MAZDA 6 2002 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 511 of 909

K2–96

AUTOMATIC TRANSAXLE

TCC solenoid valve signal (lock up on)

•TCM terminal: 2S (+)—2P (–)

•Oscilloscope setting: 5 V/DIV (Y) 5 ms/DIV (X)

•Measuring condition: Drive the vehicle with lock

up

End Of SieTCM REMOVAL/INSTALLATIONA6E5714189012121. Disconnect the negative battery cable.

2. For R.H.D., perform the following procedures.

(1) Remove the front side trim (left-side).

(2) Partially peel back the flower covering.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

U.K. specs.

.

AMU0517W059

2

1

3

SET BOLT

7.8—10.8

{80—110 kgf·cm,

69.5—95.4 in·lbf}

SET NUT

A6E5714W123

1 Control unit bracket

2 TCM connector3TCM

Page 512 of 909

AUTOMATIC TRANSAXLE

K2–97

K2

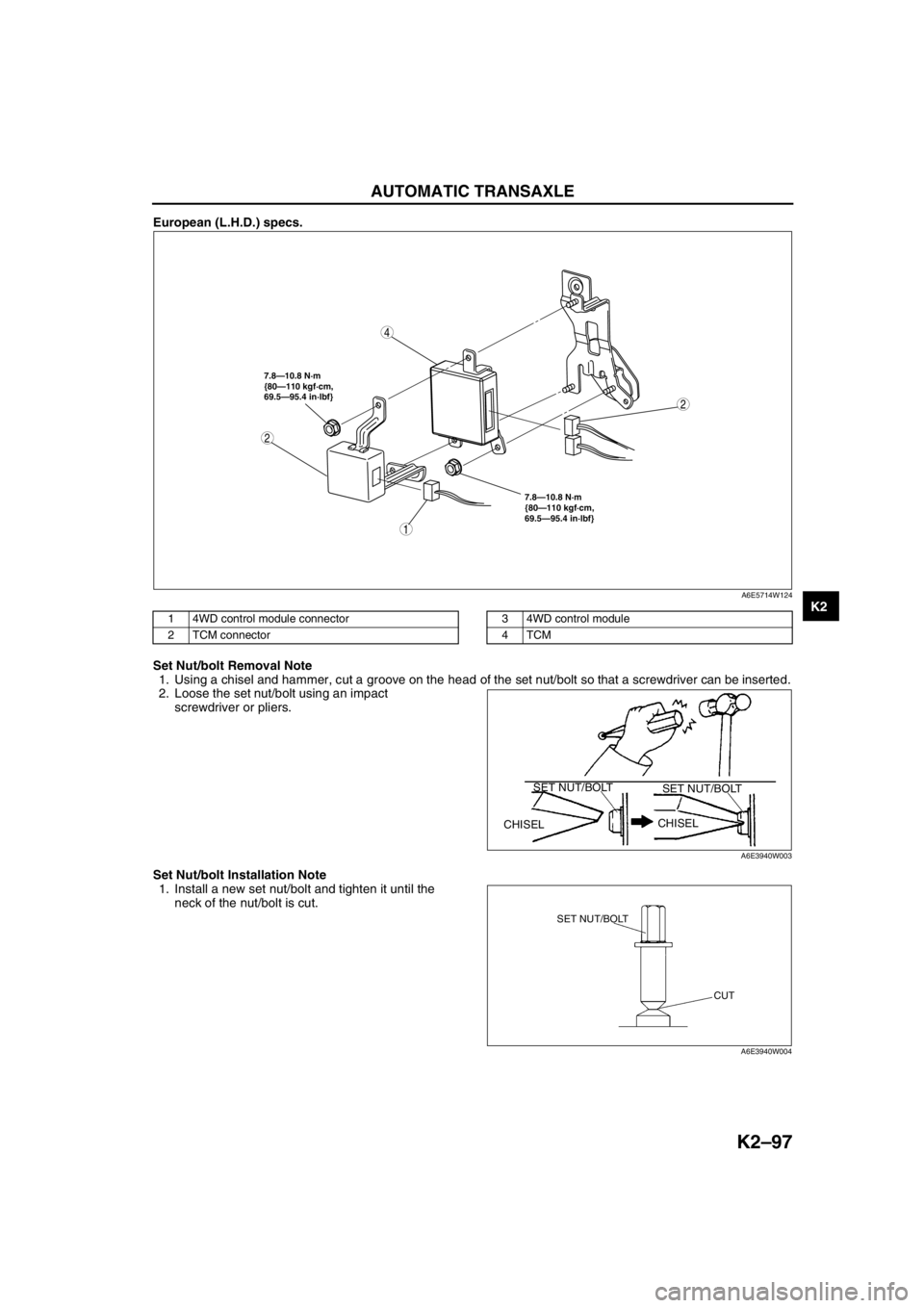

European (L.H.D.) specs.

.

Set Nut/bolt Removal Note

1. Using a chisel and hammer, cut a groove on the head of the set nut/bolt so that a screwdriver can be inserted.

2. Loose the set nut/bolt using an impact

screwdriver or pliers.

