MAZDA 6 2002 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 531 of 909

K2–116

TRANSFER

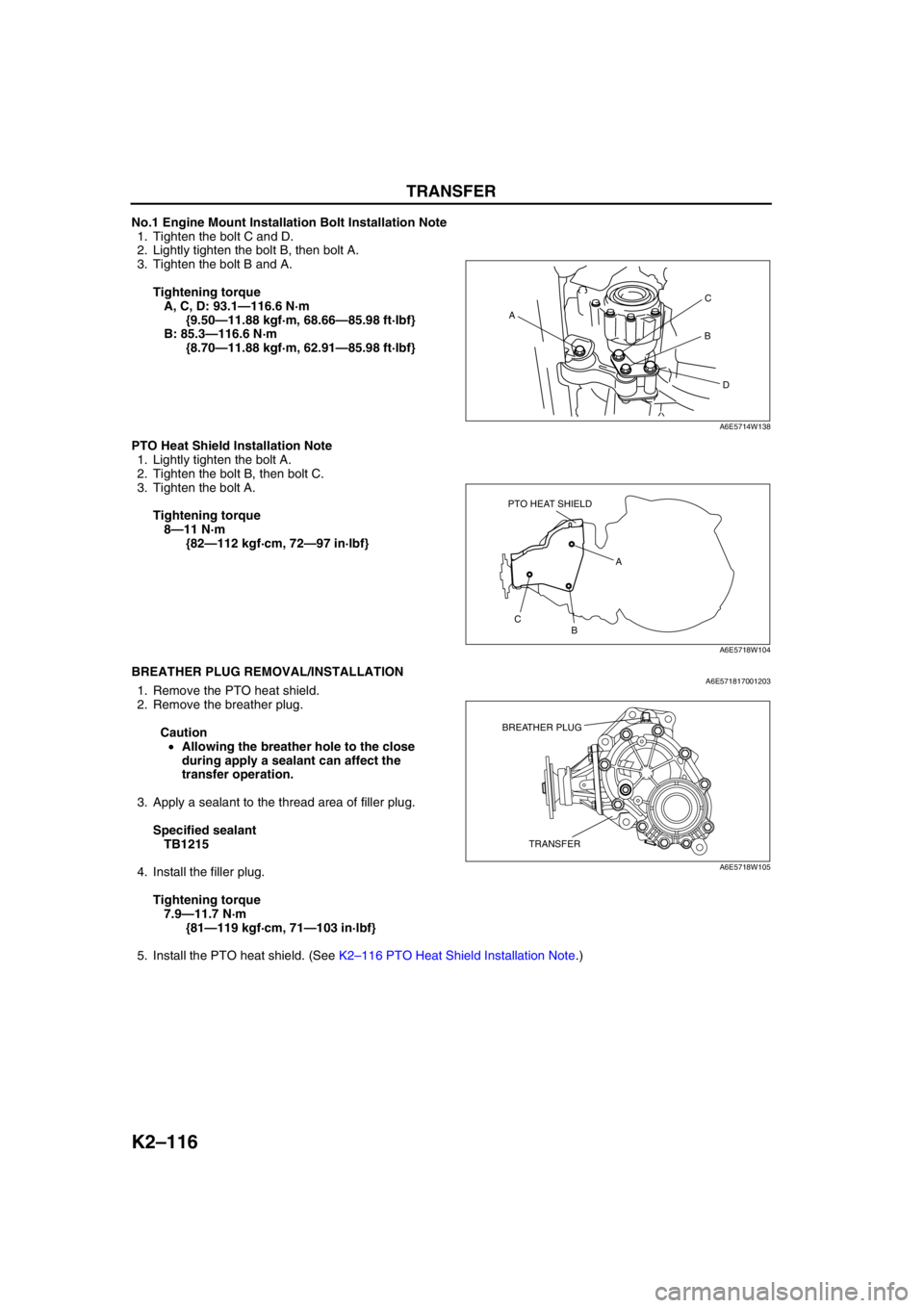

No.1 Engine Mount Installation Bolt Installation Note

1. Tighten the bolt C and D.

2. Lightly tighten the bolt B, then bolt A.

3. Tighten the bolt B and A.

Tightening torque

A, C, D: 93.1—116.6 N·m

{9.50—11.88 kgf·m, 68.66—85.98 ft·lbf}

