timing belt MAZDA 626 1987 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 58 of 1865

1 A ON-VEHICLE MAINTENANCE (VALVE SEAL)

VALVE SEAL

Removal

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the sequence shown in the figure referring to the removal note for specially marked parts.

76G01A-114

11. Fuel hose (carb.)

12. Rear housing

13. Rocker arm and shaft assembly

14. Camshaft cap (12-valve)

15. Camshaft

16. Valve keeper

17. Upper valve spring seat

18. Valve spring

19. Lower valve spring seat

20. Valve seal

1. Air cleaner assembly (carb.)

2. Air intake pipe (Fl)

3. High-tension lead and spark plug

4. Upper timing belt cover

5. Timing belt

6. Cylinder head cover

7. Camshaft pulley

8. Front housing

9. Distributor

10. Upper radiator hose

1A—26

Page 59 of 1865

1 A ON-VEHICLE MAINTENANCE (VALVE SEAL)

12-valve

O ® ® ® ©

Removal note

Timing belt

Remove the timing belt. (Refer to page 1A—14.)

Rocker arm and shaft assembly

Loosen the rocker arm shaft bolts in two or three steps

in the order shown in the figure.

76G01A-037

8-valve

CD © CD

12-valve Valve seal

1. Remove the rocker arms and springs from the

rocker arm shaft.

2. Install the camshaft caps and rocker arm shafts

onto the cylinder head.

3. Plug the oil drain hole with a rag to prevent the pos-

sibility of the valve keepers from falling into the oil

pan.

86U01X-045

1A—27

Page 64 of 1865

ON-VEHICLE MAINTENANCE (VALVE SEAL) 1 A

76G01A-044

86U01X-212

76G01A-045

(8-valve)

Install the rocker arm and shaft assemblies on the cyl-

inder head and tighten them in three steps in the or-

der shown in the figure.

Tightening torque:

18—26 N-m (1.8—2.7 m-kg, 13—20 ft-lb)

Front housing

1. Replace the oil seal in the front housing.

2. Apply engine oil to the oil seal lip.

3. Install the front housing along with a new gasket.

Tightening torque:

19—25 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

Rear housing

Install the rear housing along with a new gasket.

Tightening torque:

19—25 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

Camshaft pulley

1. Install the camshaft pulley so that the mating mark

is aligned with the camshaft dowel pin straight up.

Note

For FE engine, align "2" mark.

For F8, F6 engine, align "3" mark.

2. Tighten the lock bolt.

Tightening torque:

47—65 N-m (4.8—6.6 m-kg, 35—48 ft-lb)

Timing belt

Install the timing belt. (Refer to TIMING BELT of ON-

VEHICLE MAINTENANCE.)

