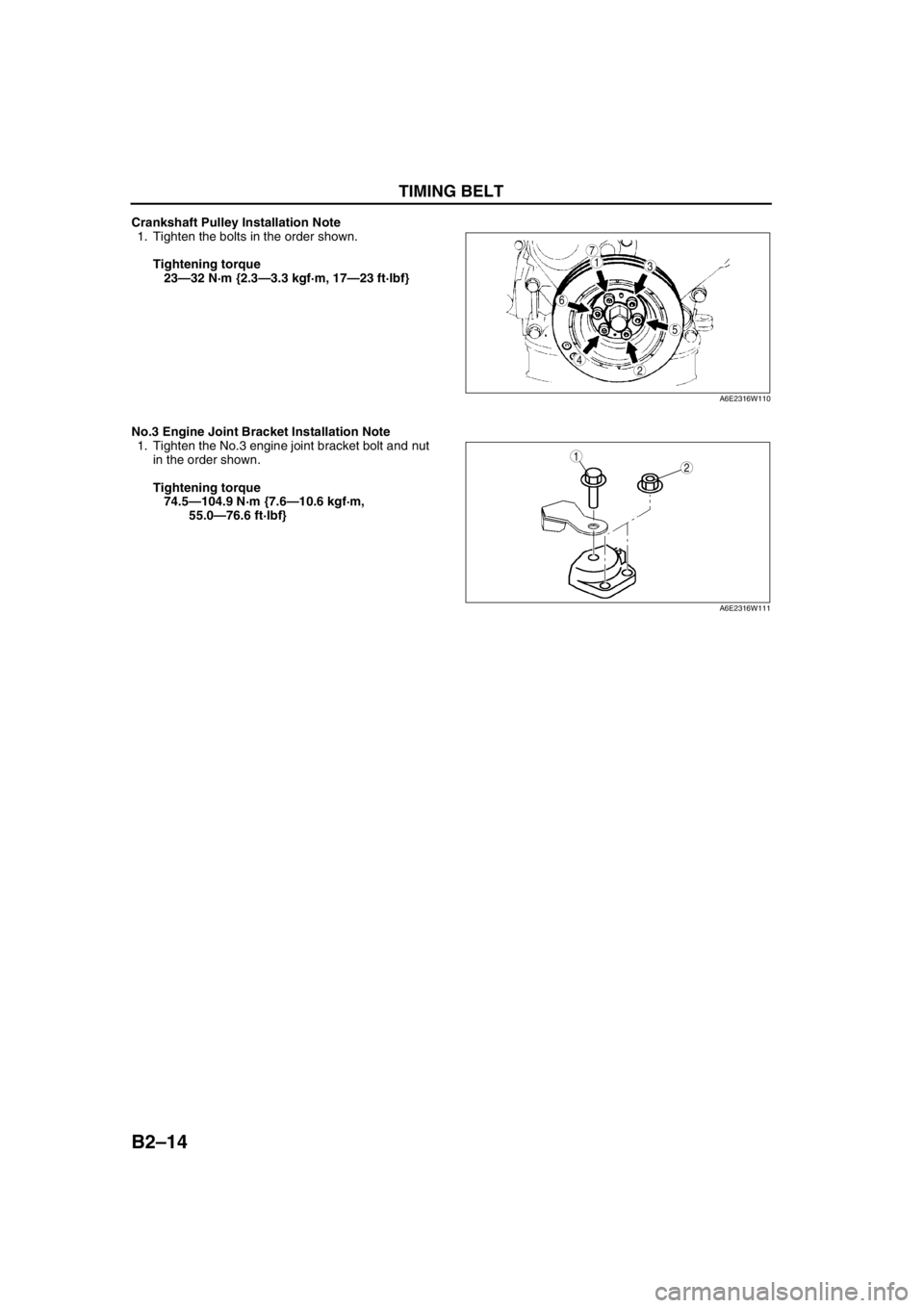

Crankshaft Pulley Installation Note

1. Tighten the bolts in the order shown.

Tightening torque

23—32 N·m {2.3—3.3 kgf·m, 17—23 ft·lbf}

No.3 Engine Joint Bracket Installation Note

1. Tighten the No.3 engine joint bracket bolt and nut

in the order shown.

Tightening torque

74.5—104.9 N·m {7.6—10.6 kgf·m,

55.0—76.6 ft·lbf}

7

5

4

3

6

1

2

A6E2316W110

12

A6E2316W111

Page 46 of 909

CYLINDER HEAD GASKET

B2–15

B2

End Of Sie

CYLINDER HEAD GASKET REPLACEMENTA6E231810271201

Warning

•Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, always complete the “Fuel Line

Safety Procedure”. (See F2–45 Fuel Line Safety Procedures.)

1. Remove the timing belt. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

2. Remove the vacuum pump. (See P–13 VACUUM PUMP REMOVAL/INSTALLATION (MZR-CD (RF

TURBO)).)

3. Remove the P/S oil pump with the oil hose still connected. Position the P/S oil pump so that it is out of the way.

Use wire or rope to secure. (See N–16 POWER STEERING OIL PUMP (MZR-CD (RF Turbo)) REMOVAL/

INSTALLATION.)