Set Nut/bolt Installation Note

1. Install a new set nut/bolt and tighten it until the

neck of the nut/bolt is cut.

2

4

7.8—10.8 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf} 7.8—10.8 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}

2

1

A6E5714W124

1 4WD control module connector

2 TCM connector3 4WD control module

4TCM

CHISELCHISEL SET NUT/BOLT

SET NUT/BOLT

A6E3940W003

SET NUT/BOLT

CUT

A6E3940W004

Page 513 of 909

K2–98

AUTOMATIC TRANSAXLE

THIS PAGE IS

INTENTIONALLY

LEFT BLANK

End Of Sie

Page 514 of 909

AUTOMATIC TRANSAXLE

K2–99

K2

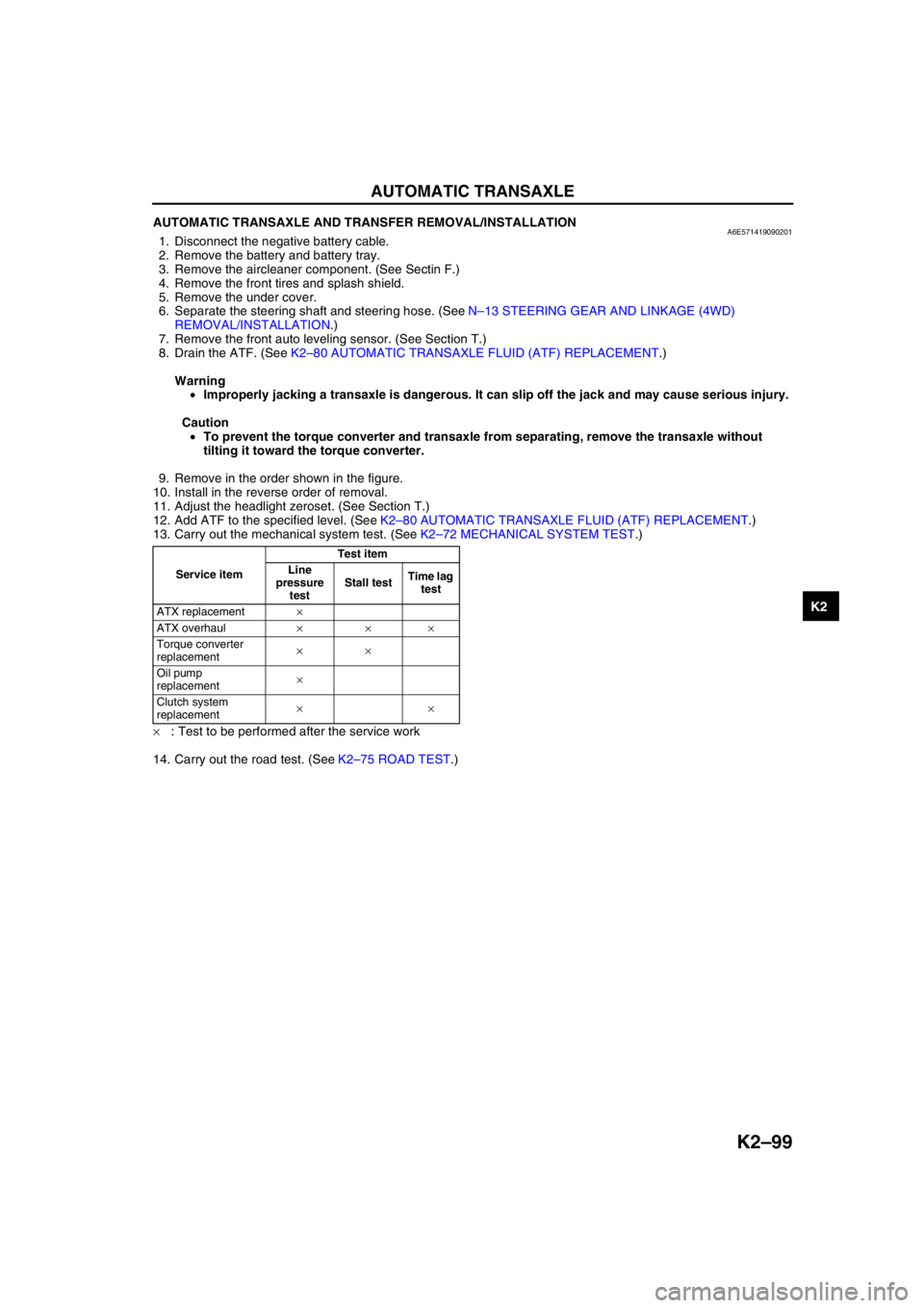

AUTOMATIC TRANSAXLE AND TRANSFER REMOVAL/INSTALLATIONA6E5714190902011. Disconnect the negative battery cable.

2. Remove the battery and battery tray.

3. Remove the aircleaner component. (See Sectin F.)

4. Remove the front tires and splash shield.

5. Remove the under cover.

6. Separate the steering shaft and steering hose. (See N–13 STEERING GEAR AND LINKAGE (4WD)

REMOVAL/INSTALLATION.)