86U01X-052

1A—32

Page 70 of 1865

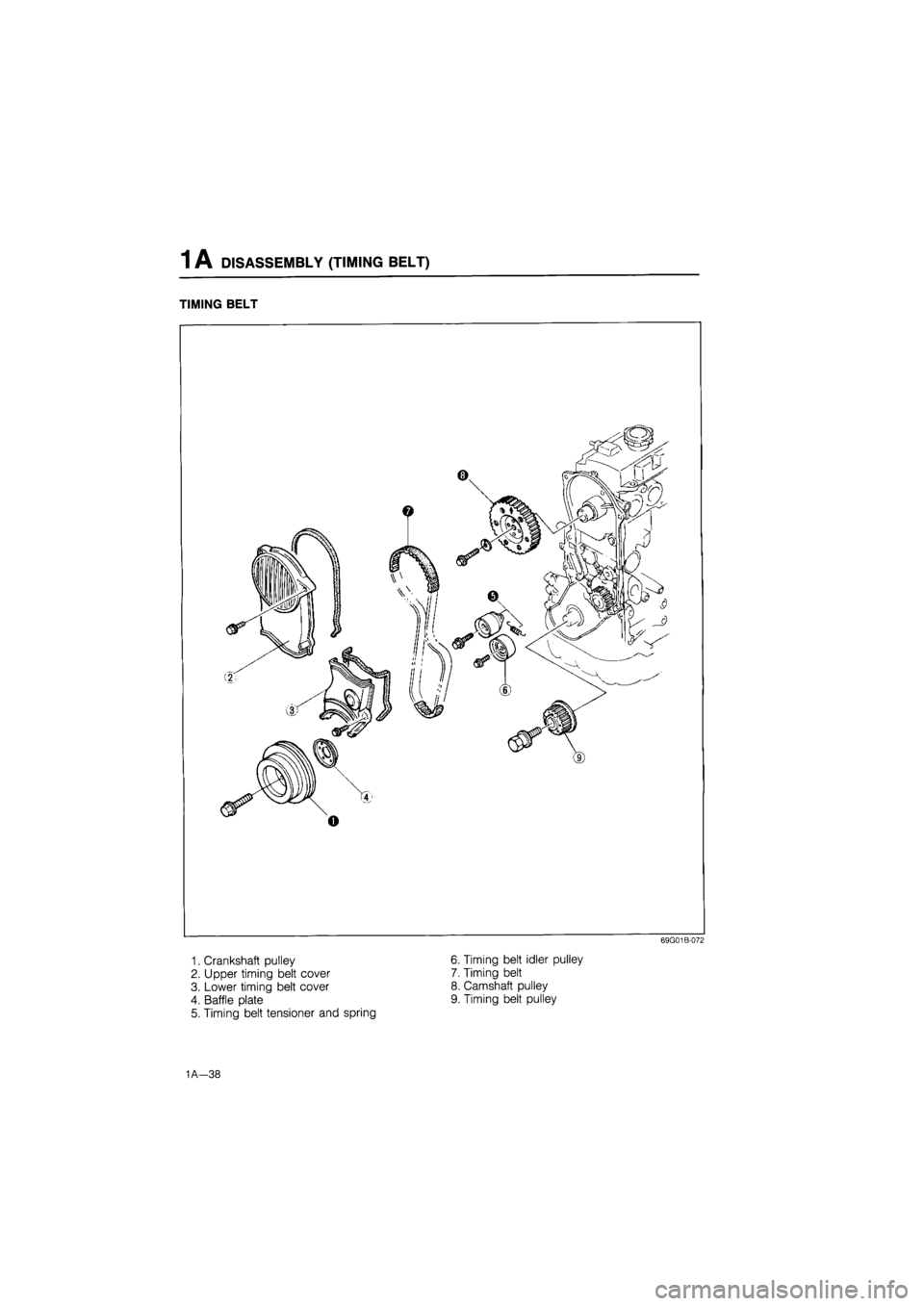

1 A DISASSEMBLY (TIMING BELT)

TIMING BELT

69G01B-072

6. Timing belt idler pulley

7. Timing belt

8. Camshaft pulley

9. Timing belt pulley

1. Crankshaft pulley

2. Upper timing belt cover

3. Lower timing belt cover

4. Baffle plate

5. Timing belt tensioner and spring

1A—38

Page 71 of 1865

DISASSEMBLY (TIMING BELT) 1 A

Mark the

direction of

rotation

76G01A-121

76G01A-122

*

/ V \

T^pJl/1

Disassembly Note

Crankshaft pulley

1. Set the SST against the flywheel.

2. Remove the crankshaft pulley.

Timing belt

1. Loosen the tensioner lock bolt, and remove the ten-

sioner spring.

2. Mark the timing belt rotation for proper reinstalla-

tion if it is reused.

3. Remove the timing belt.

Caution

Be careful not to allow oil or grease on the

belt.

Camshaft pulley

Remove the pulley lock bolt using a screw driver to

prevent the camshaft from turning.