4. Remove the turbocharger. (See F2–57 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

5. Remove all the glow plugs. (See F2–42 GLOW PLUG REMOVAL/INSTALLATION.)

6. Remove in the order shown in the table.

7. Install in the reverse order of removal.

8. Inspect valve clearance. (See B2–5 VALVE CLEARANCE INSPECTION.)

9. Inspect the engine oil level.

•If necessary, add oil. (See D–8 ENGINE OIL INSPECTION.)

10. Inspect the compression. (See B2–8 COMPRESSION INSPECTION.)

11. Start the engine and:

(1) Inspect the pulleys and the drive belt for runout and contact.

(2) Inspect the engine oil, engine coolant, and fuel leakage.

(3) Inspect the idle speed. (See F2–34 IDLE SPEED INSPECTION.)

CYLINDER HEAD GASKET

Page 55 of 909

B2–24

FRONT OIL SEAL

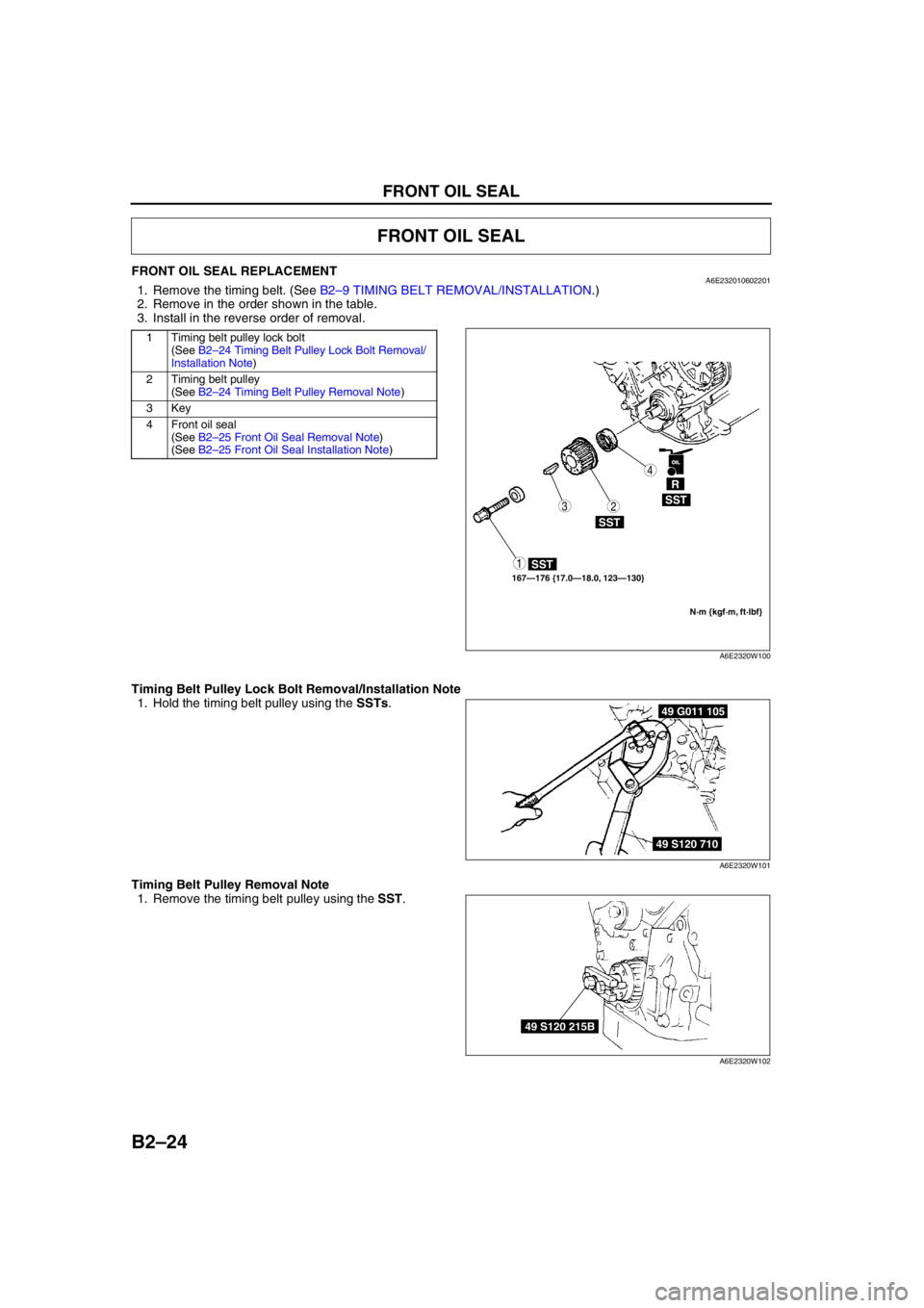

FRONT OIL SEAL REPLACEMENTA6E2320106022011. Remove the timing belt. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

2. Remove in the order shown in the table.

3. Install in the reverse order of removal.

.

