Brake MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1125 of 1865

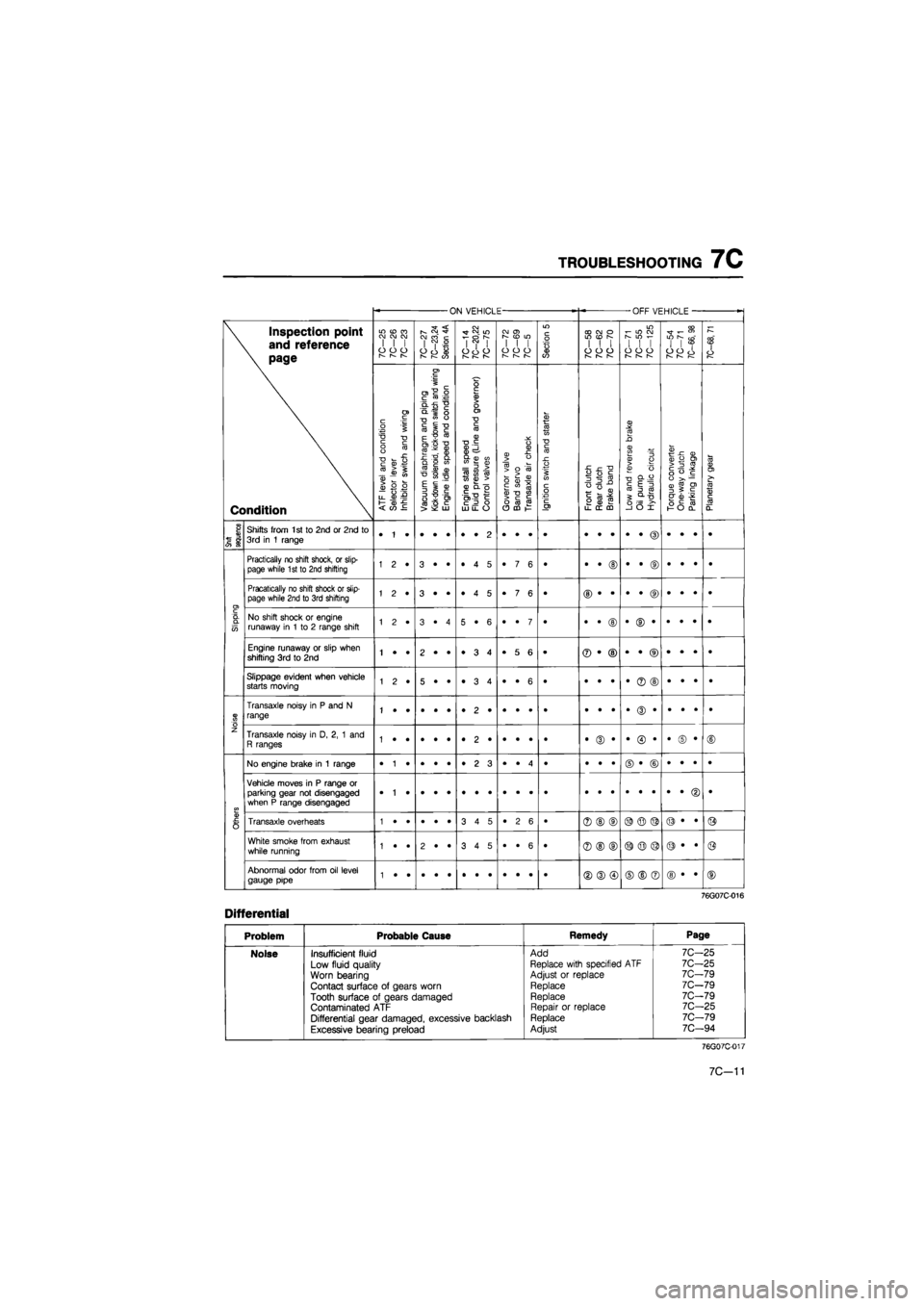

TROUBLESHOOTING

7C

ON VEHICLE -OFF VEHICLE

-

\ Inspection point

\

and

reference

\ page

Condition

in cd

ra

CM CM CM

I

I I

o

o o

I—

r~—

r—

7C—27

7C—23,24

Section

4A

7C—14

7C—20,22

7C-75

CM

0>

[—

CO

LO I

I I

O

O O

r^ r—

Section

5

CD CM

O

in (D

s

I

I I

o

o o

r—

r^

w

CM

r-

m f-

I

I I

o

o o

r-— I—

r-—

7C—54

7C-71

7C—66,

98

7C-68,

71 \ Inspection point

\

and

reference

\ page

Condition

ATR

level

and

condition

Selector

lever

Inhibitor

switch

and

wiring

Vacuum

diaphragm

and

piping

Kick-down

solenoid,

kick-down

switch

and

wiring

Engine

idle

speed

and

condition

Engine

stall

speed

Fluid

pressure

(Line

and

governor)