B: 85.3—116.6 N·m

{8.70—11.88 kgf·m, 62.91—85.98 ft·lbf}

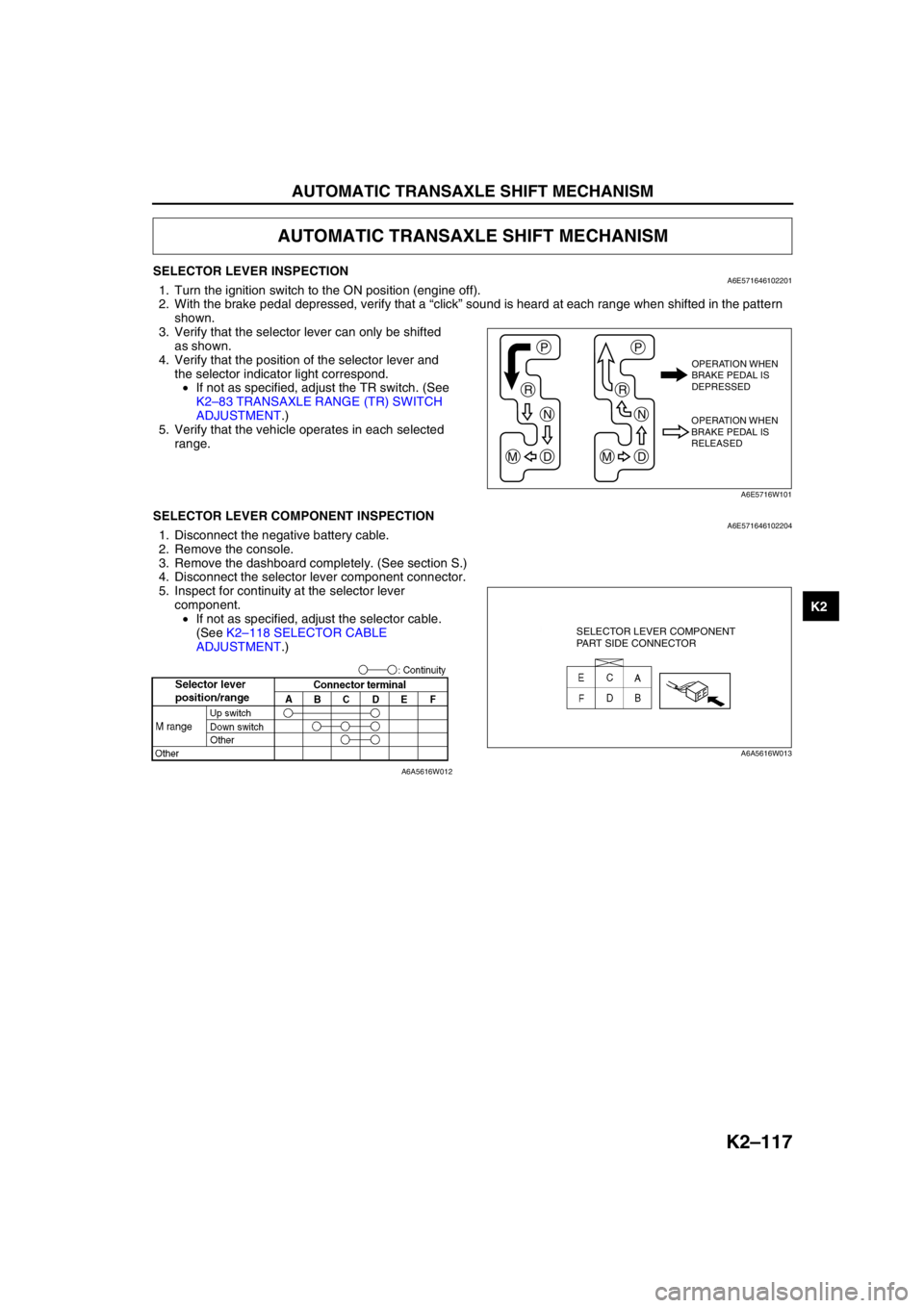

PTO Heat Shield Installation Note

1. Lightly tighten the bolt A.

2. Tighten the bolt B, then bolt C.

3. Tighten the bolt A.

Tightening torque

8—11 N·m

{82—112 kgf·cm, 72—97 in·lbf}

End Of SieBREATHER PLUG REMOVAL/INSTALLATIONA6E5718170012031. Remove the PTO heat shield.

