lock MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1478 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

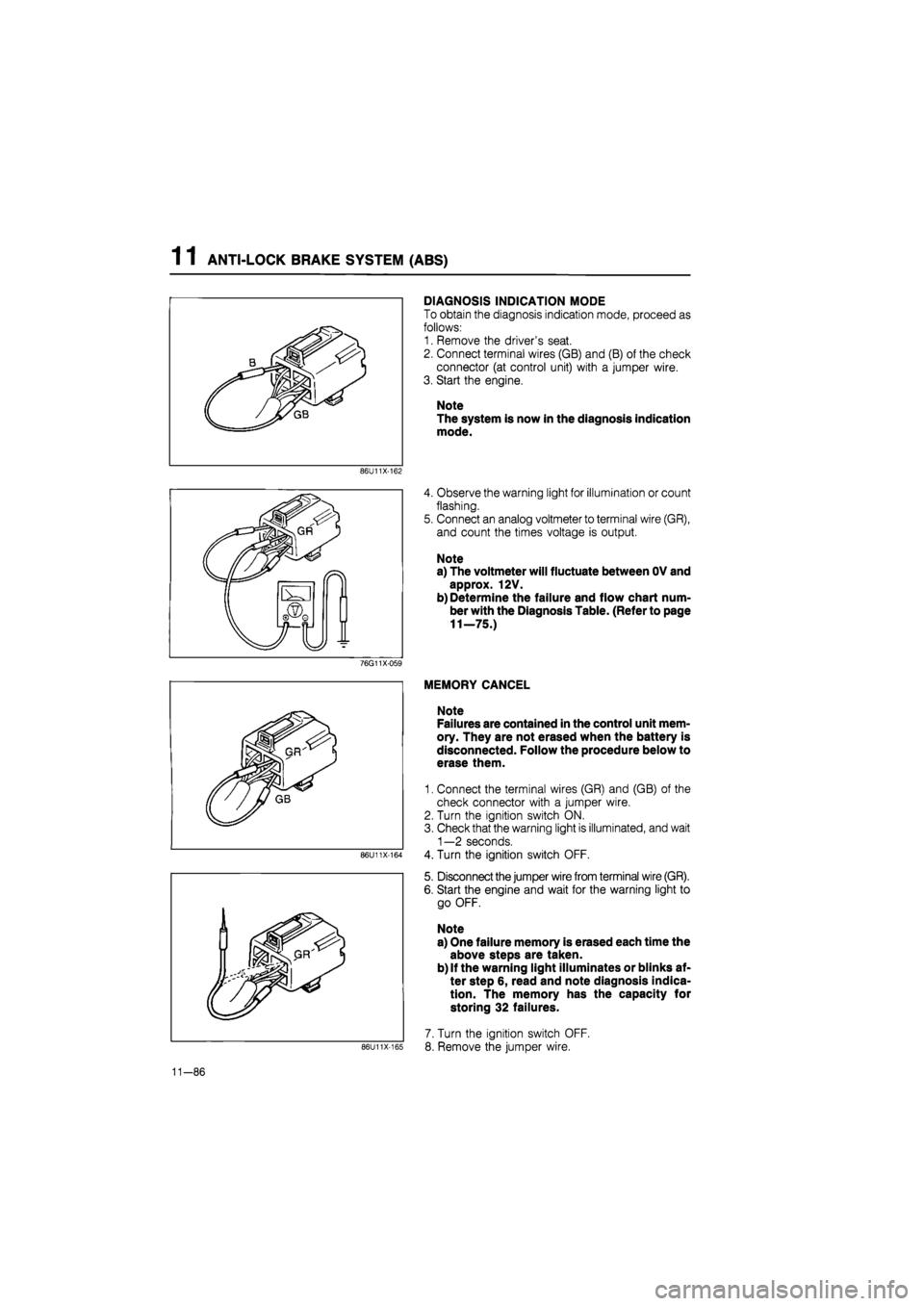

DIAGNOSIS INDICATION MODE

To obtain the diagnosis indication mode, proceed as

follows:

1. Remove the driver's seat.

2. Connect terminal wires (GB) and (B) of the check

connector (at control unit) with a jumper wire.

3. Start the engine.

Note

The system is now in the diagnosis indication

mode.

86U11X-162

4. Observe the warning light for illumination or count

flashing.