7. Remove the front auto leveling sensor. (See Section T.)

8. Drain the ATF. (See K2–80 AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT.)

Warning

•Improperly jacking a transaxle is dangerous. It can slip off the jack and may cause serious injury.

Caution

•To prevent the torque converter and transaxle from separating, remove the transaxle without

tilting it toward the torque converter.

9. Remove in the order shown in the figure.

10. Install in the reverse order of removal.

11. Adjust the headlight zeroset. (See Section T.)

12. Add ATF to the specified level. (See K2–80 AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT.)

13. Carry out the mechanical system test. (See K2–72 MECHANICAL SYSTEM TEST.)

×: Test to be performed after the service work

14. Carry out the road test. (See K2–75 ROAD TEST.)

Service itemTest item

Line

pressure

testStall testTime lag

test

ATX replacement×

ATX overhaul×××

Torque converter

replacement××

Oil pump

replacement×

Clutch system

replacement××

Page 515 of 909

K2–100

AUTOMATIC TRANSAXLE

.

13

119.6—154.8

{12.20—15.78,

88.22—114.1}

5

6

7

24

8

17

16

9

102115

12

22

19

20

18

11

14

23

R

R

R

R

37—52

{3.8—5.3, 28—38}

42—62

{4.3—6.3, 31—45}6.9—9.8

{71—99 kgf·cm,

62—86 in·lbf}34.3—60.5

{3.50—6.16, 25.3—44.6}

66.6—93.1

{6.80—9.49, 49.2—68.6}

37—52

{3.8—5.3, 28—38}

A

4

31

2

A

B

D

D

B

C

E

C

N·m {kgf·m, ft·lbf} —

E85.3—116.6

{8.70—11.88,

62.91—85.98}85.3—116.6

{8.70—11.88, 62.91—85.98} 93.1—126.4

{9.50—12.88,

68.67—93.22}33.0—44.1

{3.21—4.49,

23.2—32.5}

93.1—131.3

{9.50—13.38, 68.67—96.84}166.6—200.0

{16.99—20.39,

