MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1221 of 1865

ASSEMBLY 7C

76G07C-279

76G07C-280

76G07C-281

Procedure

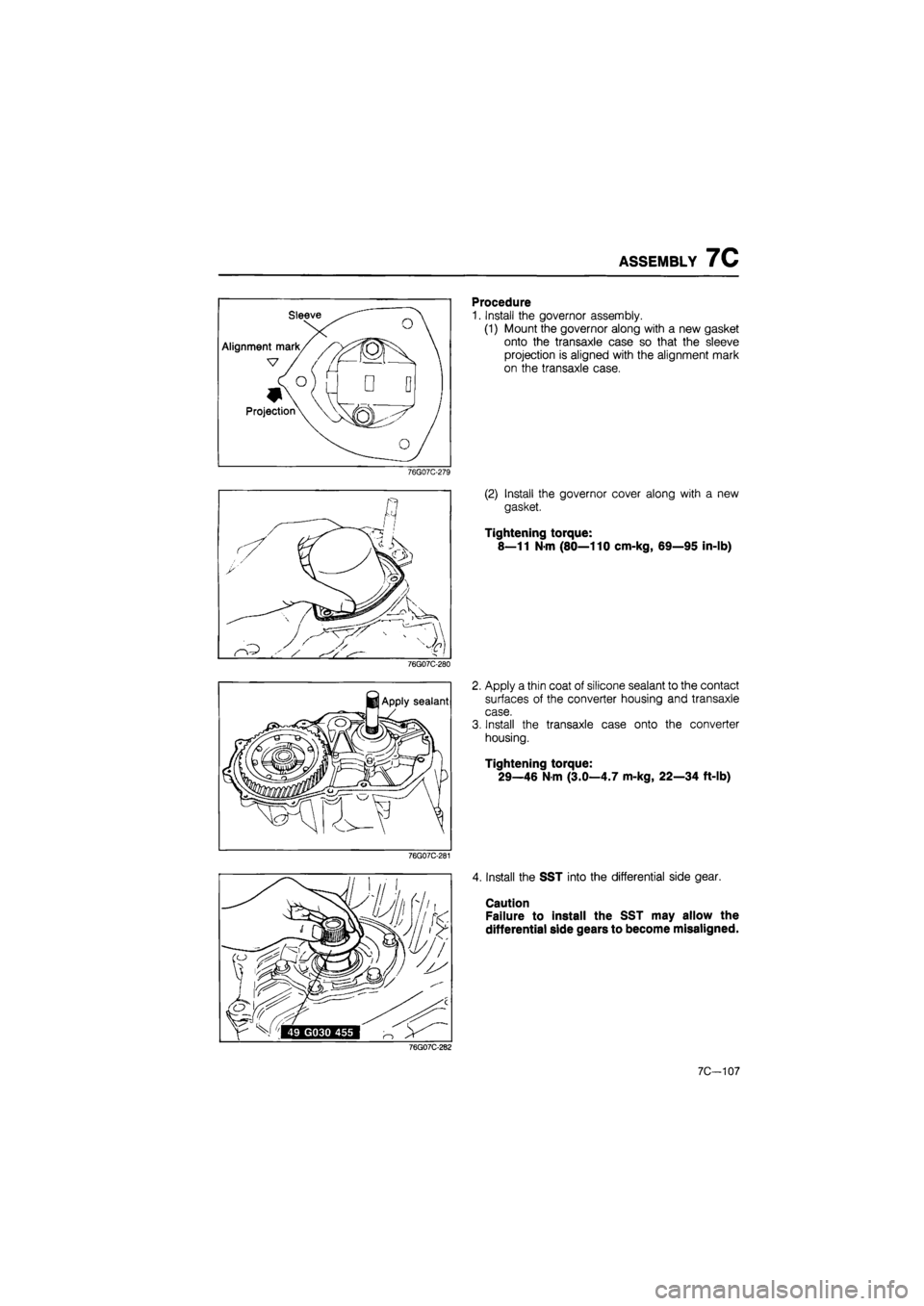

1. Install the governor assembly.

(1) Mount the governor along with a new gasket

onto the transaxle case so that the sleeve

projection is aligned with the alignment mark

on the transaxle case.

(2) Install the governor cover along with a new

gasket.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

2. Apply a thin coat of silicone sealant to the contact

surfaces of the converter housing and transaxle

case.

3. Install the transaxle case onto the converter

housing.

Tightening torque:

29—46 N-m (3.0—4.7 m-kg, 22—34 ft-lb)

4. Install the SST into the differential side gear.

Caution

Failure to install the SST may allow the

differential side gears to become misaligned.