76G01A-123

1A—39

Page 92 of 1865

INSPECTION AND REPAIR 1 A

Crankpin

,/f

Main journal

76G01A-132

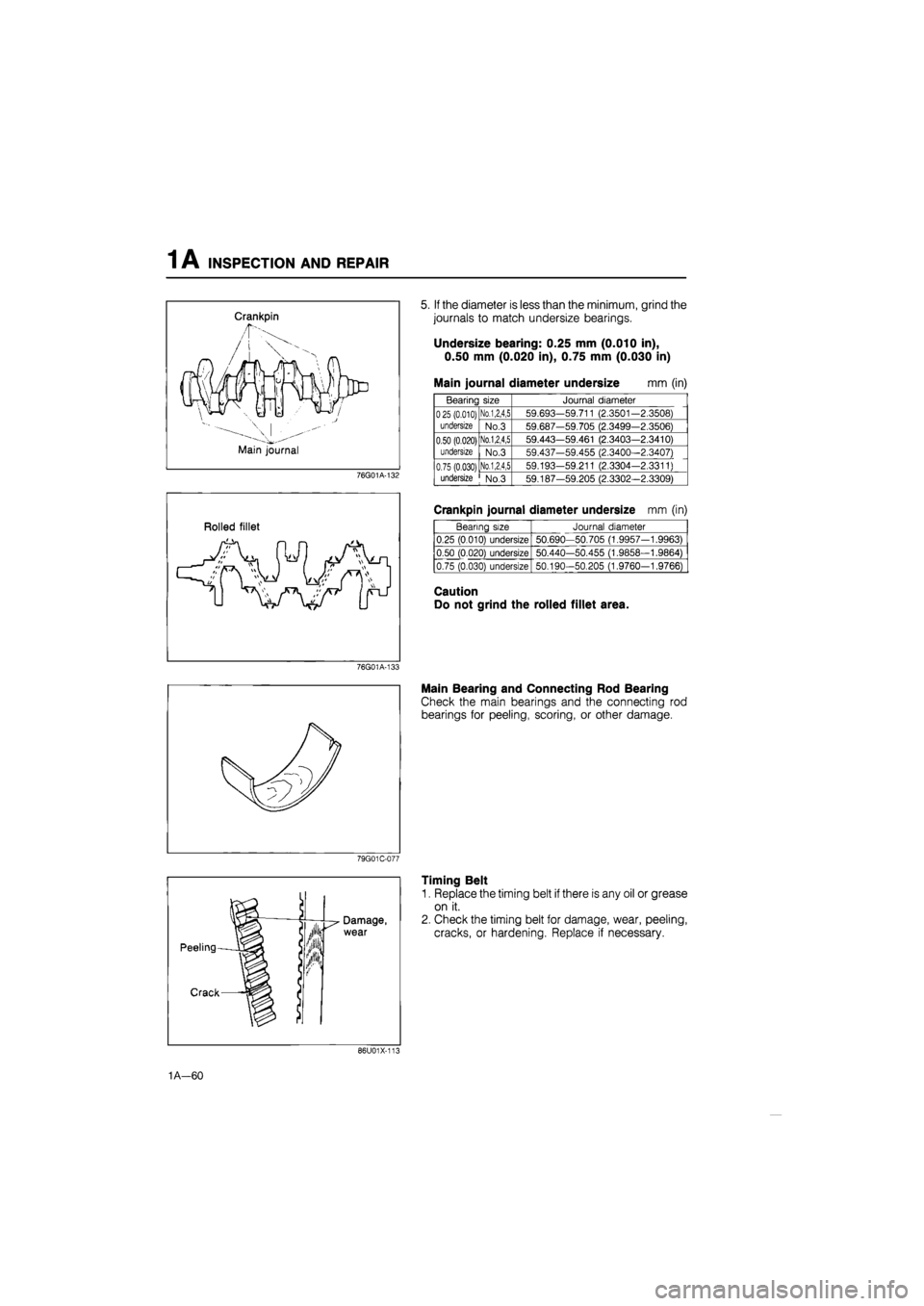

5. If the diameter is less than the minimum, grind the

journals to match undersize bearings.