122.9—147.5} 43.1—60.8

{4.40—6.19,

31.8—44.8}

A6E5714W131

Page 516 of 909

AUTOMATIC TRANSAXLE

K2–101

K2

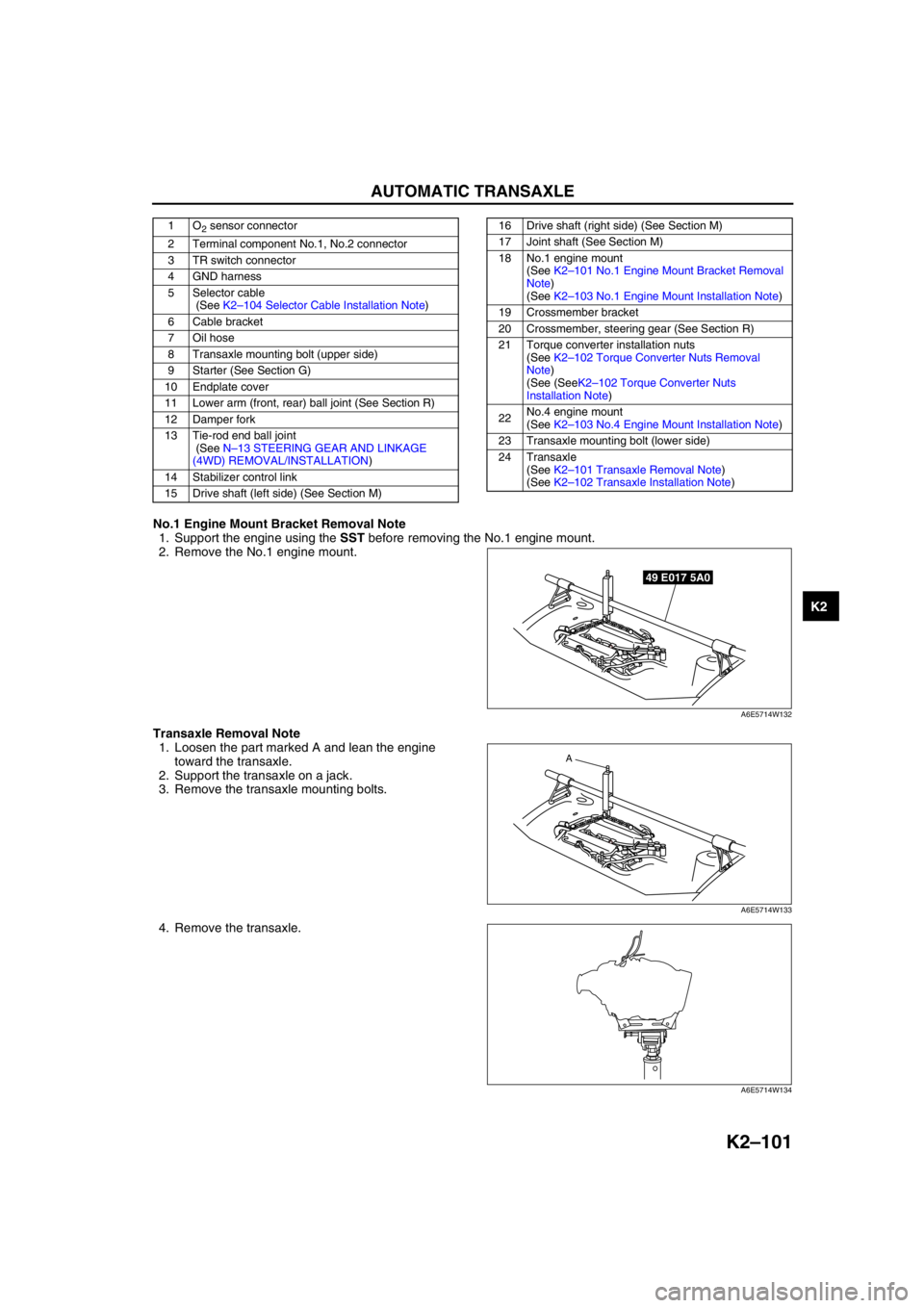

No.1 Engine Mount Bracket Removal Note

1. Support the engine using the SST before removing the No.1 engine mount.

2. Remove the No.1 engine mount.

Transaxle Removal Note

1. Loosen the part marked A and lean the engine

toward the transaxle.

2. Support the transaxle on a jack.

3. Remove the transaxle mounting bolts.

4. Remove the transaxle.

1O2 sensor connector

2 Terminal component No.1, No.2 connector

3 TR switch connector

4 GND harness

5 Selector cable

(See K2–104 Selector Cable Installation Note)

6 Cable bracket

7 Oil hose

8 Transaxle mounting bolt (upper side)

9 Starter (See Section G)

10 Endplate cover

11 Lower arm (front, rear) ball joint (See Section R)

12 Damper fork

13 Tie-rod end ball joint

(See N–13 STEERING GEAR AND LINKAGE

(4WD) REMOVAL/INSTALLATION)

14 Stabilizer control link

15 Drive shaft (left side) (See Section M)16 Drive shaft (right side) (See Section M)

17 Joint shaft (See Section M)

18 No.1 engine mount

(See K2–101 No.1 Engine Mount Bracket Removal

Note)

(See K2–103 No.1 Engine Mount Installation Note)

19 Crossmember bracket

20 Crossmember, steering gear (See Section R)

21 Torque converter installation nuts

(See K2–102 Torque Converter Nuts Removal

Note)

(See (SeeK2–102 Torque Converter Nuts

Installation Note)

22No.4 engine mount

(See K2–103 No.4 Engine Mount Installation Note)

23 Transaxle mounting bolt (lower side)

24 Transaxle

(See K2–101 Transaxle Removal Note)

(See K2–102 Transaxle Installation Note)

