check engine MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 922 of 1865

7B TROUBLESHOOTING (G4A-HL)

F8 engine

8/8-1

7/8-

6/8-

O) I

i ! O) Q.

o 3/8- [ ^ I o

jE 2/8-1 I

1/8- |

0/8 ' 1 ' 1 ' 1 1 1 1 1 1— ' l 0 20 40 60 80 100 120 140 (12) (25) (37) (50) (63) (74) (87)

Vehicle speed km/h (mph)

76G07B-060

Noise and vibration

Drive the vehicle in 1st gear and check for abnormal noise or vibration.

Note

Abnormal noise and vibration can also be caused by the torque converter, drive shaft or

differential. Therefore, checking of cause must be made with extreme care.

P Range Test

1. Shift into P range on a gentle slope, release the brake and check that the vehicle does not roll.

2. Shift into P range while driving the vehicle at maximum of 4 km/h (2.5 mph) on a level surface,

and check that the vehicle stops.

Vehicle Speed at Gearshift Table

Range Throttle condition Shifting Vehicle speed km/h (mph) Range Throttle condition Shifting FE engine F8 engine

D

Fully opened 1st ->• 2nd 50-65 (31-40) 47-62 (29-38)

D

Fully opened 2nd - 3rd 100-115 (62-71) 94-109 (58—68)

D

Half throttle (1/2)

1st - 2nd 17-32 (11-20) 16—31 (10—19)

D

Half throttle (1/2) 2nd -> 3rd 42-57 (26-35)

D

Half throttle (1/2) 3rd -> OD 79-94 (49-58) 74-89 (46-55)

D

Half throttle (1/2)

Lock-up 74-89 (46-55) D

Kick-down

OD - 3rd More than 88 (55) More than 82 (51) D

Kick-down

OD -> 2nd 34-103 (21-64) 33-97 (20-60)

D

Kick-down OD - 1st 27-49 (17-30) 26-48 (16-30)

D

Kick-down 3rd - 2nd 34—103 (21-64) 33-97 (20-60)

D

Kick-down

3rd - 1st

11

-49 (7—30) 10-48 (6-30)

D

Kick-down

2nd - 1st

1st - 2nd

4-49 (2-30) 3-48 (2-30)

1

Fully opened

2nd - 1st

1st - 2nd 56-71 (35-44) 52—67 (32—42)

1 Half throttle (1/2) 1st - 2nd 56-71 (35-44) 52-67 (32—42) 1

Kick-down 2nd -> 1st 46-61 (29-38) 43-58 (27-36)

D Fully opened 3rd lock-up 106-121 (66—75) 100-115 (62-71)

7B-56

Page 923 of 1865

TROUBLESHOOTING (G4A-HL) 7B

Evaluation

Condition Possible Cause

No 1-2 shift

Insufficient governor pressure

No 1-2 shift

Stuck 1 range control valve

No 1-2 shift Stuck 1-2 shift control valve No 1-2 shift

Stuck 1-2 shift valve

No 1-2 shift

No check ball (rubber ball)

No 2-3 shift

Insufficient governor pressure

No 2-3 shift

Stuck 2 range control valve

No 2-3 shift Stuck servo control valve No 2-3 shift

Stuck 2-3 shift valve

No 2-3 shift

No check ball (rubber ball)

No 3-OD shift

Insufficient governor pressure

No 3-OD shift

Excessive throttle pressure

No 3-OD shift Stuck OD release valve No 3-OD shift Stuck needle valve of the OD release solenoid valve No 3-OD shift

Stuck 3-4 shift valve

No 3-OD shift

No check ball (rubber ball)

No. Lock-up (Electric circuit is OK)

Insufficient governor pressure

No. Lock-up (Electric circuit is OK)

Stuck OD release valve

Stuck needle valve of the OD release solenoid valve No. Lock-up (Electric circuit is OK)

Stuck OD lock-up valve

No. Lock-up (Electric circuit is OK)