76G07C-282

7C-107

Page 1222 of 1865

7C ASSEMBLY

76G07C-283

76G07C-284

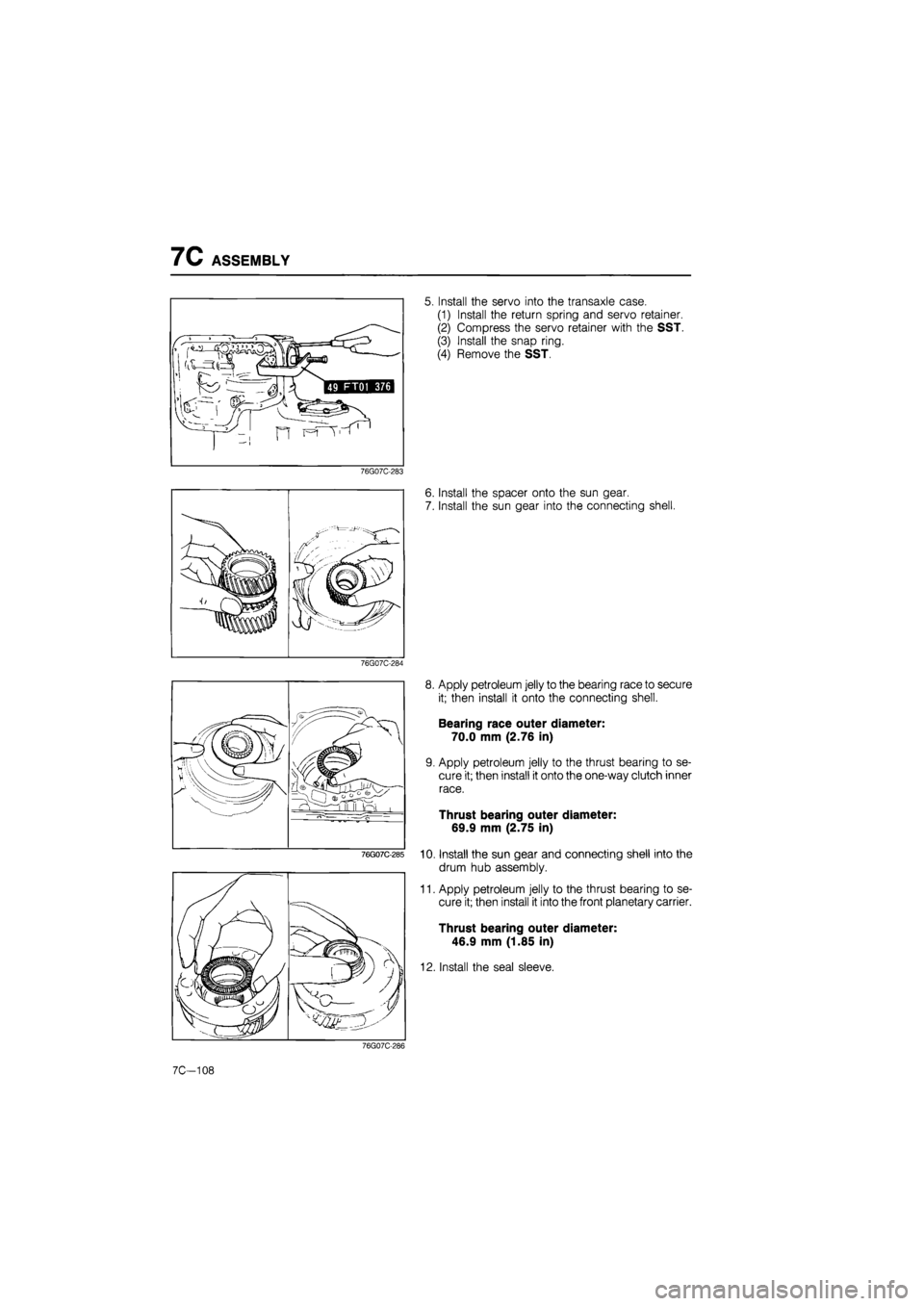

5. Install the servo into the transaxle case.

(1) Install the return spring and servo retainer.

(2) Compress the servo retainer with the SST.

(3) Install the snap ring.

(4) Remove the SST.

6. Install the spacer onto the sun gear.

7. Install the sun gear into the connecting shell.

8. Apply petroleum jelly to the bearing race to secure

it; then install it onto the connecting shell.

Bearing race outer diameter:

70.0 mm (2.76 in)

9. Apply petroleum jelly to the thrust bearing to se-

cure it; then install it onto the one-way clutch inner

race.

Thrust bearing outer diameter:

69.9 mm (2.75 in)

76G07C-285 10. Install the sun gear and connecting shell into the

drum hub assembly.

11. Apply petroleum jelly to the thrust bearing to se-

cure it; then install it into the front planetary carrier.

Thrust bearing outer diameter:

46.9 mm (1.85 in)

