MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 751 of 1865

STARTER (GASOLINE ENGINE, 1.4 KW TYPE) 5

STARTER (GASOLINE

ENGINE, 1.4

KW TYPE)

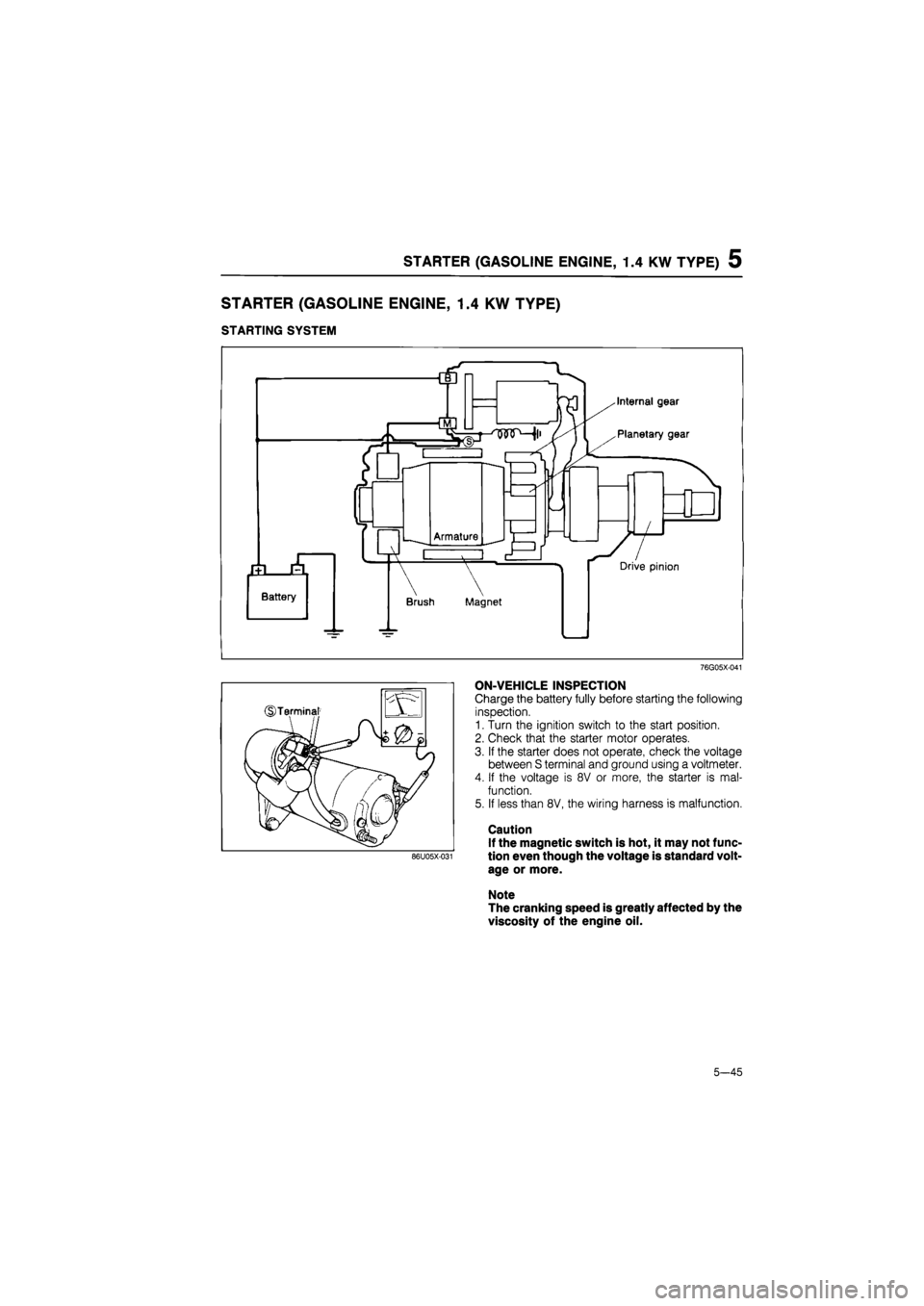

STARTING SYSTEM

76G05X-041

ON-VEHICLE INSPECTION

Charge the battery fully before starting the following

inspection.

1. Turn the ignition switch to the start positron.

2. Check that the starter motor operates.

3. If the starter does not operate, check the voltage

between S terminal and ground using a voltmeter.

