MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 771 of 1865

5 STARTER (DIESEL ENGINE, 2.0 KW TYPE)

(S) terminal Switch (K)

(B) terminal

Amp. meter

Voltmeter

4BG05X-105

No-load Test

1. After adjusting the pinion gap, form a test circuit

with a voltmeter and an ammeter.

Note

Use wires as thick as possible and tighten

each terminal fully.

2. Close switch "K" to run the starter.

If

the voltmeter

and ammeter show the following values while the

starter is running, it is normal.

Battery voltage: 11.5 volts

Current: 120 amperes or less

Gear shaft speed: at 4,000 or more

3. If any abnormality is noted, check it according to

"INSPECTION"

5—65

Page 772 of 1865

5 STARTER (DIESEL ENGINE, 2.0 KW TYPE)

STARTER (DIESEL

ENGINE, 2.2

KW TYPE)

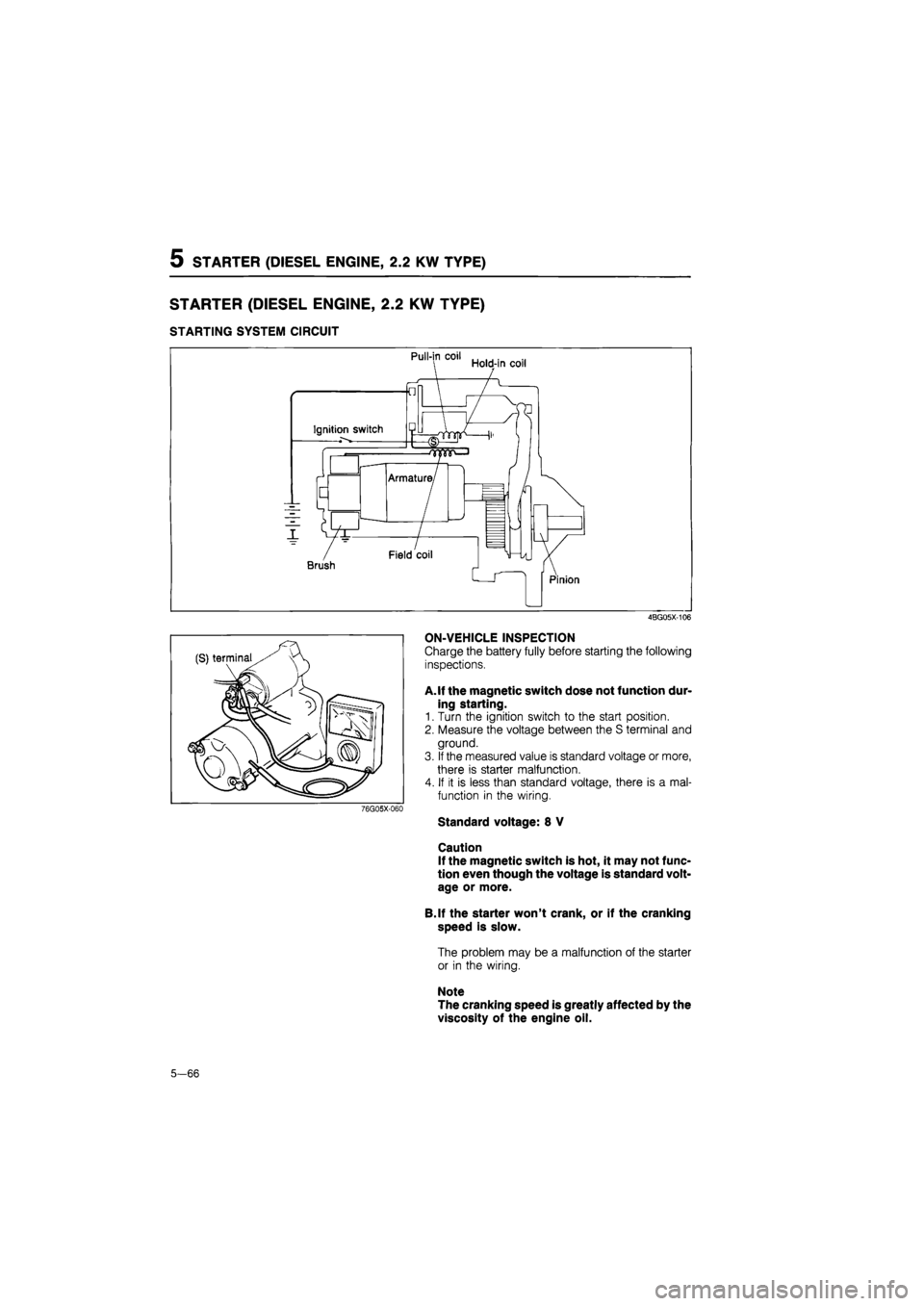

STARTING SYSTEM CIRCUIT

4BG05X-106

76G05X-060

ON-VEHICLE INSPECTION

Charge the battery fully before starting the following

inspections.

A. If the magnetic switch dose not function dur-

ing starting.

1. Turn the ignition switch to the start position.

2. Measure the voltage between the S terminal and

ground.

3.

If

the measured value is standard voltage or more,

there is starter malfunction.

4. If it is less than standard voltage, there is a mal-

function in the wiring.

Standard voltage: 8 V

Caution

If the magnetic switch is hot, it may not func-

tion even though the voltage is standard volt-

age or more.

B.lf the starter won't crank, or if the cranking

speed is slow.

The problem may be a malfunction of the starter

or in the wiring.

Note

The cranking speed is greatly affected by the

viscosity of the engine oil.

5—66

Page 773 of 1865

5 STARTER (DIESEL ENGINE, 2.0 KW TYPE)

REMOVAL AND INSTALLATION

Removal is as follows:

1. Disconnect the negative battery cable.

2. Disconnect the wiring from the starter.

3. Remove the starter.

