MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987,

Model line: 626,

Model: MAZDA 626 1987

Pages: 1865, PDF Size: 94.35 MB

MAZDA 626 1987 Workshop Manual

626 1987

MAZDA

MAZDA

https://www.carmanualsonline.info/img/28/57059/w960_57059-0.png

MAZDA 626 1987 Workshop Manual

Trending: remote control, horn, battery replacement, child lock, lights, fuses, fuel tank capacity

Page 1211 of 1865

ASSEMBLY 7C

76G07C-249

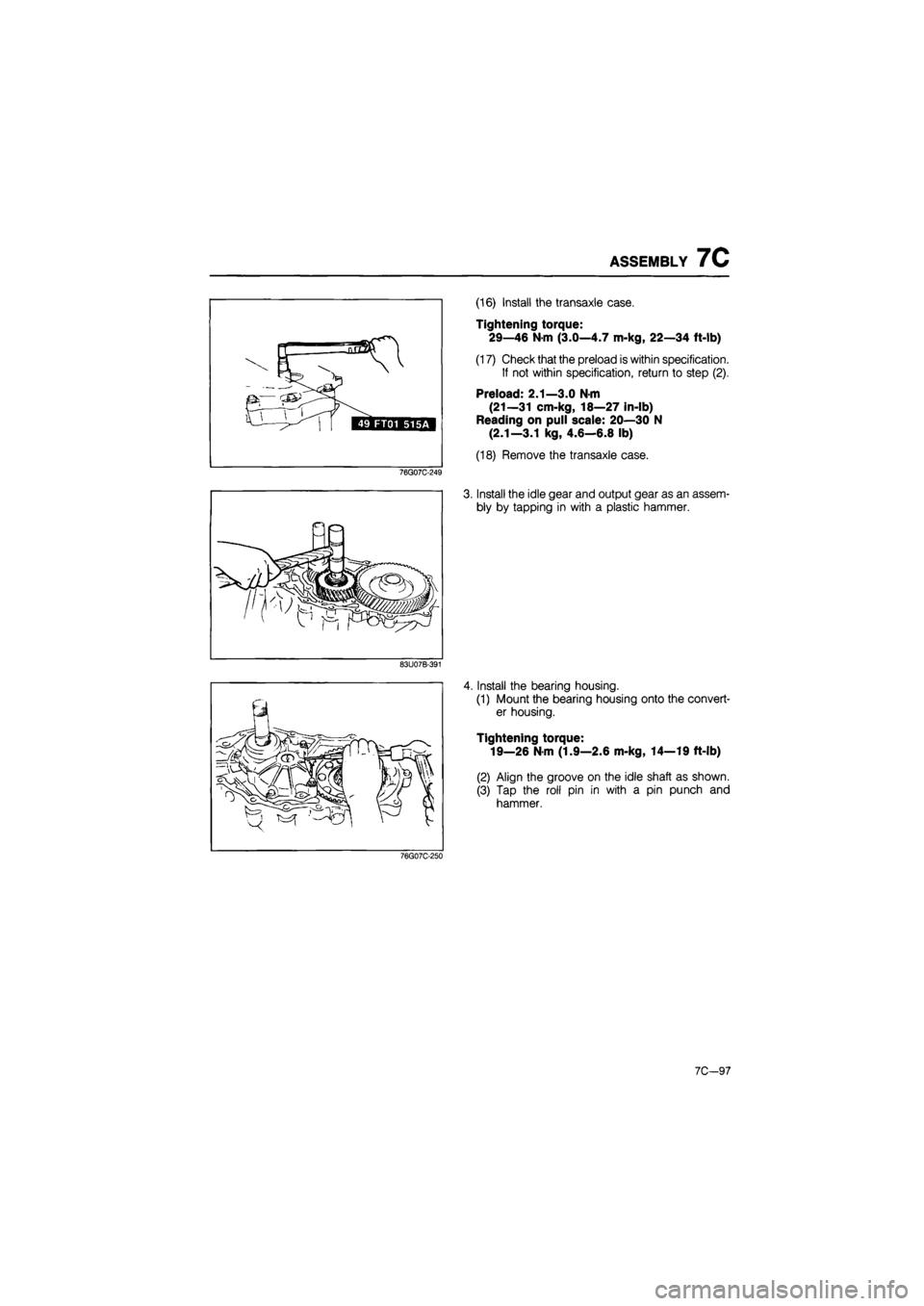

(16) Install the transaxle case.

Tightening torque:

29—46 N-m (3.0—4.7 m-kg, 22—34 ft-lb)

(17) Check that the preload is within specification.

If not within specification, return to step (2).

Preload: 2.1—3.0 N-m

(21—31 cm-kg, 18—27 in-lb)

Reading on pull scale: 20—30 N

(2.1—3.1 kg, 4.6—6.8 lb)

(18) Remove the transaxle case.

3. Install the idle gear and output gear as an assem-

bly by tapping in with a plastic hammer.

83U07B-391

4. Install the bearing housing.

(1) Mount the bearing housing onto the convert-

er housing.

Tightening torque:

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

(2) Align the groove on the idle shaft as shown.

(3) Tap the roll pin in with a pin punch and

hammer.

