MAZDA 6 2002 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 241 of 909

ON-BOARD DIAGNOSTIC

F2–89

F2

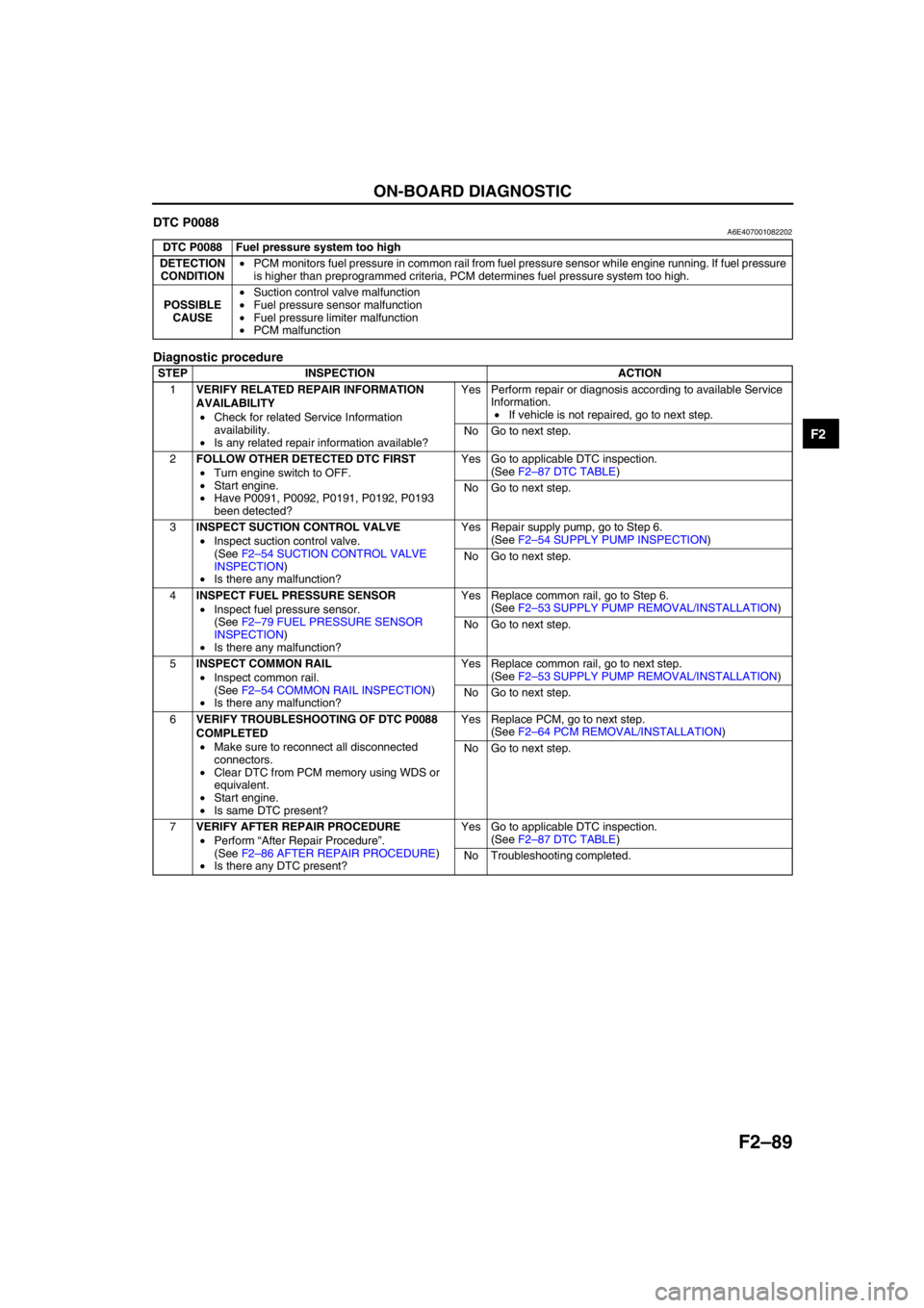

DTC P0088A6E407001082202

Diagnostic procedure

End Of Sie

DTC P0088 Fuel pressure system too high

DETECTION

CONDITION•PCM monitors fuel pressure in common rail from fuel pressure sensor while engine running. If fuel pressure

is higher than preprogrammed criteria, PCM determines fuel pressure system too high.