Control

valves

Governor

valve

Band

servo

Transaxle

air

check

Ignition

switch

and

starter

Front

clutch

Rear

clutch

Brake

band

Low

and

reverse

brake

Oil

pump

Hydraulic

circuit

Torque

converter

One-way

clutch

Parking

linkage

Planetary

gear

Snift

sequence

Shifts from

1st to

2nd

or

2nd

to

3rd

in 1

range

Slipping

Practically

no

shift shock,

or

slip-page while 1st

to

2nd shifting 1

2 •

3

• •

•

4 5

•

7 6

• •

• ©

•

• ©

•

• •

•

Slipping

Pracatically

no

shift shock

or

slip-page while 2nd

to

3rd shifting 1

2 •

3

• •

•

4 5

•

7 6

•

Slipping

No shift shock

or

engine runaway

in 1 to 2

range shift 1

2 •

3

• 4

5

• 6

•

• 7

• •

• ©

•

© •

•

• •

•

Slipping

Engine runaway

or

slip when shifting

3rd to 2nd

1

• •

2

• •

•

3 4

•

5 6

• ®

• ©

•

• ®

•

• •

•

Slipping

Slippage evident when vehicle starts moving 1

2 •

5

• •

•

3 4

•

• 6

• •

• •

•

® ©

•

• •

•

Noise

Transaxle noisy

in P and N

range

Noise

Transaxle noisy

in D, 2, 1 and

R ranges •

(D •

•

© •

•

© •

©

Others

No engine brake

in 1

range •

1 •

•

• •

•

2 3

•

• 4

• •

• •

©

• ©

•

• •

•

Others

Vehicle moves

in P

range

or

parking gear

not

disengaged when

P

range disengaged

•

Others

Transaxle overheats 3

4 5

•

2 6

• ®

©

(D ©

© ©

©

• •

©

Others

White smoke from exhaust while running 1

• •

2

• •

3

4 5

•

• 6

• ®

© ©

©

© ©

©

• •

@

Others

Abnormal odor from

oil

level gauge pipe ©

® ©

©

© ®

©

• •

©

76G07C-016

Differential

Problem Probable Cause Remedy Page

Noise Insufficient fluid Add 7C—25

Low fluid quality Replace with specified

ATF

7C-25

Worn bearing Adjust

or

replace 7C-79

Contact surface

of

gears worn Replace 7C-79

Tooth surface

of

gears damaged Replace 7C-79

Contaminated

ATF

Repair

or

replace 7C-25

Differential gear damaged, excessive backlash Replace 7C-79

Excessive bearing preload Adjust 7C—94

76G07C-017

7C—11

Page 1126 of 1865

7C TROUBLESHOOTING

STEP 1 (PRELIMINARY INSPECTION)

In this step, the main points related to the automatic transaxle are checked. These items must be kept

in the correct condition at all times in order to assure proper operation of the automatic transaxle.

1. Automatic Transaxle Fluid (ATF)

Check ATF level and condition. (Refer to page 7C—25.)

2. Selector Lever

Check selector lever position and adjust it if necessary. (Refer to page 7C—26.)

76G07C-018

3. Oil Leakage

Check for oil leakage.

(1) Warm up the ATF.

(2) Apply the parking brake and block the wheels

to prevent the vehicle from rolling.

(3) Shift the selector lever to R range.

(4) Check if oil leaks from the noted oil seals or

gaskets.

(5) If oil leaks, replace the seal or gasket.

76G07C-019

7C-12

Page 1128 of 1865

7C TROUBLESHOOTING

STEP 2 (STALL TEST)

This step is performed to determine if there is slippage of the friction elements or malfunction of the

hydraulic components.

Preparation

Check the following items prior to testing:

1. Engine coolant, engine oil and ATF levels.

2. Warm the engine thoroughly to raise the ATF temperature to operating level (50—80°C, 122—176°F).

3. Set the parking brake and block the front and rear of the wheels.

Pull the parking brake Water temperature

ATF

7C—14

76G07C-024

Page 1129 of 1865

TROUBLESHOOTING 7C

Procedure

76G07C-025

1. Connect a tachometer to the engine.

2. Shift the selector lever to D range.

3. Depress the brake pedal firmly with the left foot, and gradually depress the accelerator pedal with

the right foot.

4. Read and note the engine speed as soon as it becomes constant; then release the accelerator pedal.

Caution

Steps 3 to 4 must be done within 5 seconds.

5. Shift the selector to N range and let the engine idle for one minute or more.

Note The idling cools the ATF and prevents oil degeneration.

