differential MAZDA MX-5 1994 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 364 of 1708

J TRANSMISSION REMOVAL 1. Obtain the code number and deactivate the audio antitheft system before disconnecting the battery. (Refer to section T.) 2. is connect the negative battery cable. 3. On level grand, jack up the vehicle and support it evenly on safety stands. 4. Drain the transmission oil into a suitable container. 5. Remove in the order shown in the figure, referring to Removal Note. I. Shift lever knob ?. Rear console 9. Clutch release cylinder 10. Starter I 1 3. Shift lever 11. speedometer cable 4. Undercover 12. Power plant frame (PPF) 5. Performance rod Removal Note ............... page J-1 1 6. Differential mounting pipe 13. Transmission 7. Exhaust pipe J Removal Note ............... page J-12 8. Propeller shaft Service ...................... section L Gartner Banana

Page 365 of 1708

TRANSMISSION J Removal note Power plant frame (PPF) 1. Disconnect the wire harness from the PPF. 2. Support the transmission with a jack. 3. Remove the PPF bracket. DIFFERENTIAT MOUNTING SPACER BOLT BOLT (MI 4 x 1.5) d1 SLEEVE BLOCK 35UOJX-031 4. Remove the differential-side bolts, and pry out the spacer. 5. Remove the differential mounting spacer. 6. Screw a long bolt (MI 4 x 1.5) into the sleeve. 7. Twist and pull the bolt and sleeve downward. 8. Install a bolt (M6 x 1) into the hole in the block to keep the sleeve from turning, and unscrew the long bolt (MI4 x 1.5). 9. Remove the bolt (M6x 1). Gartner Banana

Page 399 of 1708

TRANSMISSION J INSTALLATION 1. On level ground, jack up the vehicle and support it evenly on safety stands. 2. Install in the order shown in the figure, referring to lnstallation Note. L 3. Add the specified amount of the specified transmission oil. (Refer to page J-8.) 4. Warm up the engine and transmission, and inspect for oil leakage and transmission problems. 1. Transmission 7. Exhaust pipe Installation Note ............. page J-46 8. Performance rod 2. Power plant frame (PPF) 9. Differential mounting pipe Installation Note ............. page J-46 10. Undercover 3. S~eedometer cable 11. Shift lever w 4. ~iarter Installation Note ............. page J-47 5. Clutch release cylinder 12. Rear console 6. Propeller shaft 13. Shift lever knob Service ...................... section L Gartner Banana

Page 400 of 1708

J TRANSMISSION -=DIFFERENTIAL MOUNTING SPACER 45UOJX-054 Installation note Transmission 1. Tilt the engine by pushing up on the front of the oil pan with a wooden block and a transmission jack. d 2. Support the transmission with a transmission jack. 3. Raise the transmission into place and install and tighten the installation bolts. Tightening torque: 64-89 N-m (6.5--9.1 kgf-m, 48-65 ft.lbf) Power plant frame (PPF) 1. Install the differential mounting spacer. Tightening torque: 38-51 N.m (3.8-5.3 kgf-m, 28-38 ft-lbf) 2. Support the transmission with a jack so that it is level. 3. Position the PPF and tighten the transmission-side bolts by hand. 4. Verify that the sleeve is installed into the block. 5. Install the spacer and reamer bolts in the forward hole, then hand tighten them. 6. Snugly install the power plant frame bracket. 7. Tighten the transmission-side bolts. Tightening torque: 104-123 N-m (10.S12.6 kgf.m, 76.7-91.1 ft.lbf) 8. Tighten the differential-side bolts. Tightening torque: 104-1 23 N-m (1 0.S12.6 kgf.m, 76.7-91.1 ft-lbf) Gartner Banana

Page 432 of 1708

ROAD TEST K Evaluation I No lockup shift Condition No 1-2 up or downshift No 2-3 up or downshift No 3-4 up or downshift I Stuck lockup control solenoid valve Stuck locku~ control valve Possible Cause Stuck 1-2 shift solenoid valve Stuck 1-2 shift valve Stuck 2-3 shift solenoid valve Stuck 2-3 shift valve Stuck 3-4 shift solenoid valve Stuck 3-4 shift valve Incorrect shift point I No enaine brakina effect I Worn clutches, brakes I Misadjusted throttle position sensor Sticking shift valves Excessive shift shock or slippage Noise and Vibration Drive the vehicle in fourth gear (lockup), fourth gear (no lockup), and third gear (Hold) and listen closely for any out of the ordinary noise or vibration. The torque converter, propeller shaft, and differential can be sources of abnormal noise and vibration if they are not functioning properly. Check these when searching for sources of noise and vibration. Stuck accumulators Stuck or no one-way check orifice Stuck 3-2 control solenoid valve Stuck 3-2 control valve Worn clutches, brakes, or one-way clutch Kickdown Drive the vehicle in fourth gear, third gear, and 2nd gear and check that kickdown occurs for 4-+3,4-+2, 4+1,3+2,3+1, 2+1, and that the shift points are as shown in the shift diagram. ,U (Refer to pages K-29, 30.) S-RANGE TEST Shift Pattern For this test it is not necessary to inspect shift shock and shift points, since they are almost exactly the same as those for the D-range test. However, in the D-range (Normal) shift diagram, the shift points are different. In S range, the shift patterns for Normal mode are the same. 1. Shift the selector lever to S range and select the Normal mode. 2. Accelerate the vehicle and verify that 1-2 and 2-3 up-and downshifts are obtained, and that no fourth gear and no lockup (below approx. 100 kmlh (63 mph}) are obtained. 3. While driving in S range (Normal mode) and third gear, select the Hold mode and verify that third gear is held until ihe 3-2 downshift point as shown in the S range (Hold) shift diagram is achieved. 4. Accelerate the vehicle in S range (Hold mode) and verify that 2nd gear is held. S-range (Power) shift diagram LOCKUP AVAILABLE WHEN ACCELERATING AND CRUSING LOCKUP AVAILABLE WHEN COASTING -. - VEHICLE SPEED kmlh (rnph} Gartner Banana