Stuck lock-up control valve

Shift occurred in 2 range Stuck 1-2 control valve Shift occurred in 2 range Stuck 2 range control valve

No kick-down Stuck throttle valve No kick-down Stuck kick-down valve

Incorrect shift point In D and 1 range

Excessive or insufficient governor pressure

Incorrect shift point In D and 1 range Excessive or insufficient throttle pressure Incorrect shift point In D and 1 range

Excessive or insufficient line pressure Incorrect shift point

In 1 range Stuck 1 range control valve

No engine braking effect

Stuck coasting bypass valve

No engine braking effect Fluid leakage from 2-3 accumulator seal rings No engine braking effect

No check ball (rubber ball)

Shift shock or slippage

In 1-2 and/or 3-OD shift

Fluid leakage from 1-2 accumulator seal rings

Shift shock or slippage

In 1-2 and/or 3-OD shift No check ball (rubber ball) or leakage

Shift shock or slippage

In 1-2 and/or 3-OD shift

No one-way check orifice or leakage

Shift shock or slippage In 2-3 shift

Fluid leakage from 2-3 accumulator seal ring

Shift shock or slippage In 2-3 shift

Stuck bypass valve

Shift shock or slippage In 2-3 shift

Stuck 2-3 timing valve

Shift shock or slippage In 2-3 shift Stuck coast bypass valve Shift shock or slippage In 2-3 shift

Stuck servo control valve Shift shock or slippage In 2-3 shift

No one-way check orifice or leakage

Shift shock or slippage In 2-3 shift

No check ball (rubber ball) or leakage

Shift shock or slippage

In 3-2 shift

Fluid leakage from 1-2 accumulator seal ring

Shift shock or slippage

In 3-2 shift No check ball (rubber ball) or leakage

Shift shock or slippage

In 3-2 shift Stuck 3-2 timing valve

Shift shock or slippage

In 3-2 shift

Stuck 3-2 capacity valve

83U07B-046

7B—57

Page 924 of 1865

7B TROUBLESHOOTING (G4A-HL)

Line Pressure Test

Preparation

1. Connect the SST to the line pressure output point

(square head plug L).

2. Connect a tachometer to the engine.

3. Perform the preparation procedure shown in STEP

3 (STALL TEST).

STEP 6 (OIL PRESSURE TEST)

This step checks line, throttle, and governor pressures to check the operation of hydraulic compo-

nents and for oil leakage.

83U07B-047

Procedure

76G07B-062

1. Start the engine and check that the idle speed is 900 rpm.

2. Shift the selector lever to D range.

3. Read the line pressure at idle.

4. Depress the brake pedal firmly with the left foot and gradually depress the accelerator pedal with

the right foot.

5. Read the line pressure as soon as the engine speed becomes constant, then release the accelera-

tor pedal.

Caution

Steps 4 to 5 must be performed within 5 seconds.

5. Shift the selector lever to N range and run the engine at idle for at least one minute.

6. Read the line pressure at idle and engine stall speeds for each range in the same manner.

7B—58

Page 926 of 1865

7B TROUBLESHOOTING (G4A-HL)

Throttle Pressure Test

Preparation

1. Connect the SST to the throttle pressure output

point (Square head plug T).

2. Connect a tachometer to the engine.

3. Perform the preparation procedure shown in STEP

3 (STALL TEST).

83U07B-052

Procedure

76G07B-064

1. Start the engine and check that the idle speed is 900 _5o rpm.

2. Shift the selector to D range.

3. Read the throttle pressure at idle.

4. Depress the brake pedal firmly with the left foot and gradually depress the accelerator pedal with

the right foot.

5. Read the throttle pressure as soon as the engine speed becomes constant, then release the ac-

celerator pedal.

Caution

Steps 4 to 5 must be performed within 5 seconds.

7B-60

Page 928 of 1865

7B TROUBLESHOOTING (G4A-HL)

Governor Pressure Test

Preparation

1. Connect the SST to the governor pressure output

point.

