differential MAZDA MX-5 1994 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 588 of 1708

OUTLINE OUTLINE Front axle Rear axle Differentlal Drive shaft Item I Specifications TY pe Bearing Double-wishbone Angular ball bearing Maximum wheel bearing play mm {in} TY pe Bearing 0.05 {0.002} Double-wishbone Angular ball bearing Maximum wheel bearing play mm {in} Type Reduction gear Reduction ratio Oil I Viscosity 0.05 {0.002} -- ---- Differential gear Ring gear size mm {in} Grade Above -1 8°C {O°F}: SAE 90 Below -1 8°C {O°F}: SAE 80 Standard Hypoid gear Straight-bevel gear 182.88 {7.20) API service GL-5 I Capacity L {US qt. imp qt} I 1 .OO {I .06,0.88) "TORSEN" LSD Worm gear 4.100 TY ~e Length mm {in} Constant velocity (double offset) joint 640.6 I25.220) 45UOMX-00 Gartner Banana

Page 589 of 1708

TROUBLESHOOTING GUIDE TROUBLESHOOTING GUIDE FRONT AXLE I Problem Posslbk Cause Worn or damaged wheel bearing Worn or damaged wheel bearing Steering wheel vibration braking Action Replace Replace REAR AXLE Page M- 6 M-6 I Problem Possible Cause Bent drive shaft Page Action Replace I Abnormal nolse Worn or damaged wheel bearing Worn drive shaft spline Worn or deteriorated upper arm bushing M-13 Replace I M-17 Body "rolls" I Replace section R Body leans Weak upper arm bushing Abnormal nolse from suspension system Worn or deteriorated upper arm bushing DIFFERENTIAL Problem Posrlble Cause lnsufficient differential oil Incorrect differential oil lmproperly adjusted ring gear backlash Poor contact of ring gear teeth Worn or damaged side bearing Worn or damaged ring gear Worn or damaged drive pinion bearing Worn or damaged pinion and side gear (STANDARD) Worn or damaged gear in LSD assembly ("TORSEN" LSD) Seized side gear and case Worn side gear spline Worn pinion shaft Worn thrust washer Worn or damaged needle bearing ("TORSEN" LSD) lmproperly adjusted side gear backlash lmproperly adjusted drive pinion gear preload Action Add oil Replace Adjust Adjust Replace Replace Replace Replace Replace Page M-25 M-25 M40 M4l M-32 M-32 M-32 M-32 M-32 M-32 M-32 M-32 M-32 M-32 M-40 M-39 Abnormal nolse Replace Replace Replace Replace Replace Adjust Adjust Heat buildup lnsufficient differential oil lnsufficient drive pinion gear backlash Excessive bearing preload Add oil Adjust Adjust Oil leakage Excessive differential oil Loose differential carrier Worn or damaged oil seal Remove oil Tighten or repair Replace I - No dlfferentlal operation I Misassembled or damaged Repair Gartner Banana

Page 606 of 1708

DRIVE SHAFT M TAPE 45UOMX-031 DIFFERENTIAL SlDE WHEEL SlDE 45UOMX-031 SNAP RING GROOVE I 45UOMX-032 Boots 1. Wrap the shaft splines with tape. 2. Remove the boot. Assembly note Boots 1. Before putting the boot onto the shaft, wrap the shaft splines with tape. 2. lnstall the wheel-side and differential-side boots, noting the shape and size of each one in the figure. Outer diameter of large boot end Differential side : 87.4mm (3.441 in) Wheel side : 90.8mm (3.575 in) Cage, inner ring, and balls 1. Align the marks and install the balls to the inner ring. 2. Install the cage, inner ring, and ball assembly to the drive shaft in the direction shown in the figure. The larger diameter of the (age should be) facing the snap ring groove. 3. Install a new snap ring in the drive shaft snap ring groove. 4. Apply the specified grease (molybdenum disulfide) to the joints and boots. Total quantity Differential side : 75-95 g (2.65-3.35 oz) Wheel side : 55-75 g (1.94--2.65 oz) Gartner Banana

