MAZDA MX-5 1994 Workshop Manual

Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 251 of 1708

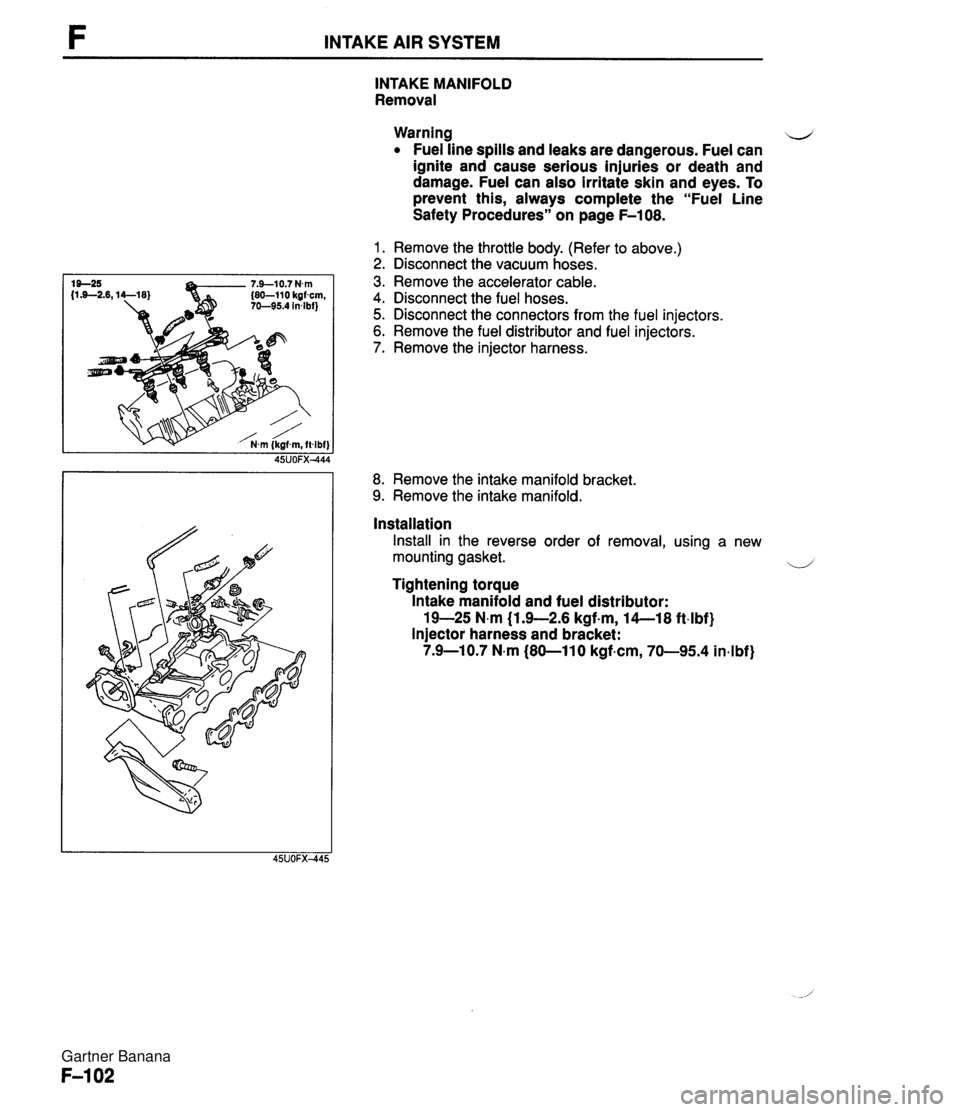

INTAKE AIR SYSTEM INTAKE MANIFOLD Removal Warning e Fuel line spills and leaks are dangerous. Fuel can ignite and cause serious injuries or death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete the "Fuel Line Safety Procedures" on page F-108. 1. Remove the throttle body. (Refer to above.) 2. Disconnect the vacuum hoses. 3. Remove the accelerator cable. 4. Disconnect the fuel hoses. 5. Disconnect the connectors from the fuel injectors. 6. Remove the fuel distributor and fuel injectors. 7. Remove the injector harness. 8. Remove the intake manifold bracket. 9. Remove the intake manifold. Installation Install in the reverse order of removal, using a new mounting gasket. 4 Tightening torque Intake manifold and fuel distributor: 19-25 N.m (1.9--2.6 kgf-m, 14--18 ft4bf) Injector harness and bracket: 7.9-1 0.7 N-m 180-110 kgf,cm, 70-95.4 in4bf) Gartner Banana