49 E017 5A0

A6E5714W132

A

A6E5714W133

A6E5714W134

Page 517 of 909

K2–102

AUTOMATIC TRANSAXLE

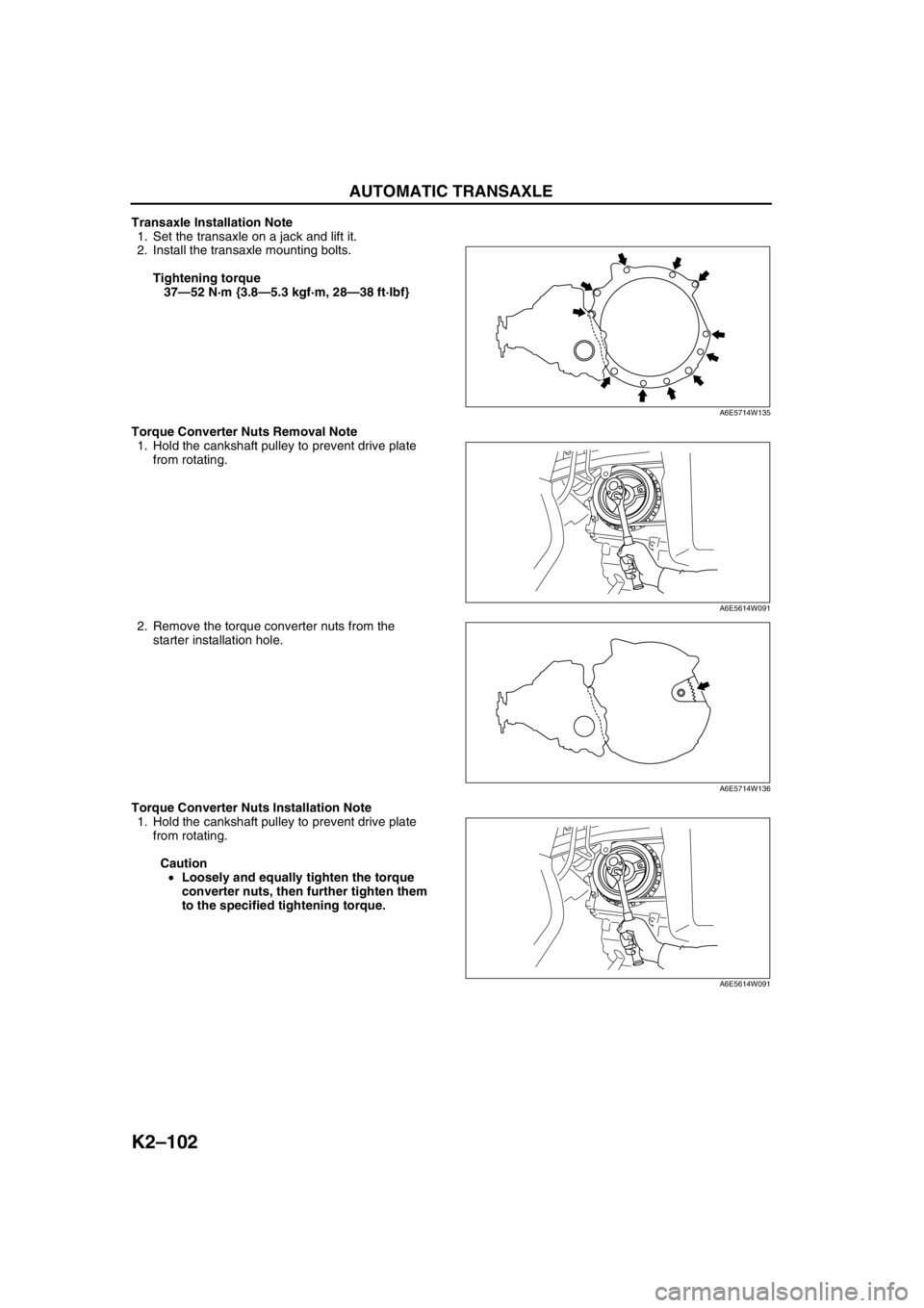

Transaxle Installation Note

1. Set the transaxle on a jack and lift it.

2. Install the transaxle mounting bolts.

Tightening torque

37—52 N·m {3.8—5.3 kgf·m, 28—38 ft·lbf}

Torque Converter Nuts Removal Note

1. Hold the cankshaft pulley to prevent drive plate

from rotating.

2. Remove the torque converter nuts from the

starter installation hole.

Torque Converter Nuts Installation Note

1. Hold the cankshaft pulley to prevent drive plate

from rotating.

Caution

•Loosely and equally tighten the torque

converter nuts, then further tighten them

to the specified tightening torque.