Timing Belt Pulley Lock Bolt Removal/Installation Note

1. Hold the timing belt pulley using the SSTs.

Timing Belt Pulley Removal Note

1. Remove the timing belt pulley using the SST.

FRONT OIL SEAL

1 Timing belt pulley lock bolt

(See B2–24 Timing Belt Pulley Lock Bolt Removal/

Installation Note)

2 Timing belt pulley

(See B2–24 Timing Belt Pulley Removal Note)

3Key

4 Front oil seal

(See B2–25 Front Oil Seal Removal Note)

(See B2–25 Front Oil Seal Installation Note)

SST

SST

SST

R

OILOIL

167—176 {17.0—18.0, 123—130}

N·m {kgf·m, ft·lbf}

3

1

2

4

A6E2320W100

49 G011 105

49 S120 710

A6E2320W101

49 S120 215B

A6E2320W102

Page 58 of 909

ENGINE

B2–27

B2

ENGINE REMOVAL/INSTALLATIONA6E232401001201

Warning

•Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injures or death and

damage. Fuel can also irritate skin and eyes. To prevent this, always complete the “Fuel Line

Safety Procedure”. (See F2–45 Fuel Line Safety Procedures.)

1. Disconnect the negative battery cable.

2. Drain the engine coolant, engine oil, and transaxle oil.

3. Remove the radiator.

4. Remove the engine cover. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

5. Remove the air cleaner and air hose. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

6. Disconnect the fuel hose. (See F2–45 BEFORE REPAIR PROCEDURE.)

7. Remove the front pipe. (See F2–57 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

8. Remove the battery and tray. (See G–5 BATTERY REMOVAL/INSTALLATION.)

9. Remove the shift cable, select cable and clutch release cylinder related to the transaxle. (See J2–7 MANUAL

TRANSAXLE REMOVAL/INSTALLATION.)

10. Remove the clutch release cylinder.

11. Remove the vacuum hose and the heater hose.

12. Disconnect the P/S oil pump pressure pipe and P/S oil pump relief hose from the P/S oil pump side. (See N–16

POWER STEERING OIL PUMP (MZR-CD (RF Turbo)) REMOVAL/INSTALLATION.)

Note

•The P/S oil pump will not be removed from the engine.

13. Remove the A/C compressor with the pipe still connected. Position the A/C compressor so that it is out of the

way. Use wire or rope to secure it. (See U–11 A/C COMPRESSOR REMOVAL/INSTALLATION.)

14. Remove the joint shaft.

15. Remove the front drive shaft (LH) from the transaxle.

16. Remove in the order indicated in the table.

17. Install in the reverse order of removal.

18. Fill the engine coolant, engine oil, and transaxle oil.

19. Bleed the air from the fuel line. (See F2–45 AFTER REPAIR PROCEDURE.)

20. Start the engine and:

•Inspect the pulleys and the drive belt for runout and contact.

•Inspect the engine oil, engine coolant transaxle oil, P/S fluid, and fuel for leakage.

•Inspect the idle speed. (See F2–34 IDLE SPEED INSPECTION.)