Undersize bearing: 0.25 mm (0.010 in),

0.50 mm (0.020 in), 0.75 mm (0.030 in)

Main journal diameter undersize mm (in)

Bearing size Journal diameter

025 (0.010)

undersize

No.1,2,4,5 59.693-59.711 (2.3501-2.3508) 025 (0.010)

undersize No.3 59.687-59.705 (2.3499-2.3506)

0.50 (0.020)

undersize

No.1,2,4,5 59.443-59.461 (2.3403—2.3410) 0.50 (0.020)

undersize No.3 59.437-59.455 (2.3400—2.3407)

0.75 (0.030) undersize

No.1,2,4,5 59.193-59.211 (2.3304-2.3311) 0.75 (0.030) undersize No.3 59.187-59.205 (2.3302-2.3309)

Rolled fillet

Crankpin journal diameter undersize mm (in)

Bearing size Journal diameter

0.25 (0.010) undersize 50.690—50.705 (1.9957-1.9963)

0.50 (0.020) undersize 50.440-50.455 (1.9858—1.9864)

0.75 (0.030) undersize 50.190-50.205 (1.9760-1.9766)

Caution

Do not grind the rolled fillet area.

76G01A-133

Main Bearing and Connecting Rod Bearing

Check the main bearings and the connecting rod

bearings for peeling, scoring, or other damage.

79G01C-077

Timing Belt

1. Replace the timing belt if there is any oil or grease

on it.

2. Check the timing belt for damage, wear, peeling,

cracks, or hardening. Replace if necessary.