5. Connect an analog voltmeter to terminal wire (GR),

and count the times voltage is output.

Note

a) The voltmeter will fluctuate between OV and

approx. 12V.

b) Determine the failure and flow chart num-

ber with the Diagnosis Table. (Refer to page

11—75.)

76G11X-059

86U11X-164

86U11X-165

MEMORY CANCEL

Note

Failures are contained in the control unit mem-

ory. They are not erased when the battery is

disconnected. Follow the procedure below to

erase them.

1. Connect the terminal wires (GR) and (GB) of the

check connector with a jumper wire.

2. Turn the ignition switch ON.

3. Check that the warning light is illuminated, and wait

1—2 seconds.

4. Turn the ignition switch OFF.

5. Disconnect the jumper wire from terminal wire (GR).

6. Start the engine and wait for the warning light to

go OFF.

Note

a) One failure memory is erased each time the

above steps are taken.

b) If the warning light illuminates or blinks af-

ter step 6, read and note diagnosis indica-

tion. The memory has the capacity for

storing 32 failures.

7. Turn the ignition switch OFF.

8. Remove the jumper wire.

11-86

Page 1479 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

86U11X-1C

Q-08

Q-08

Fail-safe relay

B B BG

(Q-08)(Q-09)

V

BL BR

Motor relay

B BR (Q-09)

