oil type MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 311 of 1865

INSTALLATION 1C

Accelerator Cable

Install the accelerator cable.

76G01C-235

76G01C-236

Engine Oil

Add the specified amount and type of engine oil. (Re-

fer to Section 2B)

Coolant

Close the drain plug, fill the radiator and reservoir tank

with the specified amount and type of coolant. (Re-

fer to Section 3B)

Check Engine Condition

1. Check for leaks.

2. Perform engine adjustments if necessary.

3. Perform a road test.

4. Recheck the oil and coolant levels.

1C—99

Page 315 of 1865

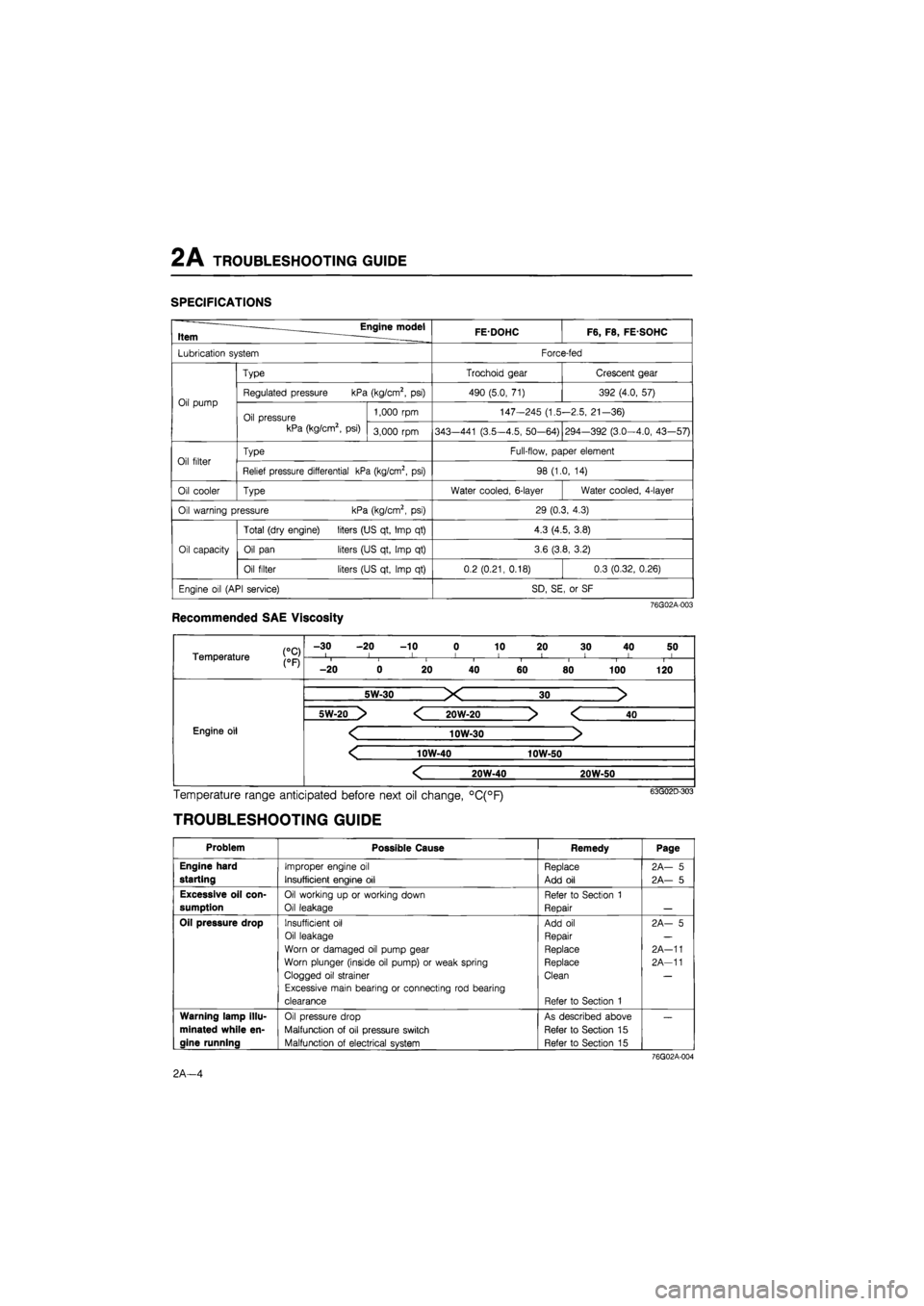

2 A TROUBLESHOOTING GUIDE

SPECIFICATIONS

Engine model Item . FEDOHC F6, F8, FE SOHC

Lubrication system Force-fed

Oil pump

Type Trochoid gear Crescent gear

Oil pump Regulated pressure kPa (kg/cm2, psi) 490 (5.0, 71) 392 (4.0, 57) Oil pump

Oil pressure kPa (kg/cm2, psi)

1,000 rpm 147-245 (1.5-2.5, 21-36) Oil pump

Oil pressure kPa (kg/cm2, psi) 3,000 rpm 343—441 (3.5-4.5, 50-64) 294-392 (3.0-4.0, 43—57)

Oil filter Type Full-flow, paper element Oil filter Relief pressure differential kPa (kg/cm2, psi) 98 (1.0, 14)

Oil cooler Type Water cooled, 6-layer Water cooled, 4-layer

Oil warning pressure kPa (kg/cm2, psi) 29 (0.3, 4.3)

Oil capacity

Total (dry engine) liters (US qt, Imp qt) 4.3 (4.5, 3.8)

Oil capacity Oil pan liters (US qt, Imp qt) 3.6 (3.8, 3.2) Oil capacity

Oil filter liters (US qt, Imp qt) 0.2 (0.21, 0.18) 0.3 (0.32, 0.26)

Engine oil (API service) SD, SE, or SF

76G02A-003

Recommended SAE Viscosity

Temperature j0pj

-30 -20 -10 0 10 20 30 40 50 I l I I 1 < ! I I Temperature j0pj i i i i I i 1 1

-20 0 20 40 60 80 100 120