2. Place the pressure gauge inside the vehicle.

3. Warm up ATF and check ATF level.

83U07B-054

Procedure

76G07B-065

1. Drive the vehicle in D range.

2. Read the governor pressure at the speeds listed in the table below.

Specified governor pressure:

Vehicle Speed km/h (mph) Governor Pressure kPa (kg/cm2, psi) Vehicle Speed km/h (mph) FE engine F8 engine

30 (19) 79-114 (0.81-1.16, 12-16) 82-117 (0.84-1.19, 12-17)

55 (34) 146-190 (1.49-1.94, 21-28) 157-201 (1.60-2.05, 23-29)

85 (53) 276-339 (2.81-3.46, 40-49) 302-366 (3.08-3.73, 44-53)

Evaluation

Condition Possible Cause

Not within specification

Fluid leakage from the line pressure hydraulic circuit

Not within specification Fluid leakage from the governor pressure hydraulic circuit Not within specification

Defective or stuck governor valve

7B-62

Page 936 of 1865

7B ELECTRICAL SYSTEM COMPONENTS

Terminal Connected to Voltage Condition

1J — — —

1K — — —

1L (Input) Idle switch Below 1.5V At idle 1L (Input) Idle switch Approx. 12V Other speeds

1M — — —

1N (Input) Brake light switch Approx. 12V Brake pedal depressed 1N (Input) Brake light switch Below 1.5V Brake pedal released

10 (Input) Throttle sensor

Approx. 5V Ignition switch ON 10 (Input) Throttle sensor Below 1,5V Ignition switch OFF

1P (Input)

Throttle sensor

Approx. 0.5—4.3V Throttle valve fully closed to fully open

1Q (Input) Vehicle speed sensor

Approx. 4.5V During driving

1Q (Input) Vehicle speed sensor Approx. 4.5V or below 1.5V Vehicle stopped

1R (Ground) Throttle sensor Below 1,5V —

1S (Input) Pulse generator Approx. 12V Engine running 1S (Input) Pulse generator Below 1,5V Engine stopped

1S (Ground) Pluse generator Below 1.5V —

2A (Battery power) Battery Approx. 12V Ignition switch ON 2A (Battery power) Battery Below 1,5V Ignition switch OFF

2B (Ground) Body ground Below 1,5V —

2C (Memory power) Battery Approx. 12V —

2D (Ground) Body ground Below 1,5V —

2E (Output) 1-2 shift solenoid valve Approx. 12V

Refer to page 7B—26 of solenoid valve

operation table

2E (Output) 1-2 shift solenoid valve Below 1.5V Refer to page 7B—26 of solenoid valve

operation table

2F (Output) 2-3 shift solenoid valve Approx. 12V

Refer to page 7B—26 of solenoid valve

operation table

2F (Output) 2-3 shift solenoid valve Below 1,5V

Refer to page 7B—26 of solenoid valve

operation table

2G — — —

2H (Output) 3-4 shift solenoid valve Approx. 12V Refer to page 7B—26 of solenoid valve operation table 2H (Output) 3-4 shift solenoid valve Below 1.5V

Refer to page 7B—26 of solenoid valve operation table

21 — — —

2J (Output) Lock-up solenoid valve Approx. 12V Lock-up 2J (Output) Lock-up solenoid valve Below 1,5V Other

2K (Output) Hold indicator Below 1,5V Hold mode 2K (Output) Hold indicator Approx. 12V Other modes

2L (Output) Mode indicator Approx. 12V Hold mode 2L (Output) Mode indicator Below 1,5V Power or economy mode

2M (Output) EC-AT Tester

(malfunction code)

Approx. 12V Normal

2M (Output) EC-AT Tester

(malfunction code) Below 1,5V If malfunction present 2M (Output) EC-AT Tester

(malfunction code) Code signal Self-diagnosis check connector grounded

2N — — —

20 (Input) Fluid temperature switch Below 1,5V Above 150°C (302°F) 20 (Input) Fluid temperature switch Approx. 10—12V Below 143°C (289°F)