POSSIBLE

CAUSE•Suction control valve malfunction

•Fuel pressure sensor malfunction

•Fuel pressure limiter malfunction

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2FOLLOW OTHER DETECTED DTC FIRST

•Turn engine switch to OFF.

•Start engine.

•Have P0091, P0092, P0191, P0192, P0193

been detected?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Go to next step.

3INSPECT SUCTION CONTROL VALVE

•Inspect suction control valve.

(See F2–54 SUCTION CONTROL VALVE

INSPECTION)

•Is there any malfunction?Yes Repair supply pump, go to Step 6.

(See F2–54 SUPPLY PUMP INSPECTION)

No Go to next step.

4INSPECT FUEL PRESSURE SENSOR

•Inspect fuel pressure sensor.

(See F2–79 FUEL PRESSURE SENSOR

INSPECTION)

•Is there any malfunction?Yes Replace common rail, go to Step 6.

(See F2–53 SUPPLY PUMP REMOVAL/INSTALLATION)

No Go to next step.

5INSPECT COMMON RAIL

•Inspect common rail.

(See F2–54 COMMON RAIL INSPECTION)

•Is there any malfunction?Yes Replace common rail, go to next step.

(See F2–53 SUPPLY PUMP REMOVAL/INSTALLATION)

No Go to next step.

6VERIFY TROUBLESHOOTING OF DTC P0088

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

7VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

Page 242 of 909

F2–90

ON-BOARD DIAGNOSTIC

DTC P0091A6E407001082203

Diagnostic procedure

DTC P0091 Suction control valve circuit low input

DETECTION

CONDITION•PCM monitors input voltage from suction control valve while engine is running. If input voltage from suction

control valve does not change from off to on, PCM determines suction control valve circuit low input.

POSSIBLE

CAUSE•Suction control valve malfunction

•Connector or terminal malfunction

•Short to GND in wiring between suction control valve terminal A and PCM terminal 93

•Short to GND in wiring between suction control valve terminal B and PCM terminal 94

•Open circuit in wiring between suction control valve terminal A and PCM terminal 93

•Open circuit in wiring between suction control valve terminal B and PCM terminal 94

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

A

B93

94

BA SUCTION CONTROL VALVE

HARNESS SIDE CONNECTOR

94

93PCM

HARNESS SIDE CONNECTORPCM

SUCTION CONTROL VALVE

5

4

36

2

2

365

Page 243 of 909

ON-BOARD DIAGNOSTIC

F2–91

F2

End Of Sie

2INSPECT POOR CONNECTION OF SUCTION

CONTROL VALVE CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

3INSPECT SUCTION CONTROL VALVE CIRCUIT

FOR SHORT TO GND

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—Suction control valve terminal A and body

GND.

—Suction control valve terminal B and body

GND.

•Is there continuity?Yes Repair or replace harness for short to GND, go to Step 7.

No Go to next step.

4INSPECT SUCTION CONTROL VALVE

•Inspect suction control valve.

(See F2–54 SUCTION CONTROL VALVE

INSPECTION)

• Is there any malfunction?Yes Repair supply pump, go to Step 7.

(See F2–54 SUPPLY PUMP INSPECTION)

No Go to next step.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

6INSPECT SUCTION CONTROL VALVE CIRCUIT

FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—Suction control valve terminal A and PCM

terminal 93.

—Suction control valve terminal B and PCM

terminal 94.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to next step.

7VERIFY TROUBLESHOOTING OF DTC P0091

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

8VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 244 of 909

F2–92

ON-BOARD DIAGNOSTIC

DTC P0092A6E407001082204

Diagnostic procedure

DTC P0092 Suction control valve circuit high input

DETECTION

CONDITION•PCM monitors input voltage from suction control valve while engine is running. If input voltage from suction

control valve does not change from on to off, PCM determines suction control valve circuit high input.

POSSIBLE

CAUSE•Suction control valve malfunction

•Connector or terminal malfunction

•Short to power circuit in wiring between suction control valve terminal A and PCM terminal 93

•Short to power circuit in wiring between suction control valve terminal B and PCM terminal 94

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2

2

3

3

5

593

94 A

B

4

BA

94 93PCM

SUCTION CONTROL VALVE

SUCTION CONTROL VALVE

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

Page 245 of 909

ON-BOARD DIAGNOSTIC

F2–93

F2

End Of Sie

2INSPECT POOR CONNECTION OF SUCTION

CONTROL VALVE CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

• Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 6.