Page 252 of 1708

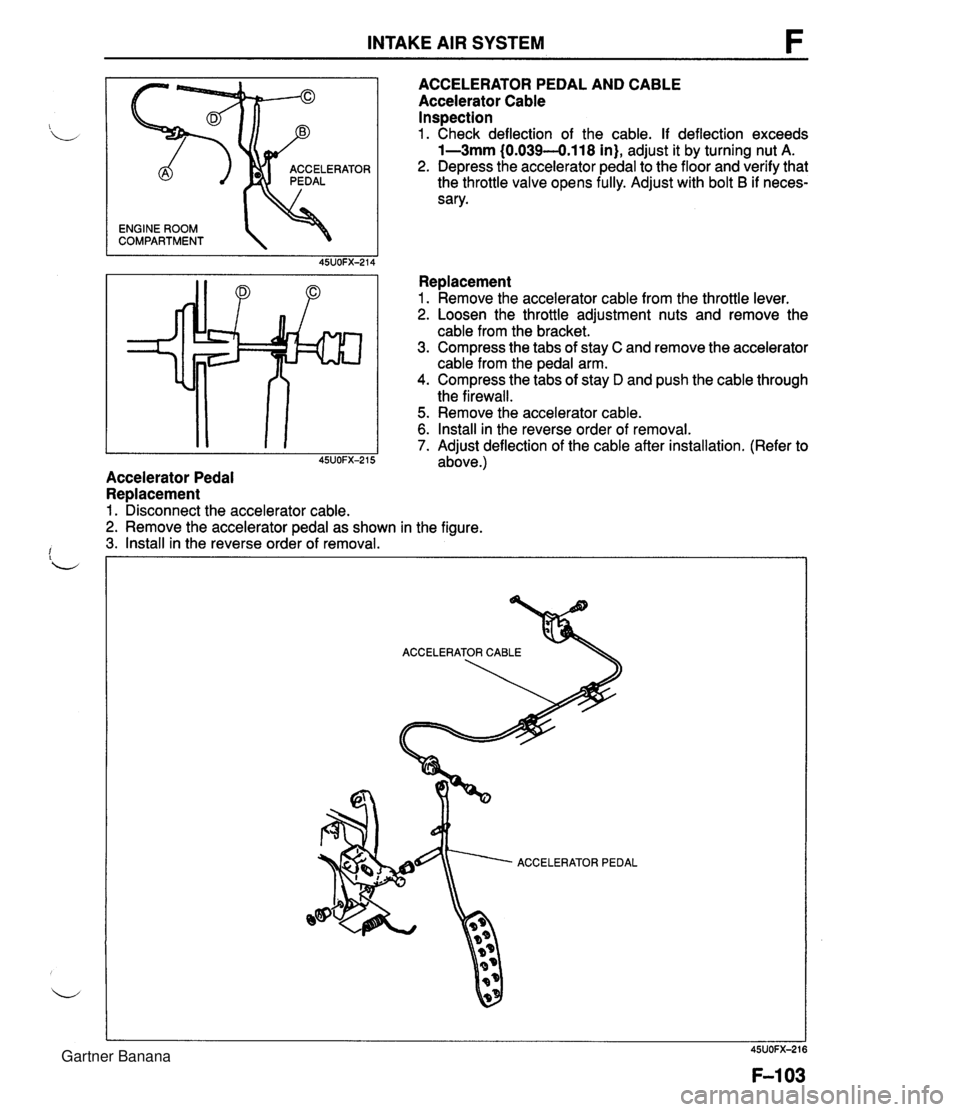

INTAKE AIR SYSTEM ENGINE ROOM COMPARTMENT 'OR ACCELERATOR PEDAL AND CABLE Accelerator Cable Inspection 1. Check deflection of the cable. If deflection exceeds 1-3mm (0.039-0.118 in), adjust it by turning nut A. 2. Depress the accelerator pedal to the floor and verify that the throttle valve opens fully. Adjust with bolt B if neces- sary. Replacement 1. Remove the accelerator cable from the throttle lever. 2. Loosen the throttle adjustment nuts and remove the cable from the bracket. 3. Compress the tabs of stay C and remove the accelerator cable from the pedal arm. 4. Compress the tabs of stay D and push the cable through the firewall. 5. Remove the accelerator cable. 6. Install in the reverse order of removal. 7. Adiust deflection of the cable after installation. (Refer to I 45~0~~-215 adbve.) Accelerator Pedal Replacement 1. Disconnect the accelerator cable. 2. Remove the accelerator pedal as shown in the figure. 3. Install in the reverse order of removal. ACCELERATOR PEDAL Gartner Banana