LO RY

View from male-pin side

86U11X-167

76G11X-096

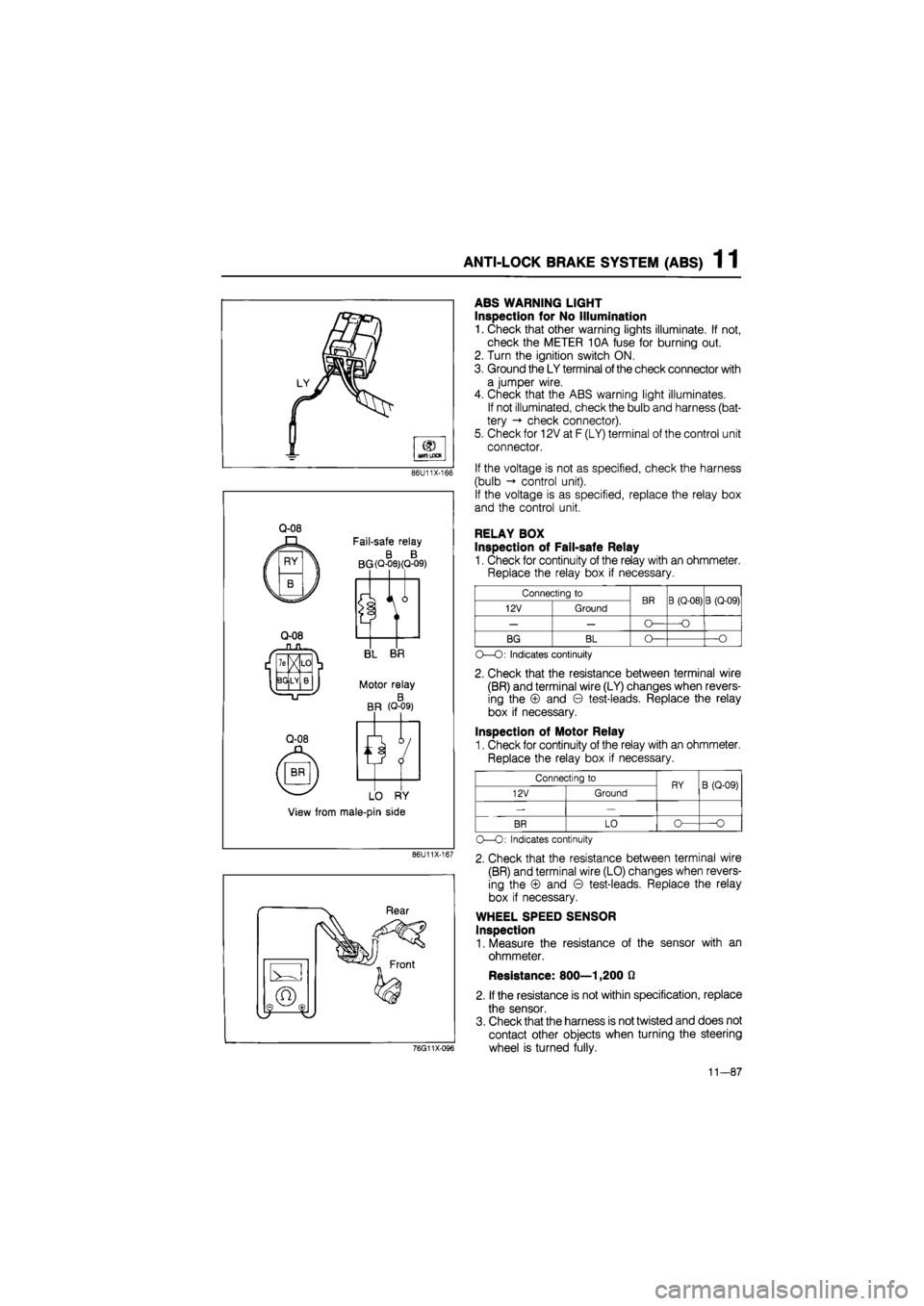

ABS WARNING LIGHT

Inspection for No Illumination

1. Check that other warning lights illuminate. If not,

check the METER 10A fuse for burning out.

2. Turn the ignition switch ON.

3. Ground the LY terminal

of

the check connector with

a jumper wire.

4. Check that the ABS warning light illuminates.

If not illuminated, check the bulb and harness (bat-

tery -» check connector).

5. Check for 12V at F (LY) terminal of the control unit

connector.

If the voltage is not as specified, check the harness

(bulb control unit).

If the voltage is as specified, replace the relay box

and the control unit.

RELAY BOX

Inspection of Fail-safe Relay

1. Check for continuity of the relay with an ohmmeter.

Replace the relay box if necessary.

Connecting to BR B (Q-08) B (Q-09) 12V Ground BR B (Q-08) B (Q-09)

— — O— —O

BG BL O— —O

O—O: Indicates continuity

2. Check that the resistance between terminal wire

(BR) and terminal wire (LY) changes when revers-

ing the © and © test-leads. Replace the relay

box if necessary.

Inspection of Motor Relay

1. Check for continuity of the relay with an ohmmeter.

Replace the relay box if necessary.

Connecting to RY B (Q-09) 12V Ground RY B (Q-09)

-—

BR LO o— O

O—O: Indicates continuity

2. Check that the resistance between terminal wire

(BR) and terminal wire (LO) changes when revers-

ing the © and © test-leads. Replace the relay

box if necessary.

WHEEL SPEED SENSOR

Inspection

1. Measure the resistance of the sensor with an

ohmmeter.

Resistance: 800—1,200 0

2. If the resistance is not within specification, replace

the sensor.

3. Check that the harness is not twisted and does not

contact other objects when turning the steering

wheel is turned fully.

11-87

Page 1480 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

86U11X-170

86U11X-171

Removal of Front Wheel Speed Sensor

1. Remove the wheel and tire.

2. Remove the parts shown in the figure, and remove

the sensor from the knuckle.

Installation of Front Wheel Speed Sensor

1. Install the sensor to the knuckle.

Tightening torque:

16—23 N m (1.6—2.3 m-kg, 12—17 ft-lb)

Caution

The left and right sensors are not interchange-

able. L or R is indicated on the bracket.

2. Install the sensor harness bracket onto the knuckle.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

3. Push the sensor harness through the splash shield

and secure it with the clip.

4. Install the sensor harness bracket to the body.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

Caution

Verify that the harness is not twisted and does

not contact the shock absorber or body when

the steering wheel is turned.