86U01X-117

1A—60

Page 93 of 1865

INSPECTION AND REPAIR 1 A

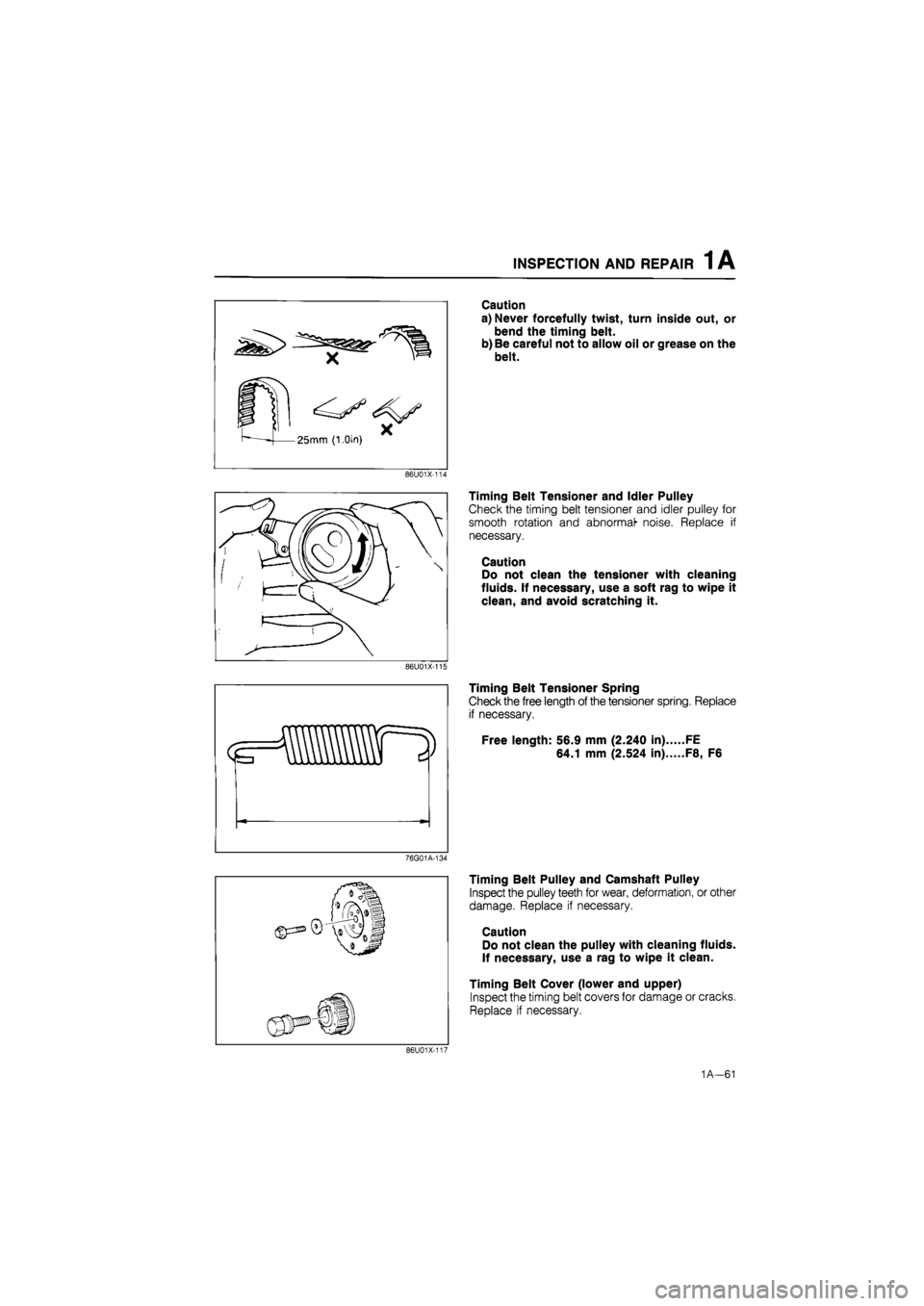

Caution

a) Never forcefully twist, turn inside out, or

bend the timing belt.

b) Be careful not to allow oil or grease on the

belt.

86U01X-114

Timing Belt Tensioner and Idler Pulley

Check the timing belt tensioner and idler pulley for

smooth rotation and abnormal- noise. Replace if

necessary.

Caution

Do not clean the tensioner with cleaning

fluids. If necessary, use a soft rag to wipe it

clean, and avoid scratching it.

86U01X-115

Timing Belt Tensioner Spring

Check the free length of the tensioner spring. Replace

if necessary.

Free length: 56.9 mm (2.240 in) FE

64.1 mm (2.524 in) F8, F6

76G01A-134

Timing Belt Pulley and Camshaft Pulley

Inspect the pulley teeth for wear, deformation, or other

damage. Replace if necessary.

Caution

Do not clean the pulley with cleaning fluids.

If necessary, use a rag to wipe it clean.

Timing Belt Cover (lower and upper)

Inspect the timing belt covers for damage or cracks.

Replace if necessary.

