torque MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 724 of 1865

5 DISTRIBUTOR

INSTALLATION

Note

After installing the distributor, adjust the ig-

nition timing (Refer to 5—11).

1. Apply engine oil to the O-ring and driven gear.

76G05X-056

Note

Gear driven type, check that the No.1 cylin-

der is at top dead center and aline the distrib-

utor matching marks.

76G05X-016

2. Install the distributor and connect the high-tension

leads and distributor connector.

3. Tighten lock bolt to the specified torque.

Torque specification:

19—25 Nm (1.9—2.6 m-kg, 14—18 ft-lb)

86U05X-064

5—18

Page 741 of 1865

ALTERNATOR 5

Stopper spring

Rear bearing

86U05X-026

86U05X-027

86U05X-028

.

',

; i

(S) -^jJSTjT^/

ASSEMBLY

Assemble in the reverse order of disassembly, refer-

ring to assembly note.

Assembly Note

Stopper spring installation

1. Fit the stopper spring into the eccentric groove of

the rear bearing circumference.

2. Check that the protruding part of the spring is fitted

into the deepest part of the groove.

Front bracket and rotor

When assembling the front bracket and rotor, tight-

en the locknut to the specified torque.

Tightening torque:

49—88 N-m (5—9 m-kg, 36—65 ft-lb)

Brush lifting

1. Before assembly, use a finger to hold the brushes

into the brush holder; then pass a wire

(

mm,

40—50 mm, 00.08 in, 1.6—2.0 in) through the

hole shown in the figure.

2. Secure the brushes in position.

Note

Be sure to remove wire after assembly is com-

pleted.

Rear bearing installation

1. Heat the rear bracket.

2. Press the rear bearing into the rear bracket.

3. Check that the rotor turns easily.

4BG05X-054

5-35

Page 742 of 1865

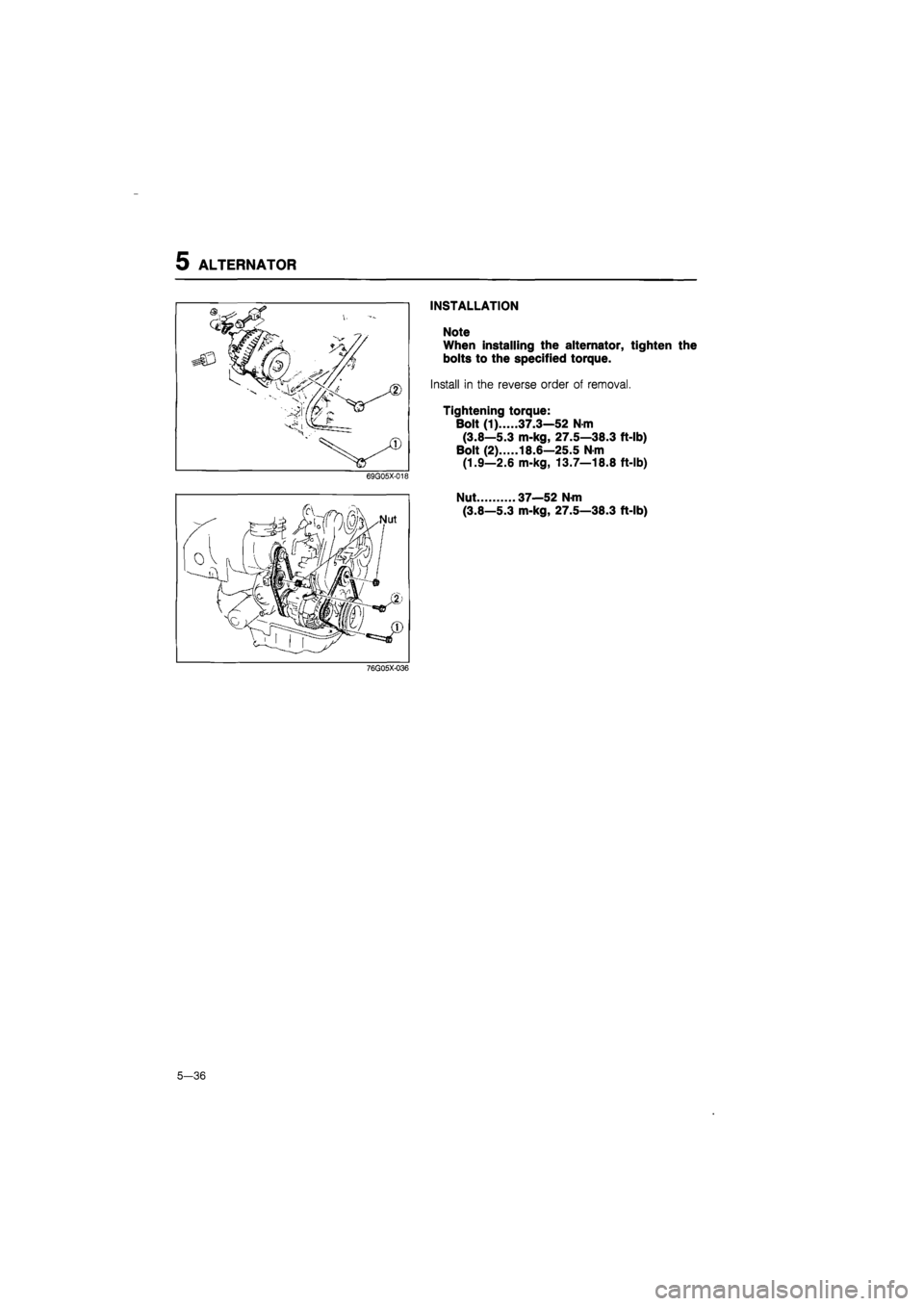

5 ALTERNATOR

INSTALLATION

Note

When installing the alternator, tighten the

bolts to the specified torque.

Install in the reverse order of removal.

Tightening torque:

Bolt (1) 37.3—52 N-m

(3.8—5.3 m-kg, 27.5—38.3 ft-lb)

Bolt (2) 18.6—25.5 Nm

(1.9—2.6 m-kg, 13.7—18.8 ft-lb)

69G05X-018

Nut 37—52 N-m

(3.8—5.3 m-kg, 27.5—38.3 ft-lb)

76G05X-036

5—36

Page 745 of 1865

STARTER (GASOLINE ENGINE, 0.85, 0.95 KW TYPE) 5

76G05X-040

REMOVAL AND INSTALLATION

1. Disconnect the negative battery cable.

2. Disconnect the wiring from the starter.

3. Raise the front of the vehicle and support it with

safety stands.

4. Remove the intake manifold bracket. (Fuel Injec-

tion Engine)

5. Remove the starter bolts.

6. Draw out the starter from lower side of the vehicle.

Installation in the revers order of removal.

Tightening torque

Bolts 37—52 N m

(3.8—5.3 m-kg, 27—38 ft-lb)

B terminal 9.8—11.8 N-m

(1.0—1.2 m-kg, 87—104 in-lb)

Intake manifold bracket bolt

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

Nut

19—25 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

DISASSEMBLY AND ASSEMBLY

1. Disassemble in the numbered order shown in the figure.

2. Assembly is the reverse order of disassembly. 4BG05X-049

4BG05X-075

1. Magnetic switch

2. Bolt

3. Rear cover

4. Brush-holder assembly

5. Yoke

6. Lever

7. Drive housing

(front cover)

8. Drive pinion

9. Armature

5-39

Page 761 of 1865

STARTER (GASOLINE ENGINE, 1.4 KW TYPE) 5

Ammeter £

Battery 12V

Switch K sf

Voltmeter W Starter

86U05X-040

No-Load Test

1. After adjusting the pinion gap, form a test circuit

with a voltmeter and an ammeter.

Note

Use heavy gauge wires and tighten each ter-

minal fully.

2. Close switch K to run the starter.

3. Check for the following:

Voltage (V) 11.0

Current (A) 90 max.

Gear shaft speed (rpm) 3,000 min.

4. If any abnormality is noted, check for the cause

according to "Inspection".

INSTALLATION

Install in the reverse order of removal.

Note

When installing the starter, tighten the bolts

to the specified torque.

Tightening torque:

Bolts 37—52 N m

(3.8—5.3 m-kg, 27—38 ft-lb)

B terminal 9.8—11.8 N-m

(1.0—1.2 m-kg, 87—104 in-lb)

76G05X-043

5—55

Page 763 of 1865

5 STARTER (DIESEL ENGINE, 2.0 KW TYPE)

REMOVAL AND INSTALLATION

Removal is as follows:

1. Disconnect the negative battery cable.

2. Disconnect the wiring from the starter.

3. Remove the starter.

Install in the reverse order of removal.