5. Connect the sensor connector.

6. Install the wheel and tire.

86U11X-172

11-88

Page 1481 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

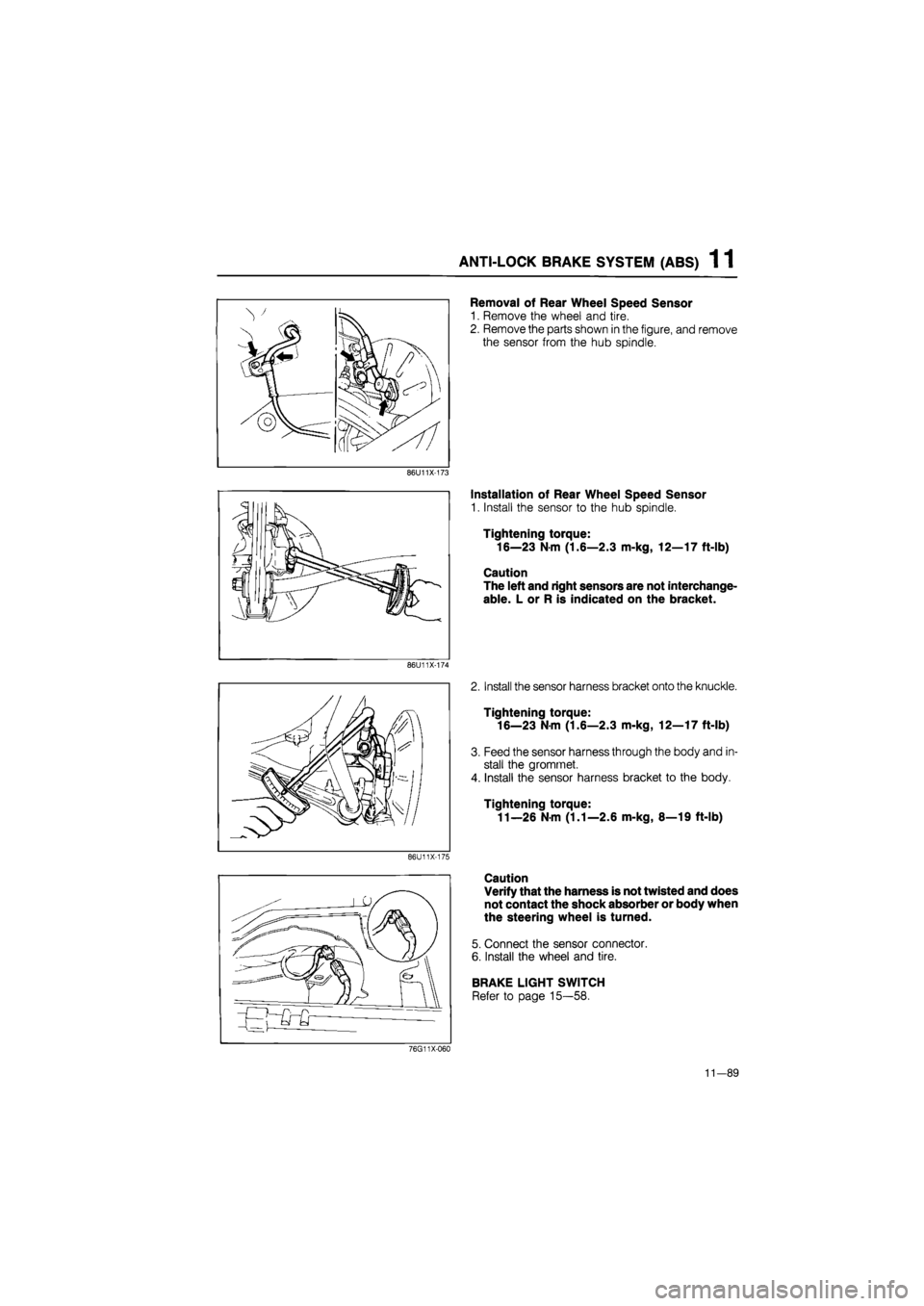

Removal of Rear Wheel Speed Sensor

1. Remove the wheel and tire.

2. Remove the parts shown in the figure, and remove

the sensor from the hub spindle.

86U11X-173

86U11X-174

86U11X-175

Installation of Rear Wheel Speed Sensor

1. Install the sensor to the hub spindle.

Tightening torque:

16—23 N m (1.6—2.3 m-kg, 12—17 ft-lb)

Caution

The left and right sensors are not interchange-

able. L or R is indicated on the bracket.

2. Install the sensor harness bracket onto the knuckle.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

3. Feed the sensor harness through the body and in-

stall the gromrnet.

4. Install the sensor harness bracket to the body.

Tightening torque:

11—26 N m (1.1—2.6 m-kg, 8—19 ft-lb)

Caution

Verify that the harness is not twisted and does

not contact the shock absorber or body when

the steering wheel is turned.

5. Connect the sensor connector.

6. Install the wheel and tire.

BRAKE LIGHT SWITCH

Refer to page 15—58.