Page 253 of 1708

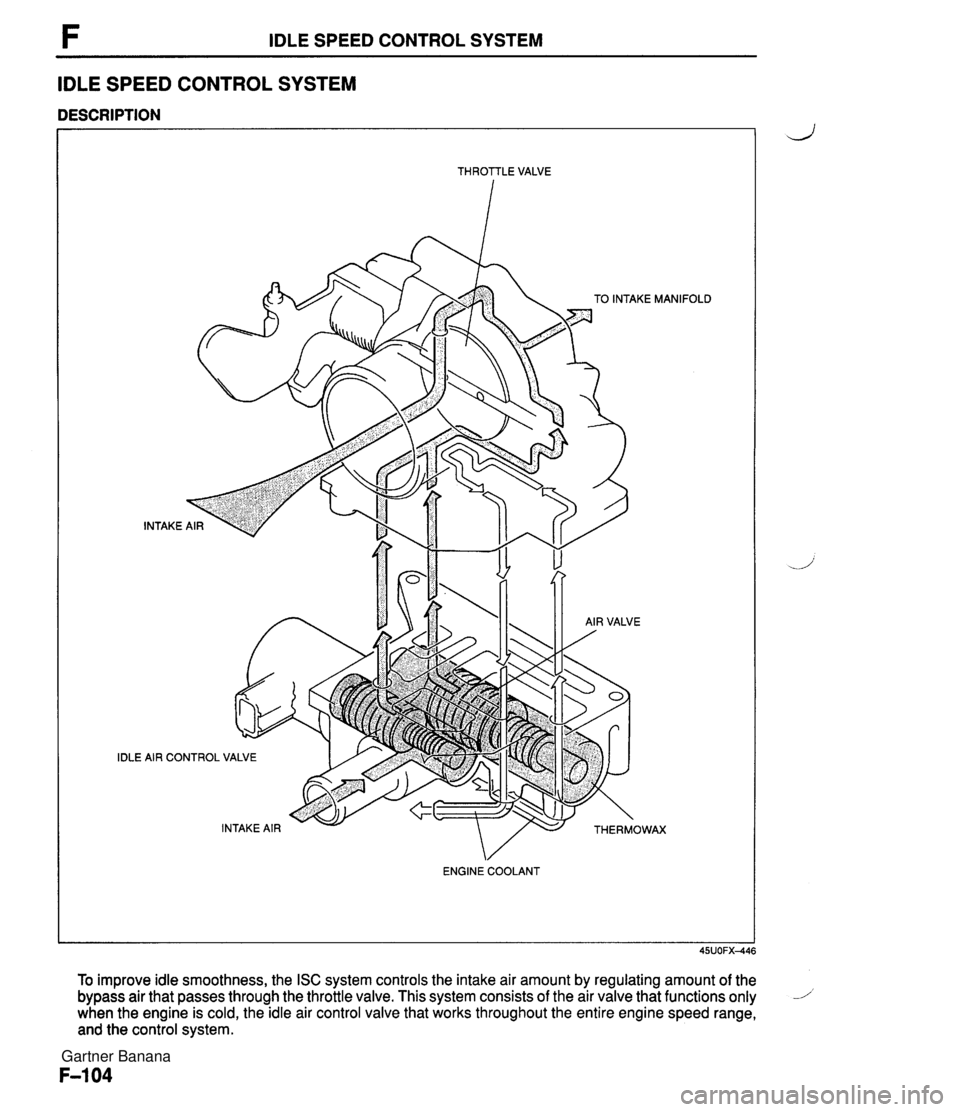

F IDLE SPEED CONTROL SYSTEM IDLE SPEED CONTROL SYSTEM DESCRIPTION - -- - THROTTLE VALVE IDLE TO INTAKE MANlF INTAKE i AIR CONTROL VALVE ENGINE COOLANT To improve idle smoothness, the ISC system controls the intake air amount by regulating amount of the bypass air that passes through the throttle valve. This system consists of the air valve that functions only 1 when the engine is cold, the idle air control valve that works throughout the entire engine speed range, and the control system. Gartner Banana