No Go to next step.

3INSPECT SUCTION CONTROL VALVE CIRCUIT

FOR SHORT TO POWER

•Turn engine switch to ON (Engine OFF).

•Inspected voltage between following

harnesses:

—Suction control valve terminal A and body

GND.

—Suction control valve terminal B and body

GND.

•Is voltage below 1.0 V?Yes Go to next step.

No Repair or replace harness for short to power, go to Step 6.

4INSPECT SUCTION CONTROL VALVE

•Inspect suction control valve.

(See F2–54 SUCTION CONTROL VALVE

INSPECTION)

• Is there any malfunction?Yes Repair supply pump, go to Step 6.

(See F2–54 SUPPLY PUMP INSPECTION)

No Go to next step.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 6.

No Go to next step.

6VERIFY TROUBLESHOOTING OF DTC P0092

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

7VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

• Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 246 of 909

F2–94

ON-BOARD DIAGNOSTIC

DTC P0093A6E407001082205

Diagnostic procedure

End Of Sie

DTC P0093 Fuel system leak detection

DETECTION

CONDITION•PCM monitors fuel pressure in common rail from fuel pressure sensor while engine running. If fuel pressure

is lower after fuel injection than preprogrammed criteria, PCM determines fuel system leak detection.

POSSIBLE

CAUSE•Fuel leakage or clogged fuel line

•Suction control valve malfunction

•Fuel pressure sensor malfunction

•Fuel injector malfunction

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2FOLLOW OTHER DETECTED DTC FIRST

•Turn engine switch to OFF.

•Start engine.

•Have P0192, P0193, P1190 been detected?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Go to next step.

3INSPECT FUEL LINE

•Turn engine switch to OFF.

•Inspect for fuel leakage or clogs in following

fuel lines for each cylinder:

—Supply pump and Common rail.

—Common rail and fuel injector.

• Is there any malfunction?Yes Repair or replace suspected fuel line, go to Step 7.

No Go to next step.

4INSPECT SUCTION CONTROL VALVE

•Inspect suction control valve.

(See F2–54 SUCTION CONTROL VALVE

INSPECTION)

•Is there any malfunction?Yes Repair supply pump, go to Step 7.

(See F2–54 SUPPLY PUMP INSPECTION)

No Go to next step.

5INSPECT FUEL PRESSURE SENSOR

•Inspect fuel pressure sensor.

(See F2–79 FUEL PRESSURE SENSOR

INSPECTION)

•Is there any malfunction?Yes Replace common rail, go to Step 7.

(See F2–53 SUPPLY PUMP REMOVAL/INSTALLATION)

No Go to next step.

6INSPECT FUEL INJECTOR

•Inspect fuel injector.

(See F2–56 FUEL INJECTOR INSPECTION)

•Is there any malfunction?Yes Replace fuel injector, go to next step.

(See F2–55 FUEL INJECTOR REMOVAL/INSTALLATION)

No Go to next step.

7VERIFY TROUBLESHOOTING OF DTC P0093

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

8VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

Page 247 of 909

ON-BOARD DIAGNOSTIC

F2–95

F2

DTC P0097A6E407001082206

Diagnostic procedure

DTC P0097 IAT sensor No.1 circuit low input

DETECTION

CONDITION•PCM monitors input voltage from IAT sensor No.1 while engine is running. If input voltage from IAT sensor

No.1 is below 0.1 V, PCM determines IAT sensor No.1 circuit low input.

POSSIBLE

CAUSE•IAT sensor No.1 malfunction

•Connector or terminal malfunction

•Short to GND in wiring between MAF/IAT sensor terminal D and PCM terminal 60

•IAT sensor No.1 signal and GND circuits short each other

•PCM malfunction

STEP INSPECTION ACTION

1PERFORM DTC CONFIRMATION PROCEDURE

•Perform “DTC Confirmation Procedure”.

(See F2–85 DTC CONFIRMATION

PROCEDURE)

•Is same DTC present during KOEO or KOER

self-test?Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

2INSPECT POOR CONNECTION OF IAT

SENSOR NO.1 CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

3CLASSIFY IAT SENSOR NO.1 MALFUNCTION

OR HARNESS MALFUNCTION

•Turn engine switch to ON (Engine OFF).