Install in the reverse order of removal.

Tightening torque:

Bolts 64—89 N-m

(6.5—9.1 m-kg, 47—66 ft-lb)

B terminal 9.8—11.8 N-m

(1.0—1.2 m-kg, 87—104 in-lb)

76G05X-046

DISASSEMBLY AND ASSEMBLY

1. Disassemble in the numbered order shown in the figure.

2. Assembly in the reverse order of disassembly.

4BG05X-107

1. Magnetic switch 7. Lever

2. Rear cover 8. Cover

3. Brush-holder assembly 9. Drive pinion and over-running

4. Yoke clutch assembly

5. Armature 10. Reduction gear

6. Front housing 11. Center bracket

5—67

Page 774 of 1865

5 STARTER (DIESEL ENGINE, 2.2 KW TYPE)

Disassembly

1. Remove the magnetic switch.

4BG05X-108

2. Remove the rear housing.

4EG05X-069

3. Using radio pliers or a similar tool, raise the posi-

tive (+) side brush spring, and remove the brush.

36G05X-032

4. Remove the brush holder assembly and the ar-

mature.

36G05X-033

5—68

Page 775 of 1865

STARTER (DIESEL ENGINE, 2.2 KW TYPE) 5

36G05X-034

36G05X-035

36G05X-036

5. Remove the front cover, and remove the lever and

springs (two).

6. Separate the yoke and center bracket.

7. Remove the cover and pull out the snap ring and

washer.

8. Remove the pinion, over-running clutch assembly

and reduction gear from the center bracket.

36G05X-037

5-69

Page 776 of 1865

5 STARTER (DIESEL ENGINE, 2.2 KW TYPE)

Reduction gear

Adjusting washer

-Pinion shaft

-Thrust gap

-Snap ring

-Washer

Washer bracket

4BG05X-109

4BG05X-110

4BG05X-111

Assembly (main point)

Pinion shaft play

1. Measure the thrust gap by moving the pinion shaft

axial direction.

Standard play: Less than 0.5 mm (0.02 in)

2. Adjust the play with the adjusting washer.

Lever installation

Install the lever as shown in figure.

Rear bracket installation

Align the matching marks when assembling the rear

bracket.

Greasing

When disassembling or assembling the starter,

grease each sliding part, gear and bearing.