2. Remove the breather plug.

Caution

•Allowing the breather hole to the close

during apply a sealant can affect the

transfer operation.

3. Apply a sealant to the thread area of filler plug.

Specified sealant

TB1215

4. Install the filler plug.

Tightening torque

7.9—11.7 N·m

{81—119 kgf·cm, 71—103 in·lbf}

5. Install the PTO heat shield. (See K2–116 PTO Heat Shield Installation Note.)

End Of Sie

AC

B

D

A6E5714W138

PTO HEAT SHIELD

A

B C

A6E5718W104

TRANSFER BREATHER PLUG

A6E5718W105

Page 532 of 909

AUTOMATIC TRANSAXLE SHIFT MECHANISM

K2–117

K2

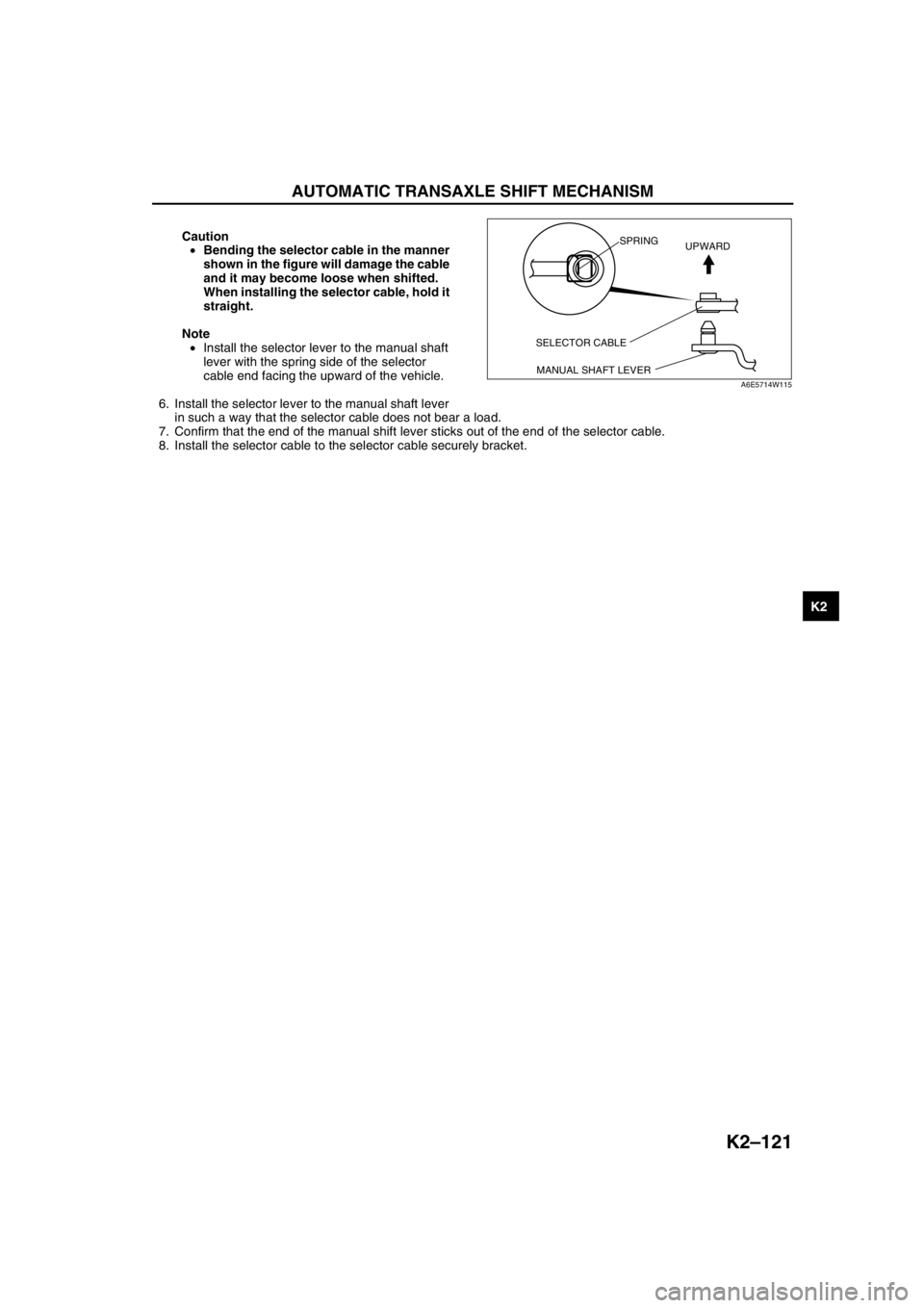

SELECTOR LEVER INSPECTIONA6E5716461022011. Turn the ignition switch to the ON position (engine off).