Engine oil Engine oil

5W-30 X 30 >

Engine oil Engine oil

5W-20 > < 20W-20 > < 40

Engine oil < 10W-30 > Engine oil

< 10W-40 10W-50

Engine oil Engine oil

< 20W-40 20W-50

Engine oil

Temperature range anticipated before next oil change, °C(°F)

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Engine hard

starting

Improper engine oil

Insufficient engine oil

Replace

Add oil

2A— 5

2A— 5

Excessive oil con-

sumption

Oil working up or working down

Oil leakage

Refer to Section 1

Repair

Oil pressure drop Insufficient oil

Oil leakage

Worn or damaged oil pump gear

Worn plunger (inside oil pump) or weak spring

Clogged oil strainer

Excessive main bearing or connecting rod bearing

clearance

Add oil

Repair

Replace

Replace

Clean

Refer to Section 1

2A- 5

2A-11

2A-11

Warning lamp illu-

minated while en-

gine running

Oil pressure drop

Malfunction of oil pressure switch

Malfunction of electrical system

As described above

Refer to Section 15

Refer to Section 15

76G02A-004

2A—4

Page 317 of 1865

2A OIL FILTER, OIL COOLER

j

F

k

4

4. Install the drain plug and a new gasket.

5. Refill the engine with the specified type and amount

of oil.

6. Refit the oil filler cap.

Oil pan capacity:

3.6 liters (3.8 US qt, 3.2 Imp qt)

7. Recheck the oil level after the engine has been run.

76G02A-006

TbJ

r

86U02X-008

76G02A-007

0

A

if \ lO

/O

f \ 11 • V jJ

VJ f .fa,-

n D

©

76G02A-008

OIL FILTER

REPLACEMENT

1. Remove the oil filter with a suitable wrench.

2. Use a clean rag to wipe off the mounting surface

on the engine.

3. Apply a small amount of engine oil to the rubber

seal of the new filter.