Page 608 of 1708

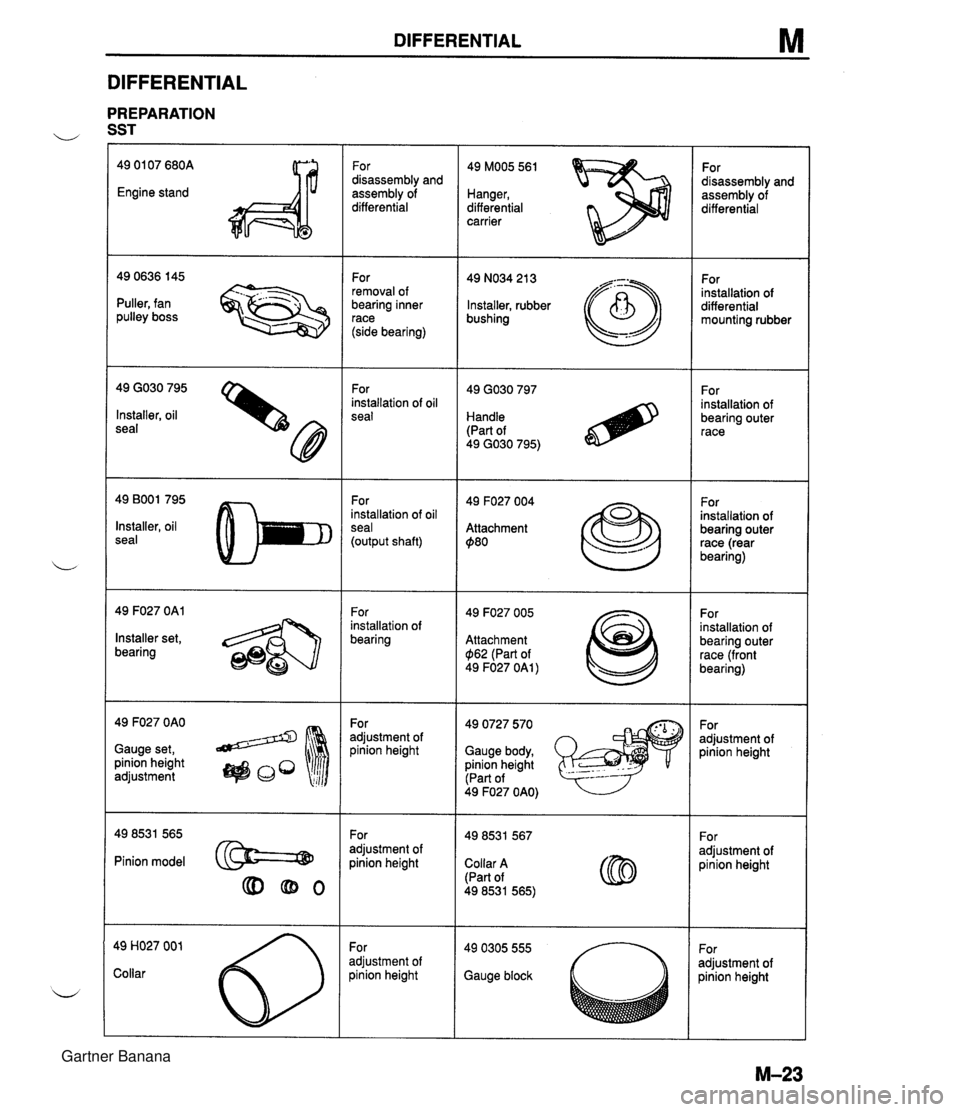

DIFFERENTIAL M DIFFERENTIAL PREPARATION u SST 49 01 07 680A Engine stand For disassembly and assembly of differential 49 MOO5 561 Hanger, differential carrier For disassembly and assembly of differential For removal of bearing inner race (side bearing) 49 NO34 21 3 Installer, rubber bushing For installation of differential mounting rubber - --.. - Puller, fan pulley boss 49 GO30 795 Installer, oil seal For installation of oil seal For installation of bearing outer race Handle (Part of 49 GO30 795) 49 BOO1 795 Installer, oil seal For installation of oil seal (output shaft) 49 F027 004 Attachment $80 For installation of bearing outer race (rear bearing) 49 F027 OAl For installation of bearing 49 F027 005 Attachment $I62 (Part of 49 F027 OAl ) For installation of bearing outer race (front bearing) Installer set, bearing 49 F027 OAO Gauge set, pinion height adjustment 49 0727 570 Gauge body, pinion height (Part of For adjustment of pinion height For adjustment of pinion height 49 F027 OAO) For adjustment of pinion height For adjustment of oinion height Pinion model @==@ Collar A (Part of 49 8531 565) For adjustment of oinion height adjustment of )inion height Gauge block Gartner Banana

Page 609 of 1708

M DIFFERENTIAL 49 DO1 7 2A1 Installer set, bearing 49 F401 331 Body (Part of 49 DO17 2A1) 49 GO30 338 Attachment E (Part of 49 DO1 7 2A1) Puller set, bearing 49 0259 720 Wrench, differential side bearing adjusting nut For installation of bearing For installation of bearing inner race (rear bearing) For installation of bearing inner race (side bearing) For removal and installation of companion flange For adjustment of drive pinion and ring gear backlash 49 F401 337A Attachment C (Part of 49 DO17 2A1) Holder, main shaft Holder, coupling flange 49 U027 003 Installer, oil seal For installation of bearing inner race (rear bearing) For prevention of oil leakage For removal and installation of companion flange For installation of oil seal (companion flange) Gartner Banana