2. With the brake pedal depressed, verify that a “click” sound is heard at each range when shifted in the pattern

shown.

3. Verify that the selector lever can only be shifted

as shown.

4. Verify that the position of the selector lever and

the selector indicator light correspond.

•If not as specified, adjust the TR switch. (See

K2–83 TRANSAXLE RANGE (TR) SWITCH

ADJUSTMENT.)

5. Verify that the vehicle operates in each selected

range.

End Of SieSELECTOR LEVER COMPONENT INSPECTIONA6E5716461022041. Disconnect the negative battery cable.

2. Remove the console.

3. Remove the dashboard completely. (See section S.)

4. Disconnect the selector lever component connector.

5. Inspect for continuity at the selector lever

component.

•If not as specified, adjust the selector cable.

(See K2–118 SELECTOR CABLE

ADJUSTMENT.)

End Of Sie

AUTOMATIC TRANSAXLE SHIFT MECHANISM

P

R

N

DM

P

R

N

DM

OPERATION WHEN

BRAKE PEDAL IS

DEPRESSED

OPERATION WHEN

BRAKE PEDAL IS

RELEASED

A6E5716W101

SELECTOR LEVER COMPONENT

PART SIDE CONNECTOR

A6A5616W013

A6A5616W012

Page 533 of 909

K2–118

AUTOMATIC TRANSAXLE SHIFT MECHANISM

SELECTOR CABLE ADJUSTMENTA6E5716465002011. Remove the center console.

2. Shift the selector lever to P position.

3. Unlock the lock piece of the selector cable

(selector lever side) in the order shown in the

figure.

4. Verify that the manual shaft is in P position.

5. Lock the lock piece of the selector cable (selector

lever side) in the order shown in the figure.

6. Install the center console.

7. Shift the selector lever from P position to M range,

and make sure that there are no other

components in that area to interfere with the lever.

End Of Sie

1

2

SAFETY

LOCK

LOCK PIECE

A6E5716W102

2

1

SAFETY

LOCK

LOCK PIECE

A6E5716W103

Page 534 of 909

AUTOMATIC TRANSAXLE SHIFT MECHANISM

K2–119

K2

SELECTOR LEVER REMOVAL/INSTALLATIONA6E5716461022021. Disconnect the negative battery cable.

2. Remove the battery and battery tray.

3. Remove the air cleaner compornent. (See Section F.)

4. Remove the console.

5. Remove the dashboard compleat. (See Section S.)

6. Remove the SAS control module. (See Section T.)

7. Remove the climate control unit. (See Section U.)

8. Remove the rear heat duct. (See Section U.)

9. Remove in the order shown in the figure.

10. Install in the reverse order of removal.

.

1

2

A

A

B

15.68—22.5

{1.60—2.29, 11.6—16.5}

B6.86—9.8 N·m

{70—99 kgf·cm, 61—86 in·lbf}

N·m {kgf·m, ft·lbf}

A6E5716W104

1 Selector cable

(See K2–120 Selector Cable Removal Note.)

(See K2–120 Selector Cable Installation Note.)2Selector lever

Page 535 of 909

K2–120

AUTOMATIC TRANSAXLE SHIFT MECHANISM

Selector Cable Removal Note

1. Remove the spring.

2. Remove the selector cable.

Selector Cable Installation Note

1. Install the selector cable to the selector lever certainly.

2. Install the selector cable to the bracket certainly.

Note

•Step 3, 4 is for the selector cable

replacement only.

3. Verify that the selector lever is in P position.

4. Lock the lock piece of the selector cable (selector

lever side) in the order shown in the figure.