12. Install the seal sleeve.

76G07C-286

7C—108

Page 1223 of 1865

ASSEMBLY 7C

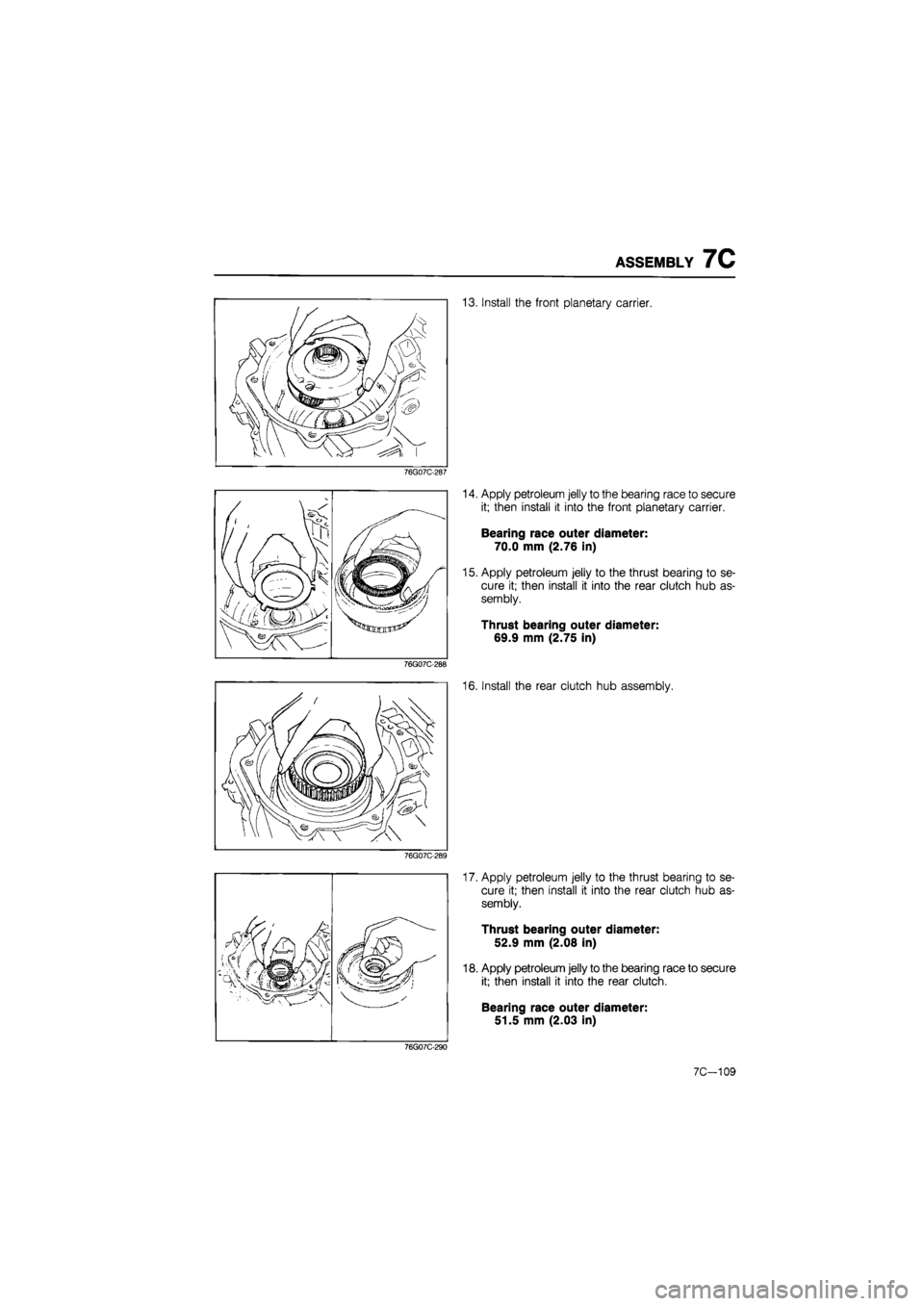

13. Install the front planetary carrier.

76G07C-287

MP"

^tlTrfnnnr®^

76G07C-288

14. Apply petroleum jelly to the bearing race to secure

it; then install it into the front planetary carrier.

Bearing race outer diameter:

70.0 mm (2.76 in)

15. Apply petroleum jelly to the thrust bearing to se-

cure it; then install it into the rear clutch hub as-

sembly.

Thrust bearing outer diameter:

69.9 mm (2.75 in)

16. Install the rear clutch hub assembly.

76G07C-289

m

i?

17. Apply petroleum jelly to the thrust bearing to se-

cure it; then install it into the rear clutch hub as-

sembly.

Thrust bearing outer diameter:

52.9 mm (2.08 in)

18. Apply petroleum jelly to the bearing race to secure

it; then install it into the rear clutch.

Bearing race outer diameter:

51.5 mm (2.03 in)