•Disconnect MAF/IAT sensor connector.

•Access IAT PID using WDS or equivalent.

•Is IAT PID below 0.1 V?Yes Go to next step.

No Replace MAF/IAT sensor, go to Step 7.

(See F2–36 INTAKE-AIR SYSTEM REMOVAL/

INSTALLATION)

4INSPECT IAT SENSOR NO.1 SIGNAL CIRCUIT

FOR SHORT TO GND

•Turn engine switch to OFF.

•Inspect continuity between MAF/IAT sensor

terminal D and body GND.

•Is there continuity?Yes Repair or replace harness for short to GND, go to Step 7.

No Go to next step.

D

E

2

24

5

5

6

660

91 IAT SENSOR NO.1PCM

ED

C

B

A

60 91 MAF/IAT SENSOR

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

Page 248 of 909

F2–96

ON-BOARD DIAGNOSTIC

End Of Sie

5INSPECT IAT SENSOR NO.1 CIRCUIT FOR

SHORT WITH EACH OTHER

•Turn engine switch to OFF.

•Inspect continuity between MAF/IAT sensor

terminals D and E.

•Is there continuity?Yes Repair or replace harness for short with each other, go to

Step 7.

No Go to next step.

6INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to next step.

No Go to next step.

7VERIFY TROUBLESHOOTING OF DTC P0097

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Perform KOEO/KOER self-test.

(See F2–86 KOEO/KOER SELF-TEST

PROCEDURE)

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

8VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 249 of 909

ON-BOARD DIAGNOSTIC

F2–97

F2

DTC P0098A6E407001082207

Diagnostic procedure

DTC P0098 IAT sensor No.1 circuit high input

DETECTION

CONDITION•PCM monitors input voltage from IAT sensor No.1 while engine is running. If input voltage from IAT sensor

No.1 is above 5.0 V, PCM determines IAT sensor No.1 circuit high input.

POSSIBLE

CAUSE•IAT sensor No.1 malfunction

•Connector or terminal malfunction

•Short to power circuit in wiring between MAF/IAT sensor terminal D and PCM terminal 60

•Open circuit in wiring between MAF/IAT sensor terminal D and PCM terminal 60

•Open circuit in wiring between MAF/IAT sensor terminal E and PCM terminal 91

•PCM malfunction

STEP INSPECTION ACTION

1PERFORM DTC CONFIRMATION PROCEDURE

•Perform “DTC Confirmation Procedure”.

(See F2–85 DTC CONFIRMATION

PROCEDURE)

•Is same DTC present during KOEO or KOER

self-test?Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

2INSPECT POOR CONNECTION OF IAT

SENSOR NO.1 CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

3CLASSIFY IAT SENSOR NO.1 MALFUNCTION

OR HARNESS MALFUNCTION

•Turn engine switch to ON (Engine OFF).

•Connect jumper wire between MAF/IAT sensor

connector terminal D and E.

•Access IAT PID using WDS or equivalent.

•Is IAT PID below 1.0 V?Yes Replace MAF/IAT sensor, go to Step 7.

(See F2–36 INTAKE-AIR SYSTEM REMOVAL/

INSTALLATION)

No Go to next step.

D

E

2

246

65

560

91 IAT SENSOR NO.1PCM

9160 EDCB

A MAF/IAT SENSOR

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

Page 250 of 909

F2–98

ON-BOARD DIAGNOSTIC

End Of Sie

4INSPECT IAT SENSOR NO.1 SIGNAL CIRCUIT

FOR SHORT TO POWER

•Turn engine switch to ON (Engine OFF).

•Inspect voltage between MAF/IAT sensor

terminal D and body GND.

•Is voltage below 1.0 V?Yes Go to next step.

No Repair or replace harness for short to power, go to Step 7.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

6INSPECT IAT SENSOR NO.1 CIRCUIT FOR

OPEN

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—MAF/IAT sensor terminal D and PCM

terminal 60.

—MAF/IAT sensor terminal E and PCM

terminal 91.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to next step.

7VERIFY TROUBLESHOOTING OF DTC P0098

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Perform KOEO/KOER self-test.

(See F2–86 KOEO/KOER SELF-TEST

PROCEDURE)

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

8VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION