lights MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 885 of 1865

TROUBLESHOOTING (G4A-EL) 7B

79G07C-068

Drive at 50

km/h

(31

mph)

Kick-down

Stop

the

vehicle

79G07C-069

After-repair Procedure

1. Cancel the memory of malfunctions by disconnect-

ing the negative battery terminal for at least five sec-

onds, then reconnect it.

2. Remove the EC-AT tester if it is connected.

3. Drive the vehicle at 50 km/h (31 mph), then de-

press the accelerator pedal fully to activate kick-

down. Stop the vehicle gradually.

KICK goimsv

BRAKE LIGHTS*

CRUISE CONTROL

C V,. DEPRESS FULL*

Ox

azsa

ORUti rpn

"J

i"

•

rm uu

£ZL ofF

4. Reconnect the EC-AT tester to the 6-pin service

connector.

5. Ground the 1 -pin service connector with a jumper

wire.

6. Turn the ignition switch ON.

7. Check that no code numbers are displayed.

79G07C-070

Inspection Procedure

No. 06 code display (Vehicle speed sensor)

76G07B-017

7B-19

Page 929 of 1865

ELECTRICAL SYSTEM COMPONENTS 7B

Economy position

Power position • POWER

•ECONO

76G07B-066

86U07B-049

86U07B-050

ELECTRICAL

SYSTEM COMPONENTS

MODE SWITCH (G4A-EL)

Inspection of Operation

1. Turn the ignition switch ON.

2. Check that the mode indicator illuminates at each

model.

3. If it is not working properly, check terminal voltage

of mode switch.

Inspection of Continuity

1. Disconnect the mode switch.

2. Turn the ignition switch ON and light switch OFF.

3. Check the voltage between each terminal and

ground.

Mode Voltage Mode a b d e f

Power Approx. 12V

Below 1.5 V Below 1.5 V Below 1.5 V Below 1.5 V

Economy Below

1.5 V

Below

1.5 V Below 1.5 V

Below

1.5 V

Approx.

12V

4.

If

correct, check for continuty between the terminal.

Inspection of Terminal Voltage

1. Disconnect the mode switch connector.

2. Check continuity of the terminals.

Mode

Economy

Power

Connector terminal

O

O

f

o

-o

o

o

-o

-o

O—O: Indicates continuity

3. If not correct, replace the mode switch.

HOLD SWITCH (G4A-EL)

Inspection of Operation

1. Turn the ignition switch ON.

2. Check that the hold indicator illuminates while

switch depressed. Release the switch and mode

indicator lights are out.

3. If it is not working properly, check terminal voltage

of hold switch.

76G07B-067

7B—63

Page 1137 of 1865

ELECTRIC COMPONENTS 7C

76G07C-036

76G07C-037

76G07C-038

ELECTRIC COMPONENTS

INHIBITOR SWITCH

Inspection

1. Check that engine starts only at P and N range.

2. Check that the backup lights illuminate in R range

with the ignition switch ON.

3. If the inhibitor switch is not operating properly, dis-

connect it and check the continuity between the

terminals.

Connection guide

Position

N

D, 1, 2

Connector terminal

-O

O -O

-O

O—O: Indicates continuity

4. If not correct, replace the inhibitor switch.

KICK-DOWN SWITCH

Inspection of Terminal Voltage

1. Turn the ignition switch ON.

2. Check the voltage at terminal (V) with a voltmeter.

Depressing stroke Terminal voltage

7/8-8/8 (Full) Approx. 12 V

0-7/8 Below 1,5V

3. If not correct, check the wiring harness or switch,

or adjust the switch position.

Inspection of Switch

1. Disconnect the kick-down switch connector.

2. Check for continuity of the switch with an

ohmmeter.