Tightening torque:

Bolts 64—89 N-m

(6.5—9.1 m-kg, 47—66 ft-lb)

B terminal 9.8—11.8 N-m

(1.0—1.2 m-kg, 87—104 in-lb)

76G05X-044

DISASSEMBLY AND ASSEMBLY

1. Disassemble in the order shown in the figure.

2. Assemble in the reverse order of disassembly.

4BG05X-047

1. Yoke assembly 7. Over-running clutch assembly

2. Brush holder 8. Pinion gear

3. Armature 9. Steel ball

4. Magnetic switch assembly 10. Coil spring

5. Idler gear 11. Housing

6. Retainer and rollers

5—57

Page 773 of 1865

5 STARTER (DIESEL ENGINE, 2.0 KW TYPE)

REMOVAL AND INSTALLATION

Removal is as follows:

1. Disconnect the negative battery cable.

2. Disconnect the wiring from the starter.

3. Remove the starter.

Install in the reverse order of removal.

Tightening torque:

Bolts 64—89 N-m

(6.5—9.1 m-kg, 47—66 ft-lb)

B terminal 9.8—11.8 N-m

(1.0—1.2 m-kg, 87—104 in-lb)

76G05X-046

DISASSEMBLY AND ASSEMBLY

1. Disassemble in the numbered order shown in the figure.

2. Assembly in the reverse order of disassembly.

4BG05X-107

1. Magnetic switch 7. Lever

2. Rear cover 8. Cover

3. Brush-holder assembly 9. Drive pinion and over-running

4. Yoke clutch assembly

5. Armature 10. Reduction gear

6. Front housing 11. Center bracket

5—67

Page 796 of 1865

6 CLUTCH MASTER CYLINDER

1. Install the one-way valve spring and piston. (FE

DOHC, RF-N, RF-CX)

2. Tighten the joint bolt with new gasket. (FE DOHC,

RF-N, RF-CX)

Tightening torque:

83—113 Nm (8.5—11.5 m-kg, 61—83 ft-lb)

76G06X-017

3. Install the connector and new gaskets. (LHD ABS,

RHD without ABS)

Caution

Install the connector at the angle shown in the

figure.

Tightening torque:

20—29 N m (2—3 m-kg, 14—22 ft-lb)

76G06X-018

4. Install the new bushing.

5. Install the reserve tank, baffle and tank cap.

6. Install the following parts:

(1) Return spring

(2) Primary cup

(3) Spacer

(4) New piston and secondary cup assembly

Caution

A new primary cup, piston, and secondary cup

assembly must be used.

76G06X-019

w

\o/

7. While pressing the piston with a screwdriver, in-

stall the snap ring.

76G06X-020

6-10

•

Page 797 of 1865

CLUTCH RELEASE CYLINDER

INSTALLATION

1. Install the clutch master cylinder.

2. Tighten the mounting nuts.

Tightening torque:

19—26 Nm (1.9—2.6 m-kg, 14—19 ft-lb)

3. Tighten the clutch pipe flare nut securely with the

SST.

Tightening torque:

13—22 N m (1.3—2.2 m-kg, 9—16 ft-lb)

76G06X-021 4. Install the ABS relay box. (LHD)

After installation

1. Perform air bleeding. (Refer to page 6—14.)

2. Verify that there is no leakage.

3. Perform a road test.

CLUTCH RELEASE CYLINDER

86U06X-019

6-11

Page 800 of 1865

6 AIR BLEEDING

76U06X-031

4. Install the following parts:

(1) Push rod

(2) Boot

INSTALLATION

1. Install the release cylinder.

2. Tighten the installation bolts.

Tightening torque:

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

3. Tighten the clutch pipe flare nut securely with the

SST

Tightening torque:

13—22 N-m (1.3—2.2 m-kg, 9—16 ft-lb)

After installation

1. Perform air bleeding.

2. Verify that there is no leakage from the hydraulic

circuit.

3. Perform a road test.

49 0259 770B

AIR BLEEDING

The clutch hydraulic system must be bled to remove

air that entered when the pipes were disconnected.

This bleeding is done as described below.

Note

a) The fluid in the reserve tank must be main-

tained at the 3/4 level or higher during air

bleeding.

b) Use only the specified fluid type. (Refer to

page 6—3)

c) Be careful not to spill clutch fluid onto a

painted surface.

1. Remove the bleeder cap, and attach a vinyl hose

to the bleeder screw.

2. Place the other end of the vinyl tube in a glass con-

tainer of the appropriate capacity.

3. Slowly pump the clutch pedal several times by

hand.

4. While the clutch pedal is depressed, loosen the

bleeder screw to let fluid and air escape.

Then close the bleeder screw.

5. Repeat step 3 and 4 until no more air bubbles are

in the fluid.

6. Check for correct clutch operation.

86U06X-027

86U06X-028

49 0259 770B

76G06X-023

6—14

expert22 ajia http://rutracker.org