6. Perform stall tests for the following ranges in the same manner.

(1) 2 range

(2) 1 range

(3) R range

Standard stall speed:

FE engine 2050—2150 rpm

F6 engine 1800—2050 rpm

Caution

Always provide adequate cooling time between individual range stall tests.

7C-15

Page 1130 of 1865

7C TROUBLESHOOTING

Evaluation

Condition Possible cause

Worn oil pump

In all ranges Insufficient line

pressure

Oil leakage from oil pump, control

valve, and/or transaxle case

Stuck pressure regulator valve

In D, 2, and 1 Rear clutch slipping

Above specification In D range only One-way clutch slipping

In 2 range only Brake band slipping

Low and reverse brake slipping

Brake band slipping

In R range only Road test to determine if cause is low and reverse brake or reverse clutch:

a) Engine braking in 1 range Front clutch b) No engine braking in 1 range .... Low and reverse brake

Within specification All shift control elements within transaxle functioning normally

Below specification Engine out of tune Below specification

One-way clutch slipping within torque converter

76G07C-026

7C—16

Page 1131 of 1865

TROUBLESHOOTING 7C

STEP 3 (TIME LAG TEST)

When the selector lever is shifted while the engine is idling, there is a certain time lapse, or time lag,

before shock is felt. This time lag test checks the condition of the front, rear, and one-way clutch, low

and reverse brake, and orifice check valve.

Preparation

Follow the test preparation procedure shown in STEP 2 (STALL TEST).

Procedure

1. Start the engine and verify that the idle speed is 950tso rpm.

2. Shift from N range to D range

3. Measure the time it takes from shifting until shock is felt with a stop watch.

4. Shift the selector to N range and run the engine at idle for one minute or more.

5. Perform the test for N range to R range in the same manner.

Note

Make three measurements for each test and take the average value.

Specified time lag: N D range 0.5—1.0 second

N R range 0.5—1.0 second

Evaluation

Condition Possible Cause

N -» D shift More than specification

Insufficient line pressure

N -» D shift More than specification Rear clutch slipping N -» D shift More than specification

One-way clutch slipping N -» D shift

Less than specification N-D accumulator not operating properly

N-R shift

More than specification

Insufficient line pressure

N-R shift

More than specification Low and reverse brake slipping

N-R shift

More than specification

Front clutch slipping N-R shift

Less than specification Stuck orifice check valve

N-R shift

Less than specification Excessive line pressure

76G07C-027

7C-17

Page 1132 of 1865

7C TROUBLESHOOTING

STEP 4 (ROAD TEST)

This step is performed to check for problems in the various ranges. If these tests show any problems,

adjust or replace by referring to the QUICK DIAGNOSIS CHART and mechanical sections.

Caution

Perform the test at normal ATF operating temperature (50—80°C, 122—176°F).

Gearshift Function Check Items

1. Shift shock must be minimal, and shifting must be smooth.

2. Engine speed must not run away, and the shifting must not be delayed.

3. Transaxle must shift through Di D2 -»• D3 in D range.

4. Transaxle must shift from 3rd in D range to 2nd gear when 2 range is selected.

5. Transaxle must shift from 2nd to 1st when 1 range is selected from 3rd gear in D range.

6. Transaxle must not upshift in 1 range.

7. Transaxle must remain in 2nd gear in 2 range.

8. Transaxle must positively lock in P range.

The transaxle must positively lock when P range is selected while moving at a speed below 4 km/h

(2.5 mph) on level ground. The transaxle must positively lock when set in P range with the vehicle

on a gentle slope and the brakes disengaged.

Shift Speed

Throttle condition

(manifold vacuum) Hange Shift Vehicle speed km/h (mph) Throttle condition

(manifold vacuum) Hange Shift FE engine F6 engine

Fully opened 0—100 mmHg (0-3.94 inHg)

D

1st - 2nd 47—57 (29—35) 44-54 (27-33)

Fully opened 0—100 mmHg (0-3.94 inHg)

D 2nd - 3rd 106-119 (66—74) 95-108 (59-67) Fully opened 0—100 mmHg (0-3.94 inHg)

D 3rd - 2nd 95-103 (59-64) 86-94 (53-58)

Fully opened 0—100 mmHg (0-3.94 inHg)

D

2nd - 1st 35-39 (22-24) 34-38 (21-24)

Half-throttle 130 mmHg (5.12 inHg) D 1st - 2nd 18-31 (11-19) 18-31 (11-19) Half-throttle 130 mmHg (5.12 inHg) D 2nd -»• 3rd 39-68 (24—42) 44-73 (27-45)

Fully closed D 2nd - 1st 10-15 (6-9) 10-15 (6-9) Fully closed 1 2nd - 1st 32—39 (20-24) 33-40 (20-25)

1. Full-throttle: The throttle opening during kick-down when the manifold vacuum is between 0—100

mmHg (0—3.94 inHg)

2. Half-throttle: The throttle opening at manifold vacuum of 130 mmHg (5.12 inHg) 76G07C-028

7C-18

Page 1134 of 1865

7C TROUBLESHOOTING

STEP 5 (OIL PRESSURE TEST)

This step determines line pressure, and governor pressure to check the hydraulic components and

for oil leakage.