Switch Continuity

Pushed Yes

Released No

3. If not correct, replace the kick-down switch.

83U07B-060

7C—23

Page 1479 of 1865

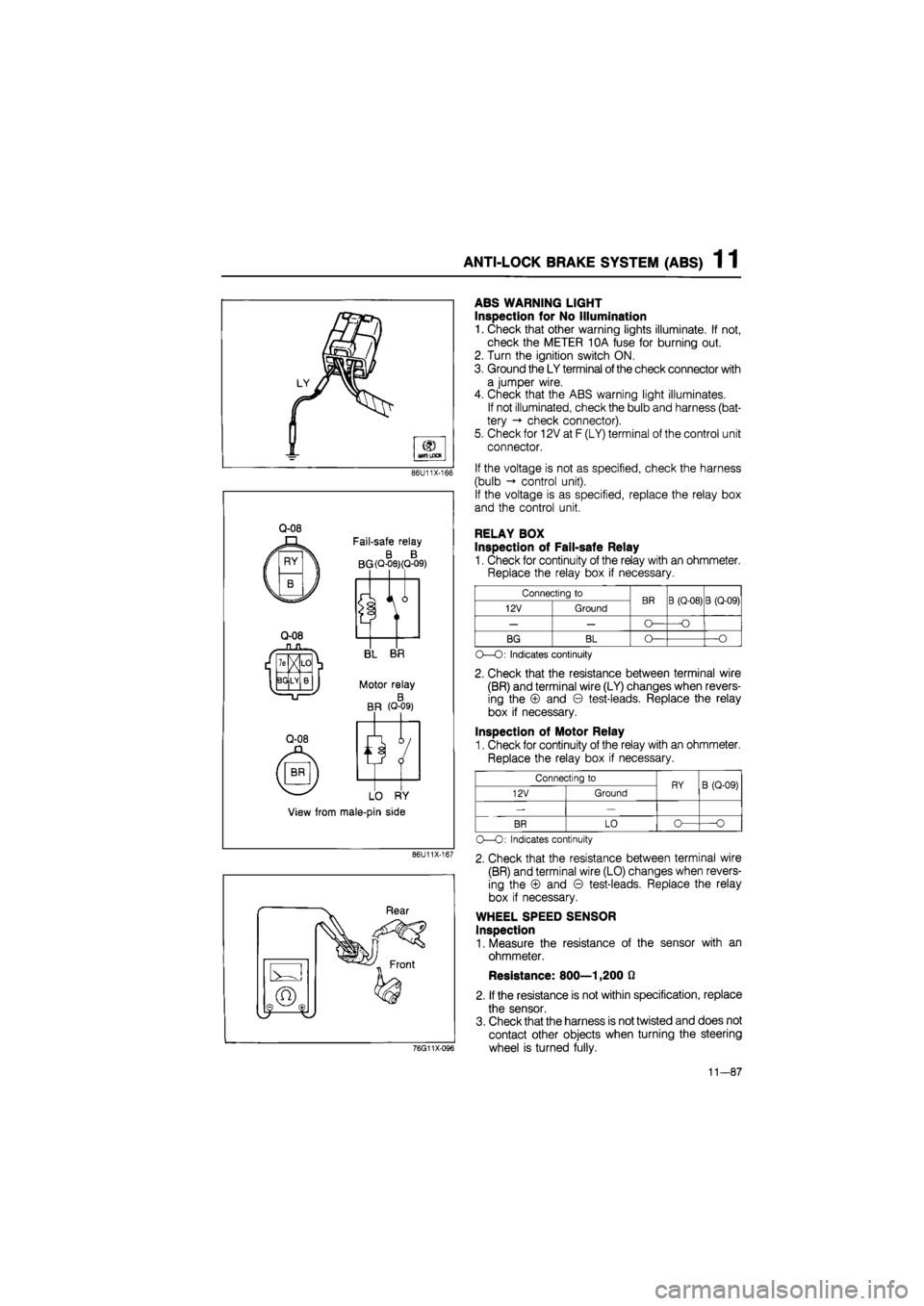

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

86U11X-1C

Q-08

Q-08

Fail-safe relay

B B BG

(Q-08)(Q-09)

V

BL BR

Motor relay

B BR (Q-09)

LO RY

View from male-pin side

86U11X-167

76G11X-096

ABS WARNING LIGHT

Inspection for No Illumination

1. Check that other warning lights illuminate. If not,

check the METER 10A fuse for burning out.

2. Turn the ignition switch ON.

3. Ground the LY terminal

of

the check connector with

a jumper wire.

4. Check that the ABS warning light illuminates.

If not illuminated, check the bulb and harness (bat-

tery -» check connector).

5. Check for 12V at F (LY) terminal of the control unit

connector.

If the voltage is not as specified, check the harness

(bulb control unit).

If the voltage is as specified, replace the relay box

and the control unit.

RELAY BOX

Inspection of Fail-safe Relay

1. Check for continuity of the relay with an ohmmeter.

Replace the relay box if necessary.

Connecting to BR B (Q-08) B (Q-09) 12V Ground BR B (Q-08) B (Q-09)

— — O— —O

BG BL O— —O

O—O: Indicates continuity

2. Check that the resistance between terminal wire

(BR) and terminal wire (LY) changes when revers-

ing the © and © test-leads. Replace the relay

box if necessary.

Inspection of Motor Relay

1. Check for continuity of the relay with an ohmmeter.

Replace the relay box if necessary.

Connecting to RY B (Q-09) 12V Ground RY B (Q-09)

-—

BR LO o— O

O—O: Indicates continuity

2. Check that the resistance between terminal wire

(BR) and terminal wire (LO) changes when revers-

ing the © and © test-leads. Replace the relay

box if necessary.