76G07C-250

7C-97

Page 1212 of 1865

7C ASSEMBLY

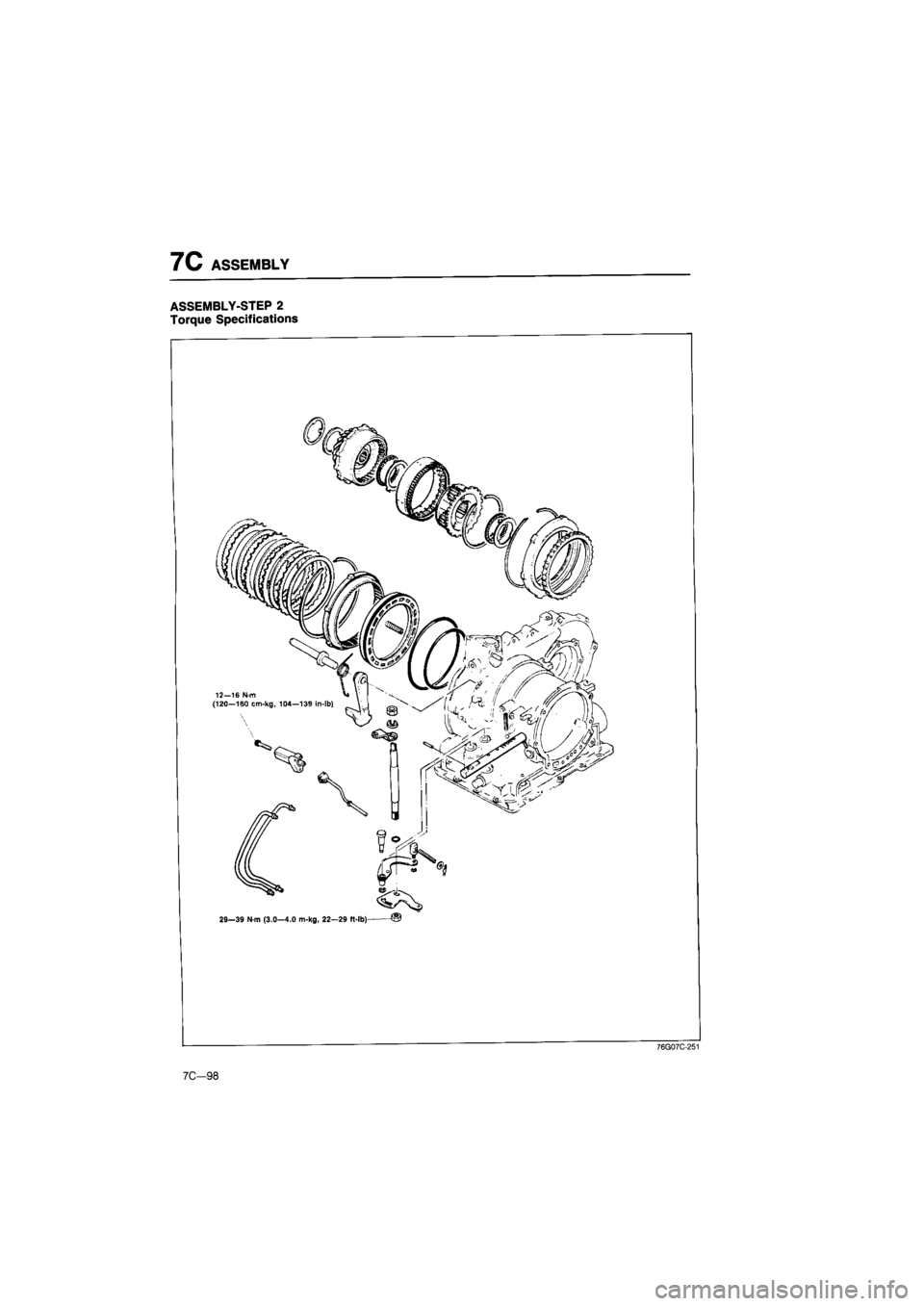

ASSEMBLY-STEP 2

Torque Specifications

29—39 N-m (3.0—4.0 m-kg, 22—29 ft-lb) ©

7C-98

76G07C-251

Page 1213 of 1865

ASSEMBLY 7C

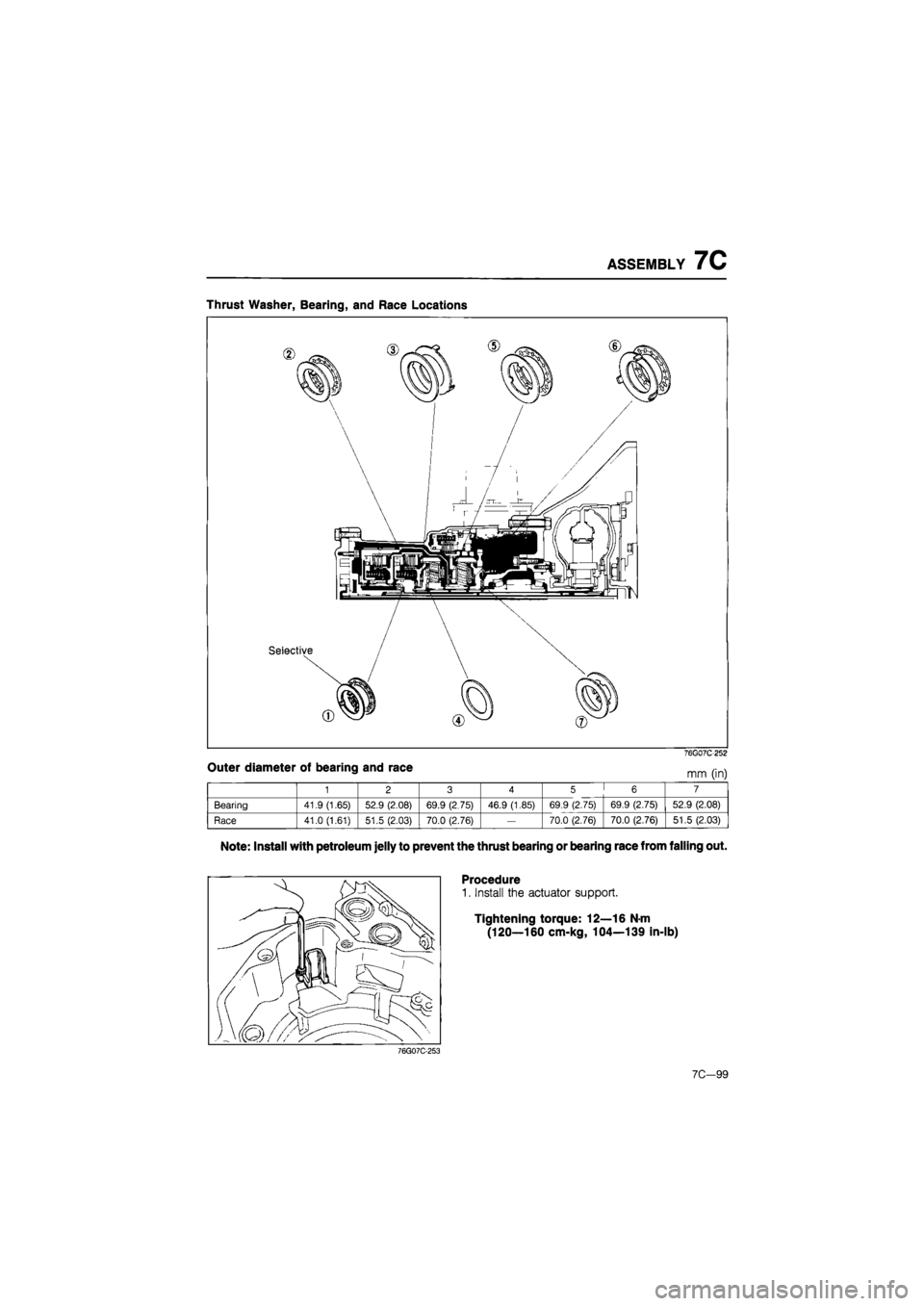

Thrust Washer, Bearing, and Race Locations

Outer diameter of bearing and race

76G07C252

mm (in)

1 2 3 4 5 6 7

Bearing 41.9 (1.65) 52.9 (2.08) 69.9 (2.75) 46.9 (1.85) 69.9 (2.75) 69.9 (2.75) 52.9 (2.08)

Race 41.0 (1.61) 51.5 (2.03) 70.0 (2.76)

—

70.0 (2.76) 70.0 (2.76) 51.5 (2.03)

Note: Install with petroleum jelly to prevent the thrust bearing or bearing race from falling out.

Procedure

1. Install the actuator support.

Tightening torque: 12—16 N-m

(120—160 cm-kg, 104—139 in-lb)