A6E5714W135

A6E5614W091

A6E5714W136

A6E5614W091

Page 518 of 909

AUTOMATIC TRANSAXLE

K2–103

K2

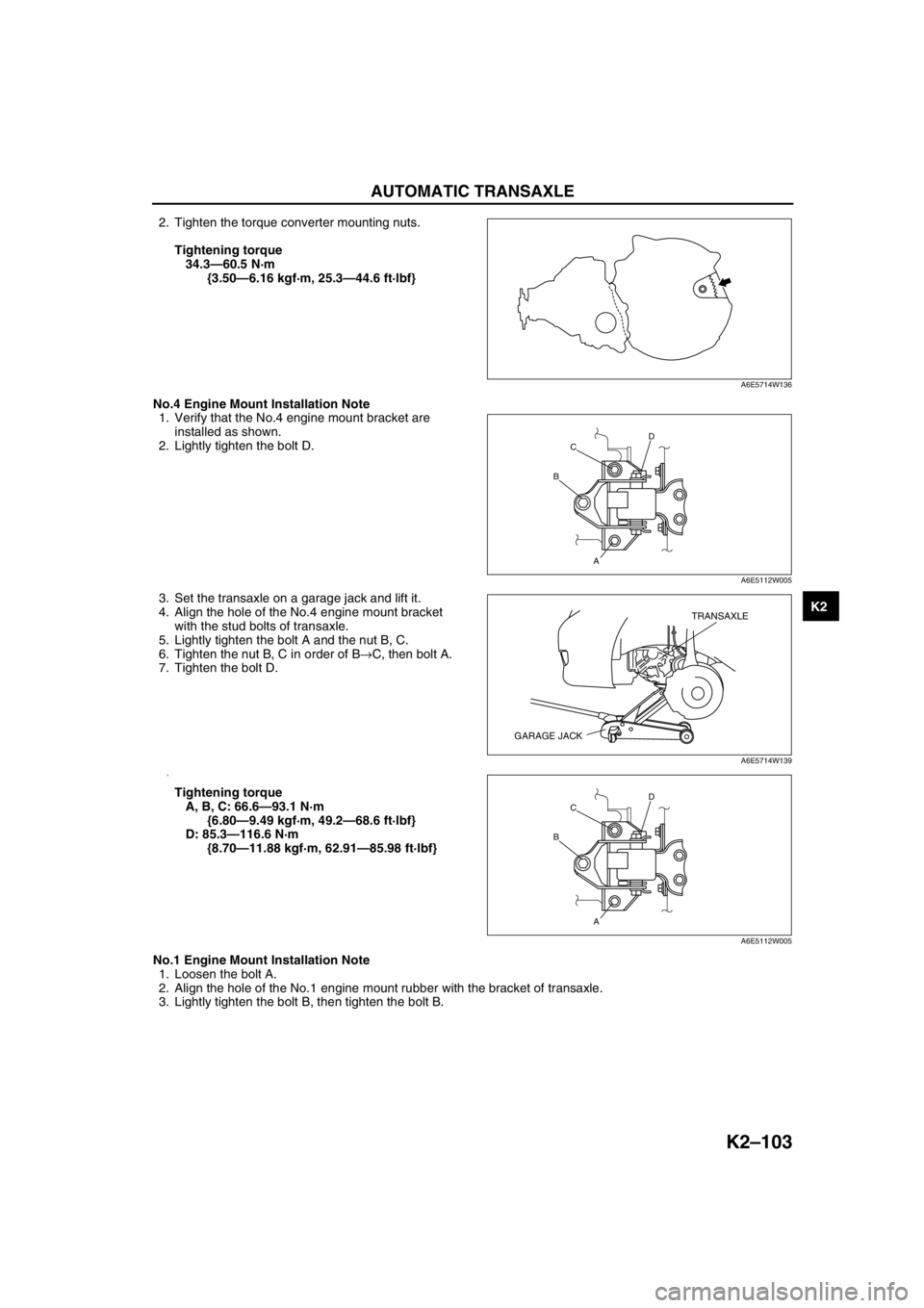

2. Tighten the torque converter mounting nuts.

Tightening torque

34.3—60.5 N·m

{3.50—6.16 kgf·m, 25.3—44.6 ft·lbf}

No.4 Engine Mount Installation Note

1. Verify that the No.4 engine mount bracket are

installed as shown.

2. Lightly tighten the bolt D.

3. Set the transaxle on a garage jack and lift it.

4. Align the hole of the No.4 engine mount bracket

with the stud bolts of transaxle.

5. Lightly tighten the bolt A and the nut B, C.

6. Tighten the nut B, C in order of B→C, then bolt A.

7. Tighten the bolt D.

8.