5. Verify that the manual shaft is in P position.

SPRING SELECTOR CABLE

A6E5716W105

SELECTOR CABLE

A6E5616W020

2

1

SAFETY

LOCK

LOCK PIECE

A6E5716W103

DO NOT BEND

A6E5616W007

Page 536 of 909

AUTOMATIC TRANSAXLE SHIFT MECHANISM

K2–121

K2

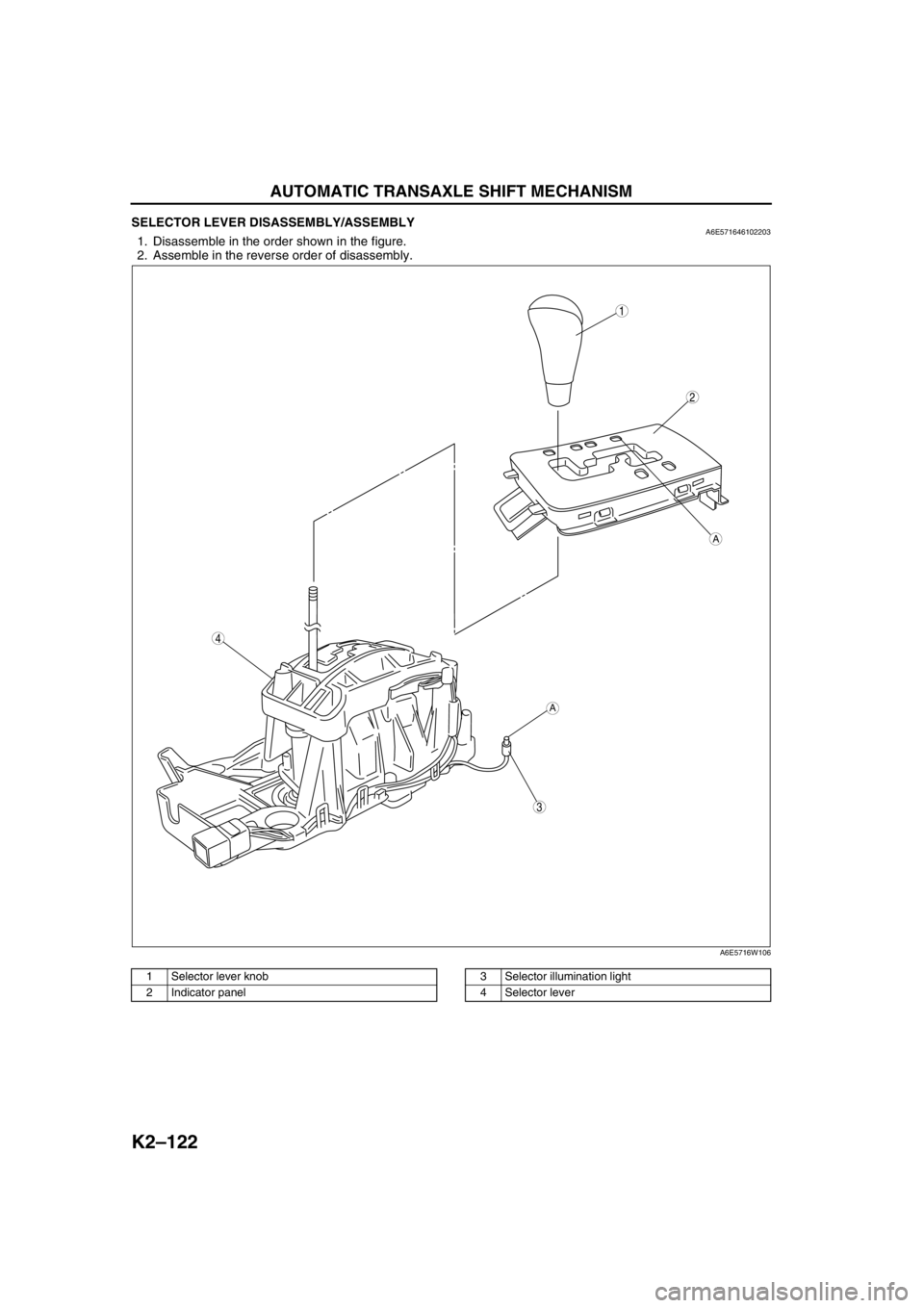

Caution

•Bending the selector cable in the manner

shown in the figure will damage the cable

and it may become loose when shifted.

When installing the selector cable, hold it

straight.

Note

•Install the selector lever to the manual shaft

lever with the spring side of the selector

cable end facing the upward of the vehicle.

6. Install the selector lever to the manual shaft lever

in such a way that the selector cable does not bear a load.

7. Confirm that the end of the manual shift lever sticks out of the end of the selector cable.

8. Install the selector cable to the selector cable securely bracket.

End Of Sie

SELECTOR CABLE

MANUAL SHAFT LEVERSPRING

UPWARD

A6E5714W115

Page 537 of 909

K2–122

AUTOMATIC TRANSAXLE SHIFT MECHANISM

SELECTOR LEVER DISASSEMBLY/ASSEMBLYA6E5716461022031. Disassemble in the order shown in the figure.

