MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 991 of 1865

INSPECTION AND REPAIR 7B

5. Install the snap ring.

86U07B-232

86U07B-233

6. Check that when the small sun gear is held, the

one-way clutch outer race turns smoothly and only

clockwise.

7. Apply petroleum jelly to the thrust bearing to se-

cure it; then install it to the sun gear drum.

Thrust bearing outer diameter:

72.0 mm (2.83 in)

86U07B-234

7B—125

Page 992 of 1865

7B INSPECTION AND REPAIR

ONE-WAY CLUTCH AND CARRIER HUB ASSEMBLY

Disassembly

Disassemble in the sequence shown in the figure.

1. One-way clutch

2. Bearing races

3. Snap ring

4. Carrier hub as-

sembly

5. Inner race (Low

and reverse hub)

86U07B-235

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn gear and operation

2. Clearance between pinion washer and planetary

carrier

Clearance:

0.2—0.7 mm (0.008—0.028 in)

86U07B-236

3. Damaged or worn inner race

4. Broken or worn snap ring

5. Damaged or worn bearing race

86U07B-237

7B-126

Page 993 of 1865

INSPECTION AND REPAIR 7B

One-way clutch 6. Damaged or worn one-way clutch and operation

7. Detached roller

Note

Assemble the one-way clutch and the inner

race, then confirm that the one-way clutch ro-

tates only clockwise and smoothly.

86U07B-238

Assembly

1. Assemble the carrier hub assembly to the inner

race.

86U07B-239

2. Install th snap ring.

86U07B-240

3. Apply petroleum jelly to the bearing races to se-

cure them; then install them to both sides of the

one-way clutch and carrier hub assembly.

Bearing race outer diameter

Sun gear drum side: 72.0 mm (2.83 in)

3-4 clutch side: 57.0 mm (2.21 in)

Note

Install the tabs of the bearing race into the

alignment holes.