2P (Input) EC-AT check connect Approx. 12V —

76G07B-084

7B-70

Page 937 of 1865

ON-VEHICLE MAINTENANCE 7B

ON-VEHICLE MAINTENANCE

AUTOMATIC TRANSAXLE FLUID (ATF)

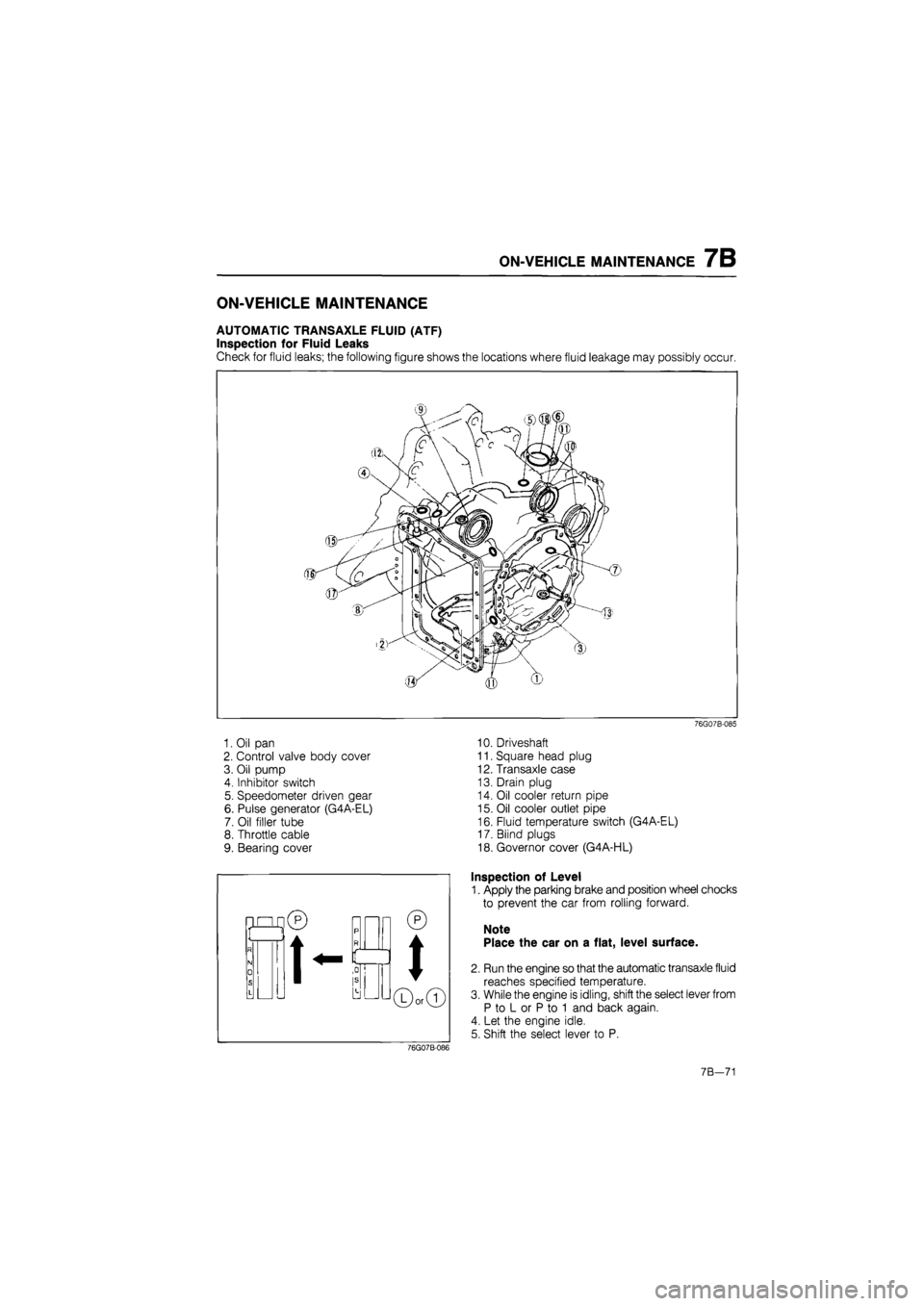

Inspection for Fluid Leaks

Check for fluid leaks; the following figure shows the locations where fluid leakage may possibly occur.