2. Assemble in the reverse order of disassembly.

.

End Of Sie

3

A

A

2

1

4

A6E5716W106

1 Selector lever knob

2 Indicator panel3 Selector illumination light

4 Selector lever

Page 538 of 909

ON-BOARD DIAGNOSTIC

K2–123

K2

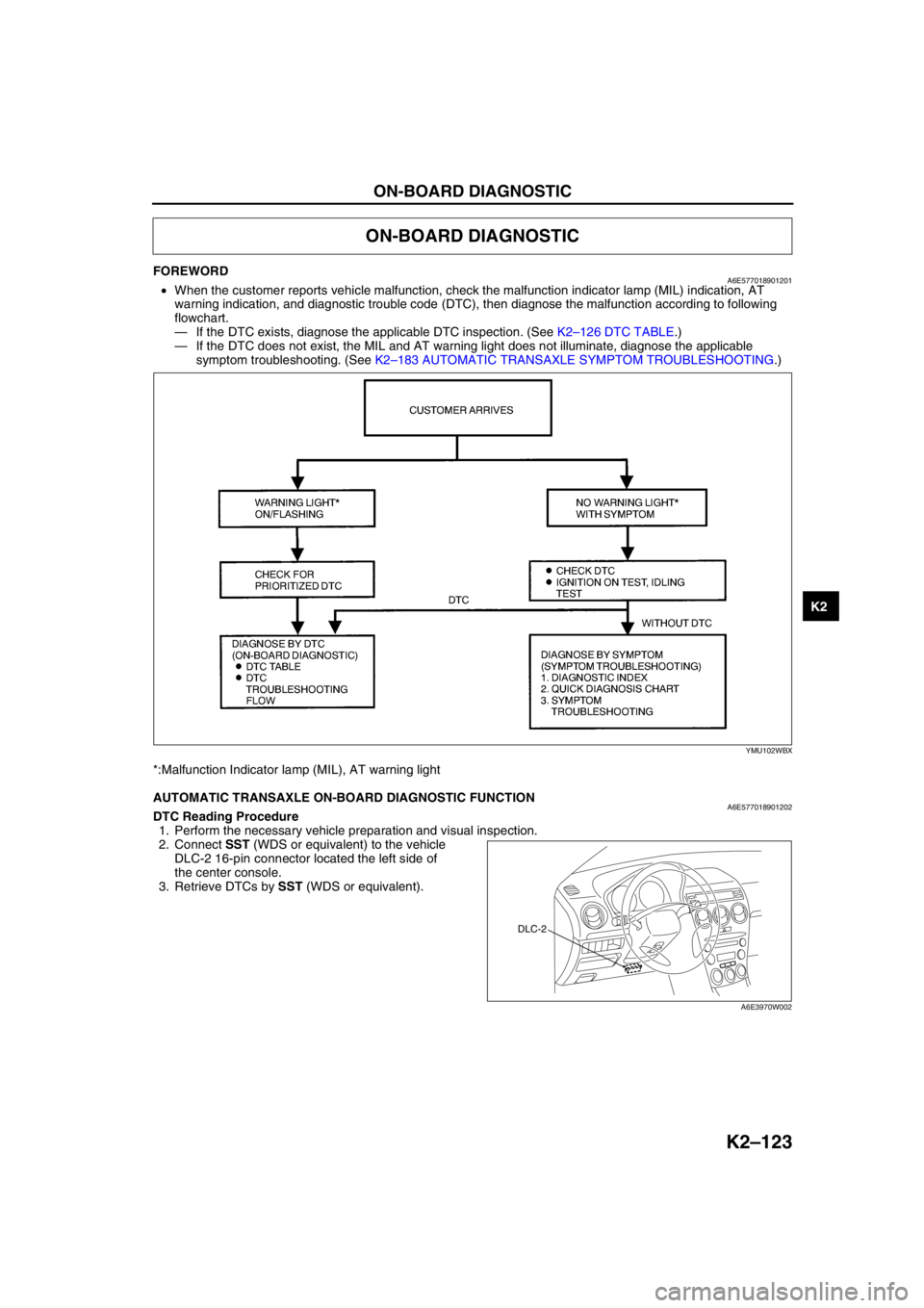

FOREWORDA6E577018901201•When the customer reports vehicle malfunction, check the malfunction indicator lamp (MIL) indication, AT

warning indication, and diagnostic trouble code (DTC), then diagnose the malfunction according to following

flowchart.