76G07C-290

7C-109

Page 1224 of 1865

7C ASSEMBLY

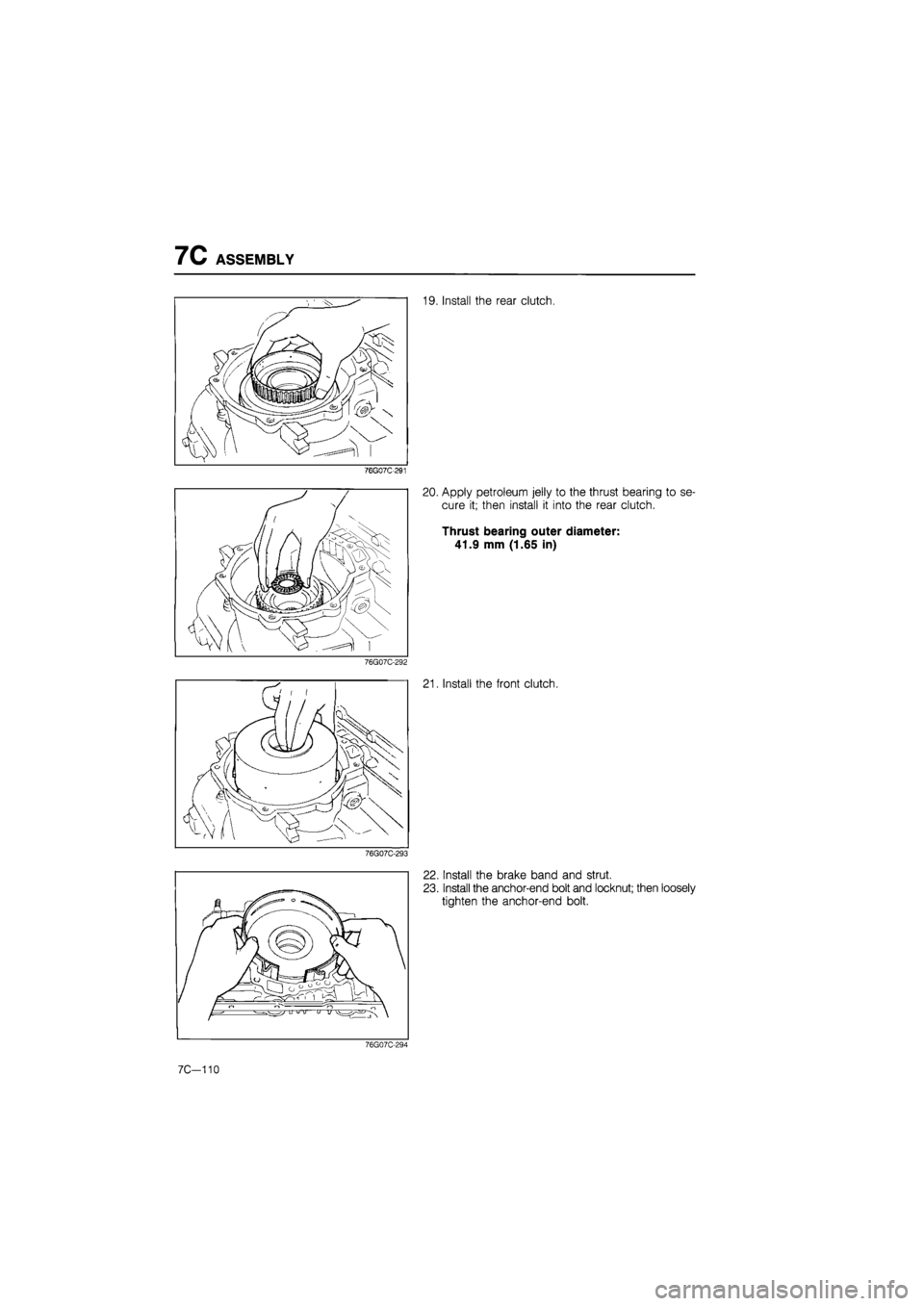

19. Install the rear clutch.

76G07C-291

76G07C-292

20. Apply petroleum jelly to the thrust bearing to se-

cure it; then install it into the rear clutch.

Thrust bearing outer diameter:

41.9 mm (1.65 in)

21. Install the front clutch.

76G07C-293

22. Install the brake band and strut.

23. Install the anchor-end bolt and locknut; then loosely

tighten the anchor-end bolt.