Warning

Be careful that the engine and filter are very

hot.

4. (DOHC)

Install the oil filter until the rubber seal contacts the

base and then tighten the filter

1

and

1

/6 turn with

a wrench.

(SOHC)

Install the oil filter and tighten it by hand only. Do

not use a wrench.

5. Start the engine and inspect around the filter seal

for leaks.

6. Check the oil level and add oil if necessary.

Oil filter capacity:

0.20 liters (0.21 US qt, 0.18 Imp qt)...DOHC

0.30 liters (0.32 US qt, 0.26 Imp qt)...SOHC

OIL

COOLER

(DOHC, 12-valve,

ECE

8-valve)

REMOVAL AND INSTALLATION

Remove in the sequence shown in the figure.

Install in the reverse order of removal.

1. Water hose

2. Oil filter

3. Nut

4. Oil cooler

Nut tightening torque:

29—39

N

m (3.0—4.0 m-kg, 22—29 ft-lb)

2A-6

Page 327 of 1865

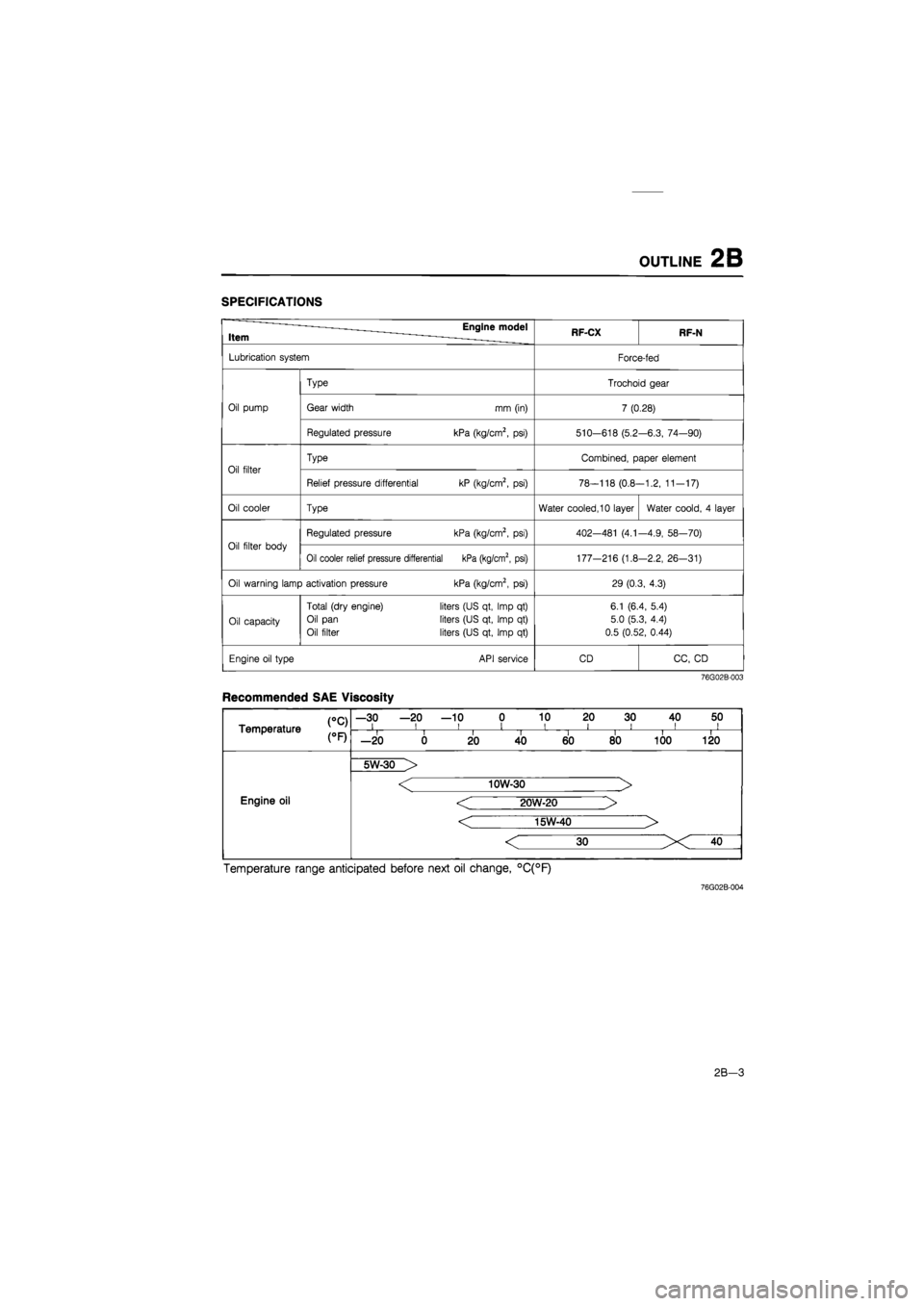

OUTLINE 2B

SPECIFICATIONS

Item Engine model RF-CX RF-N

Lubrication system Force-fed

Type Trochoid gear

Oil pump Gear width mm (in) 7 (0.28)

Regulated pressure kPa (kg/cm2,

psi)

510-618 (5.2 -6.3, 74—90)

Oil filter

Type Combined, paper element

Oil filter

Relief pressure differential kP (kg/cm2,

psi)

78-118 (0.8--1.2, 11-17)

Oil cooler Type Water cooled, 10 layer Water coold,

4

layer

Oil filter body

Regulated pressure kPa (kg/cm2,

psi)

402—481

(4.1

-4.9, 58—70)

Oil filter body

Oil cooler relief pressure differential kPa (kg/cm2, psi) 177-216 (1.8 -2.2, 26-31)

Oil warning lamp activation pressure kPa (kg/cm2,

psi)

29 (0.3, 4.3)

Oil capacity

Total (dry engine)

Oil pan