—If the DTC exists, diagnose the applicable DTC inspection. (See K2–126 DTC TABLE.)

—If the DTC does not exist, the MIL and AT warning light does not illuminate, diagnose the applicable

symptom troubleshooting. (See K2–183 AUTOMATIC TRANSAXLE SYMPTOM TROUBLESHOOTING.)

*:Malfunction Indicator lamp (MIL), AT warning light

End Of Sie

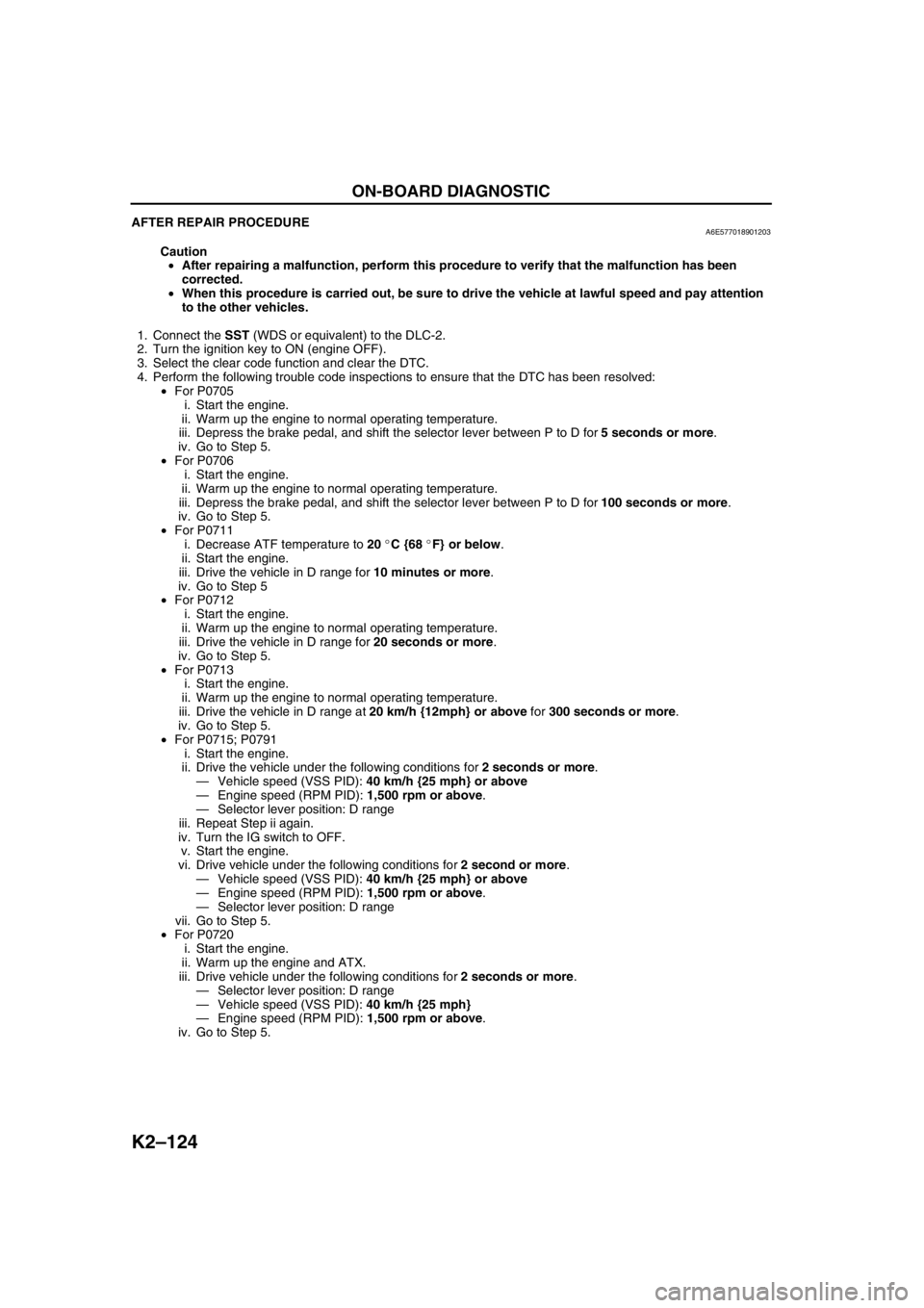

AUTOMATIC TRANSAXLE ON-BOARD DIAGNOSTIC FUNCTIONA6E577018901202DTC Reading Procedure

1. Perform the necessary vehicle preparation and visual inspection.

2. Connect SST (WDS or equivalent) to the vehicle

DLC-2 16-pin connector located the left side of

the center console.