76G07C-253

7C—99

Page 1214 of 1865

7C ASSEMBLY

76G07C-254

76G07C-255

76G07C-256

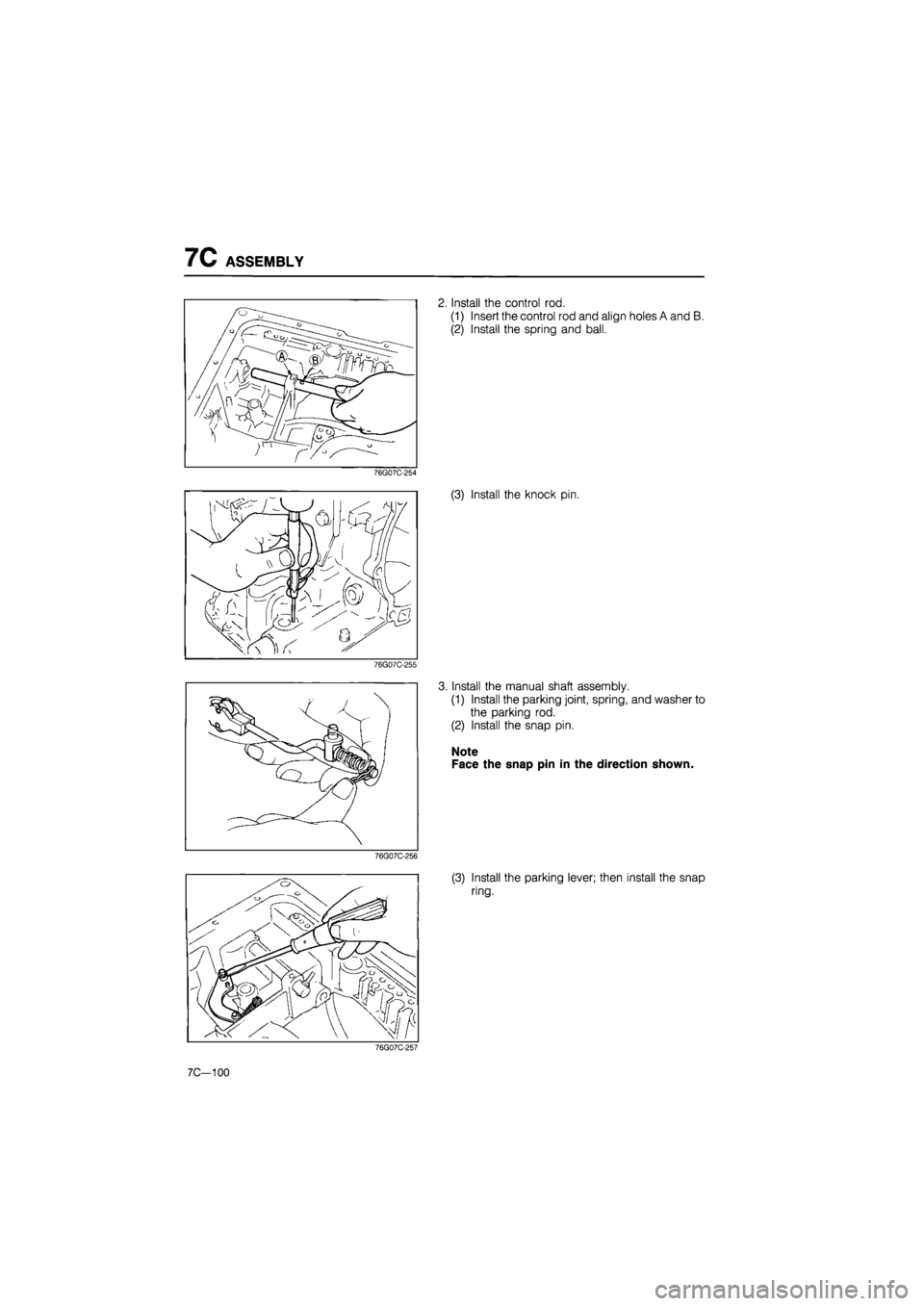

2. Install the control rod.

(1) Insert the control rod and align holes A and B.

(2) Install the spring and ball.

(3) Install the knock pin.

3. Install the manual shaft assembly.

(1) Install the parking joint, spring, and washer to

the parking rod.

(2) Install the snap pin.

Note

Face the snap pin in the direction shown.

(3) Install the parking lever; then install the snap

ring.

76G07C-257

7C—100

Page 1215 of 1865