Page 254 of 1708

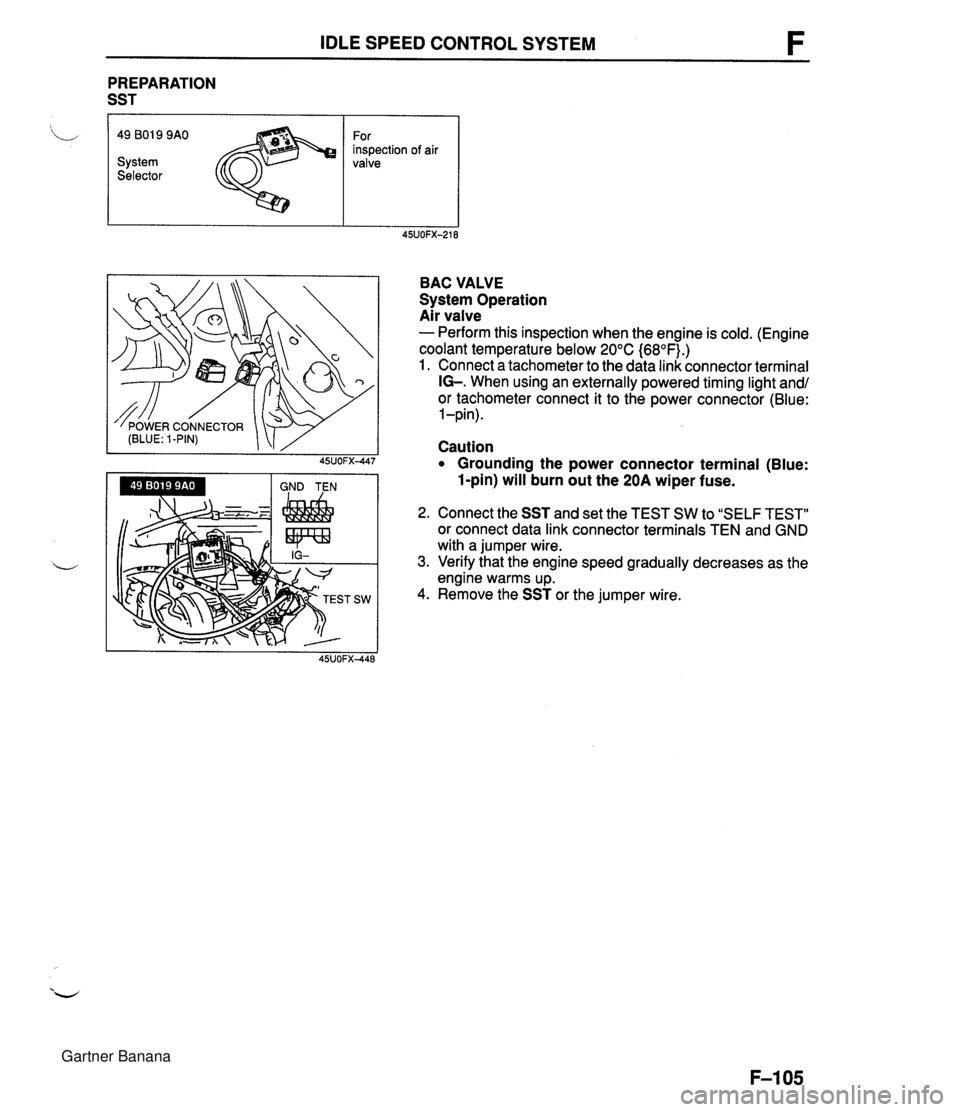

IDLE SPEED CONTROL SYSTEM PREPARATION SST I 'L 49 801 9 9AO For inspection of air System valve Selector BAC VALVE System Operation Air valve - Perform this inspection when the engine is cold. (Engine coolant temperature below 20°C {68OF).) 1. Connect a tachometer to the data link connector terminal IG-. When using an externally powered timing light and/ or tachometer connect it to the power connector (Blue: 1 -pin). Caution Grounding the power connector terminal (Blue: 1-pin) will burn out the 20A wiper fuse. 2. Connect the SST and set the TEST SW to "SELF TEST" or connect data link connector terminals TEN and GND with a jumper wire. 3. Verify that the engine speed gradually decreases as the engine warms up. 4. Remove the SST or the jumper wire. Gartner Banana

