MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 761 of 1865

STARTER (GASOLINE ENGINE, 1.4 KW TYPE) 5

Ammeter £

Battery 12V

Switch K sf

Voltmeter W Starter

86U05X-040

No-Load Test

1. After adjusting the pinion gap, form a test circuit

with a voltmeter and an ammeter.

Note

Use heavy gauge wires and tighten each ter-

minal fully.

2. Close switch K to run the starter.

3. Check for the following:

Voltage (V) 11.0

Current (A) 90 max.

Gear shaft speed (rpm) 3,000 min.

4. If any abnormality is noted, check for the cause

according to "Inspection".

INSTALLATION

Install in the reverse order of removal.

Note

When installing the starter, tighten the bolts

to the specified torque.

Tightening torque:

Bolts 37—52 N m

(3.8—5.3 m-kg, 27—38 ft-lb)

B terminal 9.8—11.8 N-m

(1.0—1.2 m-kg, 87—104 in-lb)

76G05X-043

5—55

Page 762 of 1865

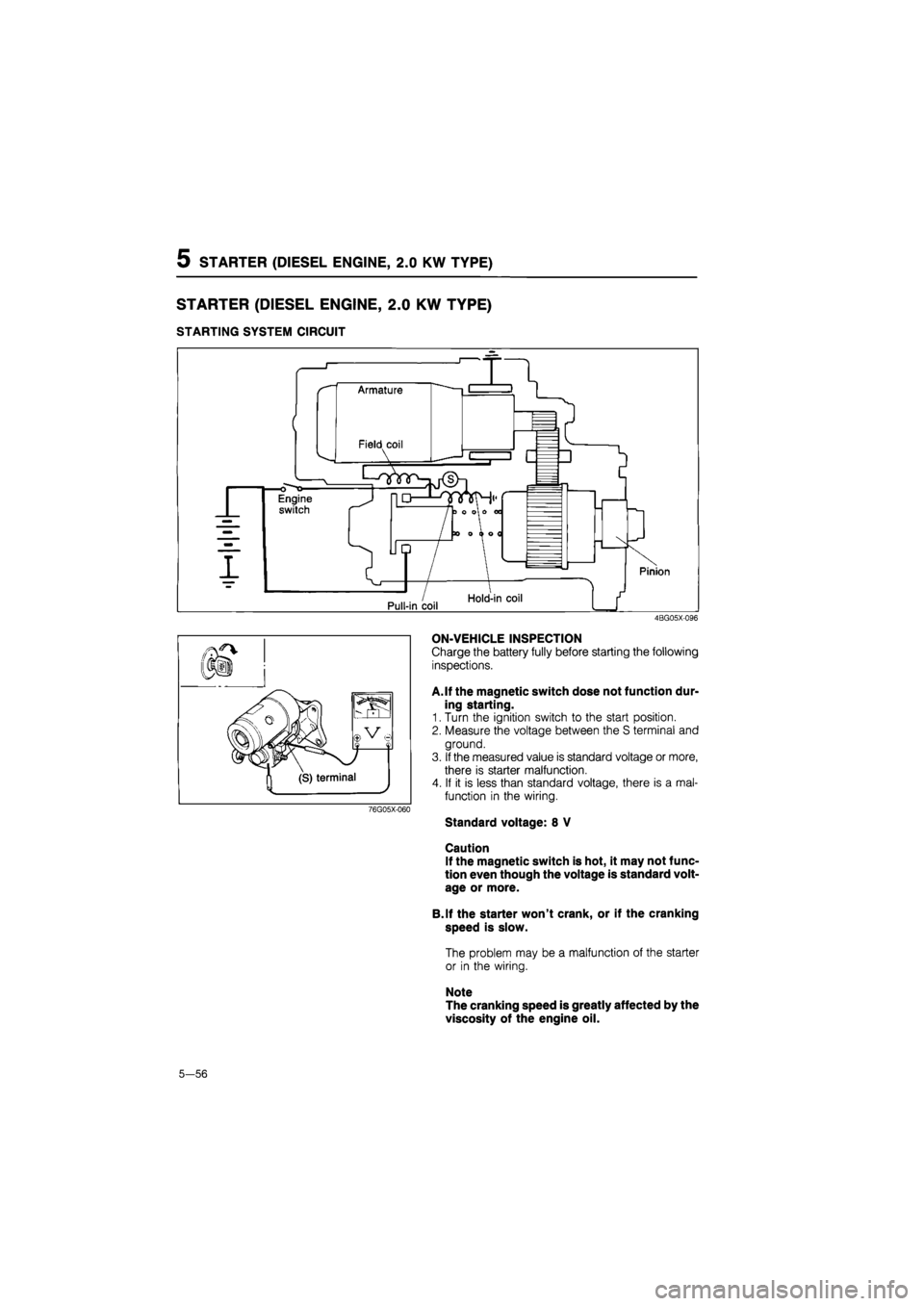

5 STARTER (DIESEL ENGINE, 2.0 KW TYPE)

STARTER (DIESEL

ENGINE, 2.0

KW TYPE)

STARTING SYSTEM CIRCUIT

4BG05X-096

76G05X-060

ON-VEHICLE INSPECTION

Charge the battery fully before starting the following

inspections.

A.If the magnetic switch dose not function dur-

ing starting.

1. Turn the ignition switch to the start position.

2. Measure the voltage between the S terminal and

ground.

3. If the measured value is standard voltage or more,

there is starter malfunction.

4. If it is less than standard voltage, there is a mal-

function in the wiring.

Standard voltage: 8 V

Caution

If the magnetic switch is hot, it may not func-

tion even though the voltage is standard volt-

age or more.

B.lf the starter won't crank, or if the cranking

speed is slow.

The problem may be a malfunction of the starter

or in the wiring.

Note

The cranking speed is greatly affected by the

viscosity of the engine oil.

5—56

Page 763 of 1865

5 STARTER (DIESEL ENGINE, 2.0 KW TYPE)

REMOVAL AND INSTALLATION

Removal is as follows:

1. Disconnect the negative battery cable.