ASSEMBLY 7C

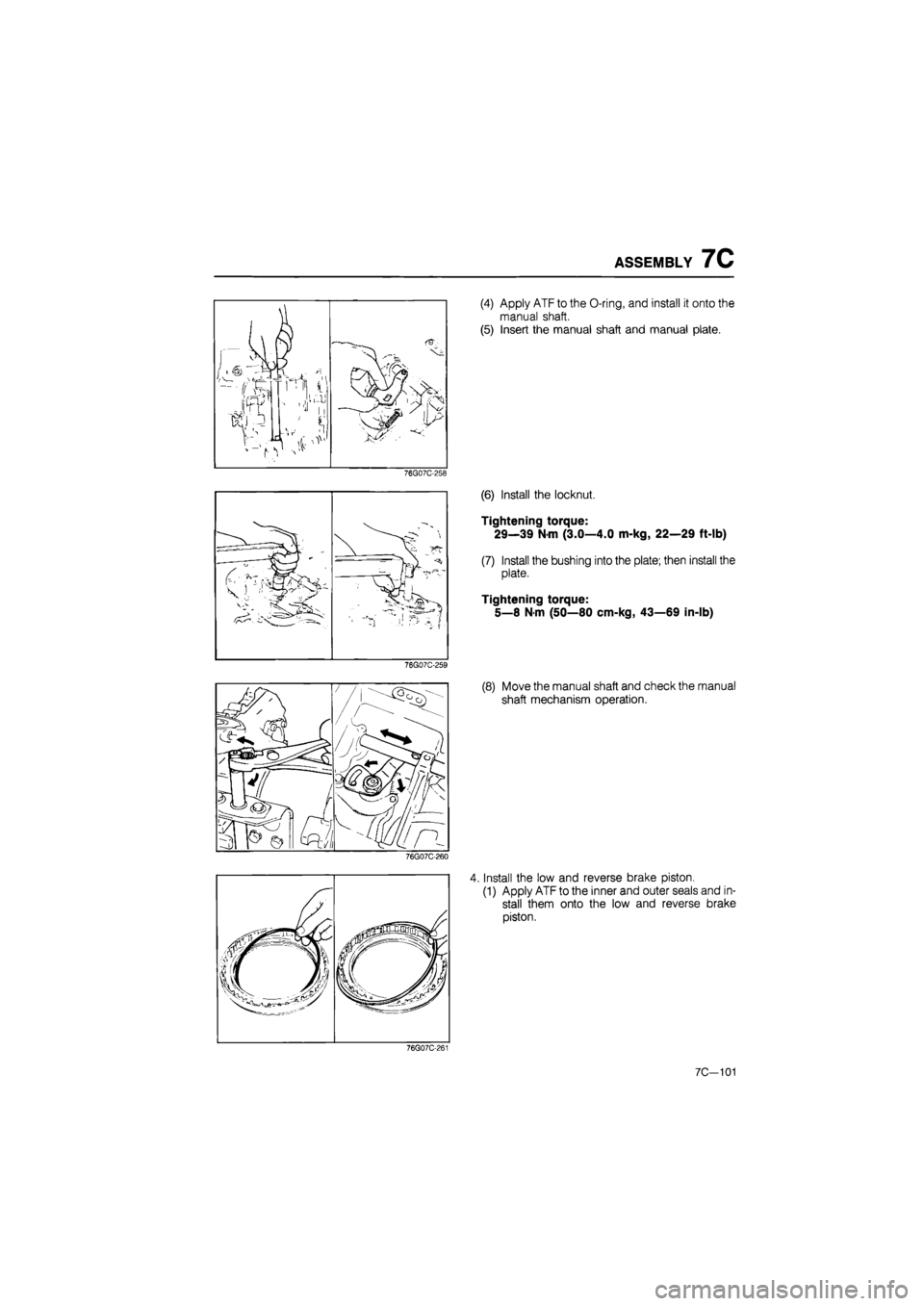

(4) Apply ATF to the O-ring, and install it onto the

manual shaft.

(5) Insert the manual shaft and manual plate.

76G07C-258

(6) Install the locknut.

Tightening torque:

29—39 N-m (3.0—4.0 m-kg, 22—29 ft-lb)

(7) Install the bushing into the plate; then install the

plate.

Tightening torque:

5—8 N-m (50—80 cm-kg, 43—69 in-lb)

76G07C-260

4. Install the low and reverse brake piston.

(1) Apply ATF to the inner and outer seals and in-

stall them onto the low and reverse brake

piston.