1. Oil pan

2. Control valve body cover

3. Oil pump

4. Inhibitor switch

5. Speedometer driven gear

6. Pulse generator (G4A-EL)

7. Oil filler tube

8. Throttle cable

9. Bearing cover

76G07B-085

10. Driveshaft

11. Square head plug

12. Transaxle case

13. Drain plug

14. Oil cooler return pipe

15. Oil cooler outlet pipe

16. Fluid temperature switch (G4A-EL)

17. Blind plugs

18. Governor cover (G4A-HL)

Inspection of Level

1. Apply the parking brake and position wheel chocks

to prevent the car from rolling forward.

Note

Place the car on a flat, level surface.

2. Run the engine so that the automatic transaxle fluid

reaches specified temperature.

3. While the engine is idling, shift the select lever from

P to L or P to 1 and back again.

4. Let the engine idle.

5. Shift the select lever to P.

76G07B-086

7B—71

Page 941 of 1865

ON-VEHICLE MAINTENANCE 7B

'mfm^i! kfOl iff t—

76G07B-093

76G07B-094

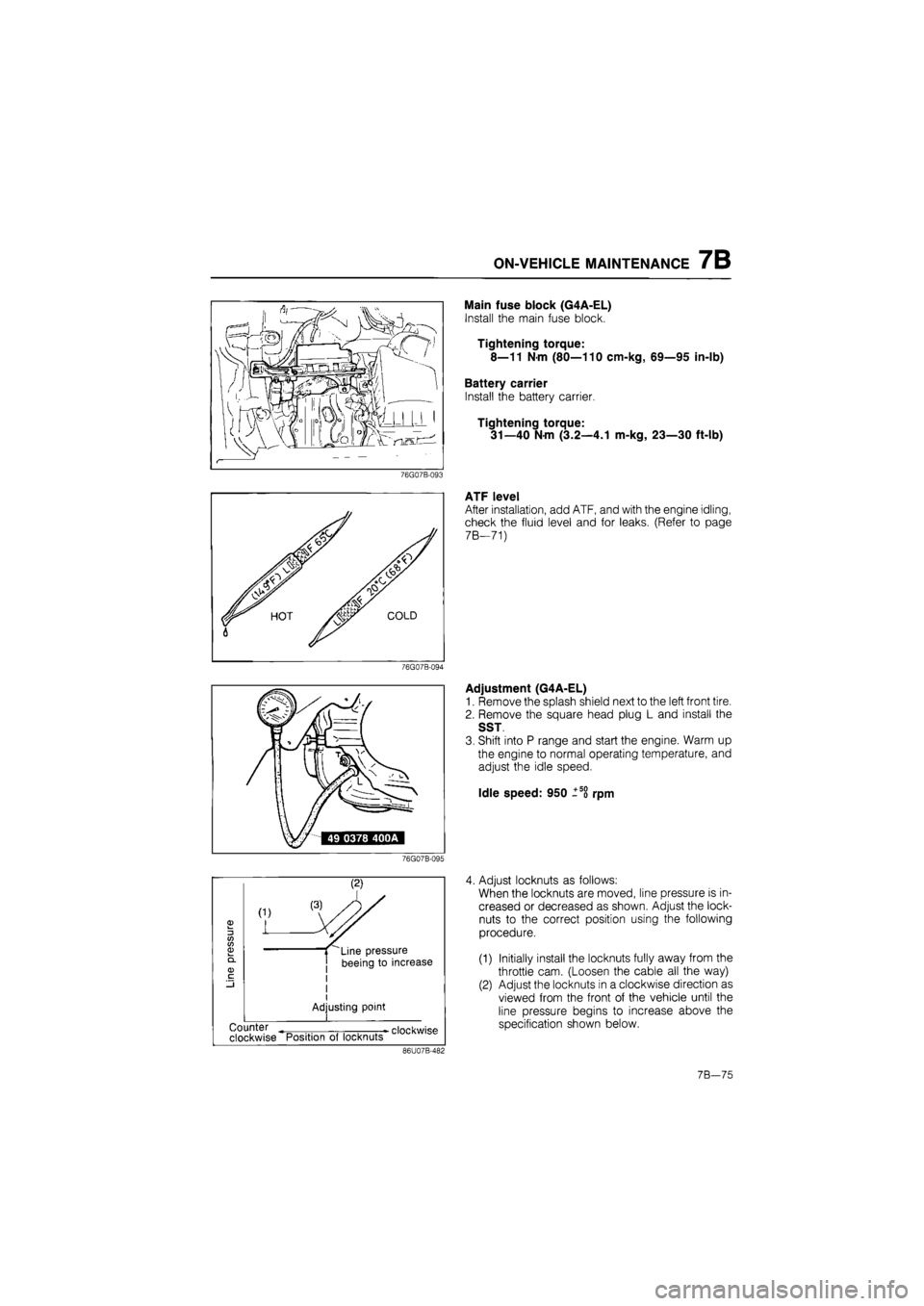

Main fuse block (G4A-EL)

Install the main fuse block.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

Battery carrier

Install the battery carrier.

Tightening torque:

31—40 Nm (3.2—4.1 m-kg, 23—30 ft-lb)

ATF level

After installation, add ATF, and with the engine idling,

check the fluid level and for leaks. (Refer to page

7 B—71)

Adjustment (G4A-EL)

1. Remove the splash shield next to the left front tire.

2. Remove the square head plug L and install the

SST

3. Shift into P range and start the engine. Warm up

the engine to normal operating temperature, and

adjust the idle speed.

Idle speed: 950 ±5o rpm

76G07B-095

3 CO CO 03

(1)

L

Line pressure

beeing to increase

I

Adjusting point

•

clockwise Counter

clockwise Position of locknuts

86U07B-482

4. Adjust locknuts as follows:

When the locknuts are moved, line pressure is in-

creased or decreased as shown. Adjust the lock-

nuts to the correct position using the following

procedure.

(1) Initially install the locknuts fully away from the

throttle cam. (Loosen the cable all the way)

(2) Adjust the locknuts in a clockwise direction as

viewed from the front of the vehicle until the

line pressure begins to increase above the

specification shown below.