76G07C-294

7C-110

Page 1225 of 1865

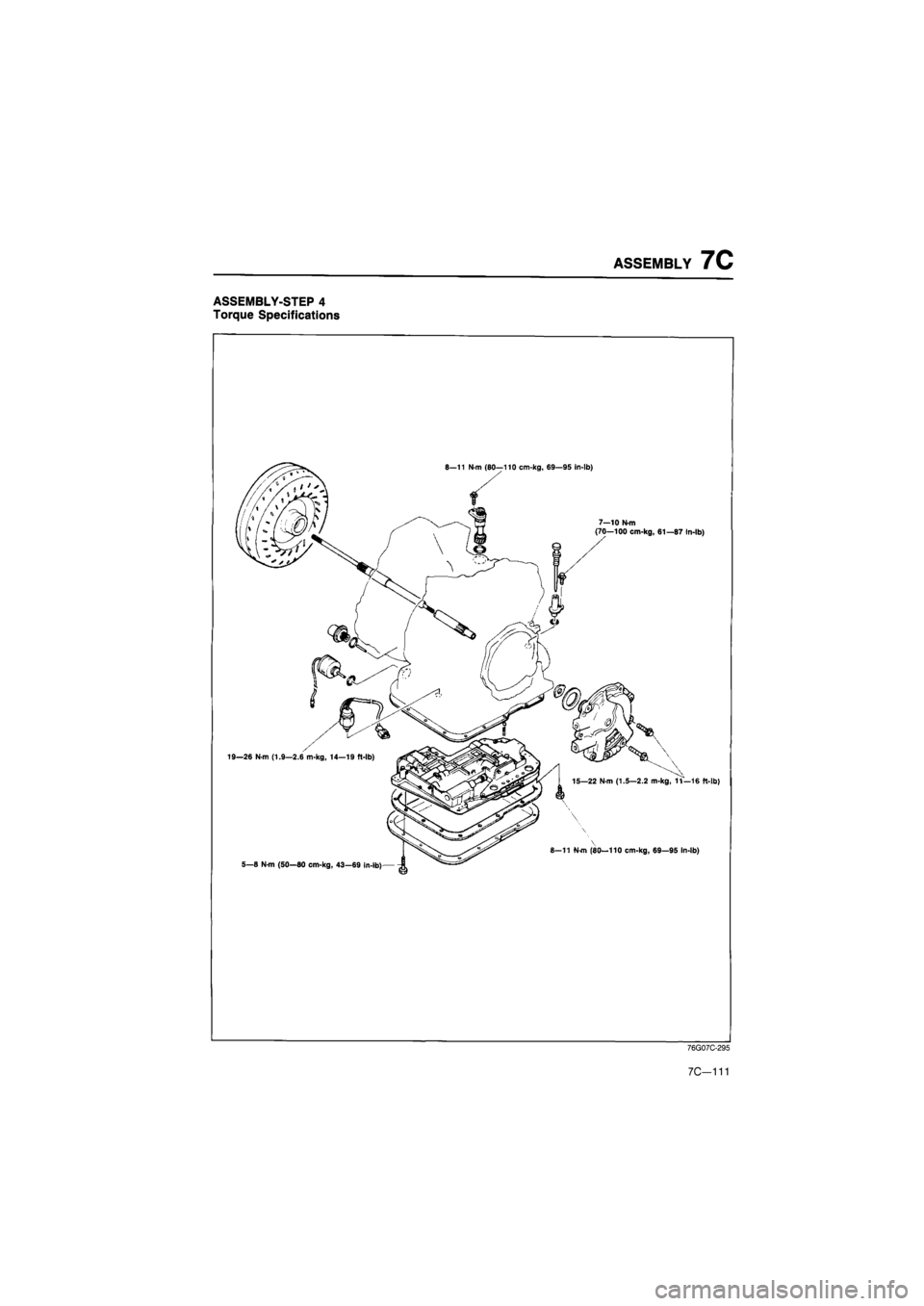

ASSEMBLY-STEP

4

Torque Specifications

ASSEMBLY

7C

76G07C-295

7C—111

Page 1226 of 1865

7C ASSEMBLY

7C-112

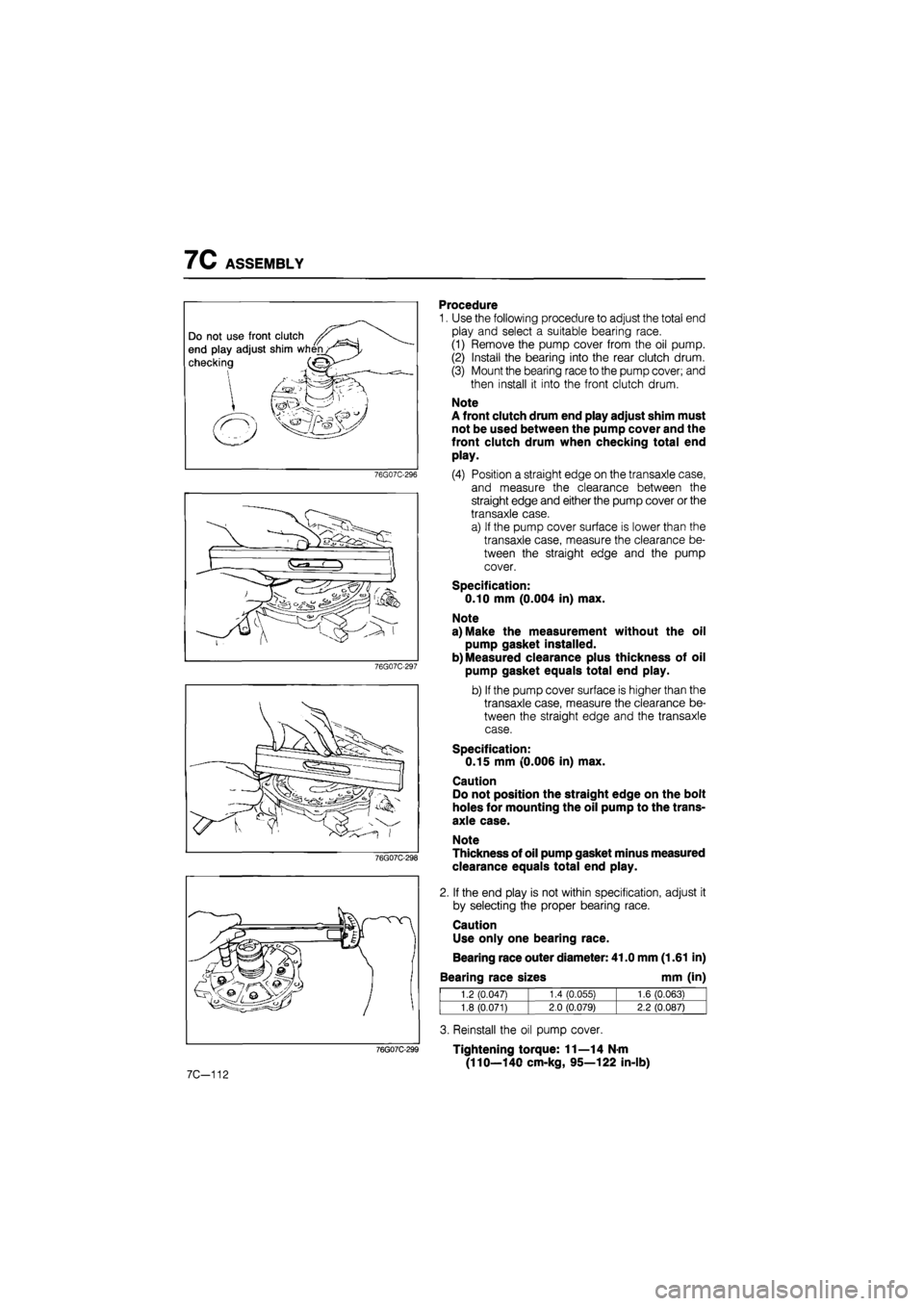

Procedure

1. Use the following procedure to adjust the total end

play and select a suitable bearing race.

(1) Remove the pump cover from the oil pump.

(2) Install the bearing into the rear clutch drum.

(3) Mount the bearing race to the pump cover; and

then install it into the front clutch drum.

Note

A front clutch drum end play adjust shim must

not be used between the pump cover and the

front clutch drum when checking total end

play.

(4) Position a straight edge on the transaxle case,

and measure the clearance between the

straight edge and either the pump cover or the

transaxle case.

a) If the pump cover surface is lower than the

transaxle case, measure the clearance be-

tween the straight edge and the pump

cover.