76G07C-261

7C-101

Page 1216 of 1865

7C ASSEMBLY

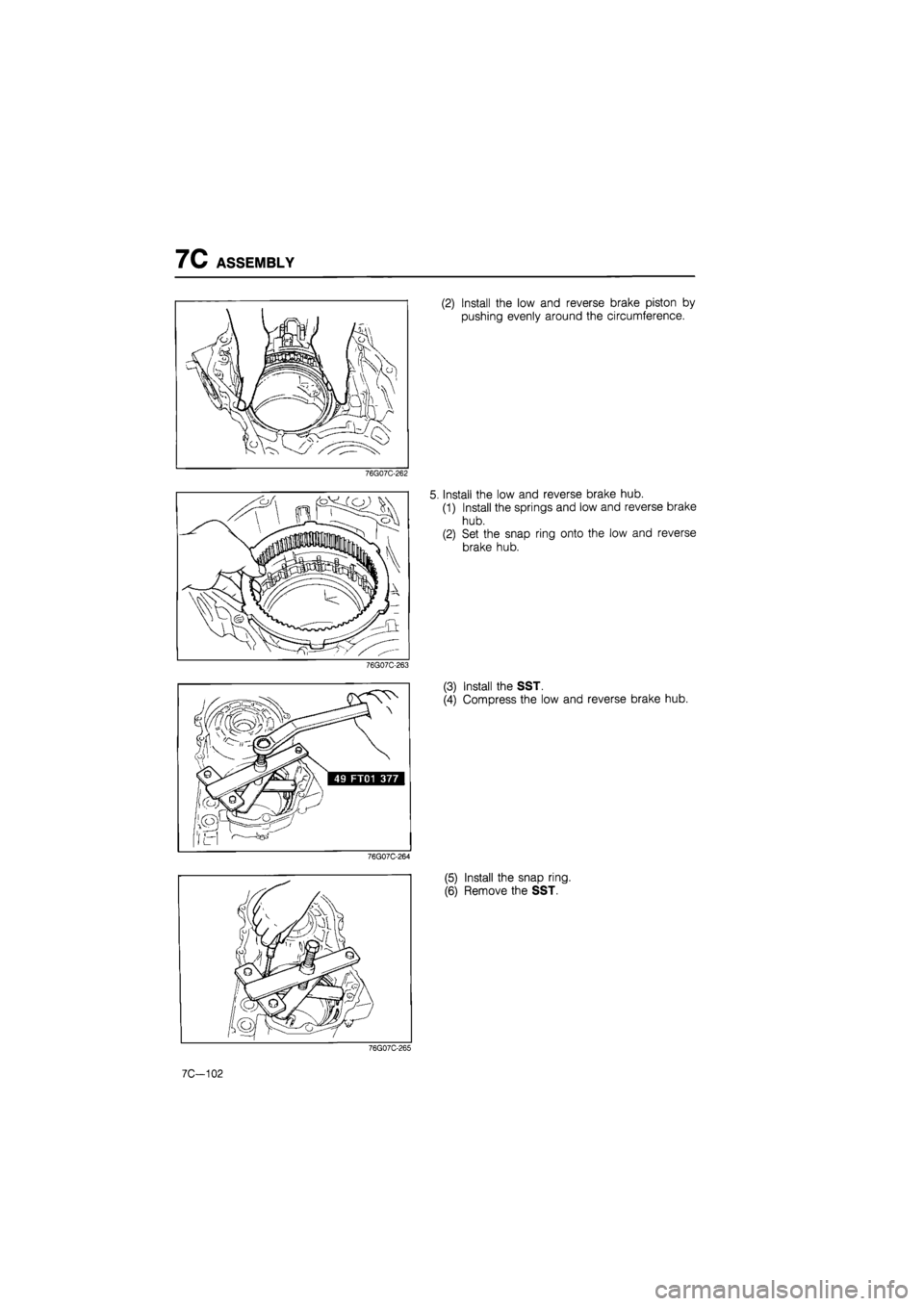

(2) Install the low and reverse brake piston by

pushing evenly around the circumference.

76G07C-262

Install the low and reverse brake hub.

(1) Install the springs and low and reverse brake

hub.

(2) Set the snap ring onto the low and reverse

brake hub.

76G07C-263

(3) Install the SST.

(4) Compress the low and reverse brake hub.

76G07C-264

(5) Install the snap ring.

(6) Remove the SST.