Page 255 of 1708

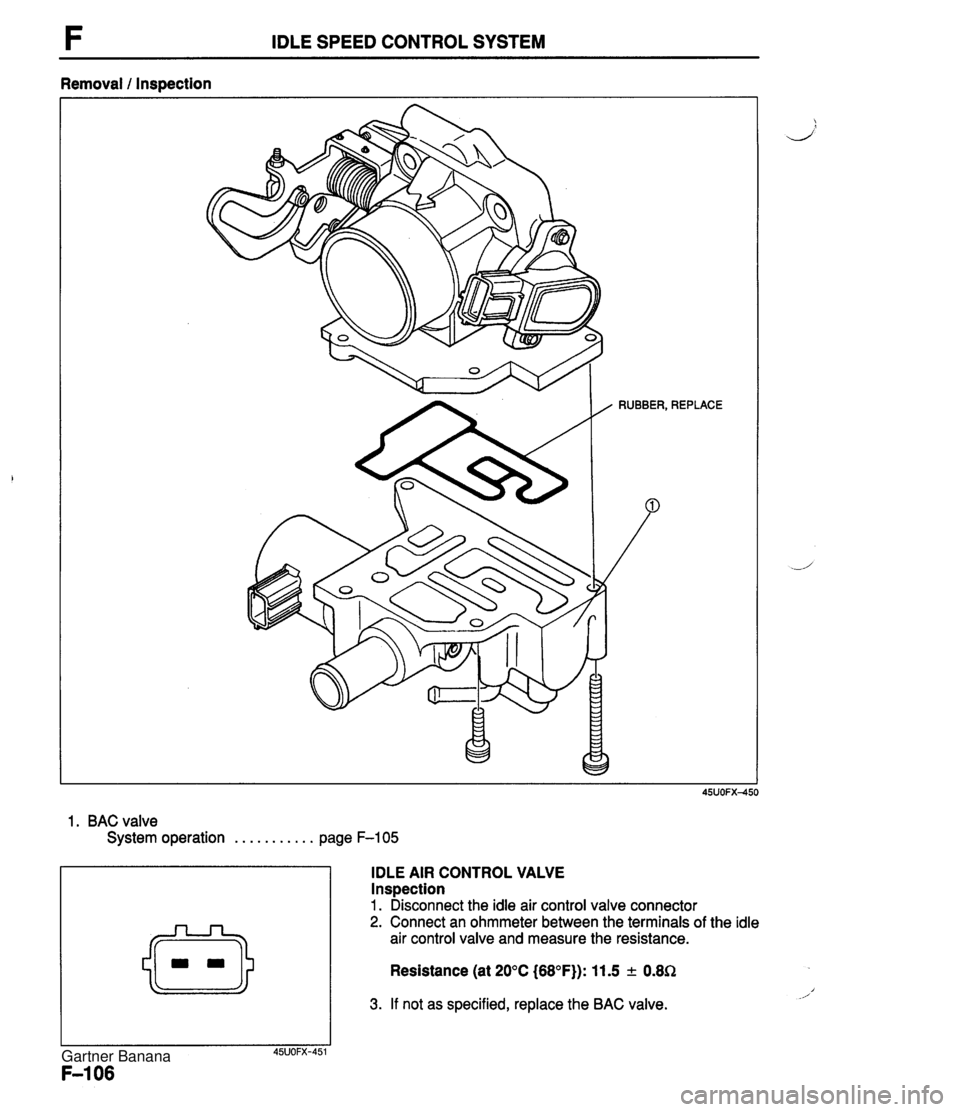

IDLE SPEED CONTROL SYSTEM Removal 1 Inspection / RUBBER, REPLACE 1. BAC valve System operation . . . . . . . . . . . page F-105 IDLE AIR CONTROL VALVE lnspection 1. Disconnect the idle air control valve connector 2. Connect an ohmmeter between the terminals of the idle air control valve and measure the resistance. Resistance (at 20°C (68°F)): 11.5 2 0.8Q 3. If not as specified, replace the BAC valve. Gartner Banana

Page 256 of 1708

FUEL SYSTEM F FUEL SYSTEM DESCRIPTION . This system supplies the necessary fuel for combustion at a constant pressure to the fuel injectors. Fuel is metered and injected into the intake manifold according to the injection control signals from the power- train control module (engine). The system consists of the fuel tank, the fuel pump, the fuel filters, the fuel distributor, the pressure regulator, the fuel injectors, and the fuel pump relay. I I 1. Fuel tank 5. Fuel pump relay Removal / Inspection / Inspection .................. page F-117 Installation ................ page F-111 Replacement ............... page F-117 2. Fuel filter 6. Pressure regulator Replacement ............... page F-113 Inspection .................. page F-118 3. Fuel pump Replacement ............... page F-119 .................. w Inspection page F-114 7. Fuel injector Replacement ............... page F-115 Inspection .................. page F-119 4. Fuel distributor Removal ................... page F-119 Installation ................. page F-121 Gartner Banana