86U01X-117

1A—61

Page 114 of 1865

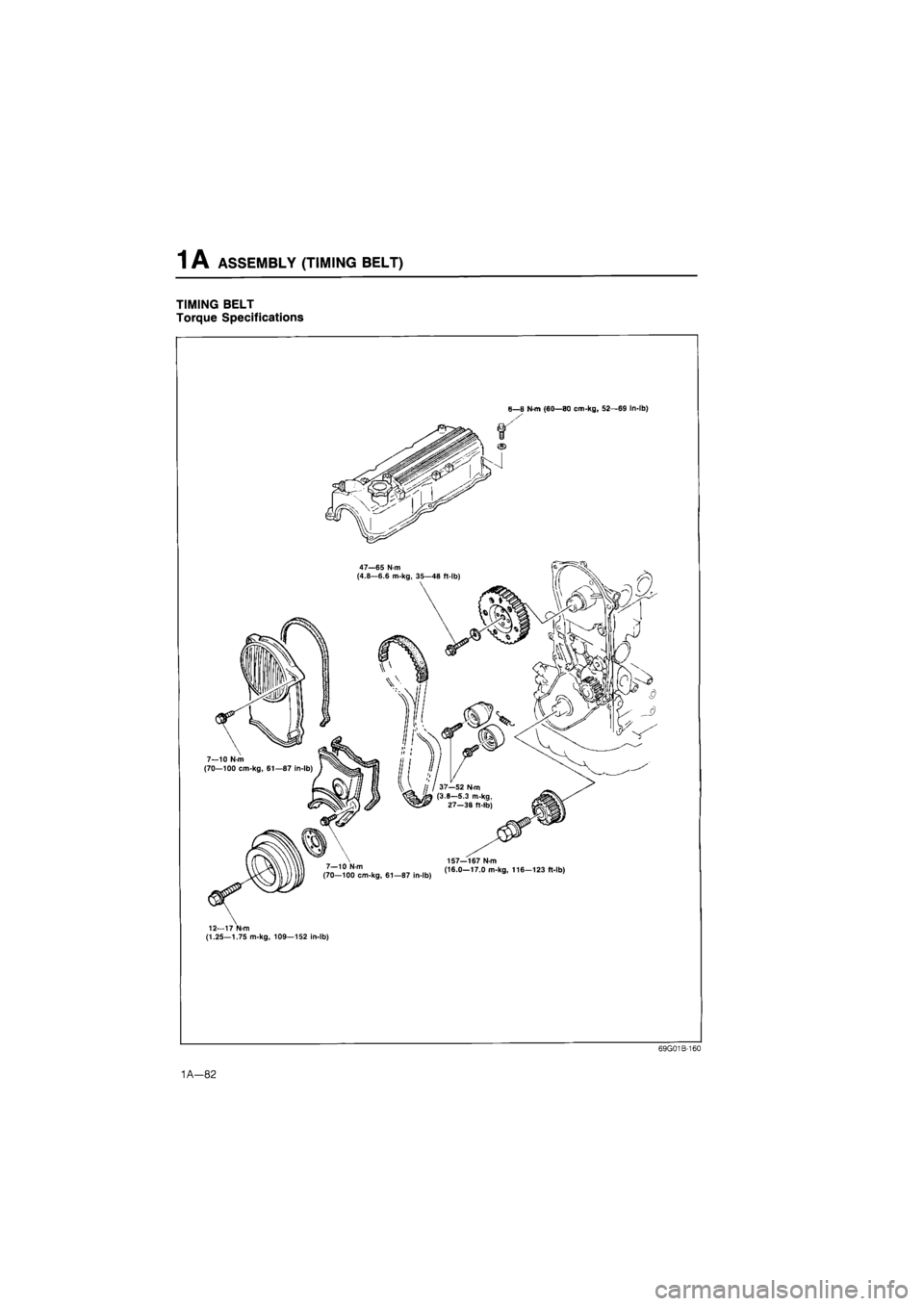

1 A ASSEMBLY (TIMING BELT)

TIMING BELT

Torque Specifications

6—B N

1

A—82

69G01B-160

Page 115 of 1865

ASSEMBLY (TIMING BELT) 1 A

Camshaft Pulley

1. Install the camshaft pulley on the camshaft with the

dowel pin fit into the hole at the 2 mark (FE) or 3

mark (F8, F6).

76G01A-083

2. Tighten the camshaft pulley lock bolt.

Tightening torque:

47—65 N-m (4.8—6.6 m-kg, 35—48 ft-lb)

76G01A-141

3. Align the mating mark on the pulley with the align-

ment mark on the front housing.

Note

For FE engine, align "2" mark.

For F8, F6 engine, align "3" mark.

76G01A-084

Timing Belt Pulley

1. Reverse the direction of the SST (ring gear brake).

2. Install the crankshaft key.

3. Install the timing belt pulley on the crankshaft.

Tightening torque: 157—167 N-m

(16.0—17.0 m-kg, 116—123 ft-lb)

4. Release the ring gear brake.

5. Align the timing belt pulley and the pump body

alignment marks.

86U01X-160

1

A—83

Page 116 of 1865

1A ASSEMBLY (TIMING BELT)

Tensioner lock bolt

69G01B-165

76G01A-085

79G01C-097

Timing Belt Idler Pulley

Install the timing belt idler pulley.

Tightening torque:

37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

Timing Belt Tensioner

1. Install the timing belt tensioner and tensioner

spring.

2. Tentatively secure the tensioner with the spring fully

extended.

Timing Belt

1. Install the timing belt, (keep the tension side of belt

as tight as possible.)

Caution

a) If the timing belt is being reused, it must be

reinstalled to rotate in the original direction.

b) Check that there is no oil, grease, or dirt on

the timing belt.

2. Loosen the tensioner lock bolt.

3. Turn the crankshaft twice in the direction of rotation.

4. Check that the mating marks are correctly aligned.

If not aligned, remove the timing belt and tension-

er, and repeat the above-mentioned procedure.

5. Tighten the timing belt tensioner lock bolt.

Tightening torque:

37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

4BGQ1A-186

1A—84