76G07C-265

7C—102

Page 1217 of 1865

ASSEMBLY 7C

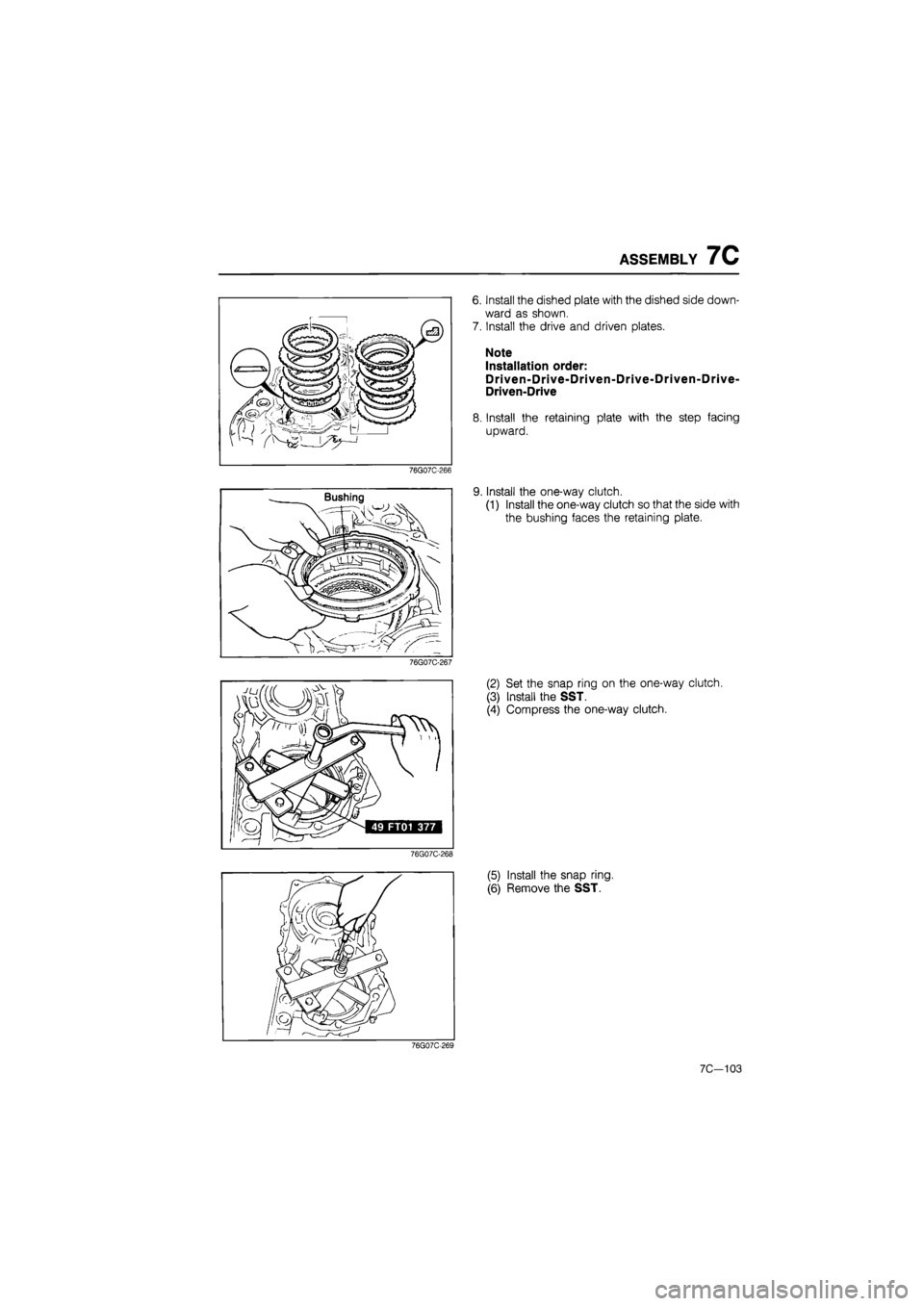

6. Install the dished plate with the dished side down-

ward as shown.

7. Install the drive and driven plates.

Note

Installation order:

Driven-Drive-Driven-Drive-Driven-Drive-

Driven-Drive

8. Install the retaining plate with the step facing

upward.

76G07C-266

9. Install the one-way clutch.

(1) Install the one-way clutch so that the side with

the bushing faces the retaining plate.

76G07C-267

(2) Set the snap ring on the one-way clutch.

(3) Install the SST.

(4) Compress the one-way clutch.

76G07C-268

(5) Install the snap ring.

(6) Remove the SST.