7B—75

Page 944 of 1865

7B ON-VEHICLE MAINTENANCE

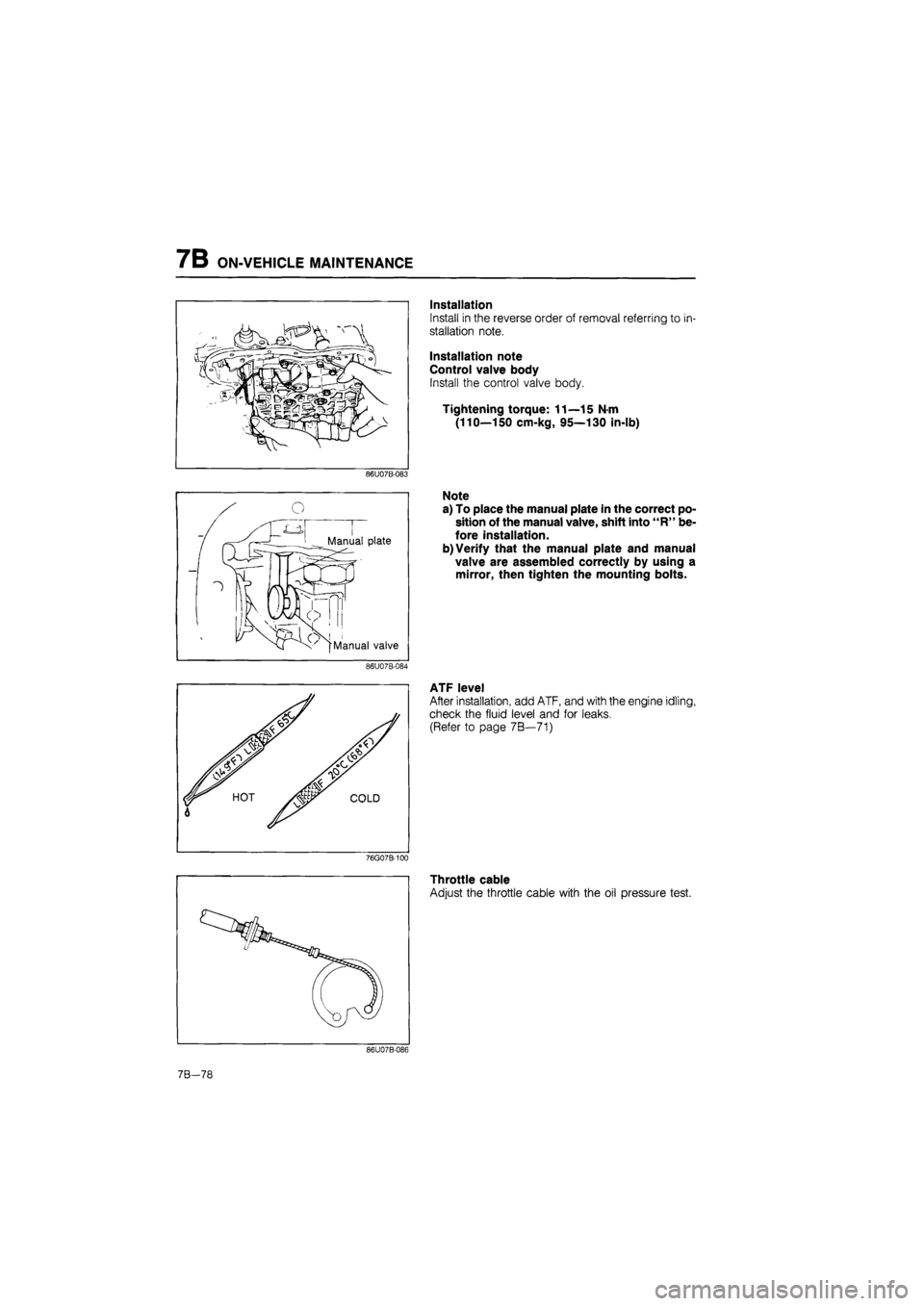

Installation

Install in the reverse order of removal referring to in-

stallation note.

Installation note

Control valve body

Install the control valve body.

Tightening torque: 11—15 N-m

(110—150 cm-kg, 95—130 in-lb)

86U07B-083

Note

a) To place the manual plate in the correct po-

sition of the manual valve, shift into "R" be-

fore installation.

b) Verify that the manual plate and manual

valve are assembled correctly by using a

mirror, then tighten the mounting bolts.

86U07B-084

w v

ATF level

After installation, add ATF, and with the engine idling,

check the fluid level and for leaks.

(Refer to page 7B—71)

76G07B-100

Throttle cable

Adjust the throttle cable with the oil pressure test.