Oil filter

liters (US qt, Imp

qt)

liters (US qt, Imp

qt)

liters (US qt, Imp

qt)

6.1 (6.4, 5.4)

5.0 (5.3, 4.4)

0.5 (0.52, 0.44)

Engine oil type API service CD CC,

CD

76G02B-003

Recommended SAE Viscosity

CC) Temperature

—30 —20 —10 0 10 20 30 40 50 i i i i i i i ii CC) Temperature i i II i i i i —20 0 20 40 60 80 100 120

Engine oil

5W-30 >

Engine oil

< 10W-30 >

< 20W-20 >

< 15W-40 >

Engine oil

Temperature range anticipated before next oil change, °C(°F)

76G02B-004

2B-3

Page 330 of 1865

2B

ENGINE OIL, OIL

FILTER

86U02X-006

76G02B-010

86U02X-008

ENGINE OIL

REPLACEMENT

1. Warm up the engine to the normal operating tem-

perature and stop it.

2. Remove the oil filler cap and the oil pan drain plug.

3. Drain the oil into a suitable container.

Warning

Be careful when draining, the oil is very hot.

4. Install the drain plug and a new gasket.

Tightening torque:

29—41 N-m (3.0—4.2 m-kg, 22—30 ft-lb)

5. Refill the engine with the specified type and amount

of oil.

6. Refit the oil filler cap.

Oil pan capacity:

5.0 liters (5.3 US qt, 4.4 Imp qt)

7. Recheck the oil level after the engine has been run.

OIL

FILTER

REPLACEMENT

1. Remove the oil filter with a suitable wrench.

2. Use a clean rag to wipe off the mounting surface

on the engine.

3. Apply a coat of engine oil to the filter rubber seal.

4. Install the oil filter until the rubber seal contacts the

oil cooler by hand. Then tighten it a 7/6 turn fur-

ther with a band type wrench.

5. Start the engine and inspect around the filter seal

for leaks.