Page 257 of 1708

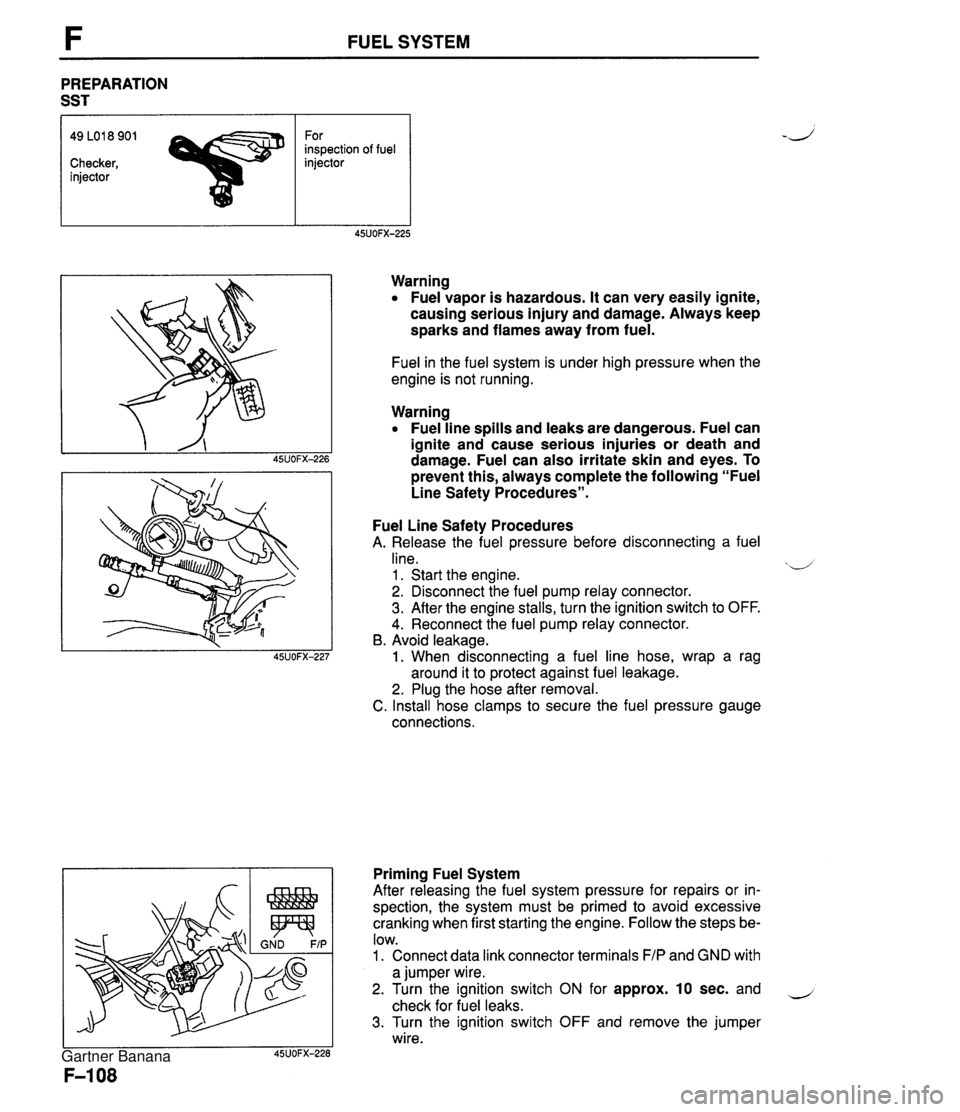

FUEL SYSTEM PREPARATION SST 49 LO1 8 901 For inspection of fuel Checker, injector injector Warning Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep sparks and flames away from fuel. Fuel in the fuel system is under high pressure when the engine is not running. Warning Fuel line spills and leaks are dangerous. Fuel can ignite and cause serious injuries or death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete the following "Fuel Line Safety Procedures". Fuel Line Safety Procedures A. Release the fuel pressure before disconnecting a fuel line. xd 1 . Start the engine. 2. Disconnect the fuel pump relay connector. 3. After the engine stalls, turn the ignition switch to OFF. 4. Reconnect the fuel pump relay connector. B. Avoid leakage. 1. When disconnecting a fuel line hose, wrap a rag around it to protect against fuel leakage. 2. Plug the hose after removal. C. Install hose clamps to secure the fuel pressure gauge connections. Priming Fuel System After releasing the fuel system pressure for repairs or in- spection, the system must be primed to avoid excessive cranking when first starting the engine. Follow the steps be- low. 1. Connect data link connector terminals F/P and GND with a jumper wire. 2. Turn the ignition switch ON for approx. 10 sec. and - check for fuel leaks. 3. Turn the ignition switch OFF and remove the jumper wire. Gartner Banana