WHEEL SPEED SENSOR

Inspection

1. Measure the resistance of the sensor with an

ohmmeter.

Resistance: 800—1,200 0

2. If the resistance is not within specification, replace

the sensor.

3. Check that the harness is not twisted and does not

contact other objects when turning the steering

wheel is turned fully.

11-87

Page 1552 of 1865

14

BONNET 14— 2

STRUCTURAL VIEW 14— 2

REMOVAL 14— 3

INSTALLATION 14— 4 ADJUSTMENT 14— 4 TRUNK LID 14— 5 STRUCTURAL VIEW (SEDAN AND COUPE/MX-6) 14— 5 REMOVAL 14— 6 INSTALLATION 14— 7 ADJUSTMENT 14— 8

REAR HATCH 14— 9 STRUCTURAL VIEW 14— 9 REMOVAL 14— 10 INSTALLATION 14— 12 ADJUSTMENT 14— 12 FRONT DOORS 14—13

STRUCTURAL VIEW 14— 13

REMOVAL 14—15

INSTALLATION 14—17 ADJUSTMENT 14— 18 REAR DOORS 14—19 STRUCTURAL VIEW 14— 19 REMOVAL 14— 20

INSTALLATION 14— 21 ADJUSTMENT 14— 22 FRONT BUMPER 14— 23

STRUCTURAL VIEW 14—23 REMOVAL 14— 24 INSTALLATION 14—24 REAR BUMPER 14— 25

STRUCTURAL VIEW 14— 25 REMOVAL 14— 26

INSTALLATION 14— 26 RADIATOR GRILLE 14— 27 REMOVAL AND INSTALLATION 14— 27 HEADLIGHT AND COMBINATION LIGHT 14— 28 REMOVAL AND INSTALLATION 14— 28

AIMING 14— 31 REAR COMBINATION LIGHTS 14— 32 REMOVAL AND INSTALLATION 14— 32

REPLACEMENT OF REAR COMBINATION LIGHT LENS 14— 33

LICENSE PLATE LIGHT AND CARGO ROOM LIGHT 14— 35 REMOVAL AND INSTALLATION 14— 35

INTERIOR LIGHT AND MAP LIGHT 14- 36 REMOVAL AND INSTALLATION 14— 36

MOLDING AND GARNISH 14— 37

STRUCTURAL VIEW 14— 37 WINDSHIELD MOLDING 14— 38 WINDSHIELD LOWER MOLDING 14— 38 DRIP MOLDING 14— 38 BELT LINE MOLDING 14— 38 REAR WINDOW SIDE MOLDING (SEDAN) .14— 39 REAR WINDOW LOWER MOLDING

(SEDAN AND COUPE/MX-6) 14— 39 REAR WINDOW UPPER MOLDING 14— 39

BONNET MOLDING

(SEDAN AND HATCHBACK) 14— 39 QUARTER WINDOW MOLDING (COUPE/MX-6) 14— 40 QUARTER WINDOW MOLDING

(HATCHBACK) 14—40 QUARTER WINDOW MOLDING (SEDAN)... 14— 40 REAR WINDOW SIDE MOLDING (COUPE/MX-6) 14— 40

TRUNK LID MOLDING (SEDAN AND HATCHBACK) 14— 41

CENTER PILLAR GARNISH

(SEDAN AND HATCH BAC K/MX-6) 14— 41 REAR FINISHER (COUPE/MX-6 AND SEDAN) 14— 41 REAR FINISHER (HATCHBACK) 14— 41

SAIL GARNISH 14— 42

SIDE PROTECTOR MOLDING 14— 42 DOOR MIRROR 14— 44 DISASSEMBLY 14— 44 ASSEMBLY 14— 44 TRUNK-LID LOCK REMOTE RELEASE 14— 45 REMOVAL AND INSTALLATION 14— 45 FUEL FILLER LID REMOTE RELEASE 14— 46

REMOVAL AND INSTALLATION 14— 46 WINDSHIELD GLASS 14—47 STRUCTURAL VIEW 14—47 REMOVAL 14— 48 INSTALLATION 14— 49 REAR WINDOW GLASS 14— 52

STRUCTURAL VIEW 14— 52 REMOVAL 14— 54

INSTALLATION 14— 55 REAR HATCH GLASS 14— 58 STRUCTURAL VIEW 14— 58 REMOVAL 14— 59 INSTALLATION 14— 59 QUARTER WINDOW GLASS 14— 62 STRUCTURAL VIEW 14— 62