2. Disconnect the wiring from the starter.

3. Remove the starter.

Install in the reverse order of removal.

Tightening torque:

Bolts 64—89 N-m

(6.5—9.1 m-kg, 47—66 ft-lb)

B terminal 9.8—11.8 N-m

(1.0—1.2 m-kg, 87—104 in-lb)

76G05X-044

DISASSEMBLY AND ASSEMBLY

1. Disassemble in the order shown in the figure.

2. Assemble in the reverse order of disassembly.

4BG05X-047

1. Yoke assembly 7. Over-running clutch assembly

2. Brush holder 8. Pinion gear

3. Armature 9. Steel ball

4. Magnetic switch assembly 10. Coil spring

5. Idler gear 11. Housing

6. Retainer and rollers

5—57

Page 764 of 1865

5 STARTER (DIESEL ENGINE, 2.0 KW TYPE)

Disassembly

1. Remove the lead wire connected to the magnetic

switch.

4BG05X-098

2. Remove the two through-bolts.

4EG05X-041

3. Remove the yoke from the magnetic switch.

4EG05X-042

f /"Spring

Brush holder f 0rf# )

N

Itfc

Sr IP Brush

4. Using radio pliers or a similar tool, raise the + side

brush spring and remove the brush.

Caution

Be careful not to scratch the brush or com-

mutator.

4EG05X-043

5—58

Page 765 of 1865

STARTER (DIESEL ENGINE, 2.0 KW TYPE) 5

5. Remove the armature from the yoke.

Caution

Be careful not to drop the armature.

4EG05X-044

6. Remove the two screws which hold the housing

and the magnetic switch.

4EG05X-045

7. Remove the housing from the magnetic switch.

4EG05X-046

8. Remove the idle gear, retainer and roller.

Caution

Be careful not to lose the roller.

4EG05X-047

5-59

Page 766 of 1865

5 STARTER (DIESEL ENGINE, 2.0 KW TYPE)

9. Remove the over-running clutch assembly from the

housing.

4EG05X-048

10. Remove the steel ball from the over-running clutch

assembly.

Caution

Be careful not to lose the steel ball.

4EG05X-049

y

/

~7| j j-jy

Coil spring Magnet switch

11. Remove the coil spring from the magnetic switch.

4EG05X-050

Assembly (main point)

Greasing

Apply grease (lithium base, NLGI No. 2) to the places

shown in the figure.