Page 258 of 1708

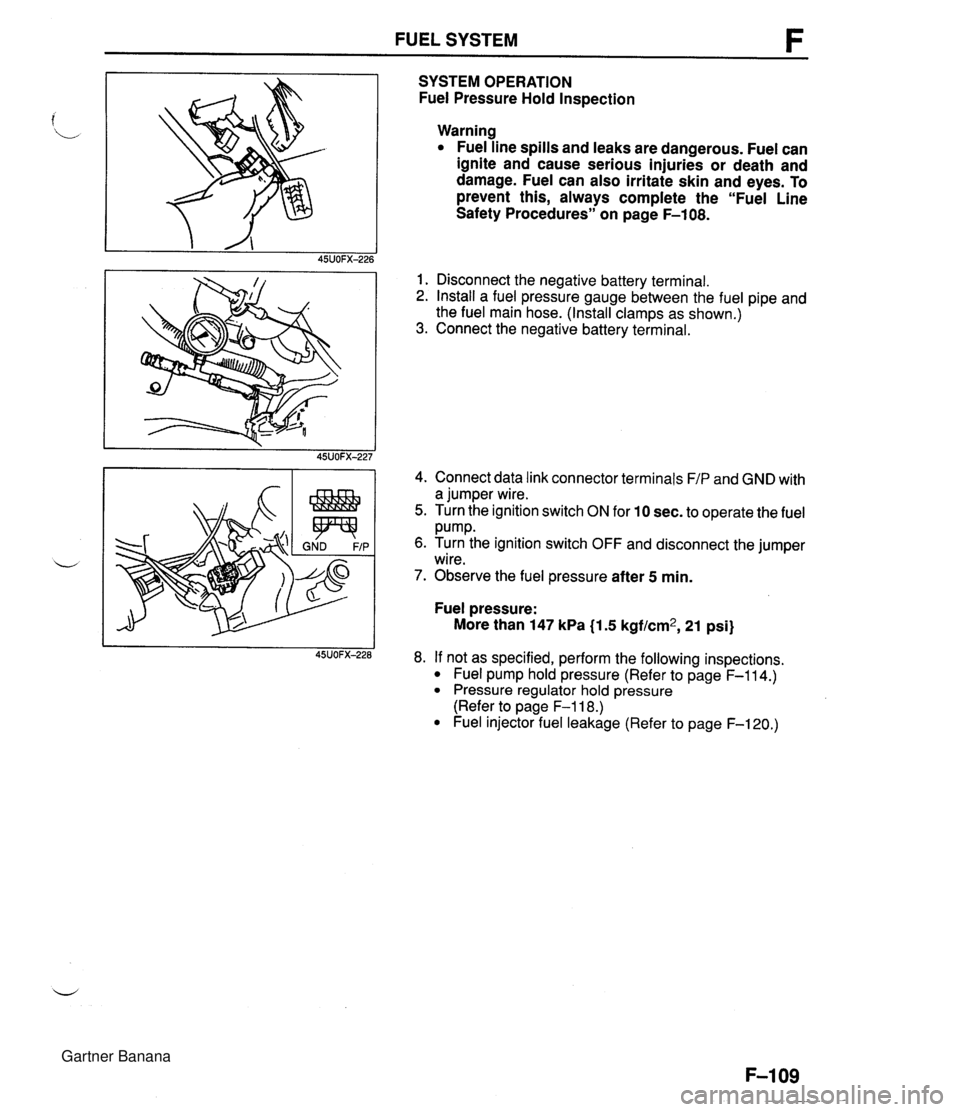

FUEL SYSTEM SYSTEM OPERATION Fuel Pressure Hold Inspection Warning Fuel line spills and leaks are dangerous. Fuel can ignite and cause serious injuries or death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete the "Fuel Line Safety Procedures" on page F-108. 1. Disconnect the negative battery terminal. 2. Install a fuel pressure gauge between the fuel pipe and the fuel main hose. (Install clamps as shown.) 3. Connect the negative battery terminal. 4. Connect data link connector terminals F/P and GND with a jumper wire. 5. Turn the ignition switch ON for 10 sec. to operate the fuel Pump. 6. Turn the ignition switch OFF and disconnect the jumper wire. 7. Observe the fuel pressure after 5 min. Fuel pressure: More than 147 kPa (1.5 kgf/cm2, 21 psi) 8. If not as specified, perform the following inspections. Fuel pump hold pressure (Refer to page F-114.) Pressure regulator hold pressure (Refer to page F-118.) Fuel injector fuel leakage (Refer to page F-120.) Gartner Banana