4. If the voltage is 8V or more, the starter is mal-

function.

5. If less than 8V, the wiring harness is malfunction.

Caution

If the magnetic switch is hot, it may not func-

tion even though the voltage is standard volt-

age or more.

Note

The cranking speed is greatly affected by the

viscosity of the engine oil.

86U05X-031

5-45

Page 752 of 1865

5 STARTER (GASOLINE ENGINE, 1.4 KW TYPE)

REMOVAL

1. Disconnect the negative battery cable.

2. Disconnect the wiring from the starter.

3. Raise the front of the vehicle and support it with

safety stands.

4. Remove the starter bolts.

5. Draw out the starter from lower side of the vehicle.

Note

Remove the lowest starter bolt last.

76G05X-042

DISASSEMBLY

86U05X-083

1. Magnetic switch

2. Plunger and spring

3. Rear housing

4. Brush holder assembly

5. Armature

6. Ball

7. Planetary gear

8. Drive housing front cover

9. Lever

10. Drive pinion

11. Overrunning clutch

12. Internal gear

13. Yoke assembly

14. Gear shaft

Caution

Do not strike the yoke with a hammer, drop it or put it in a vise when disassembling the

starter.

5—46

Page 753 of 1865

STARTER (GASOLINE ENGINE, 1.4 KW TYPE) 5

Magnetic Switch

Remove the following parts:

(1) M terminal nut

(2) Wire

(3) Switch installation screws

(4) Magnetic switch

(5) Plunger and plunger spring

86U05X-33

Rear Bracket and Brush Holder

Remove the following parts:

(1) Brush holder installation screws

(2) Through bolts

(3) Rear cover

(4) Wave washer

(5) Brush holder assembly

Note

Put an aligning mark on the yoke and rear

bracket for reassembly before removing the

rear bracket.

7BU05X-034

Yoke and Armature

Remove the armature and yoke.

Note

Put an aligning mark on the yoke and front

bracket for reassembly before removing the

front bracket.

7BU05X-035

Overrunning Clutch, Planetary Gears, and Inter-

nal Gear.

Remove the following parts:

(1) Gasket

(2) Plate

(3) Planetary gears

(4) Internal gear

(5) Drive pinion

Note

Do not lose the ball.

7BU05X-110

5—47

Page 754 of 1865

5 STARTER (GASOLINE ENGINE, 1.4 KW TYPE)

86U05X-034

Snap ring

Internal gear

Drive pinion I Gear shaft

r i

rt

n I I Washer

OC

Stopper

7BU05X-037

Overrunning Clutch Stopper

1. Remove the overrunning clutch stopper using a

pipe.

2. Disassemble the drive pinion, internal gear and

washer from the gear shaft.

Brush and Brush Holder

Remove the brush from the brush holder using a flat-

tip screwdriver.

7BU05X-038

5-48

Page 755 of 1865

STARTER (GASOLINE ENGINE, 1.4 KW TYPE) 5

INSPECTION

Armature

1. Ground of armature coil

Check for continuity between the commutator and

the core using a circuit tester. Replace the arma-

ture if there is continuity.

67U05X-048

2. Insulation of armature coil

Check for continuity between the commutator and

the shaft using a circuit tester. Replace the arma-

ture if there is continuity.

67U05X-049

Runout of commutator

(1) Place the armature on V blocks, and measure

the runout using a dial gauge.

(2)

If

the runout is excessive, replace the armature.

Runout: 0.05 mm (0.002 in)

Maximum: 0.1 mm (0.004 in)

7BU05X-039

Outer diameter of commutator

Replace the armature if the outer diameter of the

commutator is less than the grind limit.

Roughness of commutator surface

Repair using a lathe or fine sandpaper if it is rough;

wipe it with a rag if it is dirty.

Grind limit: 28.8 mm (1.13 in)

7BU05X-040

5-49

Page 756 of 1865

5 STARTER (GASOLINE ENGINE, 1.4 KW TYPE)

Segments groove depth

If the depth of the groove is less than standard,

undercut the grooves to the standard depth.

Standard depth: 0.5—0.8 mm (0.02—0.03 in)

Minimum depth: 0.2 mm (0.008 in).