(1) Armature shaft gear

(2) Reduction gear

(3) Ball bearings (both ends of armature)

(4) Bearing box of rear bracket

(5) Snap ring of pinion shaft

(6) Sleeve bearing, pinion lever sliding part, others

4BG05X-112

5—70

Page 777 of 1865

STARTER (DIESEL ENGINE, 2.2 KW TYPE) 5

4BG05X-113

4BG05X-080

Adjustment of pinion gap

1. Disconnect the wiring from terminal (M).

2. Apply battery power to the terminal (S) and ground

the starter motor body, the pinion will eject outward

and then stop.

3. Measure the clearance (pinion gap) between the

pinion and the stopper.

Note

Be careful not to let electricity flow continu-

ously for more than 10 seconds.

Pinion gap: 0.5—2.0 mm (0.020—0.079 in)

4. If the pinion gap is not within the specified range,

make the adjustment by increasing or decreasing

the number of washers used between the magnetic

switch and the drive housing. The gap will become

smaller if the number of washers is increased.

Caution

Do not use the washers more than plates.

INSPECTION

Armature Coil

1. Ground of the armature coil

Check for continuity between the commutator and

the core by using a circuit tester. Replace the ar-

mature if there is continuity.

4BG05-081

2. Vibration of the commutator

Plate the armature on V blocks, and measure the

vibration by using a dial gauge. If the vibration is

Limit or more, repair so that is standard by using

a lathe, or replace the armature.

Standard vibration: 0.05 mm (0.002 in)

Limit: 0.4 mm (0.018 in)

Note

Before checking, be sure than there is no play

in the bearings.