Page 259 of 1708

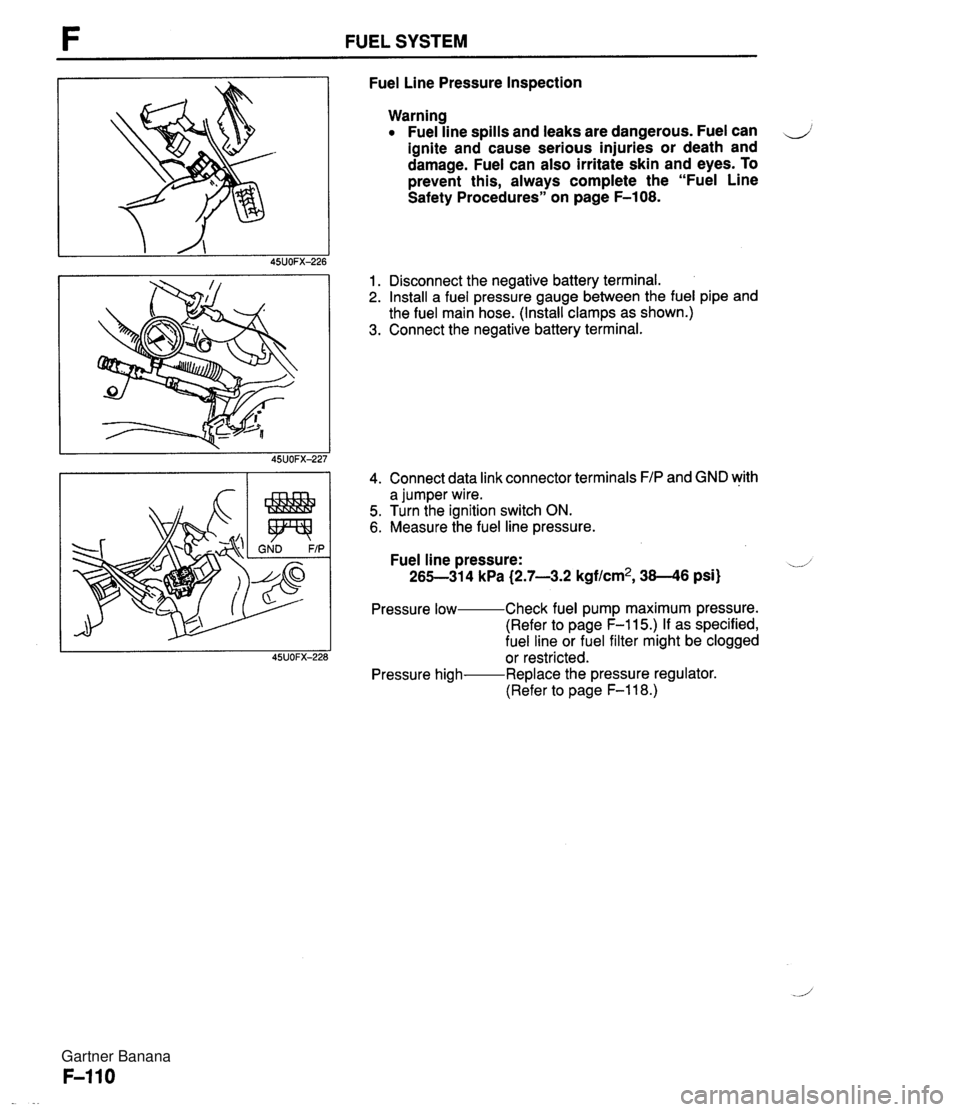

FUEL SYSTEM Fuel Line Pressure Inspection Warning Fuel line spills and leaks are dangerous. Fuel can ignite and cause serious injuries or death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete the "Fuel Line Safety Procedures" on page F-108. 1. Disconnect the negative battery terminal. 2. Install a fuel pressure gauge between the fuel pipe and the fuel main hose. (Install clamps as shown.) 3. Connect the negative battery terminal. 4. Connect data link connector terminals F/P and GND with a jumper wire. 5. Turn the ignition switch ON. 6. Measure the fuel line pressure. Fuel line pressure: 265-31 4 kPa {2.7-3.2 kgf/cm2, 38-46 psi) Pressure low- Check fuel pump maximum pressure. (Refer to page F-115.) If as specified, fuel line or fuel filter might be clogged or restricted. Pressure high- Replace the pressure regulator. (Refer to page F-118.) Gartner Banana

Page 260 of 1708

FUEL SYSTEM FUEL TANK Removal 1 Inspection / Installation b Warning Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep sparks and flames away from fuel. Warning Fuel line spills and leaks are dangerous. Fuel can ignite and cause serious injuries or death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete the "Fuel Line Safety Procedures" on page F-108. Warning Repairing a fuel tank that has not been properly steam cleaned can be dangerous. Explosion or fire may cause death or serious injury. Always properly steam clean a fuel tank before re- pairing it. 1. Disconnect the negative battery terminal. 2. Drain the fuel from the fuel tank. 3. Remove the main silencer. (Refer to page F-128.) 4. Remove the power plant frame. (Refer to section J.) 5. Remove in the order shown in the figure, referring to Removal note. 6. Install in the reverse order of removal, referring to Installation note. Gartner Banana