76G07C-269

7C—103

Page 1218 of 1865

7C ASSEMBLY

76G07C-270

76G07C-271

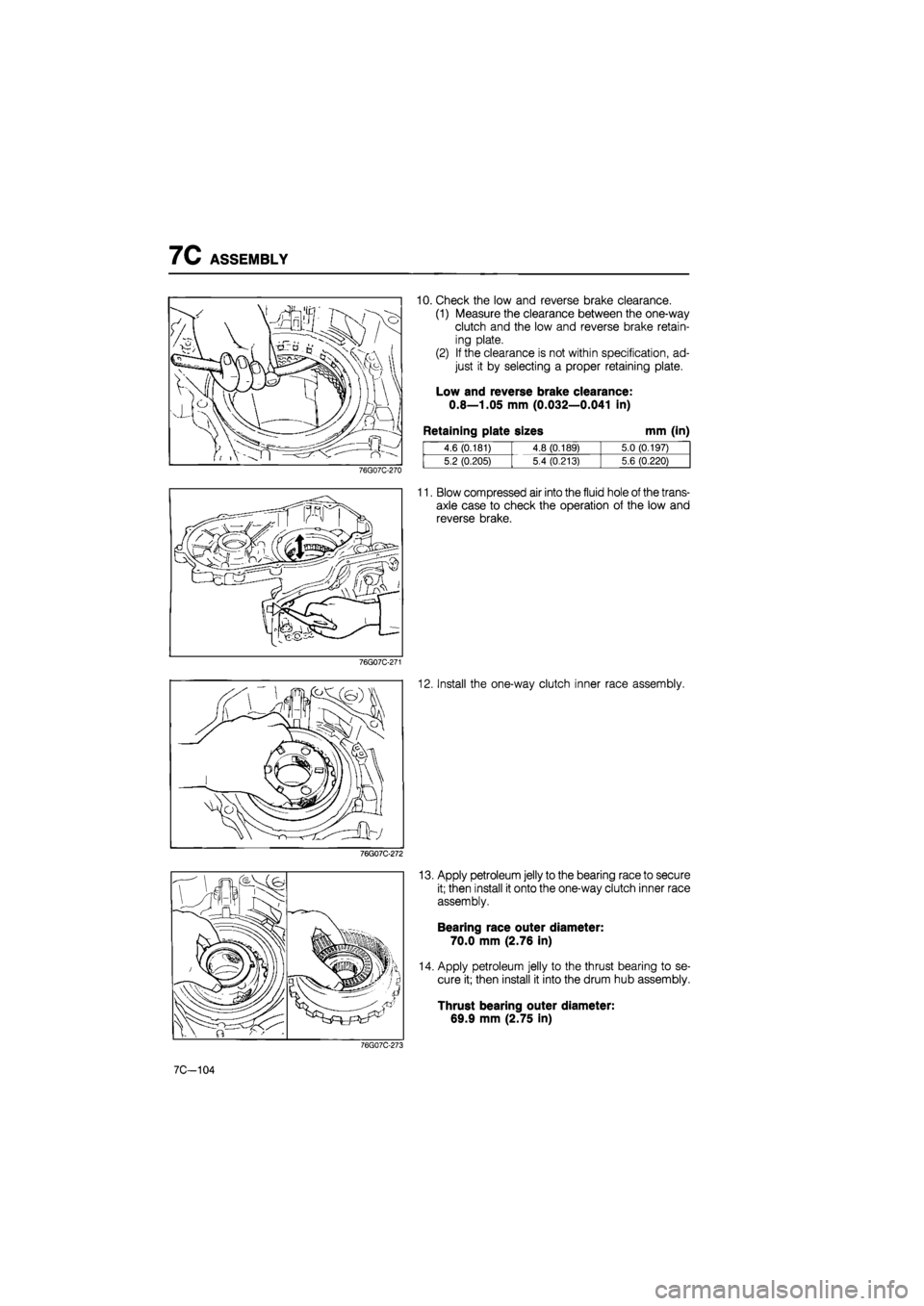

10. Check the low and reverse brake clearance.

(1) Measure the clearance between the one-way

clutch and the low and reverse brake retain-

ing plate.

(2) If the clearance is not within specification, ad-

just it by selecting a proper retaining plate.

Low and reverse brake clearance:

0.8—1.05 mm (0.032—0.041 in)

Retaining plate sizes mm (in)

4.6 (0.181) 4.8 (0.189) 5.0 (0.197)

5.2 (0.205) 5.4 (0.213) 5.6 (0.220)

11. Blow compressed air into the fluid hole of the trans-

axle case to check the operation of the low and

reverse brake.

12. Install the one-way clutch inner race assembly.

76G07C-272

13. Apply petroleum jelly to the bearing race to secure

it; then install it onto the one-way clutch inner race

assembly.

Bearing race outer diameter:

70.0 mm (2.76 in)

14. Apply petroleum jelly to the thrust bearing to se-

cure it; then install it into the drum hub assembly.

Thrust bearing outer diameter:

69.9 mm (2.75 in)