4BG05X-Q82

5-71

Page 778 of 1865

5 STARTER (DIESEL ENGINE, 2.2 KW TYPE)

4BG05X-115

4BG05X-085

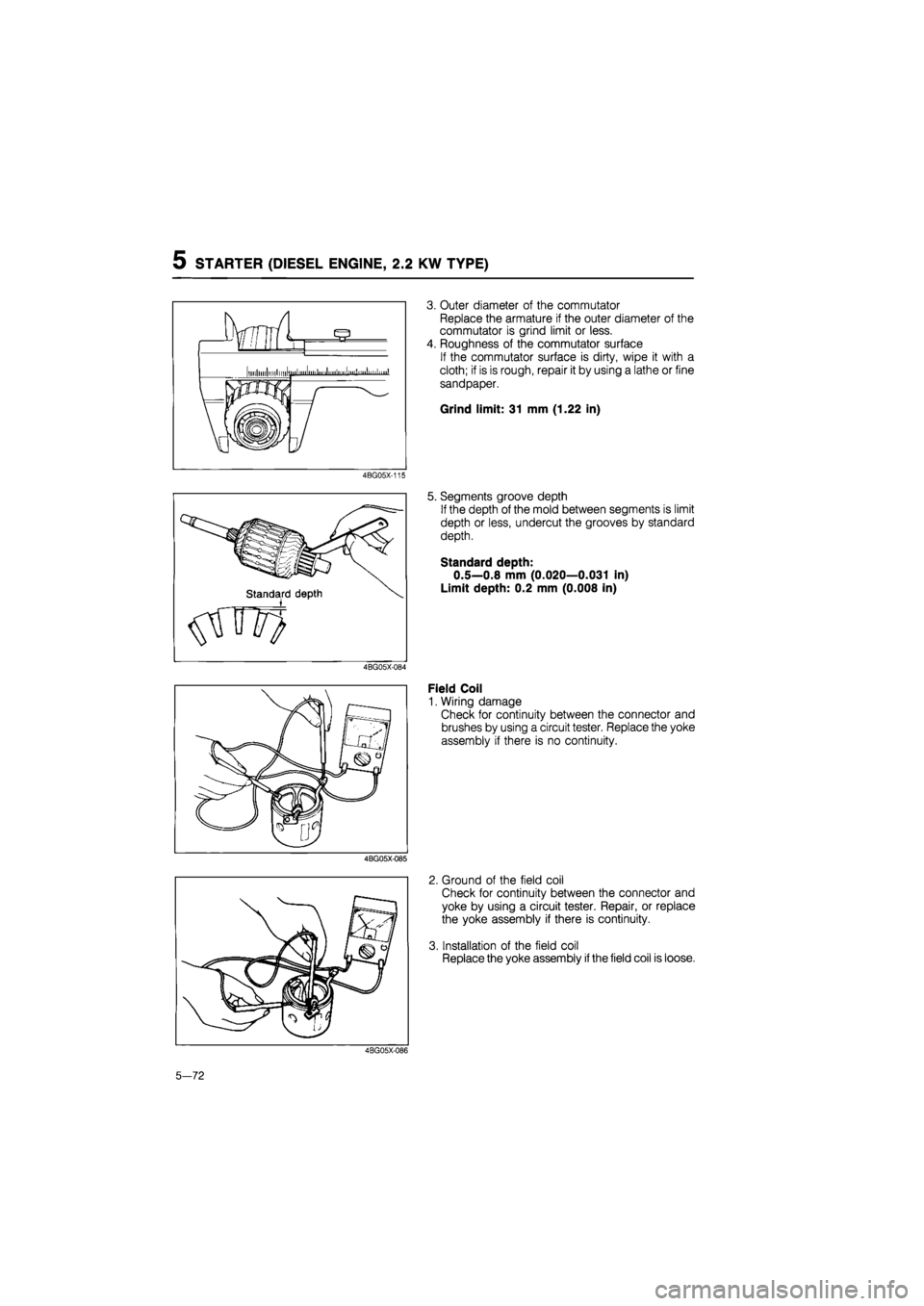

3. Outer diameter of the commutator

Replace the armature if the outer diameter of the

commutator is grind limit or less.

4. Roughness of the commutator surface

If the commutator surface is dirty, wipe it with a

cloth; if is is rough, repair it by using a lathe or fine

sandpaper.

Grind limit: 31 mm (1.22 in)

5. Segments groove depth

If the depth of the mold between segments is limit

depth or less, undercut the grooves by standard

depth.

Standard depth:

0.5—0.8 mm (0.020—0.031 in)

Limit depth: 0.2 mm (0.008 in)

Field Coil

1. Wiring damage

Check for continuity between the connector and

brushes by using a circuit tester. Replace the yoke

assembly if there is no continuity.

2. Ground of the field coil

Check for continuity between the connector and

yoke by using a circuit tester. Repair, or replace

the yoke assembly if there is continuity.

3. Installation of the field coil

Replace the yoke assembly

if

the field coil is loose.

4BG05X-086

5-72

Page 779 of 1865

STATRER (DIESEL ENGINE, 2.2 KW TYPE) 5

11*mm S (0.433 in)

A

A 18 mm

(0,709)