86U07B-241

7B—127

Page 994 of 1865

7B INSPECTION AND REPAIR

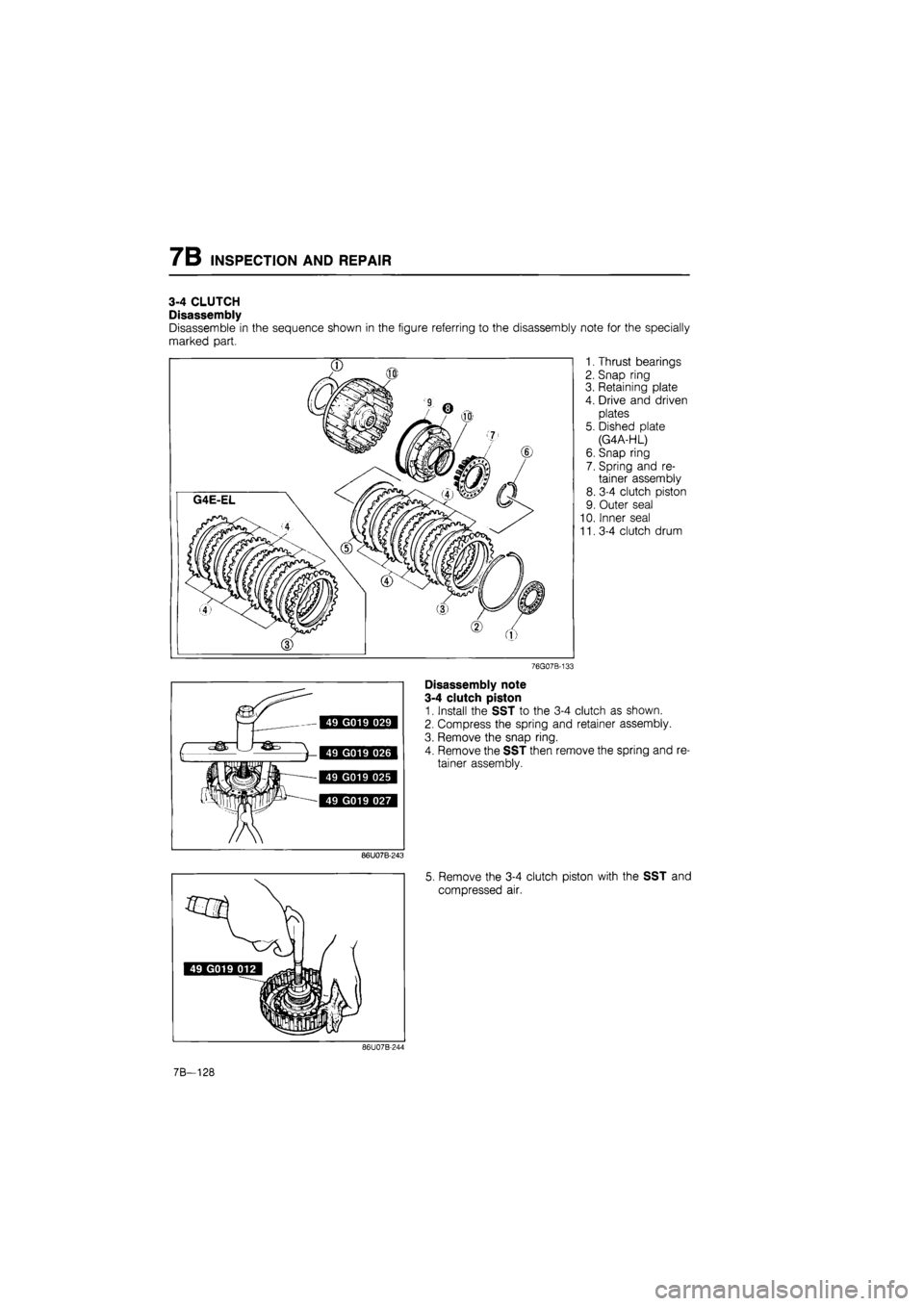

3-4 CLUTCH

Disassembly

Disassemble in the sequence shown in the figure referring to the disassembly note for the specially

marked part.

1. Thrust bearings

2. Snap ring

3. Retaining plate

4. Drive and driven

plates

5. Dished plate

(G4A-HL)

6. Snap ring

7. Spring and re-

tainer assembly

8. 3-4 clutch piston

9. Outer seal

10. Inner seal

11.3-4 clutch drum

76G07B-133

Disassembly note

3-4 clutch piston

1. Install the SST to the 3-4 clutch as shown.

2. Compress the spring and retainer assembly.

3. Remove the snap ring.

4. Remove the SST then remove the spring and re-

tainer assembly.

86U07B-243

5. Remove the 3-4 clutch piston with the SST and

compressed air.

86U07B-244

7B—128

Page 995 of 1865

INSPECTION AND REPAIR 7B

86U07B-245

SB T

g. SH -i

1

Inspection

Check the following and repair or replace any faulty

parts.

1. Drive and driven plates for damage or wear

Drive plate thickness

Standard: 1.6 mm (0.063 in)

Minimum: 1.4 mm (0.055 in)

2. Clutch piston for damage or cracks

3. Clutch drum for damage or deformation

4. Seal contact areas for damage

5. Check ball for leaking or sticking

6. Spring and retainer assembly for separation or

deformation

7. Broken or worn snap ring

8. Broken or weakened spring

Free length of spring:

33.2 mm (1.307 in)

86U07B-246

Assembly

1. Install the 3-4 clutch piston.

(1) Apply ATF to the inner and outer seals, and

install them onto the 3-4 clutch piston.

(2) Install the piston by pushing evenly around the

circumference, being careful not to damage the

seal rings.

86U07B-247

2. Install the spring and retainer assembly.

86U07B-248

7B—129

Page 996 of 1865

7B INSPECTION AND REPAIR

3. Install the SST to the 3-4 clutch as shown.

4. Compress the spring and retainer assembly.

5. Install the snap ring.

6. Remove the SST.

86U07B-249

G4A-EL G4A-HL

76G07B-134

76G07B-135

7. Install the dished plate the dished side up ward

(G4A-HL).

8. Install the drive and driven plates.

Note

Installation order:

G4A-EL

Driven-Drive-Driven-Drive-Driven-Drive-

Driven-Drive-Driven-Drive

G4A-HL

Driven-Drive-Driven-Drive-Driven-Drive-

Driven-Drive

9. Install the retaining plate with the step facing

upward.