6. Check the oil level and add oil if necessary.

Oil filter capacity:

0.50 liters (0.52 US qt, 0.44 Imp qt)

76G02B-011

2B—6

Page 380 of 1865

OUTLINE 4A

SPECIFICATIONS

F6 & F8 Engine

Engine F6 F8

Specification General Singapore General

ECE,

Hong Kong, &

Singapore

Idle speed

rpm

MTX 800

+58

Idle speed

rpm

ATX 950

t5§

(in N range)|

900 +5§ (in N

range)

CO concentration

%

2.0

± 0.5

(Without secondary

air

injection)

Carburetor

Type Down draft, two barrel

Throat diameter

mm (in)

Primary 30 (1.18) Throat diameter

mm (in)

Secondary 34 (1.34)

Venturi diameter

mm

(in) Primary 23.5 (0.93) Venturi diameter

mm

(in) Secondary 29.0 (1.14)

Main nozzle

mm (in)

Primary 2.6 (0.10) Main nozzle

mm (in)

Secondary 2.8 (0.11)

Main

jet mm (in)

Primary MTX 1.10 (0.0433) 1.09 (0.0429) 1.14 (0.045)

Main

jet mm (in)

Primary ATX 1.10 (0.0433) 1.08 (0.0425) 1.12 (0.044) Main

jet mm (in)

Secondary 1.50 (0.059)

Main

air

bleed mm (in)

Primary MTX 0.60 (0.024) 0.60 (0.024) 0.55 (0.022) Main

air

bleed mm (in)

Primary ATX 0.60 (0.024) 0.80 (0.031) 0.60 (0.024) Main

air

bleed mm (in) Secondary 0.50 (0.020)

Slow

jet mm (in)

Primary 0.48 (0.019) 0.46 (0.018) Slow

jet mm (in)

Secondary 1.00 (0.039) 1.10 (0.043)

Slow

air

bleed mm (in)

Primary No.1 0.80 (0.031)

Slow

air

bleed mm (in)

Primary No.2 1.90 (0.075) Slow

air

bleed mm (in) Secondary No.1 1.00 (0.039) 0.80 (0.031) Slow

air

bleed mm (in) Secondary No.2 0.50 (0.020)

Power

jet mm (in)

0.50 (0.0201

Fast idle adjustment

mm (in)

Clearance between

Drimarv

throttle valve and bore

1.40-1.76 (0.055—0.069) MTX: 0.48-0.64 (0.019-0.025) ATX: 0.56-0.72 (0.022-0.028)

Float level adjustment mm (in)

Max. fuel flow

"L"

Clearance between

flo

44 (17.3)

at and

air

horn without aasket Float level adjustment mm (in) Fuel stop

"H"

12.5(0.49)

Clearance between float and

air

horn without aasket; float lowered

by

own weight

Choke breaker diaphragm mmHg (inHg)

Start 180-240 (7.1—9.5) 100-160 (3.9—6.3) Choke breaker diaphragm mmHg (inHg) Stop 290-350 (11.4—13.8) 220—280 8.7—11.01

Choke opener mmHg (inHg) Start 35-65 (1.4-2.6)

...

35-65 (1.4-2.6) Choke opener mmHg (inHg) Stop

......

130-190 (5.1-7.5) 130-190 (5.1-7.5)

Fuel tank capacity

Liters (US gal, Imp gal) 60 (15.9, 13.2)

Fuel Dump

Delivery pressure kPa (kg/cm2,

psi)

20-26 (0.20-0.27, 2.8—3.8)

Feeding capacity cc/min (cu in/min) More than 860 (52.5)

at

idle

Fuel filter

Type Paper element with magnet

Air cleaner

Fresh-Hot switching Manual Diaphragm type

Element tvoe Oil permeated paper

Fuel specification Leaded regular

76G04A-513

4 A—15

Page 381 of 1865

4A OUTLINE

FE Engine

Engine FE 8Valve FE 12Valve FE 8Valve

Specification General Middle East

ECE, Hong Kong, & Singapore Unleaded fuel

Idle speed

rpm

MTX 800

+5§

850

+5§

Idle speed

rpm

ATX 900

+58 (in N

range)

CO concentration

%

2.0

± 0.5

(Without secondary

air

injection)