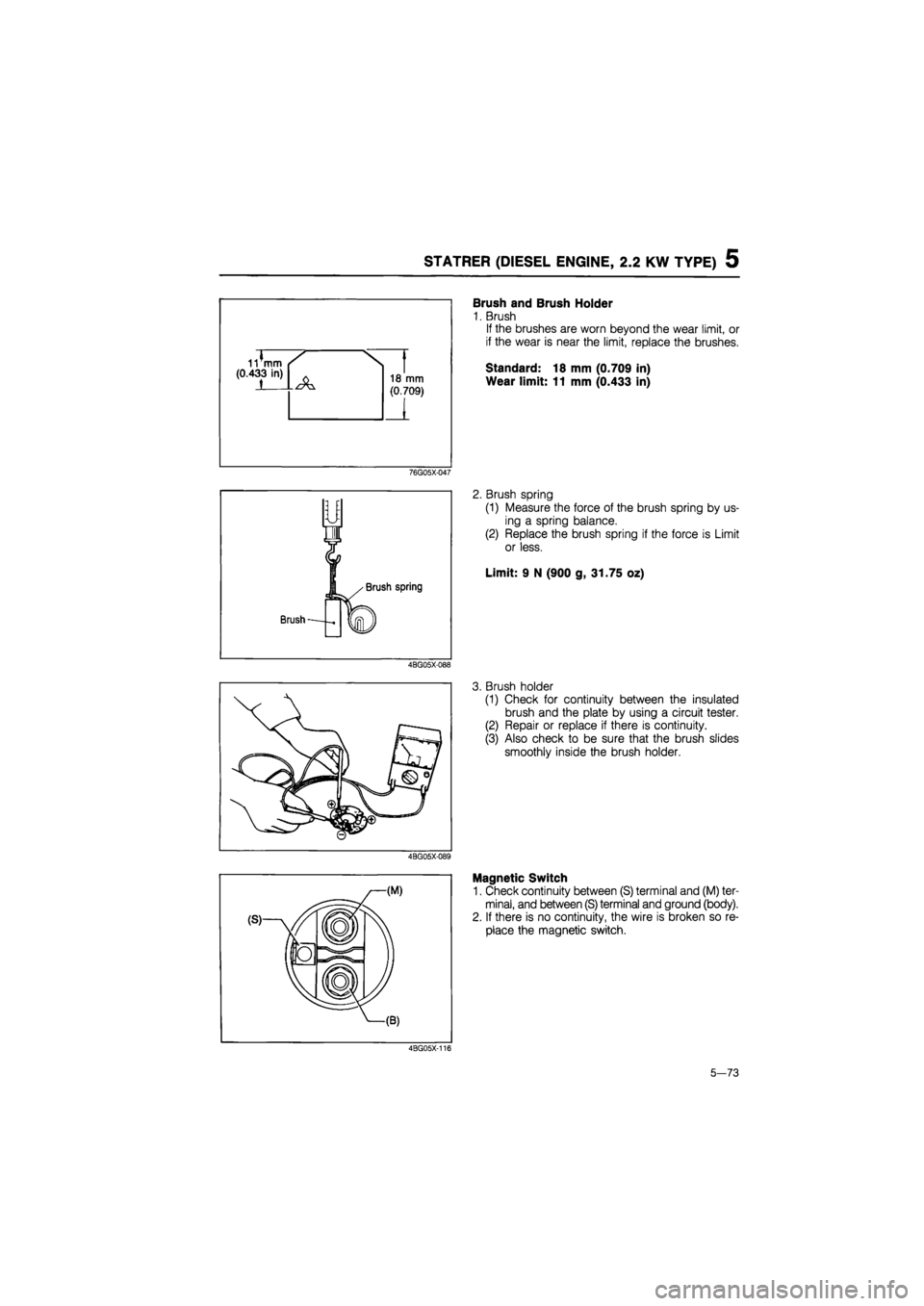

Brush and Brush Holder

1. Brush

If the brushes are worn beyond the wear limit, or

if the wear is near the limit, replace the brushes.

Standard: 18 mm (0.709 in)

Wear limit: 11 mm (0.433 in)

76G05X-047

2. Brush spring

(1) Measure the force of the brush spring by us-

ing a spring balance.

(2) Replace the brush spring if the force is Limit

or less.

Limit: 9 N (900 g, 31.75 oz)

4BG05X-088

3. Brush holder

(1) Check for continuity between the insulated

brush and the plate by using a circuit tester.

(2) Repair or replace if there is continuity.

(3) Also check to be sure that the brush slides

smoothly inside the brush holder.

4BG05X-089

Magnetic Switch

1. Check continuity between (S) terminal and (M) ter-

minal, and between (S) terminal and ground (body).

2. If there is no continuity, the wire is broken so re-

place the magnetic switch.