21. Perform a road test.

22. Reinspect the engine oil, engine coolant, transaxle oil, and P/S fluid levels.

ENGINE

Page 78 of 909

OUTLINE

E–3

E

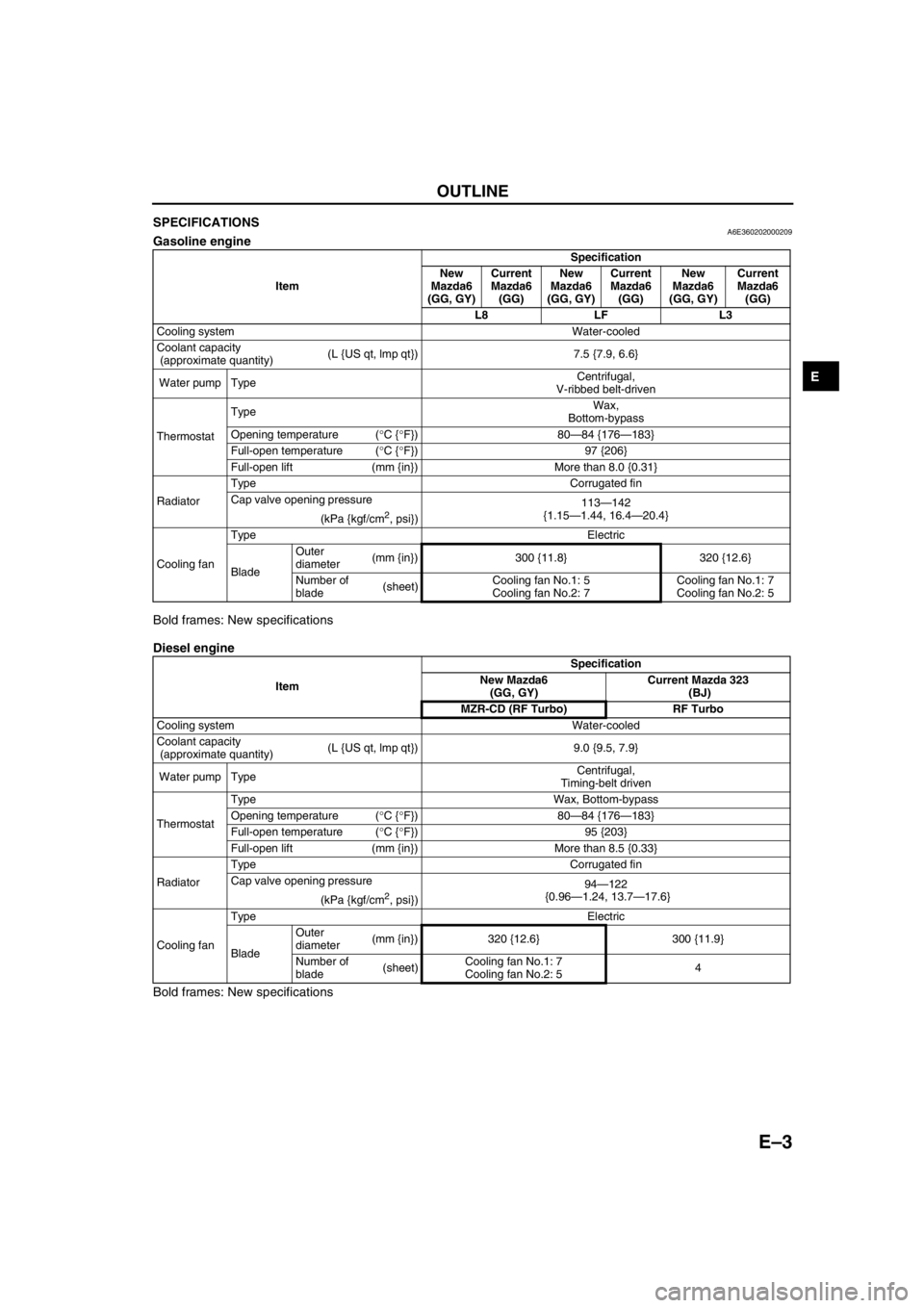

SPECIFICATIONSA6E360202000209Gasoline engine

Bold frames: New specifications

Diesel engine

Bold frames: New specifications

End Of Sie

ItemSpecification

New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)

L8 LF L3

Cooling system Water-cooled

Coolant capacity

(approximate quantity)(L {US qt, lmp qt}) 7.5 {7.9, 6.6}

Water pump TypeCentrifugal,

V-ribbed belt-driven

ThermostatTypeWax,

Bottom-bypass

Opening temperature (°C {°F}) 80—84 {176—183}

Full-open temperature (°C {°F}) 97 {206}

Full-open lift (mm {in}) More than 8.0 {0.31}

RadiatorType Corrugated fin

Cap valve opening pressure

113—142

{1.15—1.44, 16.4—20.4}

(kPa {kgf/cm

2, psi})

Cooling fanType Electric

BladeOuter

diameter(mm {in}) 300 {11.8} 320 {12.6}

Number of

blade(sheet)Cooling fan No.1: 5

Cooling fan No.2: 7Cooling fan No.1: 7

Cooling fan No.2: 5

ItemSpecification

New Mazda6

(GG, GY)Current Mazda 323

(BJ)

MZR-CD (RF Turbo) RF Turbo

Cooling system Water-cooled

Coolant capacity

(approximate quantity)(L {US qt, lmp qt}) 9.0 {9.5, 7.9}

Water pump TypeCentrifugal,

Timing-belt driven

ThermostatType Wax, Bottom-bypass

Opening temperature (°C {°F}) 80—84 {176—183}

Full-open temperature (°C {°F}) 95 {203}

Full-open lift (mm {in}) More than 8.5 {0.33}

RadiatorType Corrugated fin

Cap valve opening pressure

94—122

{0.96—1.24, 13.7—17.6}

(kPa {kgf/cm

2, psi})

Cooling fanType Electric

BladeOuter

diameter(mm {in}) 320 {12.6} 300 {11.9}

Number of

blade(sheet)Cooling fan No.1: 7

Cooling fan No.2: 54

Page 86 of 909

WATER PUMP

E–11

E

WATER PUMP REMOVAL/INSTALLATIONA6E362015010201MZR-CD (RF Turbo)

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Drain the engine coolant.