Specification:

0.10 mm (0.004 in) max.

Note

a) Make the measurement without the oil

pump gasket installed.

b) Measured clearance plus thickness of oil

pump gasket equals total end play.

b) If the pump cover surface is higher than the

transaxle case, measure the clearance be-

tween the straight edge and the transaxle

case.

Specification:

0.15 mm (0.006 in) max.

Caution

Do not position the straight edge on the bolt

holes for mounting the oil pump to the trans-

axle case.

Note

Thickness of oil pump gasket minus measured

clearance equals total end play.

2. If the end play is not within specification, adjust it

by selecting the proper bearing race.

Caution

Use only one bearing race.

Bearing race outer diameter: 41.0 mm (1.61 in)

Bearing race sizes mm (in)

1.2 (0.047) 1.4 CO.055) 1.6 (0.063)

1.8 (0.071) 2.0 (0.079) 2.2 (0.087)

3. Reinstall the oil pump cover.

Tightening torque: 11—14 N-m

(110—140 cm-kg, 95—122 in-lb)

Page 1227 of 1865

ASSEMBLY 7C

4. Use the following procedure to adjust the front

clutch drum end play and select the adjust shim.

(1) Set the oil pump gasket onto the transaxle

case.

(2) Place the adjust shim onto the front clutch

drum.

(3) Install the oil pump and bearing race into the

transaxle; then tighten the oil pump mounting

bolts to the specified torque.

Tightening torque:

15—22 N m (1.5—2.2 m-kg, 11—16 ft-lb)

76G07C-300

76G07C-301

63U07B-220

(4) Position the transaxle with the oil pump facing

down ward position.

(5) While turning the connecting shell 2 complete

turns, push the front clutch drum toward the

oil pump with a screwdriver to seat the front

clutch drum.

(6) Measure the clearance between the front clutch

drum and the connecting shell. This clearance

is the front clutch drum end play.

End play: 0.5—0.8 mm (0.020—0.031 in)

(7) If the end play is not within specification, ad-

just it by selecting the proper adjust shim.

Shim sizes mm (in)

1.3 (0.051) 1.5 (0.059) 1.7 (0.067)

2.3 (0.091) 1.9 (0.075) 2.1 (0.083)

1.7 (0.067)

2.3 (0.091)

2.5 (0.098) 2.7 (0.106)