4BG05X-099

5—60

Page 767 of 1865

STARTOR (DIESEL ENGINE, 2.0 kW TYPE) 5

Coil spring and steel ball installation

1. Install the coil spring and steel ball to the magnet-

ic switch before installing the over-running clutch

assembly.

2. Assemble the retainer and roller to the idler gear.

4BG04X-100

Brush

(

+

)

Brush installation

1. Assemble the brush holder to the yoke.

2. Assemble the two brushes on the yoke side to the

brush holder.

4BG05X-101

Magnetic switch installation

Align the cut out part with the projection of the mag-

netic switch.

4BG05X-102

INSPECTION

Armature Coil

1. Ground of the armature coil

(1) Check for continuity between the commutator

and the core by using a circuit tester.

(2) Replace the armature if there is continuity.

4BG05X-081

5-61

Page 768 of 1865

5 STARTER (DIESEL ENGINE, 2.0 KW TYPE)

4BG05X-082

4BG05X-103

Faulty repair

Bad Good

Mica

Undercut

Segments

4BG05X-084

2. Vibration of the commutator

(1) Place the armature on V blocks, and measure

the vibration by using a dial gauge.

(2) If the vibration is Limit or more, repair so that

it becomes standard by using a lathe, or re-

place the armature.

Standard vibration: 0.05 mm (0.002 in)

Limit: 0.4 mm (0.018 in)

Note

Before checking, be sure that there is no play

in the bearings.

3. Outer diameter of the commutator

Replace the armature if the outer diameter of the

commutator is grind limit or less.

4. Roughness of the commutator surface

(1) If the commutator surface is dirty, wipe it with

a cloth.

(2) If it is rough, repair it by using a lathe or fine

sandpaper.

Grind limit: 34 mm (1.34 in)

5. Segment groove depth

If the depth of the mold between segments is limit

depth or less, undercut the grooves by standard

depth.

Standard depth:

0.5—0.8 mm (0.020—0.031 in)

Limit depth: 0.2 mm (0.008 in)

Field Coil

1. Wiring damage

(1) Check for continuity between the connector

and brushes by using a circuit tester.

(2) Replace the yoke assembly if there is no con-

tinuity.

4BG05X-085

5-62

Page 769 of 1865

STARTER (DIESEL ENGINE, 2.0 KW TYPE) 5

4BG05X-086

4BG05X-087

4BG05X-088

2. Ground of the field coil

(1) Check for continuity between the connector

and yoke by using a circuit tester.

(2) Repair, or replace the yoke assembly if there

is continuity.

3. Installation of the field coil

Replace the yoke assembly

if

the field coil is loose.

Brush and Brush Holder

1. Brush

If the brushes are worn beyond the wear limit, or

if the wear is near the limit, replace the brushes.

Standard: 17 mm (0.669 in)

Wear limit: 11 mm (0.433 in)

2. Brush spring

(1) Measure the force of the brush spring by us-

ing a spring balance.

(2) Replace the brush spring if the force is limit or

less.

Limit: 9 N (900 g, 31.75 oz)

3. Brush holder

(1) Check for continuity between the insulated

brush and the plate by using a circuit tester.

(2) Repair or replace if there is continuity.

(3) Also check to be sure that the brush slides

smoothly inside the brush holder.

4BG05X-089

5-63

Page 770 of 1865

5 STARTER (DIESEL ENGINE, 2.0 KW TYPE)

Suitable _

steel plate

Armature

4BG05X-104

4BG05X-092

4BG05X-093

Bearing

Check for abnormal noise, looseness, insufficient

lubrication, etc. Replace the bearing if there is any

abnormality.

Take out the bearing, as shown in the figure, by us-

ing the suitable tools.

PERFORMANCE INSPECTION

Magnetic Switch

Disconnect the terminal M wire, and make the fol-

lowing tests.

Pull-in Test

The switch is normal

if

the pinion ejects outward when

the battery is connected as shown in the figure.

Caution

Do not supply power continuously for more

than 10 seconds.

Hold-in Test

1. After completing the pull-in test, disconnect the wire

from terminal M (with the pinion left ejected).

2. The hold-in coil is functioning properly if the pin-

ion does not return.

Return Test

1. Connect the battery between terminal M of the

magnetic switch and the body, as shown in the

figure.

2. Pull the pinion out manually to the pinion stopper

position.

3. The pinion should immediately return to its origi-

nal position when it is released.

4BG05X-094

5—64