76G11X-060

11-89

Page 1482 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

SENSOR ROTOR

Inspection

Check the sensor rotor for missing or damaged teeth.

86U11X-177

Removal of Front Sensor Rotor

1. Loosen the front wheel lug nuts.

2. Block the rear wheels.

3. Jack up the front of the vehicle and support it with safety stands.

4. Remove the wheels.

5. Remove in the sequence shown in the figure, referring to removal note for the specially marked parts.

86U11X-178

1. Hub cap

2. Locknut

3. Driveshaft (Refer to section 9)

4. Sensor rotor

11-90

Page 1483 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

Installation of Front Sensor Rotor

Install in the reverse order of removal, referring

Torque specifications

Removal note

Sensor rotor

Tap the sensor rotor off the drive shaft with a chisel.

to installation note for the specially marked parts.

Installation note

Sensor rotor

Press the sensor rotor onto the driveshaft with the

SST.

Caution

Install the sensor rotor with chamfered edge

toward the driveshaft.

11—91

Page 1484 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

Removal of Rear Sensor Rotor

1. Loosen the rear wheel lug nuts.

2. Block the front wheels.

3. Jack up the rear of the vehicle and support it with safety stands.

4. Remove the wheels.

5. Remove in the sequence shown in the figure, referring to removal note for the specially marked parts.

86U11X-182

1. Hub cap

2. Locknut

3. Caliper assembly and

mounting support

4. Disc plate

5. Sensor rotor

Removal note

Sensor rotor

Remove the sensor rotor from the hub assembly with

the SST.

86U11X-183

11—92

Page 1485 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

Installation of Rear Sensor Rotor

Install in the reverse order of removal, referring to installation note for the specially marked parts.

Torque specifications

86U11X-184

Installation

Sensor rotor

Press the sensor rotor onto the hub with the SST.

86U11X-185

Locknut

1. Install and tighten the locknut.

2. Stake a new locknut securely in the driveshaft

groove.

Caution

Do not use a pointed tool for staking.

3. Check that the hub rotates freely by hand.

86U11X-186

11—93

Page 1486 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

HYDRAULIC UNIT FLUID

Inspection of Level

1. Run the engine for 10 seconds to let the pump mo-

tor build pressure in the accumulator; then stop the

engine.

2. Check that the fluid level is between the Max and

Min lines of the reservoir.

3. If the level is lower than the Min line and leakage

from cap is not found, replace the hydraulic unit

assembly.

86U11X-187

76G11X-061

Replacement

1. Remove the reservoir cap and retainer.

2. Use a suction pump and a soft vinyl hose to suck

fluid from the reservoir.

Caution

a) A hard hose may damage the filter in the

reservoir.

b)Only the amount of fluid shown can be re-

moved from the reservoir.

3. Fill the reservoir with the specified type and amount

of brake fluid.

Caution

a) Do not allow any foreign material to enter

the reservoir.

b) Do not soak the upper filter with brake flu-

id. Otherwise, pouring fluid may be difficult.

Fluid: DOT-3 or DOT-4 or SAE J1703

4. Check the fluid level as described above.

HYDRAULIC UNIT

Warning

The accumulator contains high-pressure gas;

do not attempt to disassemble it or subject it

to hard shocks or high heat.

When the hydraulic unit is scrapped, the high-

pressure gas must be released. Turn the

screw on the accumulator bottom one full turn

only and allow the gas to escape gradually.