3. Retrieve DTCs by SST (WDS or equivalent).

End Of Sie

ON-BOARD DIAGNOSTIC

YMU102WBX

DLC-2

A6E3970W002

Page 539 of 909

K2–124

ON-BOARD DIAGNOSTIC

AFTER REPAIR PROCEDUREA6E577018901203

Caution

•After repairing a malfunction, perform this procedure to verify that the malfunction has been

corrected.

•When this procedure is carried out, be sure to drive the vehicle at lawful speed and pay attention

to the other vehicles.

1. Connect the SST (WDS or equivalent) to the DLC-2.

2. Turn the ignition key to ON (engine OFF).

3. Select the clear code function and clear the DTC.

4. Perform the following trouble code inspections to ensure that the DTC has been resolved:

•For P0705

i. Start the engine.

ii. Warm up the engine to normal operating temperature.

iii. Depress the brake pedal, and shift the selector lever between P to D for 5 seconds or more.

iv. Go to Step 5.

•For P0706

i. Start the engine.

ii. Warm up the engine to normal operating temperature.

iii. Depress the brake pedal, and shift the selector lever between P to D for 100 seconds or more.

iv. Go to Step 5.

•For P0711

i. Decrease ATF temperature to 20 °C {68 °F} or below.

ii. Start the engine.

iii. Drive the vehicle in D range for 10 minutes or more.

iv. Go to Step 5

•For P0712

i. Start the engine.

ii. Warm up the engine to normal operating temperature.

iii. Drive the vehicle in D range for 20 seconds or more.

iv. Go to Step 5.

•For P0713

i. Start the engine.

ii. Warm up the engine to normal operating temperature.

iii. Drive the vehicle in D range at 20 km/h {12mph} or above for 300 seconds or more.

iv. Go to Step 5.

•For P0715; P0791

i. Start the engine.

ii. Drive the vehicle under the following conditions for 2 seconds or more.

—Vehicle speed (VSS PID): 40 km/h {25 mph} or above

—Engine speed (RPM PID): 1,500 rpm or above.

—Selector lever position: D range

iii. Repeat Step ii again.

iv. Turn the IG switch to OFF.

v. Start the engine.

vi. Drive vehicle under the following conditions for 2 second or more.

—Vehicle speed (VSS PID): 40 km/h {25 mph} or above

—Engine speed (RPM PID): 1,500 rpm or above.

—Selector lever position: D range

vii. Go to Step 5.

•For P0720

i. Start the engine.

ii. Warm up the engine and ATX.

iii. Drive vehicle under the following conditions for 2 seconds or more.

—Selector lever position: D range

—Vehicle speed (VSS PID): 40 km/h {25 mph}

—Engine speed (RPM PID): 1,500 rpm or above.

iv. Go to Step 5.

Page 540 of 909

ON-BOARD DIAGNOSTIC

K2–125

K2

•For P0740

i. Start the engine.

ii. Warm up the engine and ATX.

iii. Drive vehicle under the following conditions for 10 seconds or more.

—Vehicle speed (VSS PID): 76 km/h {47 mph}

—Selector lever position: D range

—TCC operating

iv. Go to Step 5.

•For P0743

i. Start the engine.

ii. Warm up the engine and ATX.

iii. Drive the vehicle in D range and make sure that the gears shift smoothly from 1GR to 5GR and TCC is

operated.

iv. Go to Step 5.

•For P0748, P0751, P0752, P0753, P0756, P0757, P0758, P0761, P0762, P0763, P0768, P0773, P0778,

P0798, P1710, PC073, PC100

i. Start the engine.

ii. Warm up the engine and ATX.

iii. Drive the vehicle in D range and make sure that the gears shift smoothly from 1GR to 5GR.

iv. Go to Step 5.

5. Gradually slow down and stop the vehicle.

6. Make sure that the repaired DTC does not recur.

End Of Sie