76G07C-302

7C-113

Page 1228 of 1865

7C ASSEMBLY

76G07C-303

76G07C-304

76G07C-305

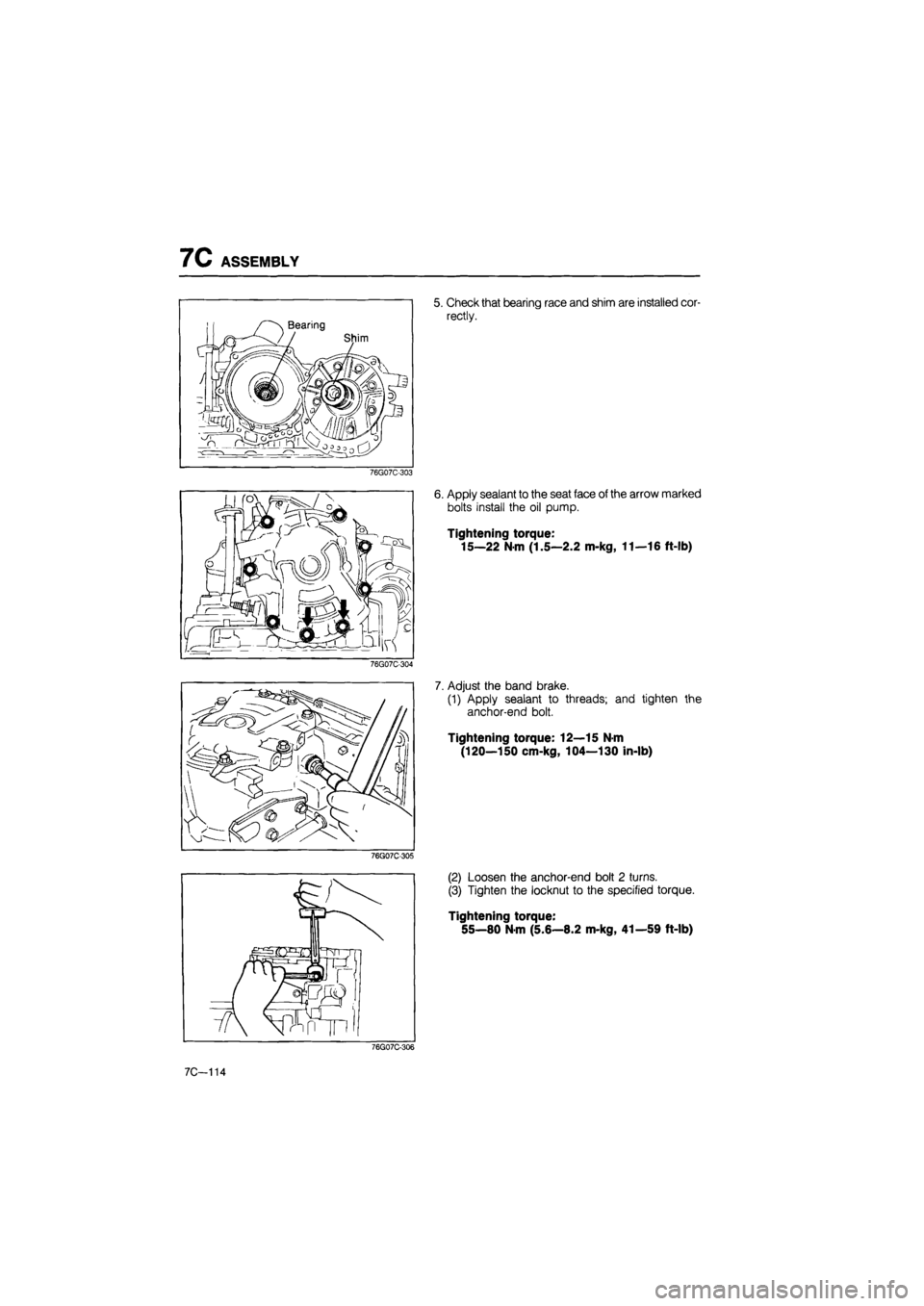

5. Check that bearing race and shim are installed cor-

rectly.

6. Apply sealant to the seat face of the arrow marked

bolts install the oil pump.

Tightening torque:

15—22 N m (1.5—2.2 m-kg, 11—16 ft-lb)

7. Adjust the band brake.

(1) Apply sealant to threads; and tighten the

anchor-end bolt.

Tightening torque: 12—15 N-m

(120—150 cm-kg, 104—130 in-lb)

(2) Loosen the anchor-end bolt 2 turns.

(3) Tighten the locknut to the specified torque.

Tightening torque:

55—80 N-m (5.6—8.2 m-kg, 41—59 ft-lb)

76G07C-306

7C-114

Page 1229 of 1865

ASSEMBLY 7C

76G07C-307

76G07C-308

76G07C-309

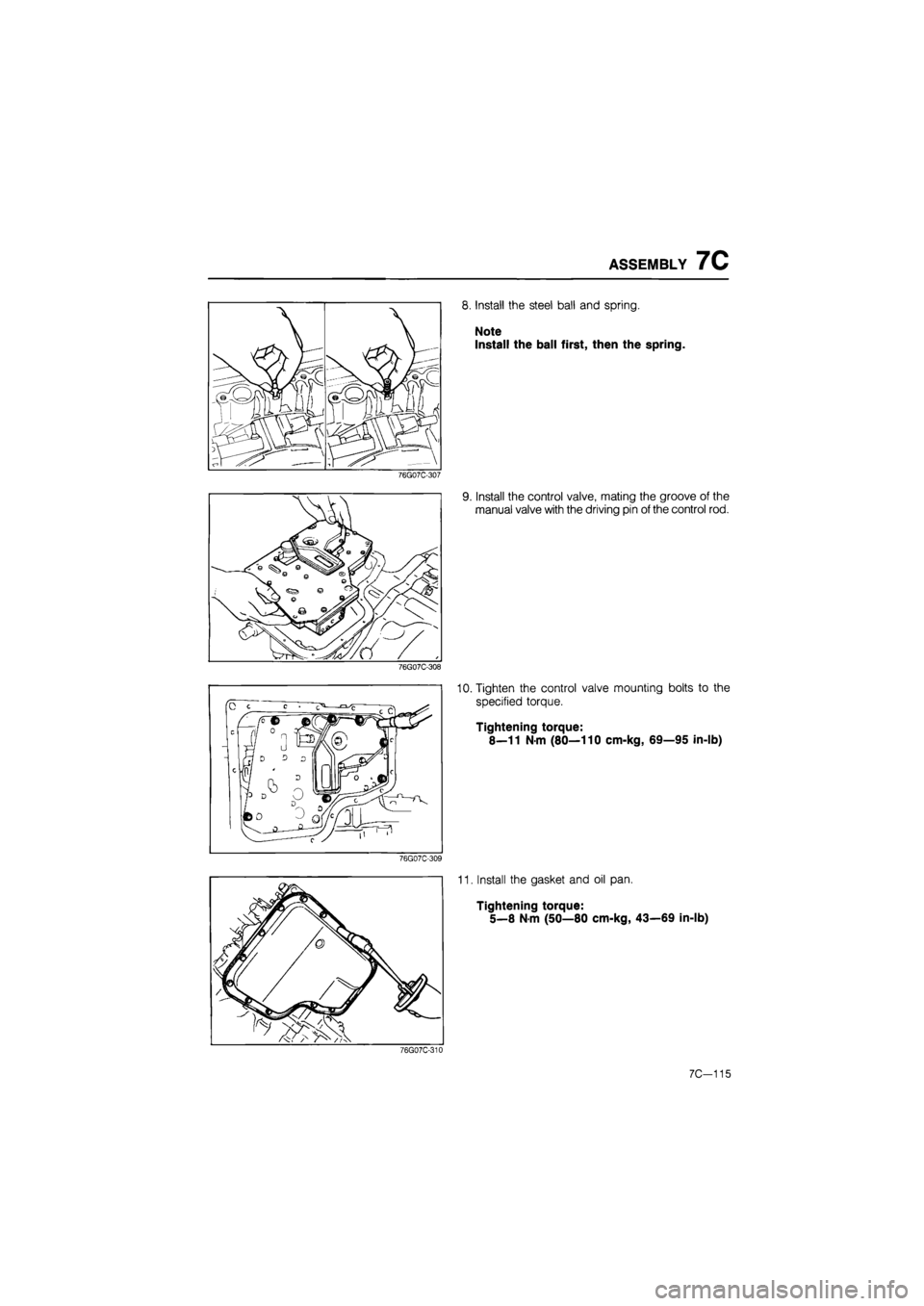

8. Install the steel ball and spring.

Note

Install the ball first, then the spring.