7BU05X-041

Magnetic Switch

1. Wiring damage (©terminal — ©terminal).

Check for continuity between the ©terminal and

the ©terminal using a circuit tester. Replace the

magnetic switch if there is no continuity.

67U05X-053

Wiring damage (©terminal — body)

Check for continuity between © terminal and

body using a circuit tester.

Replace the magnetic switch if there is no con-

tinuity.

67U05X-054

3. Ground of magnetic switch

Check for continuity between ©and ©terminals

using a circuit tester. Replace the magnetic switch

if there is continuity.

67U05X-055

5—50

Page 757 of 1865

STARTER (GASOLINE ENGINE, 1.4 KW TYPE) 5

Overrunning Clutch

Turn the pinion shaft by hand and hold the overrun-

ning clutch.

Replace the overrunning clutch if the pinion turns in

both directions or in neither direction.

Note

Do not wash the overrunning clutch with sol-

vent; it is packed with grease and sealed.

86U05X-035

Internal Gear and Planetary Gears

1. Internal gear

Check for wear or damage. Replace if necessary.

2. Planetary gears

Check for wear or damage. Replace if necessary.

67U05X-057

Yoke

Check for damage. Replace if necessary.

67U05X-058

Bearing

Check for abnormal noise, looseness, binding.

Replace the bearing if there is any problem.

Note

Use a bearing puller to remove the bearings.

67U05X-059

5-51

Page 758 of 1865

5 STARTER (GASOLINE ENGINE, 1.4 KW TYPE)

Brush and Brush Holder

1. Insulation of brush holder

Check for continuity between the insulated brush

and the plate using a circuit tester. Replace the

brush holder if there is continuity.

67U05X-060

\E

Wear limit line

—r

10.0 mm

(0.39 in)

L 17.5 mm (0.69 in)

2. Brush

Replace the brushes if they are worn beyond the

wear limit, or if the wear is near the limit.

Wear limit: 10.0 mm (0.394 in)

New brush: 17.5 mm (0.689 in)

7BU05X-043

Brush holder

Check that the brush slides smoothly inside the

brush holder.

67U05X-062

4. Brush spring

(1) Measure the force of the brush spring using

a spring balance.

(2) Replace the brush spring if the force is below

specification.

Specification: 7 N (0.7 kg, 1.5 lb)

Note

a) The force is measured at the moment the

brush spring separates from the brush.

b)The force must be 18—24 N (1.8—2.4 kg,

4.0—5.3 lb) for a new brush spring.

86U05X-036

5-52

Page 759 of 1865

STARTER (GASOLINE ENGINE, 1.4 KW TYPE) 5

86U05X-037

Internal gear

Drive pinion Gear shaft

Snap ring

Stopper

7BU05X-045

Snap ring

Stopper

Overrunning

\= clutch

7BU05X-046

ASSEMBLY

Assemble in the reverse order of disassembly, refer-

ring to the assembly note.

Assembly Note

Lubricate

During assembly lubricate the following points:

1. Gear of armature shaft

2. Internal gear and planetary gears

3. Plunger circumference

4. Lever

5. Ball

6. Gear shaft spline

7. Front bracket housing

Installation of Overrunning Clutch

1. Install the washer, internal gear, drive pinion stop-

per, and the snap ring on the gear shaft.

2. Press the stopper and the snap ring into position

as shown in the figure.

Installation of lever

Check the lever faces in the correct direction.

7BU05X-047

5—53

Page 760 of 1865

5 STARTER (GASOLINE ENGINE, 1.4 KW TYPE)

7BU05X-048

86U05X-038

7BU05X-050

Installation of Brush Holder

Install the brush holder assembly and rear cover and

align the through bolts.

CHECKING OPERATION

Magnetic Switch

Make the following tests:

Pull-out test

1. Check that the pinion is pulled out when 12V is con-

nected to the S terminal and the body is grounded.

2. Measure the pinion gap while the pinion is pulled

out.

Specification: 0.5—2.0 mm (0.02—0.08 in)

3. Adjust the pinion gap with an adjust washer (drive

housing front cover—magnetic switch) if it is not

within specification.

Return test

1. Disconnect the motor wire from the M terminal, and

then connect the battery power to the M terminal

and ground the body.

2. Pull out the overrunning clutch with a flat-tip screw-

driver. Check that the overrunning clutch returns

to its original position when released.

86U05X-039

5-54