Tightening torque

A, B, C: 66.6—93.1 N·m

{6.80—9.49 kgf·m, 49.2—68.6 ft·lbf}

D: 85.3—116.6 N·m

{8.70—11.88 kgf·m, 62.91—85.98 ft·lbf}

No.1 Engine Mount Installation Note

1. Loosen the bolt A.

2. Align the hole of the No.1 engine mount rubber with the bracket of transaxle.

3. Lightly tighten the bolt B, then tighten the bolt B.

A6E5714W136

D

A BC

A6E5112W005

TRANSAXLE

GARAGE JACK

A6E5714W139

D

A BC

A6E5112W005

Page 519 of 909

K2–104

AUTOMATIC TRANSAXLE

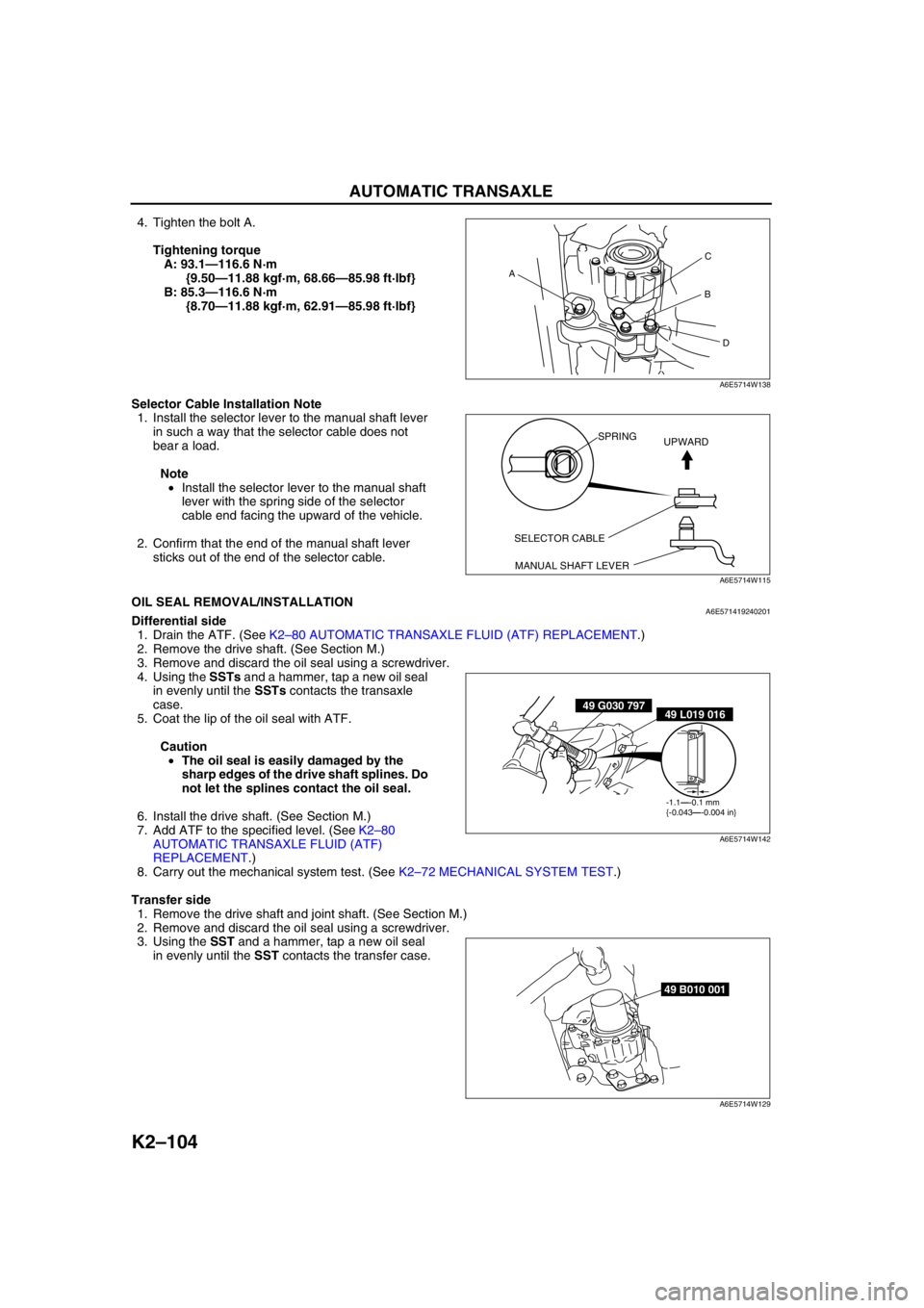

4. Tighten the bolt A.

Tightening torque

A: 93.1—116.6 N·m

{9.50—11.88 kgf·m, 68.66—85.98 ft·lbf}

B: 85.3—116.6 N·m

{8.70—11.88 kgf·m, 62.91—85.98 ft·lbf}

Selector Cable Installation Note

1. Install the selector lever to the manual shaft lever

in such a way that the selector cable does not

bear a load.

Note

•Install the selector lever to the manual shaft

lever with the spring side of the selector

cable end facing the upward of the vehicle.

2. Confirm that the end of the manual shaft lever

sticks out of the end of the selector cable.

End Of SieOIL SEAL REMOVAL/INSTALLATIONA6E571419240201Differential side

1. Drain the ATF. (See K2–80 AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT.)

2. Remove the drive shaft. (See Section M.)

3. Remove and discard the oil seal using a screwdriver.

4. Using the SSTs and a hammer, tap a new oil seal

in evenly until the SSTs contacts the transaxle

case.

5. Coat the lip of the oil seal with ATF.

Caution

•The oil seal is easily damaged by the

sharp edges of the drive shaft splines. Do

not let the splines contact the oil seal.

6. Install the drive shaft. (See Section M.)

7. Add ATF to the specified level. (See K2–80

AUTOMATIC TRANSAXLE FLUID (ATF)

REPLACEMENT.)

8. Carry out the mechanical system test. (See K2–72 MECHANICAL SYSTEM TEST.)

Transfer side

1. Remove the drive shaft and joint shaft. (See Section M.)

2. Remove and discard the oil seal using a screwdriver.

3. Using the SST and a hammer, tap a new oil seal

in evenly until the SST contacts the transfer case.

AC

B

D

A6E5714W138

SELECTOR CABLE

MANUAL SHAFT LEVERSPRING

UPWARD

A6E5714W115

49 G030 79749 L019 016

-1.1—-0.1 mm

{-0.043—-0.004 in}

A6E5714W142

49 B010 001

A6E5714W129

Page 520 of 909

AUTOMATIC TRANSAXLE

K2–105

K2

4. Coat the oil seal with transfer oil and grease as

shown in the figure.

Caution

•The oil seal is easily damaged by the

sharp edges of the drive shaft splines. Do

not let the splines contact the oil seal.

5. Install the drive shaft and joint shaft. (See Section

M.)