4. Remove the timing belt. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

5. Remove the thermostat. (See E–9 THERMOSTAT REMOVAL/INSTALLATION.)

6. Remove in the order indicated in the table.

7. Install in the reverse order of removal.

8. Insect the drive belt. (See B2–4 DRIVE BELT INSPECTION.)

9. Fill the radiator with the specified amount and type of engine coolant.

10. Inspect the engine coolant leakage. (See E–8 ENGINE COOLANT LEAKAGE INSPECTION.)

End Of Sie

WATER PUMP

3

1

2

1

19—25

{1.9—2.6, 14—18}

N·m {kgf·m, ft·lbf} 38—51

{3.8—5.3, 28—38}

7.9—10.7 N·m

{80—110 kgf·cm, 69.5—95.4 in·lbf} 38—51

{3.8—5.3, 28—38}

R

R

A6E3620W100

1Hose

2 Water pump

3 Thermostat case

Page 146 of 909

F1–58

TROUBLESHOOTING

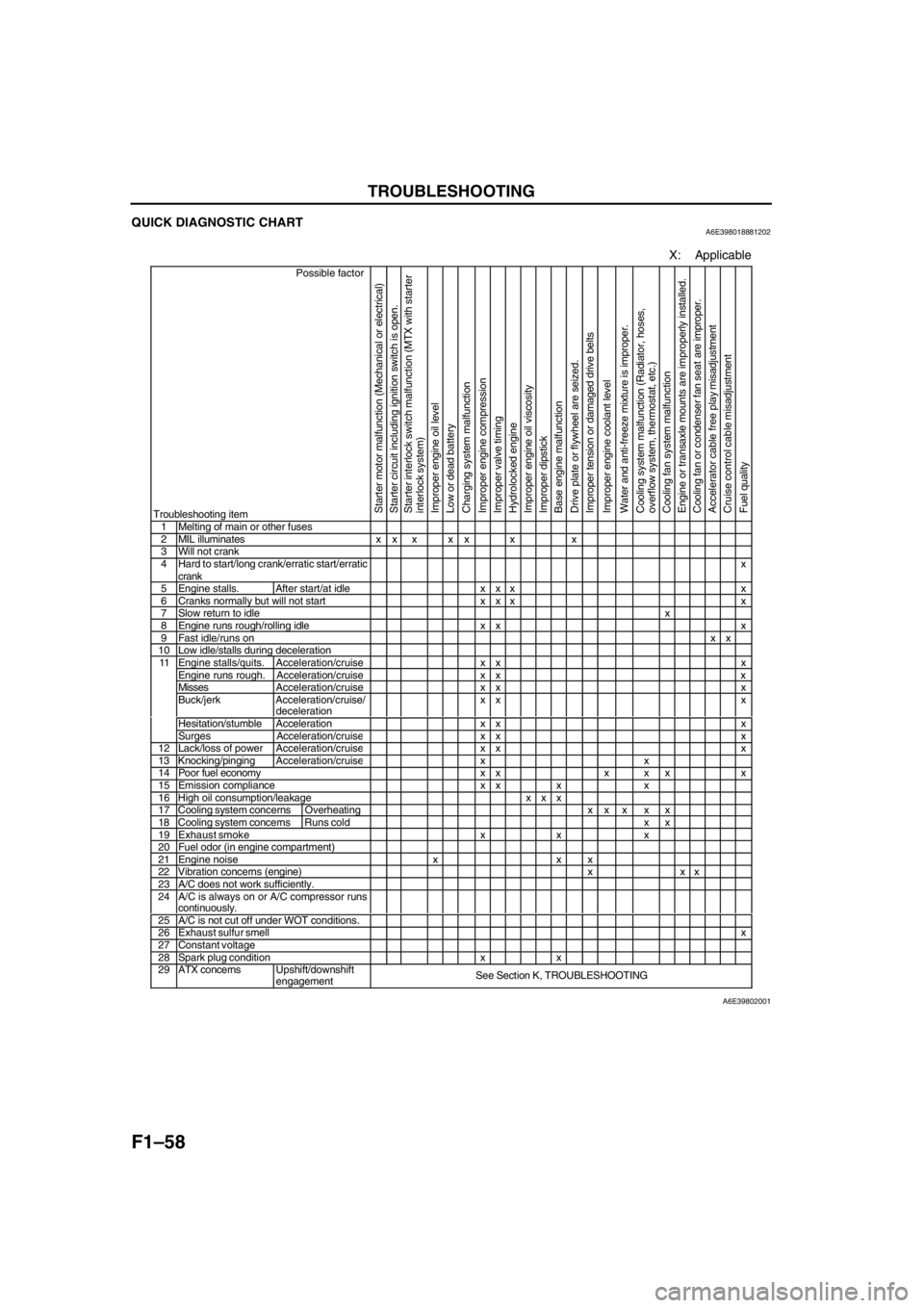

QUICK DIAGNOSTIC CHARTA6E398018881202

X: Applicable

Possible factor

Troubleshooting item

Starter motor malfunction (Mechanical or electrical)

Starter circuit including ignition switch is open.

Starter interlock switch malfunction (MTX with starter

interlock system)

Improper engine oil level

Low or dead battery

Charging system malfunction

Improper engine compression

Improper valve timing

Hydrolocked engine

Improper engine oil viscosity

Improper dipstick

Base engine malfunction

Drive plate or flywheel are seized.

Improper tension or damaged drive belts

Improper engine coolant level

Water and anti-freeze mixture is improper.

Cooling system malfunction (Radiator, hoses,

overflow system, thermostat, etc.)

Cooling fan system malfunction

Engine or transaxle mounts are improperly installed.

Cooling fan or condenser fan seat are improper.

Accelerator cable free play misadjustment

Cruise control cable misadjustment

Fuel quality

1 Melting of main or other fuses2 MIL illuminates x x x x x x x3 Will not crank4 Hard to start/long crank/erratic start/erratic

crankx

5 Engine stalls. After start/at idle x x x x6 Cranks normally but will not start x x x x7 Slow return to idlex8 Engine runs rough/rolling idle x x x9 Fast idle/runs onxx10 Low idle/stalls during decelerationEngine stalls/quits. Acceleration/cruise x x xEngine runs rough. Acceleration/cruise x x xMissesAcceleration/cruise x x xBuck/jerk Acceleration/cruise/

decelerationxx x

Hesitation/stumble Acceleration x x x

11

Surges Acceleration/cruis

exx x12 Lack/loss of powerAcceleration/cruisexx x13 Knocking/pingingAcceleration/cruisexx14 Poor fuel economy x x x x x x15 Emission compliance x x x x16 High oil consumption/leakage x x x17 Cooling system concerns Overheatingxx x x x18 Cooling system concernsRuns cold x x19 Exhaust smoke x x x20 Fuel odor (in engine compartment)21 Engine noise x x x22 Vibration concerns (engine) x x x23 A/C does not work sufficiently.24 A/C is always on or A/C compressor runs

continuously.