REMOVAL 14— 64 INSTALLATION 14—64

HEADLINER 14- 67 STRUCTURAL VIEW 14—67 REMOVAL 14— 69 INSTALLATION 14— 72 INSTRUMENT PANEL 14— 73 STRUCTURAL VIEW 14— 73

INSTALLATION VIEW 14— 74

REMOVAL 14— 75 INSTALLATION 14— 80 SLIDING SUNROOF 14— 81 STRUCTURAL VIEW 14— 81 REMOVAL 14— 82 INSTALLATION 14— 85 WINDSHIELD WIPER 14— 91

STRUCTURAL VIEW 14— 91

REMOVAL 14— 92

INSTALLATION 14— 93 ADJUSTMENT 14— 93 REAR WINDOW WIPER 14—94 STRUCTURAL VIEW (HATCHBACK) 14— 94 REMOVAL 14— 95 INSTALLATION 14—95 ADJUSTMENT 14— 96

HEADLIGHT WASHER 14— 97 REMOVAL AND INSTALLATION 14— 97 SEAT 14— 98 STRUCTURAL VIEW 14— 98 INSPECTION 14—100 SEAT BELTS 14—101

STRUCTURAL VIEW 14—101 INSPECTION 14—101

UNDERBODY PROJECTED DIMENSIONS.... 14—102 UNDERBODY STRAIGHT-LINE DIMENSIONS 14—104 76G14X-001

Page 1583 of 1865

1 4 REAR COMBINATION LIGHTS

REAR COMBINATION LIGHTS

REMOVAL AND INSTALLATION

1. Disconnect the negative battery cable.

2. Remove in the sequence shown in the figure.

3. Install in the reverse order of removal.

76G14X-010

Hatchback

1. End trim

2. Nuts

3. Lens and body

4. Cover

5. Bulb: Turn signal light 21W

Brake and tail light 21W

Side marker light 5W

Sedan and Coupe/MX-6

1. End trim

2. Nuts

3. Lens and body

4. Cover

5. Bulb: Turn signal light 21W

Brake and tail light 21W

Side marker light 5W

14—32

Page 1584 of 1865

REAR COMBINATION LIGHTS 1 4

REPLACEMENT OF REAR COMBINATION LIGHT

LENS

1. Use a hot air blower to soften the "hot melt" (bond-

ing agent) around the lens.

86U14X-077

2. Remove the lens from the light housing by push-

ing the rear of the lens with a hammer handle or

round bar.

76U14X-034

3. Heat the light housing, and remove the "hot melt"

and any fragments of the lens.

Note

a) The "hot melt" should be reused if

possible.

b) If the "hot melt" can be reused, the follow-

ing step is unnecessary.

86U14X-078

4. Put Uni-sealer (8531 77 739) adhesive in the light

housing groove.

86U14X-079

14—33

Page 1585 of 1865

1 4 REAR COMBINATION LIGHTS

5. Fit the new lens onto the light housing. Press the

lens firmly so that it will adhere.

86U14X080

6. Immerse the combination light in water to check

for leaks.

76U14X-038

14—34

Page 1674 of 1865

CLUSTER SWITCH 15

e a

frtum

Illumination light

b

f

e -Q-

f d b d I f

Indicator light

76G15X-088

86U15X-018

g

TTTT

h f d b

from f „

IG SW

from a def. relay^

from ~ TWS unit

15 minules timer

To ground

h To panel

"controller

INSPECTION OF ROCKER TYPE

Hazard switch

1. Check for continuity between the terminals in each

position with an ohmmeter.

——____Terminal Position

^

a

b d

e

f

OFF

ON

-o

O

O:

Indicates continuity

2. If continuity is not as specified, replace the switch

or replace the light(s).

Defroster switch

1. Turn the ignition switch ON.

2. Push the defroster switch to ON, and check the

lights for lighting.

3. If the lights do not light, replace the lights.

4. Check that the switch goes off after 15 min from

switch ON.

5. Check the voltage between each terminal and a

body ground.

Position Terminal voltage

(V)

Position

b d f g h

OFF 0 12 12 0 12

ON 0 0 12 0 12

ON

(head light switch

ON) 0 0 12 2-12 12

OFF (head light switch

ON) 0 12 12 2-12 12

6. If the voltage of "d" terminal is 12V with switch off

but not OV with switch on, replace the defroster

switch.

If the voltage of "d" terminal is not 12V with switch

off, trouble is in defroster relay or harness.

If the voltages of the other terminals are not cor-

rect, trouble is in the other parts or harness.

86U15X-019

15—19

Page 1677 of 1865

15 METER

METER

STRUCTURAL VIEW

DIGITAL ELECTRONIC DISPLAY METER

ANALOG DISPLAY METER

76G15X-007

1. Speedometer 5. Warning and indicator lights

2. Tachometer 6. Tripmeter

3. Water temperature gauge 7. Twin tripmeter change switch

4. Fuel gauge 8. Fuel garge scale change switch

15—22