86U07B-086

7B-78

Page 946 of 1865

7B ON-VEHICLE MAINTENANCE

86U07B-091

76G07B-101

76G07B-102

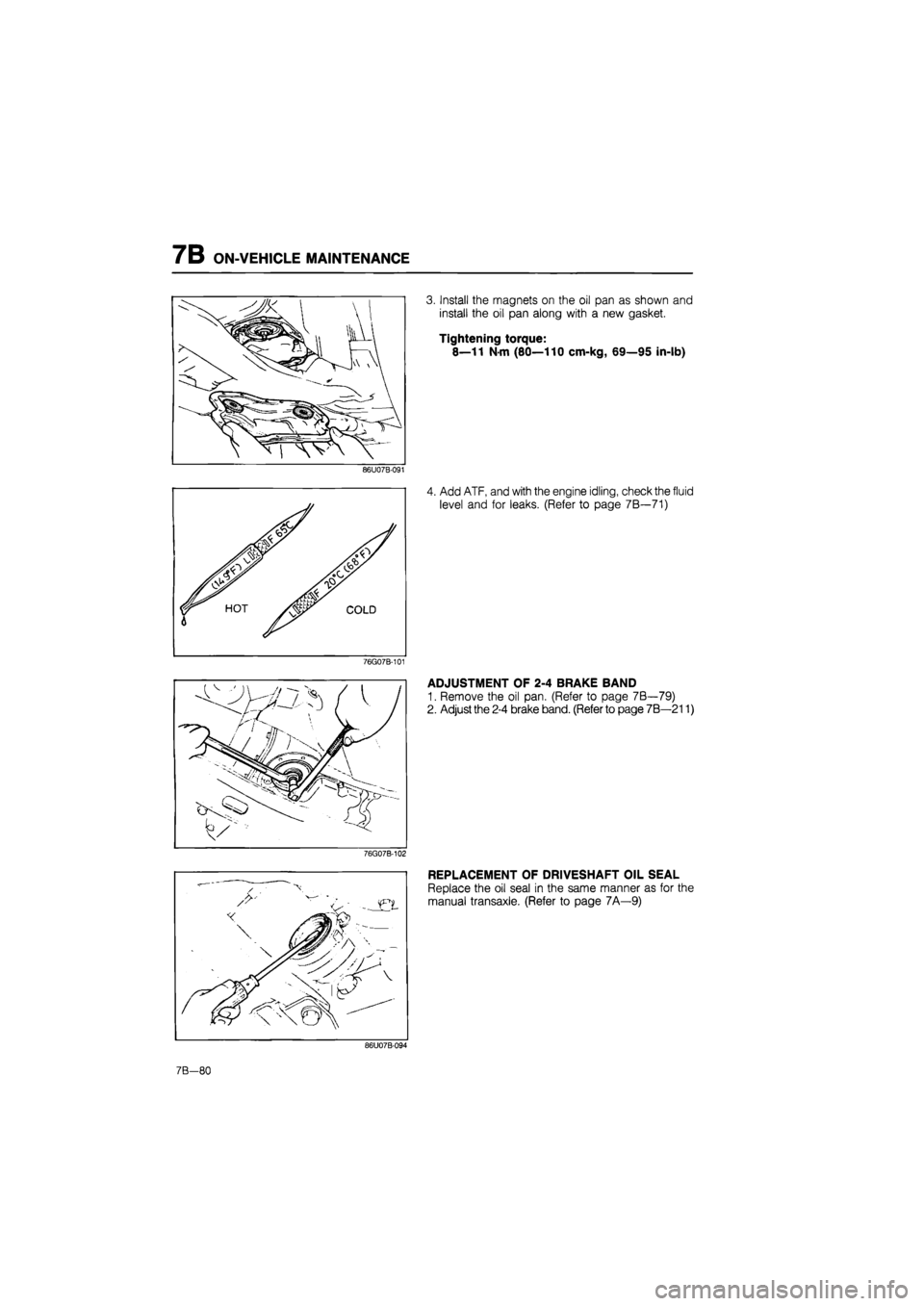

3. Install the magnets on the oil pan as shown and

install the oil pan along with a new gasket.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

4. Add ATF, and with the engine idling, check the fluid

level and for leaks. (Refer to page 7B—71)

ADJUSTMENT OF 2-4 BRAKE BAND

1. Remove the oil pan. (Refer to page 7B—79)

2. Adjust the 2-4 brake band. (Refer to page 7B—211)

REPLACEMENT OF DRIVESHAFT OIL SEAL

Replace the oil seal in the same manner as for the

manual transaxle. (Refer to page 7A—9)

86U07B-094

7B-80