25 A/C is not cut off under WOT conditions.26 Exhaust sulfur smellx27 Constant voltage28 Spark plug condition x x29 ATX concernsUpshift/downshift

engagementSee Section K, TROUBLESHOOTING

A6E39802001

Page 150 of 909

F1–62

TROUBLESHOOTING

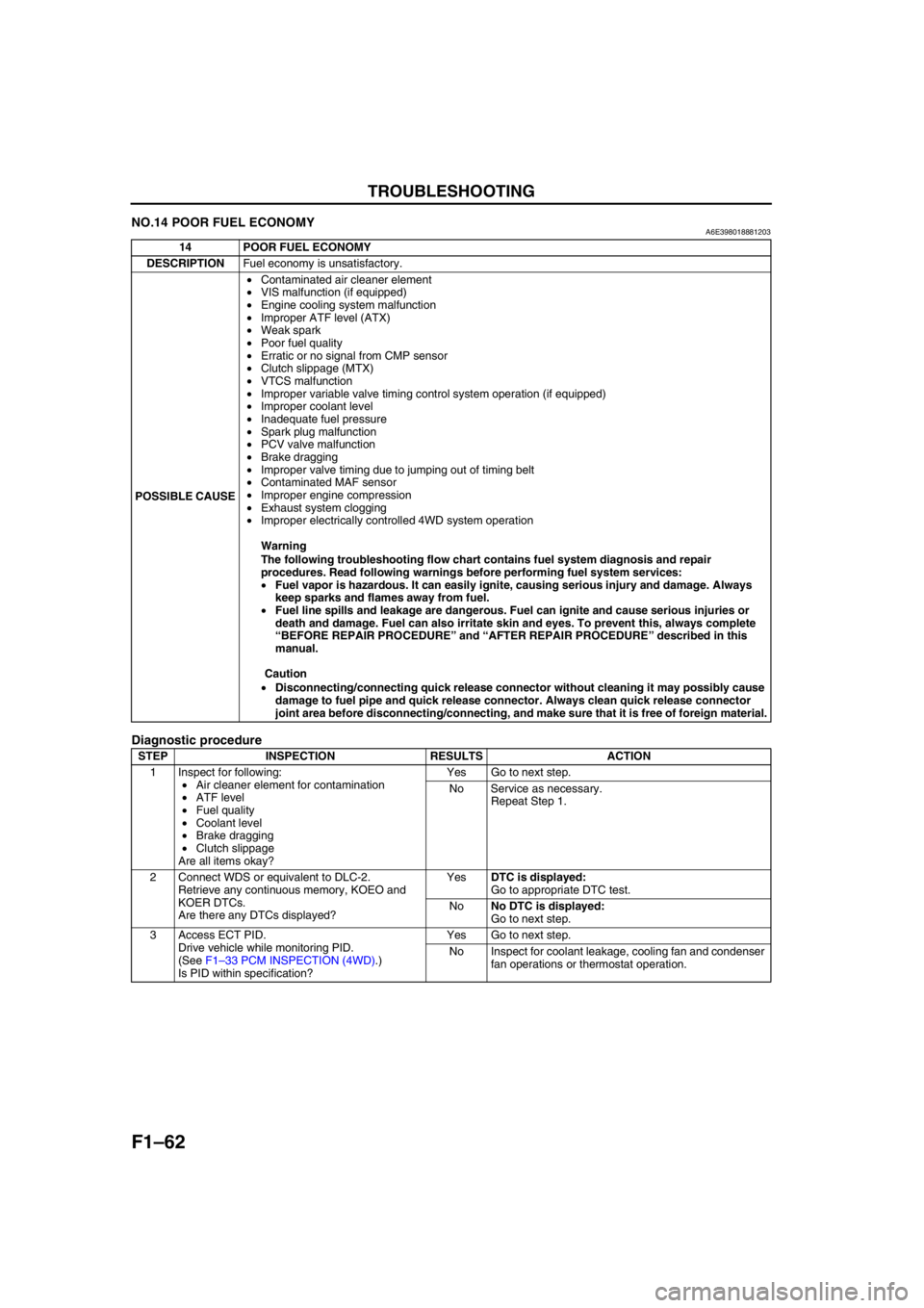

NO.14 POOR FUEL ECONOMYA6E398018881203

Diagnostic procedure

14 POOR FUEL ECONOMY

DESCRIPTIONFuel economy is unsatisfactory.

POSSIBLE CAUSE•Contaminated air cleaner element

•VIS malfunction (if equipped)

•Engine cooling system malfunction

•Improper ATF level (ATX)

•Weak spark

•Poor fuel quality

•Erratic or no signal from CMP sensor

•Clutch slippage (MTX)

•VTCS malfunction

•Improper variable valve timing control system operation (if equipped)

•Improper coolant level

•Inadequate fuel pressure

•Spark plug malfunction

•PCV valve malfunction

•Brake dragging

•Improper valve timing due to jumping out of timing belt

•Contaminated MAF sensor

•Improper engine compression

•Exhaust system clogging

•Improper electrically controlled 4WD system operation

Warning

The following troubleshooting flow chart contains fuel system diagnosis and repair

procedures. Read following warnings before performing fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always

keep sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or

death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete

“BEFORE REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this

manual.

Caution

•Disconnecting/connecting quick release connector without cleaning it may possibly cause

damage to fuel pipe and quick release connector. Always clean quick release connector

joint area before disconnecting/connecting, and make sure that it is free of foreign material.

STEP INSPECTION RESULTS ACTION

1 Inspect for following:

•Air cleaner element for contamination

•ATF level

•Fuel quality

•Coolant level

•Brake dragging

•Clutch slippage

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 1.