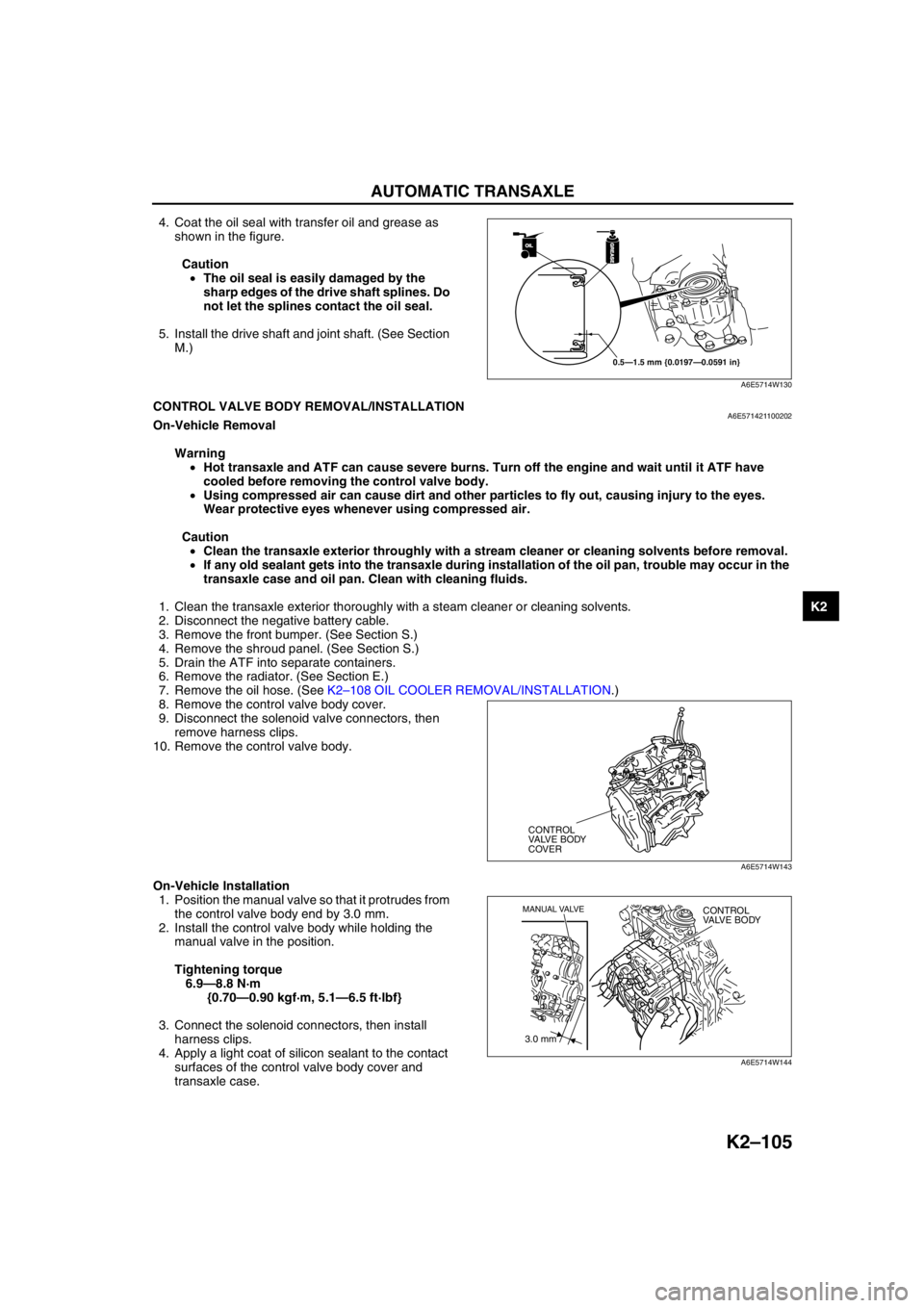

End Of SieCONTROL VALVE BODY REMOVAL/INSTALLATIONA6E571421100202On-Vehicle Removal

Warning

•Hot transaxle and ATF can cause severe burns. Turn off the engine and wait until it ATF have

cooled before removing the control valve body.

•Using compressed air can cause dirt and other particles to fly out, causing injury to the eyes.

Wear protective eyes whenever using compressed air.

Caution

•Clean the transaxle exterior throughly with a stream cleaner or cleaning solvents before removal.

•If any old sealant gets into the transaxle during installation of the oil pan, trouble may occur in the

transaxle case and oil pan. Clean with cleaning fluids.

1. Clean the transaxle exterior thoroughly with a steam cleaner or cleaning solvents.

2. Disconnect the negative battery cable.

3. Remove the front bumper. (See Section S.)

4. Remove the shroud panel. (See Section S.)

5. Drain the ATF into separate containers.

6. Remove the radiator. (See Section E.)

7. Remove the oil hose. (See K2–108 OIL COOLER REMOVAL/INSTALLATION.)

8. Remove the control valve body cover.

9. Disconnect the solenoid valve connectors, then

remove harness clips.

10. Remove the control valve body.

On-Vehicle Installation

1. Position the manual valve so that it protrudes from

the control valve body end by 3.0 mm.

2. Install the control valve body while holding the

manual valve in the position.

Tightening torque

6.9—8.8 N·m

{0.70—0.90 kgf·m, 5.1—6.5 ft·lbf}

3. Connect the solenoid connectors, then install

harness clips.

4. Apply a light coat of silicon sealant to the contact

surfaces of the control valve body cover and

transaxle case.

OILOIL

0.5—1.5 mm {0.0197—0.0591 in}

GREASEGREASE

A6E5714W130

CONTROL

VALVE BODY

COVER

A6E5714W143

3.0 mm

MANUAL VALVECONTROL

VALVE BODY

A6E5714W144