Carburetor

Type Down draft,

two

barrel

Throat diameter

mm (in)

Primary 30 (1.18) Throat diameter

mm (in)

Secondary 34 (1.34)

Venturi diameter

mm (in)

Primary 23.5 (0.93) Venturi diameter

mm (in)

Secondary 29.0 (1.14)

Main nozzle

mm (in)

Primary 2.6 (0.10) Main nozzle

mm (in)

Secondary 2.8 (0.11)

Main

jet mm (in)

Primary MTX 1.14 (0.045) 1.09 (0.0429) 1.14 (0.045) 1.09 (0.0429) Main

jet mm (in)

Primary ATX 1.12 (0.044) 1.08 (0.0425) 1.12 (0.044) 1.09 (0.0429) Main

jet mm (in)

Secondary 1.55 (0.061) 1.50 (0.059) 1.55 (0.061) 1.50 (0.059)

Main

air

bleed

mm (in)

Primary MTX 0.50 (0.020) 0.60(0.024) 0.50 (0.020) 0.50 (0.020) Main

air

bleed

mm (in)

Primary ATX 0.55 (0.022) 0.80 (0.031) 0.55 (0.022) 0.50 (0.020) Main

air

bleed

mm (in) Secondary 0.50 (0.020)

Slow

jet mm (in)

Primary 0.46 (0.018)

Slow

jet mm (in)

Secondary MTX 1.10 (0.043) 1.00 (0.039) 1.10 (0.043) 0.90 (0.035) Slow

jet mm (in)

Secondary ATX 1.10 (0.043) 1.00 (0.039) 1.10 (0.043) 1.00 (0.039)

Slow

air

bleed

mm (in)

Primary No.1 0.80 (0.031)

Slow

air

bleed

mm (in)

Primary No.2 1.90 (0.075) Slow

air

bleed

mm (in) Secondary No.1 0.80 (0.031) 1.00 (0.039) 0.80 (0.031) 1.00 (0.039)

Slow

air

bleed

mm (in) Secondary No.2 0.50 (0.020)

Power

jet mm (in)

MTX 0.50 (0.020) 0.50 (0.020) Power

jet mm (in)

ATX 0.50 (0.020) 0.40 (0.016)

Fast idle adjustment

mm (in)

Clearance between primary throttle valve and bore

MTX 0.48—0.64

(0.019-0.025) 1.40—1.76

(0.055-0.069)

0.48—0.64

(0.019-0.025) 1.40-1.76

(0.055-0.069)

Fast idle adjustment

mm (in)

Clearance between primary throttle valve and bore ATX 0.56-0.72 (0.022—0.028)

1.40—1.76

(0.055-0.069) 0.56-0.72 (0.022—0.028)

1.40-1.76

(0.055-0.069)

Float level adjust-

ment

mm (in)

Max. fuel flow

"L"

Clearance between

flo

44 (17.3)

at and

air

horn without aasket Float level adjust-

ment

mm (in)

Fuel stop

"H" |

12.5(0.49)

Clearance between float and

air

horn without aasket: float lowered

bv

own weiaht

Choke breaker diaphragm mm-Hg (in-Hg)

Start 100-160 (3.9—6.3) 180—240 (7.1-9.4) 100-160

(3.9-6.3)

180-240

(7.1-9.4) Choke breaker diaphragm mm-Hg (in-Hg) Stop 220—280

(8.7-11.0)

290-350

(11.4-13.8)

220—280

(8.7-11.0)

290-350

(11.4-13.8)

Choke opener mmHg (inHg)

Start 80—120

(3.1-8.7)

30-70 (1.2-2.8) Choke opener mmHg (inHg)

Stop 220-280 (8.7—11.0) 130-190

(5.1-7.5)

Fuel tank capacity

Liters (US aal, Imp aal) 60 (15.9, 13.2)

Fuel DumD

Delivery pressure kPa (kg/cm2,

psi)

20-26 (0.20—0.27, 2.8-3.8) 20-29 (0.20-0.30, 2.8-4.3)