2 Connect WDS or equivalent to DLC-2.

Retrieve any continuous memory, KOEO and

KOER DTCs.

Are there any DTCs displayed?YesDTC is displayed:

Go to appropriate DTC test.

NoNo DTC is displayed:

Go to next step.

3 Access ECT PID.

Drive vehicle while monitoring PID.

(See F1–33 PCM INSPECTION (4WD).)

Is PID within specification?Yes Go to next step.

No Inspect for coolant leakage, cooling fan and condenser

fan operations or thermostat operation.

Page 152 of 909

F1–64

TROUBLESHOOTING

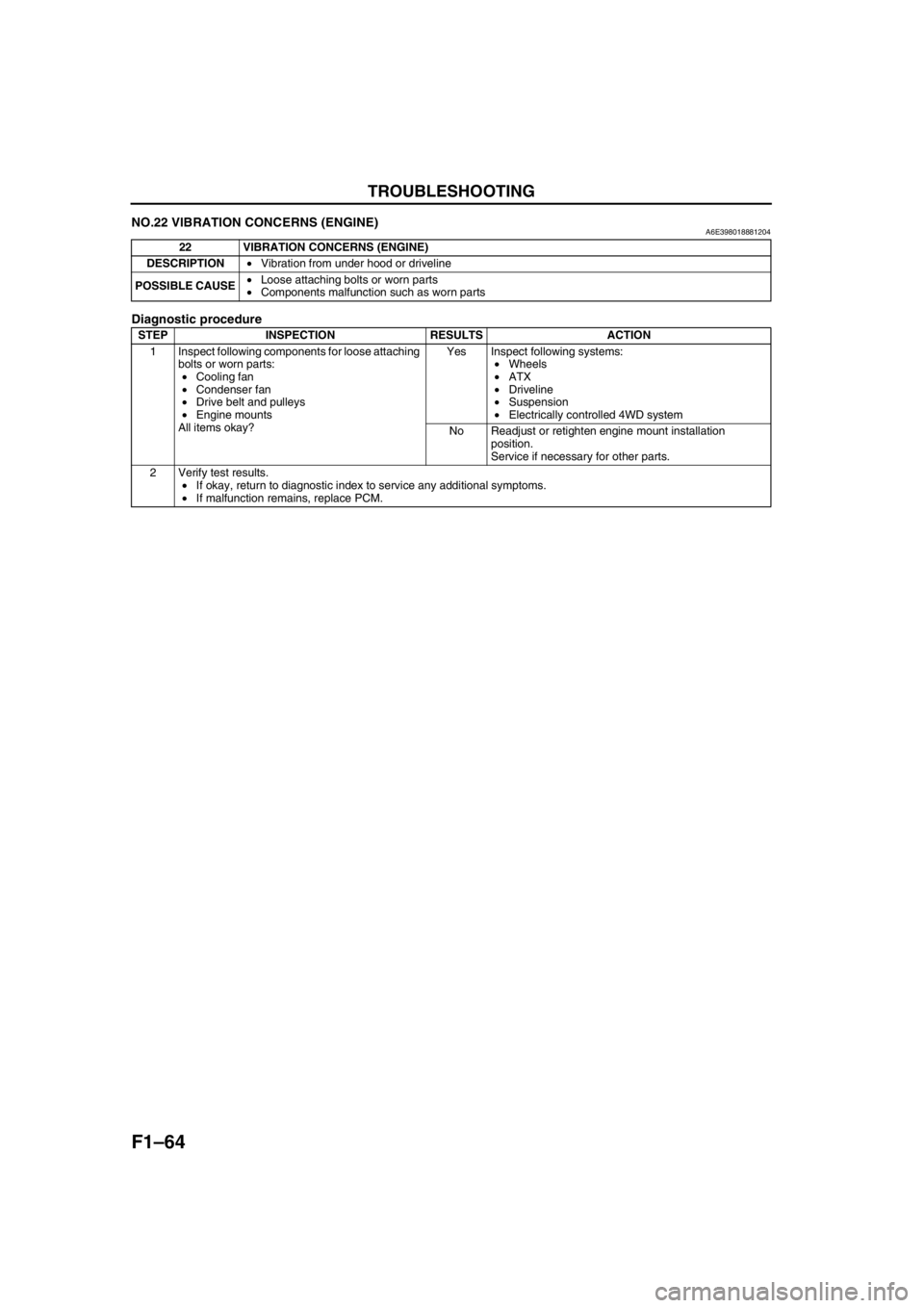

NO.22 VIBRATION CONCERNS (ENGINE)A6E398018881204

Diagnostic procedure

End Of Sie

22 VIBRATION CONCERNS (ENGINE)

DESCRIPTION•Vibration from under hood or driveline

POSSIBLE CAUSE•Loose attaching bolts or worn parts

•Components malfunction such as worn parts

STEP INSPECTION RESULTS ACTION

1 Inspect following components for loose attaching

bolts or worn parts:

•Cooling fan

•Condenser fan

•Drive belt and pulleys

•Engine mounts

All items okay?Yes Inspect following systems:

•Wheels

•ATX

•Driveline

•Suspension

•Electrically controlled 4WD system

No Readjust or retighten engine mount installation

position.

Service if necessary for other parts.

2 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM.