4BG05X-116

5-73

Page 780 of 1865

5 STARTER (DIESEL ENGINE, 2.2 KW TYPE)

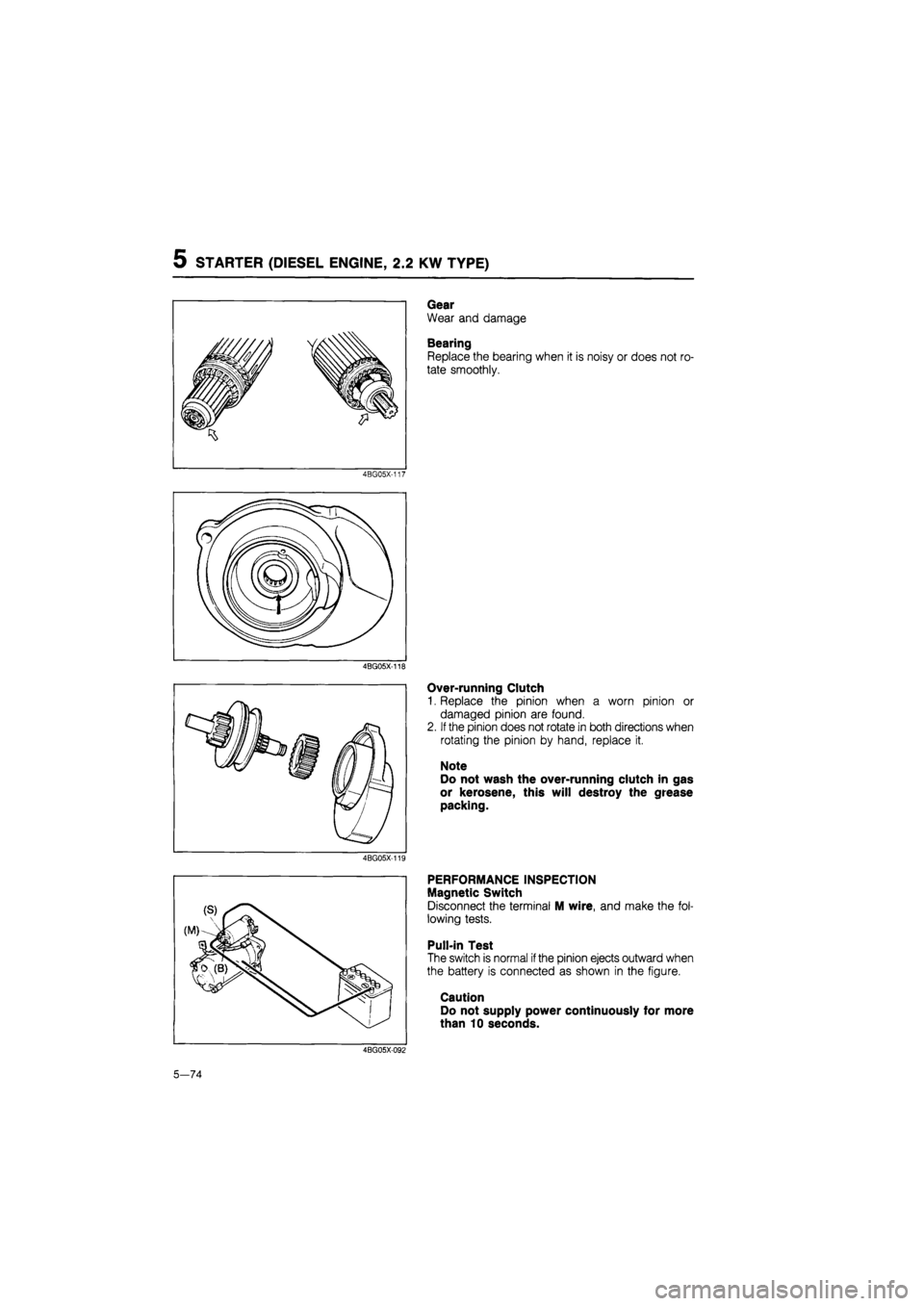

Gear

Wear and damage

Bearing

Replace the bearing when it is noisy or does not ro-

tate smoothly.

4BG05X-117

4BG05X-118

Over-running Clutch

1. Replace the pinion when a worn pinion or

damaged pinion are found.

2.

If

the pinion does not rotate in both directions when

rotating the pinion by hand, replace it.

Note

Do not wash the over-running clutch in gas

or kerosene, this will destroy the grease

packing.

4BG05X-119

PERFORMANCE INSPECTION

Magnetic Switch

Disconnect the terminal M wire, and make the fol-

lowing tests.

Pull-in Test

The switch is normal

if

the pinion ejects outward when

the battery is connected as shown in the figure.

Caution

Do not supply power continuously for more

than 10 seconds.

4BG05X-092

5—74