76G07C-273

7C-104

Page 1219 of 1865

ASSEMBLY 7C

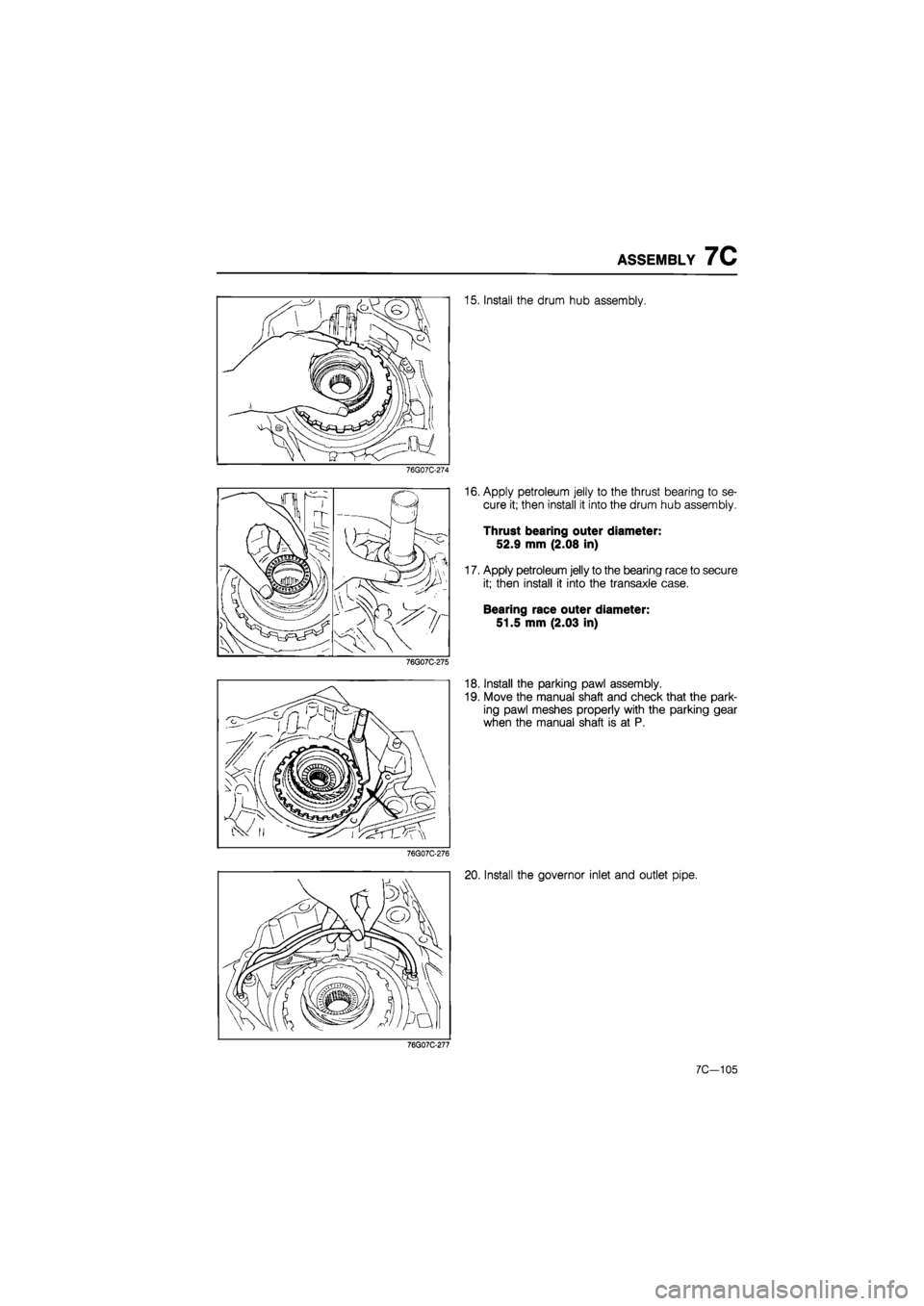

15. Install the drum hub assembly.

76G07C-274

76G07C-275

16. Apply petroleum jelly to the thrust bearing to se-

cure it; then install it into the drum hub assembly.

Thrust bearing outer diameter:

52.9 mm (2.08 in)

17. Apply petroleum jelly to the bearing race to secure

it; then install it into the transaxle case.

Bearing race outer diameter:

51.5 mm (2.03 in)

18. Install the parking pawl assembly.

19. Move the manual shaft and check that the park-

ing pawl meshes properly with the parking gear

when the manual shaft is at P.

76G07C-276

20. Install the governor inlet and outlet pipe.

76G07C-277

7C—105

Page 1220 of 1865

7C ASSEMBLY

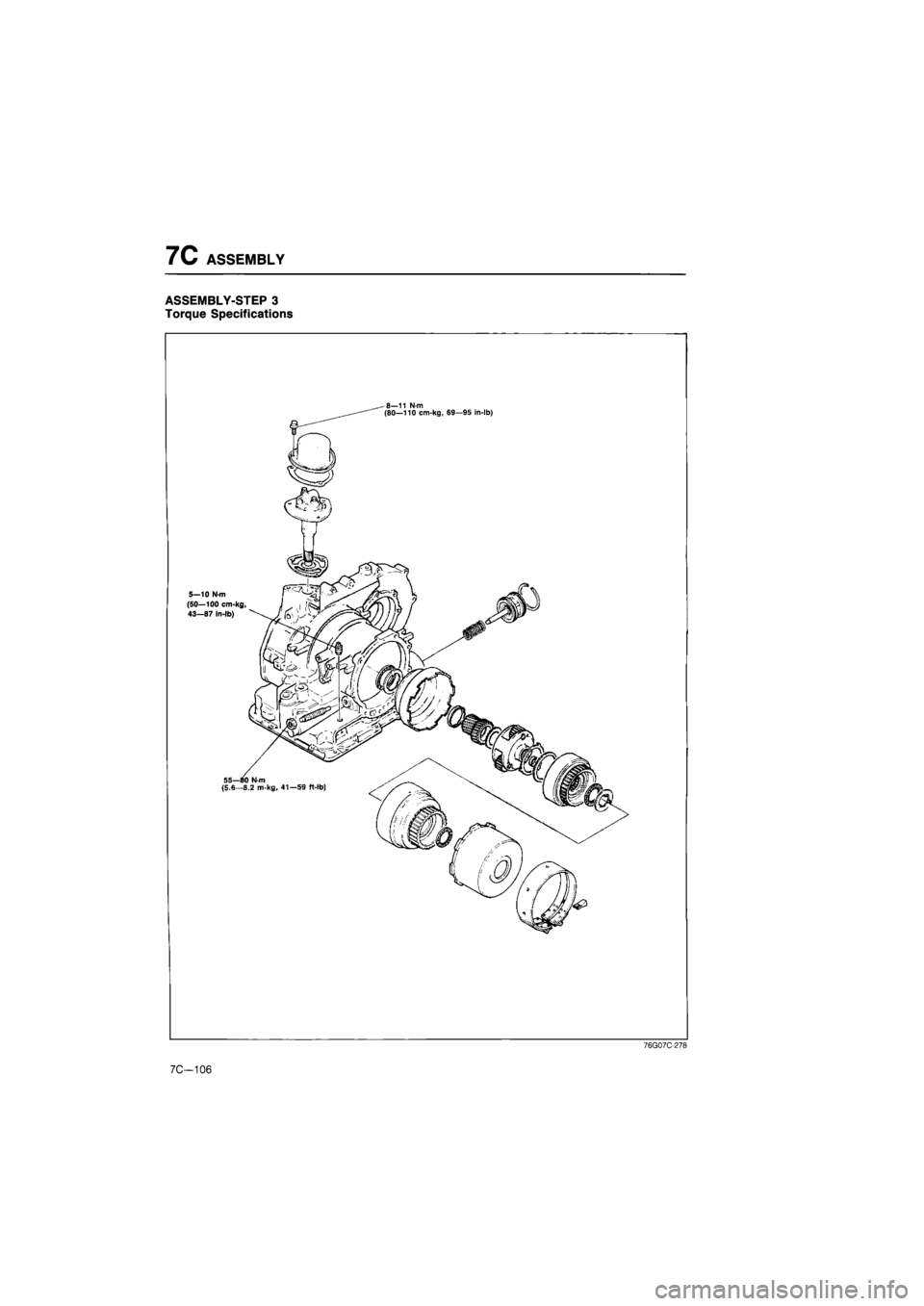

ASSEMBLY-STEP 3

Torque Specifications

76G07C-278

7C-106

Trending: tires, wipers, brake pads, service indicator, radiator cap, stop start, technical specifications