9. Install the control valve, mating the groove of the

manual valve with the driving pin of the control rod.

10. Tighten the control valve mounting bolts to the

specified torque.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

11, Install the gasket and oil pan.

Tightening torque:

5—8 N m (50—80 cm-kg, 43—69 in-lb)

76G07C-310

7C—115

Page 1230 of 1865

7C ASSEMBLY

76G07C-311

76G07C-312

76G07C-313

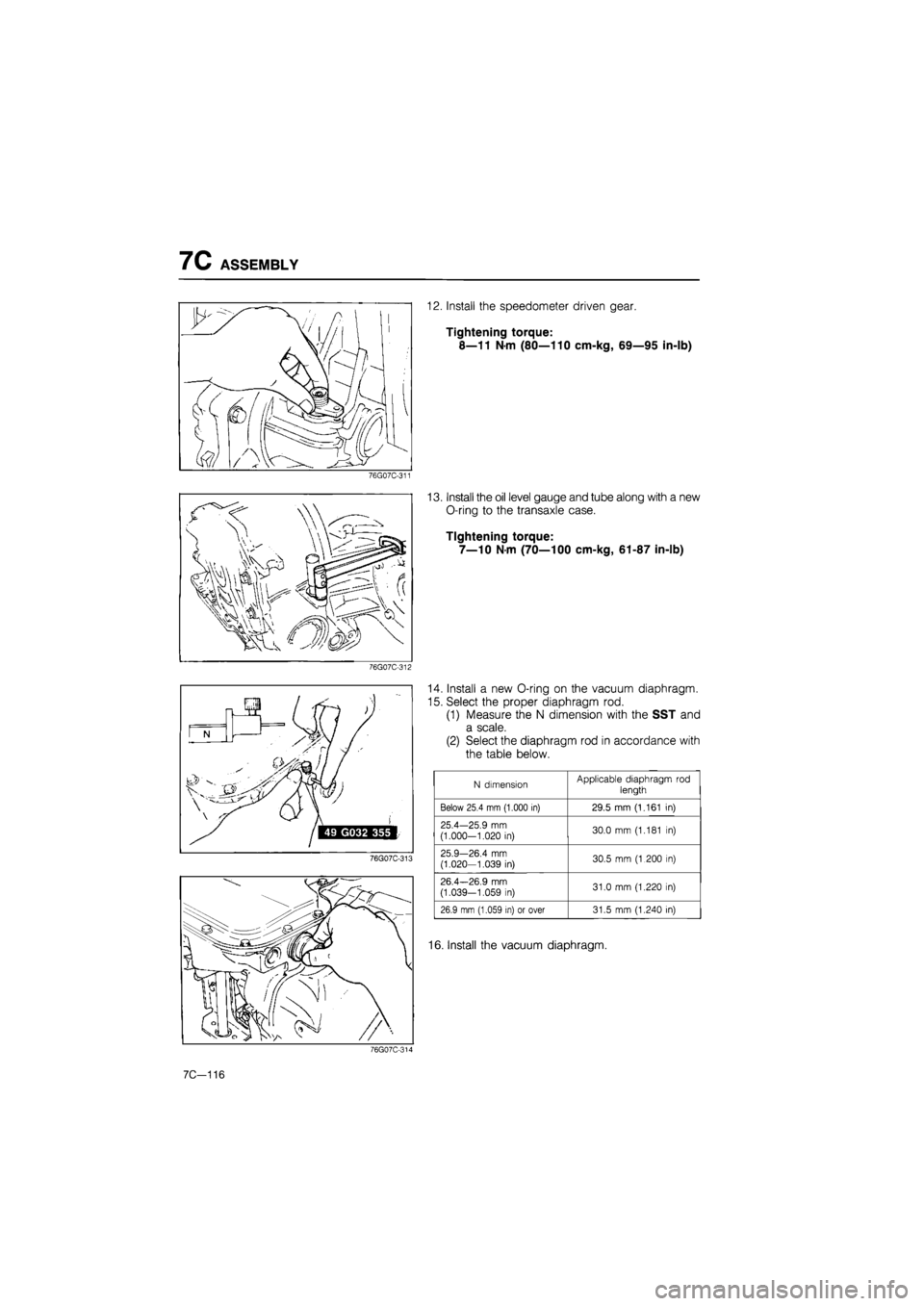

12. Install the speedometer driven gear.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

13. Install the oil level gauge and tube along with a new

O-ring to the transaxle case.

Tightening torque:

7—10 N m (70—100 cm-kg, 61-87 in-lb)

14. Install a new O-ring on the vacuum diaphragm.

15. Select the proper diaphragm rod.

(1) Measure the N dimension with the SST and

a scale.

(2) Select the diaphragm rod in accordance with

the table below.

N dimension Applicable diaphragm

rod

length

Below 25.4 mm (1.000

in)

29.5

mm

(1.161

in)

25.4—25.9

mm

(1.000-1.020

in)

30.0

mm

(1.181

in)

25.9—26.4

mm

(1.020-1.039

in)

30.5

mm

(1.200

in)

26.4—26.9

mm

(1.039-1.059

in)

31.0

mm

(1.220

in)

26.9 mm (1,059 in)

or

over 31.5

mm

(1.240

in)

16. Install the vacuum diaphragm.

76G07C-314

7C—116