10. Install the snap ring.

11. Check the 3-4 clutch clearance.

(1) Measure the clearance between the snap ring

and the retaining plate of the 3-4 clutch.

(2) If the clearance is not within specification, ad-

just it by selecting a proper retaining plate.

3-4 clutch clearance:

1.3—1.5 mm (0.051—0.059 in)

Retaining plate sizes

G4A-EL

mm (in)

3.8 (0.150) 4.0 (0.157) 4.2 (0.165)

4.4 (0.173) 4.6 (0.181) 4.8 (0.189)

G4A-HL

4.8 (0.189) 5.0 (0.197) 5.2 (0.205)

5.4 (0.213) 5.6 (0.220)

12. Check clutch operation as follows:

(1) Install the SST as shown, and check clutch

operation by applying compressed air.

Air pressure:

392 kPa (4.0 kg/cm2, 57 psi)

76G07B-136

7B-130

Page 997 of 1865

INSPECTION AND REPAIR 7B

(2) Pour ATF into the clutch drum so that the 3-4

clutch piston is fully submerged.

(3) Check that no bubbles come from the 3-4

clutch piston seal while applying compressed

air.

Caution

The compressed air must be under 392 kPa

(4.0 kg/cm2, 57 psi) and not applied for over

3 seconds.

86U07B-253

13. Apply petroleum jelly to the thrust bearings and se-

cure them to both sides of the 3-4 clutch drum.

Thrust bearing outer diameter

Carrier hub side: 56.1 mm (2.21 in)

Output shell side: 72.1 mm (2.84 in)

76G07B-137

7B—131

Page 998 of 1865

7B INSPECTION AND REPAIR

2-3 ACCUMULATOR

Disassembly

Disassemble in the sequence shown in the figure.

1. Snap ring

2. Stopper plug

3. O-ring

4. 2-3 accumulator

spring

5. 2-3 accumulator

piston

6. Large seal ring

7. Small sea ring

86U07B-255

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn piston

2. Damaged or worn stopper plug

3. Broken or weakened spring

Free length of spring:

G4A-EL 83.3 mm (3.280 in)

G4A-HL 76.0 mm (2.992 in)

76G07B-138

Assembly

1. Install the 2-3 accumulator.

(1) Apply ATF to large and small seal rings; then

install them to the accumulator piston.

(2) Insert the 2-3 accumulator.

86U07B-257

7B—132

Page 999 of 1865

INSPECTION AND REPAIR 7B

2. Install the spring to the piston.

3. Install the stopper plug.

(1) Apply ATF to O-ring, and install it onto the stop-

per plug.

(2) Install the stopper plug.

86U07B-258

4. Install the snap ring while holding in the stopper

plug.

86U07B-259

GOVERNOR ASSEMBLY (G4A-HL)

Disassembly

Disassemble in the sequence shown in the figure

referring to the disassembly note for the specially

marked part.

1. Roll pin

2. Governor driven gear

3. Governor valve

4. Governor carrier and sleeve

76G07B-139

Disassembly note

Roll pin

1. Secure the governor assembly in a vise.

Note

Use the protective plates to prevent damage

to the governor assembly.

2. Remove the roll pin from the governor assembly.

83U07B-266

7B-133

Page 1000 of 1865

7B INSPECTION AND REPAIR

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn governor gear

2. Damaged or worn governor valve

3. Cracked or damaged governor carrier and sleeve

83U07B-267

Assembly

1. Insert the governor valve to the governor carrier

and sleeve.

2. Install the governor driven gear.

3. Install the roll pin.

83U07B-268

86U07B-260

LOW AND REVERSE BRAKE

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn drive and driven plates

Drive plate thickness

Standard: 1.6 mm (0.063 in)

Minimum: 1.4 mm (0.055 in)

2. Broken or worn snap ring

3. Deformed or detached spring and retainer as-

sembly

4. Broken or weakened spring

Free length of spring:

20.5 mm (0.807 in)

5. Damaged or worn piston

6. Damaged seal contact area of transaxle case

7B—134 expert22 fl/m http://rutracker.org