Page 233 of 909

CONTROL SYSTEM

F2–81

F2

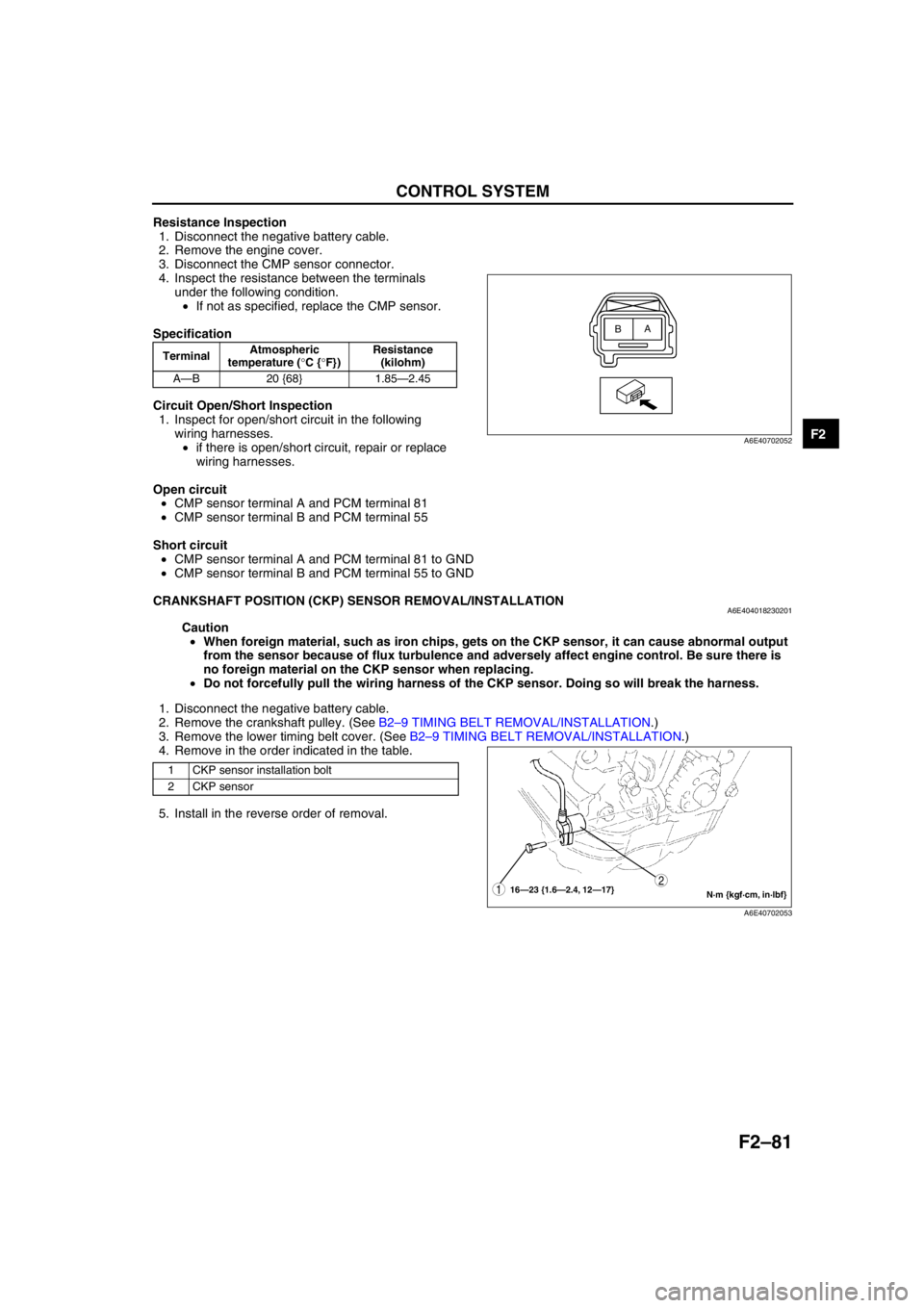

Resistance Inspection

1. Disconnect the negative battery cable.

2. Remove the engine cover.

3. Disconnect the CMP sensor connector.

4. Inspect the resistance between the terminals

under the following condition.

•If not as specified, replace the CMP sensor.

Specification

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•if there is open/short circuit, repair or replace

wiring harnesses.

Open circuit

•CMP sensor terminal A and PCM terminal 81

•CMP sensor terminal B and PCM terminal 55

Short circuit

•CMP sensor terminal A and PCM terminal 81 to GND

•CMP sensor terminal B and PCM terminal 55 to GND

End Of Sie

CRANKSHAFT POSITION (CKP) SENSOR REMOVAL/INSTALLATIONA6E404018230201

Caution

•When foreign material, such as iron chips, gets on the CKP sensor, it can cause abnormal output

from the sensor because of flux turbulence and adversely affect engine control. Be sure there is

no foreign material on the CKP sensor when replacing.

•Do not forcefully pull the wiring harness of the CKP sensor. Doing so will break the harness.

1. Disconnect the negative battery cable.

2. Remove the crankshaft pulley. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

3. Remove the lower timing belt cover. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

End Of Sie

TerminalAtmospheric

temperature (°C {°F})Resistance

(kilohm)

A—B 20 {68} 1.85—2.45

A

B

A6E40702052

1 CKP sensor installation bolt

2 CKP sensor

N·m {kgf·cm, in·lbf} 16—23 {1.6—2.4, 12—17}12

A6E40702053