76G11X-097

11—94

Page 1487 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

86U11X-190

86U11X-191

76G11X098

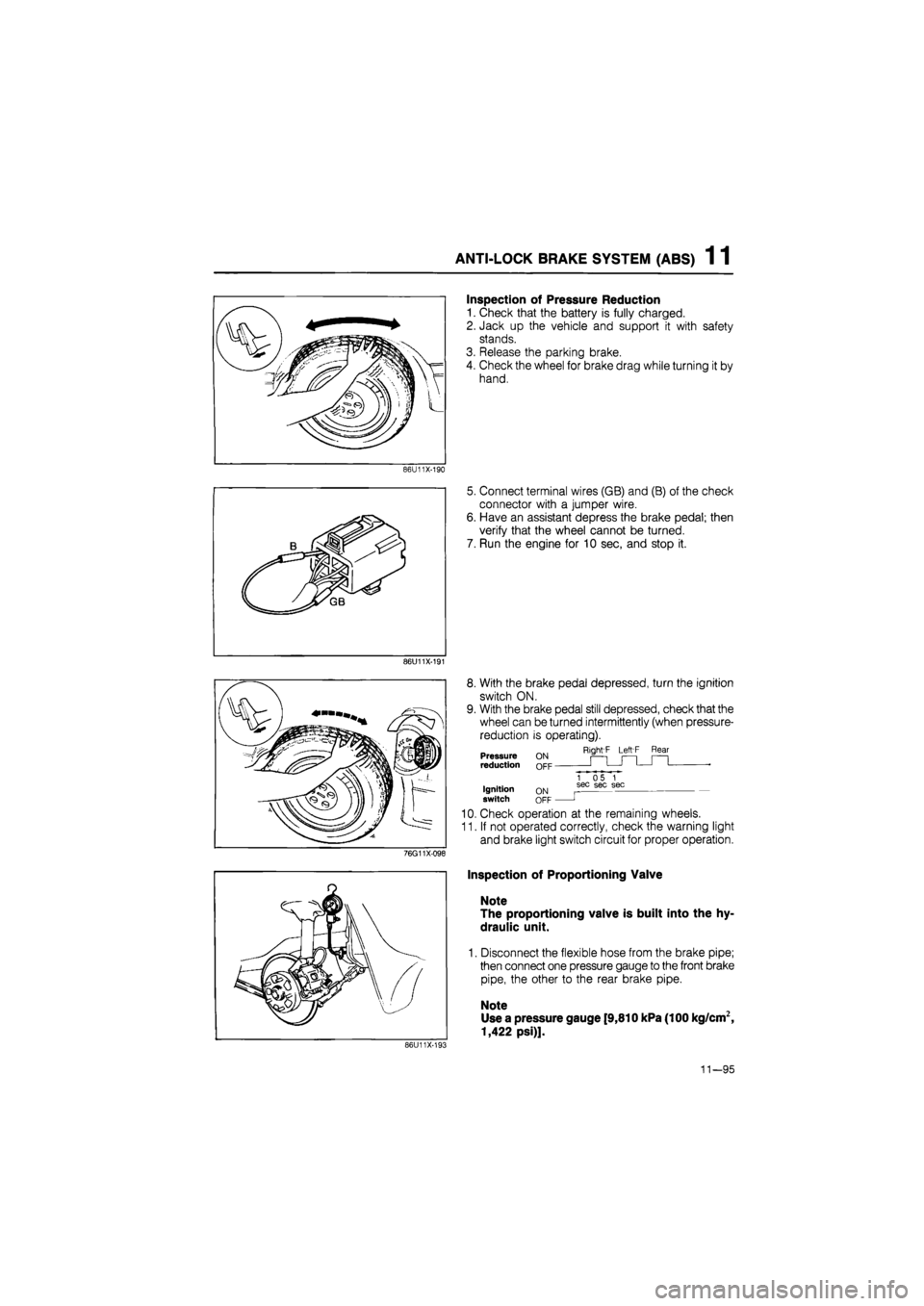

Inspection of Pressure Reduction

1. Check that the battery is fully charged.

2. Jack up the vehicle and support it with safety

stands.

3. Release the parking brake.

4. Check the wheel for brake drag while turning it by

hand.

5. Connect terminal wires (GB) and (B) of the check

connector with a jumper wire.

6. Have an assistant depress the brake pedal; then

verify that the wheel cannot be turned.

7. Run the engine for 10 sec, and stop it.

8. With the brake pedal depressed, turn the ignition

switch ON.

9. With the brake pedal still depressed, check that the

wheel can be turned intermittently (when pressure-

reduction is operating).

Right'F Left F Rear Pressure reduction

Ignition switch ON OFF

1 05 1 sec sec sec

J

10. Check operation at the remaining wheels.

11. If not operated correctly, check the warning light

and brake light switch circuit for proper operation.

Inspection of Proportioning Valve

Note

The proportioning valve is built into the hy-

draulic unit.

1. Disconnect the flexible hose from the brake pipe;

then connect one pressure gauge to the front brake

pipe, the other to the rear brake pipe.

Note

Use a pressure gauge [9,810 kPa (100 kg/cm2,

1,422 psi)].

86U11X-193

11—95