Page 433 of 1708

ROAD TEST (Hold) shift diagram LOCKUP AVAILABLE WHEN COASTING 818 718 - 618 - 518 ' 418 - 3/8 ' 218 - 118 - 018 0 20 (1 2) 40 (25) 60 (37) 80 (50) 100 (63) 120 (75) 140 (87) 160 (99) VEHICLE SPEED kmh {mph} Noise and Vibration Drive the vehicle in 2nd (Hold) and listen closely for any out of the ordinary noise or vibration. The torque converter, propeller shift, and differential can be sources of abnormal noise and vibration if they are not functioning properly. Check these when searching for sources of noise and vibration. L-RANGE TEST Shift Pattern For this test it is not necessary to inspect shift shock and shift points, since they are almost exactly the same as those for the D-range test. However, in the D-range (Normal) shift diagram, the shift points are different. ,, In L-range, the shift patterns for Normal mode are the same. 1. Shift the selector lever to L-range and select the Normal mode. 2. Accelerate the vehicle and verify that 1-2 up and downshifts are obtained, and that no third gear, no fourth gear, and no lockup are obtained. 3. Drive in 1 st gear, then decelerate and verify that engine braking effect is felt. 4. While driving in D-range (Hold mode) and third gear, shift the selector lever to L-range and verify that third gear is held until the 3-2 downshift point as shown in the L-range (Hold) shift diagram, and that 2nd gear is held until 2-1 downshift point is achieved. 5. Accelerate the vehicle in L-range (Hold mode) and verify that 1 st gear is held. L-range (Power) shift diagram LOCKUP AVAILABLE WHEN COASTING o 20 (12) 40 (25) 60 (37) 80 (50) 100 163) i 20 (75) 14dp7) 160 pgj VEHICLE SPEED kwh {mph) Gartner Banana

Page 434 of 1708

ROAD TEST L-range (Hold) shift diagram LOCKUP AVAILABLE WHEN COASTING 0 20 (1 2) 40 (25) 60 {37) 80 {50) 100 {63) 120 {75) 1 40 (87) 1 60 (99) VEHICLE SPEED kmh {mph) Noise and Vibration Drive the vehicle in 1 st (Hold) and listen closely for any out of the ordinary noise or vibration. The torque converter, propeller shift, and differential can be sources of abnormal noise and vibration if they are not functioning properly. Check these when searching for sources of noise and vibration. P-RANGE TEST 1. Shift into P range on a gentle slope, release the brake, and verify that the vehicle does not roll. 2. Shift into P range while driving the vehicle at 4 kmlh (2.5 mph) maximum on a level surface, and verify that the vehicle stops. Gartner Banana

Page 551 of 1708

K TRANSMISSION 5. Tighten the transmission-side bolts. Tightening torque: 104--123 N.m (10.6-12.6 kgf-m, 76.7-91.1 ft-lbf} 6. Tighten the differential-side bolts. Tightening torque: lO4--123 N.m {10.6-1 2.6 kgf-m, 76.7-91.1 ft-lbf} 7. Remove the jack. 8. Measure distance A with a straightedge and vernier cali- pers. Distance A: 51.5-61 Smm (2.023--2.417 in} 9. If the distance is not within specification, reposition the power plant frame at the transmission. Gartner Banana