Line Pressure Test

Preparation

1. Connect the SST to the line pressure output point.

2. Connect a tachometer to the engine.

3. Follow the test preparation procedure show in STEP 2 (STALL TEST).

Procedure

76G07C-030

1. Start the engine and verify that the idle speed is 950-5° rpm.

2. Shift the selector lever to D range.

3. Read the line pressure at idle.

4. Depress the brake pedal firmly with the left foot, and gradually depress the accelerator pedal with

the right foot.

5. Read the line pressure as soon as the engine speed becomes constant; then release the accelera-

tor pedal.

Caution

Steps 4 to 5 must be done within 5 seconds.

5. Shift the selector lever to N range and let the engine idle for one minute or more.

6. Read the line pressure at idle and engine stall speeds for each range in the same manner.

7C—20

Page 1135 of 1865

TROUBLESHOOTING 7C

Specified line pressure:

Range Pressure kPa (kg/cm2, psi) Range

Idle Stall

D 294-392 (3-4, 43-57) 883-1079 (9—11, 128-156)

2 785—1177 (8—12, 114—171) 785-1177 (8—12, 114-171)

1 294-392 (3-4, 43—57) 883-1079 (9—11, 128—156)

R 392-687 (4-7, 57-100) 1570—1864 (16—19, 228-270)

76G07C-031

Evaluation

Condition Possible cause

Below standard

In all ranges

Worn oil pump

Below standard

In all ranges Fluid leakage from the oil pump, control valve, or transaxle case

Below standard

In all ranges

Stuck pressure regulator valve Below standard

In D, 1, 2 ranges Fluid leakage from the rear clutch or governor hydraulic circuit, or both

Below standard

In R range only Fluid leakage from the low and reverse brake hydraulic circuit

Excessive line pressure at idle Leaking or disconnected vacuum hose Excessive line pressure at idle

Leaking vacuum diaphragm

76G07C-032

76G07C-033

Vacuum

gauge Line

pressure

Governor pressure

At Atmosphere Radical line Read

& 200 mmHg pressure governor

(7.87 inHg) reduction

Line Pressure Cutback Point

1. Connect the SST to the line pressure output point

and the governor pressure output point in the trans-

axle case, and place the gauges inside the vehicle.

2. Disconnect the hose to the vacuum diaphragm,

and plug it.

3. Connect a vacuum pump to the vacuum di-

aphragm, and place the pump inside the vehicle.

4. Gradually accelerate the vehicle in D range.

5. Read the governor pressure at the point where the

line pressure suddenly drops.

6. Apply 200 mmHg (7.87 inHg) vacuum, and re-

peat steps 4 and 5.

Standard

Vacuum mmHg (InHg) Governor pressure kPa (kg/cm2, psi)

Atmospheric pressure 98-157 (1.0—1.6, 14-23)

200 (7.87) 39-98 (0.4-1.0, 6—14)

Evaluation

Incorrect pressures

1. Missing diaphragm rod or rod length incorrect, or

both.

2. Stuck valve in control valve.

76G07C-034

7C—21

Page 1139 of 1865

ON-VEHICLE MAINTENANCE 7C

ON-VEHICLE MAINTENANCE

AUTOMATIC TRANSAXLE FLUID (ATF)

Inspection for Fluid Leaks

Check for fluid leaks; the following figure shows the locations where fluid leakage may possibly occur.

1. Kick-down solenoid

2. Vacuum diaphragm

3. Manual shaft

4. Speedometer driven gear

5. Oil level tube

6. Governor cover

7. Governor

8. Oil pan

9. Oil pump

10. Inhibitor switch

11. Transaxle case

12. Oil pump

13. Square head plugs

14. Bearing cover

15. Drive shaft

76G07C-041

©

i

©

[JdQ©

I

Inspection of Level

1. Apply the parking brake and block the wheels to

prevent the vehicle from rolling.

Note

Place the car on a flat, level surface.

2. Run the engine so that the automatic transaxle fluid

reaches operating temperature.

3. While the engine is idling, shift the select lever from

P to 1 and back again.

4. Let the engine idle.

5.Shift the select lever to P.

76G07C-042

7C-25