20-26 (0.20-0.27, 2.8-3.8)

Feedina caDacitv cc/min

feu

in/mini More than 860 (52.5)

at

idle

Fuel filter

Type Paper element with magnet

Air cleaner

Fresh-Hot switchina Diaphragm Manual Diaphragm Bimetal

Element

tvDe

Oil permeated paper

Fuel specification Leaded super

Unleaded super Leaded regular Leaded super Unleaded super Unleaded regular

76G04G-514

4A—16

Page 468 of 1865

4B OUTLINE

SPECIFICATIONS

Item Specification

Idle speed rpm MTX: 800 +5„° (Neutral), ATX: 900 +5S

(P

range)

Throttle body

Type Horizontal draft (1 -barrel)

Throat diameter mm (in) 50 (2.0)

Air flow meter

E2-VS More than

20

E2-VC 100-300

Resistor

Q

E2-VB 200—400 Resistor

Q

E2-THA -20°C

(

—4°F) 13,600-18,400 20°C

(

68°F) 2,210-2,690 60°C (140°F)

493- 667

Air cleaner

Element type Oil permeated

Fuel pump

Type Impeller

(in

tank)

Output pressure kPa (kg/cm2,

psi)

441-588 (4.5-6.0, 64—85)

Feeding capacity cc (cu in)/10 sec. 220 (13.4) minmum

Fuel filter

Type Low pressure side Nylon element Type High pressure side Paper element

Pressure regulator

Type Diaphragm

Regulating pressure kPa (kg/cm2,

psi)

235-275 (2.4—2.8, 34—40)

Injector

TvDe

Hiqh-ohmic

Type

of

drive Voltage

Resistance

fi

12-16

Injection amount cc (cu

in) 15

seconds 38—53 (2.3-3.2)

Fuel tank

Capacity liters (US gal, Imp gal) 60 (15.9, 13.2)

Fuel

Soecification Unleaded reaular

76G04B-506

4B—6

Page 675 of 1865

4D ON-VEHICLE MAINTENANCE

ON-VEHICLE MAINTENANCE

76G04D-004

AIR CLEANER ELEMENT

Check the air cleaner element for excessive dirt, dam-

age, or oil. Replace if necessary.

Caution

(Wet type)

Do not clean the air cleaner element with com-

pressed air, replace if necessary.

(Dry type)

When cleaning the air cleaner element, blow

dust off from the inside first, then blow off the

outside.

(General)

1. Loosen the drain plug of the sedimenter and let

the water drain. If necessary loosen the air bleed-

ing plug.

2. Bleed air from the sedimenter.

AIR BLEEDING

From Fuel Tank to Fuel Filter

1. Loosen the air bleeding plug of the fuel filter.

2. Pump the priming pump until no air bubbles flow

from the air bleeding plug hole.

3. Depress the priming pump and tighten the air

bleeding plug.

Note

Open only the air bleeding plug of the filter.

From Fuel Filter to Injection Pump

Pump the priming pump until it becomes hard to

pump.

76G04D-007

WATER DRAINING

(ECE)

1. Loosen the drain plug of the fuel filter.

2. Pump the priming pump.

3. Bleed air from the fuel filter.

4D—4

Page 679 of 1865

INTAKE AIR SYSTEM 4D

AIR DUCT AND AIR CLEANER

Removal and Installation

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

3. Check for air leakage.

1. Tire house cover

2. Air duct

3. Air hose

4. Air cleaner case

5. Air cleaner cover

6. Air cleaner

element

Inspection

Air cleaner

1. Inspect the silencer in the air cleaner cover for

damage.

2. Inspect the air cleaner element for excessive dirt,

damage, or oil. Replace if necessary.

Caution

(Wet type)

Do not clean the air cleaner element with com-

ressed air, replace it if necessary.

(Dry type)

When cleaning the air cleaner element, blow

dust off from the inside first, then blow off the

outside.

Air duct

Inspect the silencer in the air duct for damage. Re-

place if necessary.

76G04D-017

4D—8