Page 586 of 1708

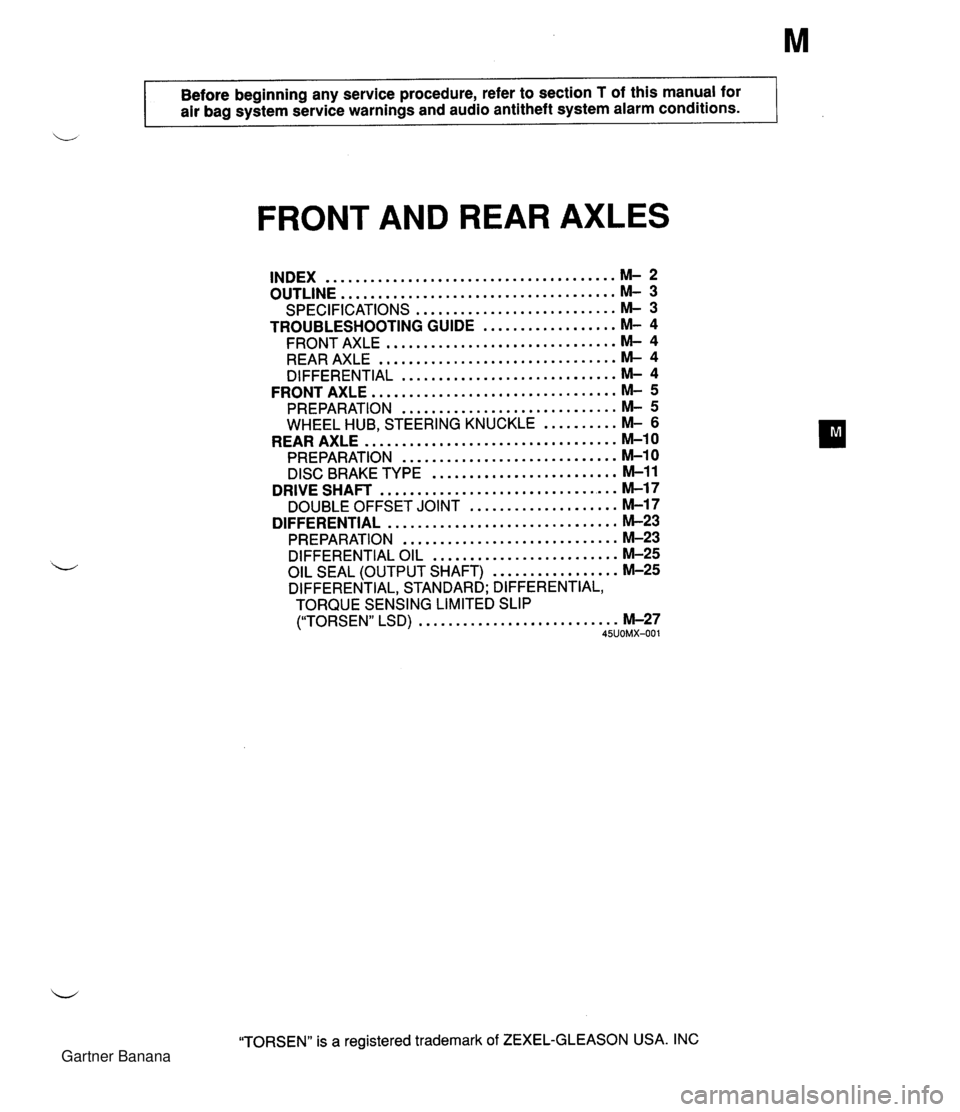

Before beginning any service procedure. refer to section T of this manual for air bag system service warnings and audio antitheft system alarm conditions . FRONT AND REAR AXLES ....................................... INDEX M- 2 ..................................... OUTLINE M- 3 SPECIFICATIONS ........................... M- 3 TROUBLESHOOTING GUIDE .................. M- 4 ............................... FRONT AXLE M- 4 ................................ REAR AXLE M- 4 ............................. DIFFERENTIAL M- 4 ................................. FRONT AXLE M- 5 PREPARATION ............................. M- 5 WHEEL HUB. STEERING KNUCKLE .......... M- 6 .................................. REAR AXLE M-10 PREPARATION ............................. M-10 ......................... DISC BRAKE TYPE M-11 ................................ DRIVE SHAFT M-17 .................... DOUBLE OFFSET JOINT M-17 ............................... DIFFERENTIAL M-23 PREPARATION ............................. M-23 DIFFERENTIAL OIL ......................... M-25 ................. OIL SEAL (OUTPUT SHAFT) M-25 DIFFERENTIAL. STANDARD; DIFFERENTIAL. TORQUE SENSING LIMITED SLIP ("TORSEN" LSD) ........................... M-27 45UOMX-001 "TORSEN" is a registered trademark of ZEXEL-GLEASON USA . INC Gartner Banana

Page 587 of 1708

INDEX INDEX OIL SPECIFICATION ABOVE -1 8°C (O°F1: GL-5. SAE 90 / I 1 ,BELOW -1 8°C Ioo~: GL-5, SAE 80 ..-.. - - - - .. - ...... SERVICE, SECTION L REAR'BRAKE PROPELLER SHACT SERVICE, SECTION P FRONT-BRAKE SERVICE SECTION P 1. Front axle Inspection / Removal / Installation ............... page M- 6 Disassembly 1 Inspection / Assembly. ............... page M- 8 2. Rear axle Inspection / Removal / Installation ............... page M-1 1 Disassembly 1 Inspection / Assembly ................ page M-13 M-2 3. Drive shaft Ins~ection / Removal 1 ............... Installation page M-17 Overhaul .................. page M-19 4. Differential (Standard, Torque sensing limited slip differential) Differential oil .............. page M-25 . Oil seal (Output shaft) ...... page M-25 Removal 1 Installation ....... page M-27 Overhaul .................. page M-32 Gartner Banana