Page 610 of 1708

DIFFERENTIAL M DIFFERENTIAL OIL Inspection 1. Remove the filler plug. 2. Verify that the oil is at the bottom of the filler plug hole. If it is low, add the specified oil. 3. Install the filler plug. Tightening torque: 39-54 N.m (4.0-5.5 kgf.m, 29-40 ft4bf) Replacement 1. Remove the filler and drain plugs. 2. Drain the differential oil into a suitable container. 3. Wipe the plugs clean. 4. Install the drain plug and a new washer. Tightening torque: 39-54 N.m (4.0-5.5 kgf-m, 29-40 ft4bf) 5. Add the specified oil from the filler plug until the level reaches the bottom of the plug hole. Specified oil TY pe Above -18°C (0°F): API GL-5, SAE 90 Below -18°C (0°F): API GL-5, SAE 80 Capacity: 1 .OO L {I .06 US qt, 0.88 Imp qt) 6. lnstall the filler plug. Tightening torque: 39-54 N.m (4.0-5.5 kgf.m, 29--40 ft.lbf) OIL SEAL (OUTPUT SHAFT) Replacement 1. On level ground, Jack up the vehicle and support it on safety stands. 2. Drain the differential gear oil. 3. Mark the drive shaft and output shaft flanges for proper reassembly. 4. Remove the upper arm installation bolt and nut. Gartner Banana

Page 611 of 1708

M DIFFERENTIAL 5. Separate the driveshaft from the differential and sus- pend it. 6. Remove the output shaft by using two pry bars as shown in the figure. J 7. Remove the oil seal. 8. Apply lithium-based grease to the new oil seal lip and install it by using'the SST. 9. Install the new clips. 10. Install the output shaft into the side gears by lightly tap- ping with a plastic hammer. 11. Verify that the output shaft is hooked into the side gears by pulling it by hand. ./ 12. Align the marks and install the drive shaft. Tightening torque: 54-64 N.m (5.5--6.5 kgf.m, 40-47 ft-lbf) 13. Install the upper arm installation bolt and nut. Tightening torque: 46-67 N.m (4.7-6.8 kgf.m, 34--49 ftlbf) 14. Add the specified oil. 15. Adjust the rear wheel alignment. (Refer to section R.) I Gartner Banana

Page 612 of 1708

DIFFERENTIAL M DIFFERENTIAL, STANDARD; DIFFERENTIAL, TORQUE SENSING LIMITED SLIP ("TORSEN" LSD) Removal 1 lnstallation 1. Drain the differential oil. ,, 2. Remove in the order shown in the figure, referring to Removal Note. 3. Install in the reverse order of removal, referring to lnstallation Note. 4. Add the specified oil to the specified level. 1. Rear wheels 7. Drive shafts 2. Differential mounting pipe Removal Note ............. page M-29 3. Exhaust pipe 8. Differential 4. Propeller shaft Removal Note ............. page M-29 Service ..................... section L Installation Note ........... page M-30 ' 5. Speedometer cable Overhaul .................. page M-32 ,, 6. Power plant frame (PPF), Differential mounting spacer Removal Note ............. page M-28 Installation Note ........... page M-30 Gartner Banana

Page 613 of 1708

M DIFFERENTIAL SLEEVE BLOCK BOLT (MI 4 x 1.5) dl Removal note Power plant frame (PPF) 1. Disconnect the wire harness from the PPF. 2. Support the transmission with a jack. 3. Remove the power plant frame bracket. (Manual trans- mission) 4. Remove the differential-side bolts, and pry out the spacer. 5. Remove the differential mounting spacer. 6. Turn a bolt (MI4 x 1.5) into the sleeve. 7. Twist and pull the bolt downward. 8. Install a bolt (M6 x 1) into the hole in the block to hold the sleeve, and remove the long bolt (MI4 x 1.5). 9. Remove the bolt ,(M6 x 1). Gartner Banana

Page 614 of 1708

DIFFERENTIAL M t- 900mm (35.43 in) 10. Remove the transmission-side bolts, and remove the PPF. Do not remove the spacers from the PPF. If they are removed, replace the PPF as an assembly. Drive shaft Mark the drive shaft and output shaft for proper installa- tion. Differential 1. Support the differential with a jack. 2. Lower the differential and move it forward. Note If the drive shaft will not separate easily from the out- put shaft, remove a bolt and nut from one side of the upper arm. 3. Separate the driveshaft from the output shaft. 4. To prevent damaging the fire wall, crank angle sensor, and engine mount, support the transmission as follows. (1) Prepare a steel plate (as shown in the figure), a wooden block, bolts (M8 x 1.25), and washers. (2) Install the parts as shown in the figure. Gartner Banana