belt MAZDA MX-5 1994 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 826 of 1708

s CONVERTIBLE TOP PUL BRACKET Removal Note Convertible top 1. Unlock the top latch assemblies. 2. Unzip the rear window, and lower the convertible top \- ' fully. Installation Note Convertible top 1. Insert the rain rail into the beltline molding lip, and mount it over the studs. 2. Align and install the link bracket over the studs with no clearance between the studs and the bracket. 3. Tighten the bolts to the specified torque. Tightening torque: lS--2S N.m (1.9--2.6 kgf.m, l5--18 ftlbf) Gartner Banana

Page 827 of 1708

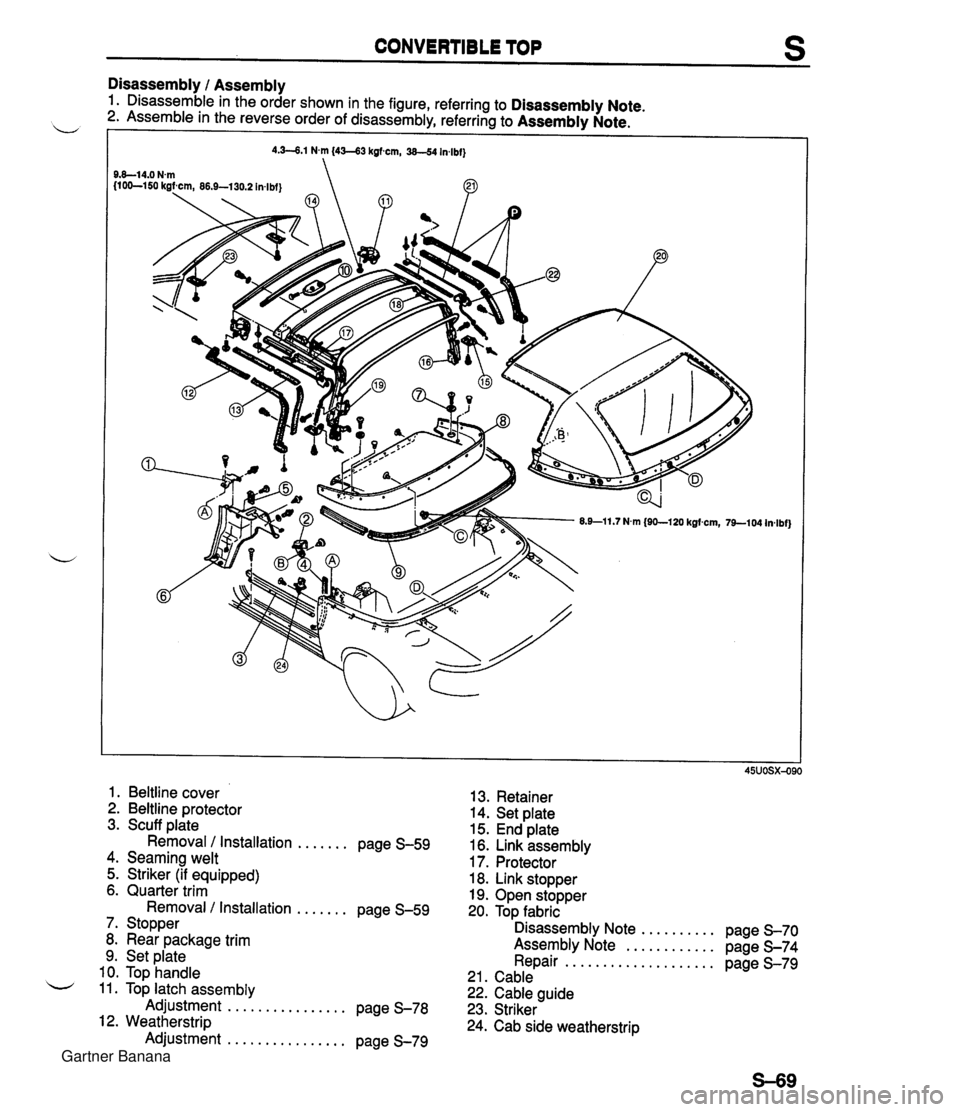

CONVERTIBLE TOP S Disassembly l Assembly 1. Disassemble in the order shown in the figure, referring to Disassembly Note. 2. Assemble in the reverse order of disassembly, referring to Assembly Note. - 1. Beltline cover 13. Retainer 2. Beltline protector 14. Set plate 3. Scuff plate 15. End plate Removal 1 Installation ....... page S-59 16. Link assembly 4. Seaming welt 17. Protector 5. Striker (if equipped) 18. Link stopper 6. Quarter trim 19. Open stopper Removal / Installation ....... page S-59 20. Top fabric 7. Stopper Disassembly Note .......... page !3-70 8. Rear package trim Assembly Note ............ page S-74 9. Set plate Repair .................... page S-79 10. Top handle 21. Cable i-/ 11. Top latch assembly 22. Cable guide Adjustment ................ page S-78 23. Striker 12. Weatherstrip 24. Cab side weatherstrip Adjustment ................ page S-79 Gartner Banana

Page 853 of 1708

T OUTLINE OUTLINE TROUBLESHOOTING GUIDE Symptom a Speedometer does not operate or indication is incorrect a Tachometer does not operate Water temperature gauge does not operate Fuel gauge does not operate a Oil pressure gauge does not operate a Brake system warning light remains illuminated Brake system warning light does not illuminate when parking brake on a Brake system warning light does not illuminate when brake fluid in reservoir is below MIN a OID off indicator light does not illuminate when OID off switch turned on Seat belt warning light remains on six seconds after ignition switch is turned on (Timer function does not operate) Seat belt warning light does not illuminate when ignition switch is first turned on a Headlights do not illuminate Headlight does not illuminate (Right or left) Retractable headlight actuator do not operate (Both sides) Retractable headlight actuator does not operate (One side) Stoplights do not illuminate (All) Stoplight does not illuminate (One only) Turn and hazard warning functions do not operate Turn signals not operate (Hazard warning function operates normally) Hazard warning function does not operate (Turn signals function normally) Back-up lights does not illuminate Taillights, side marker lights, and license plate lights do not illuminate Daytime running lights do not illuminate Daytime running light function does not cancel lnterior lights do not illuminate Interior liahts remains illuminated (Control switch: DOOR ~osition) Horn does not sound Vehicle speed cannot be set (Cruise control unit will not hold vehicle speed) Speakers do not operate (Without headrest speakers) Speakers do not operate (With headrest speakers) Poor sound quality or noise (Radio) Poor sound quality (Cassette tape player) Cassette tape will not load Cassette tape will not play Compact disc will not load Compact disc skips No sound can be heard Some speakers do not operate Bodysonic will not play Service code table (With passenger-side air bag) Service code table (With out ~assenaer-side air baa) Reference page T-24 T-25 T-26 T-27 T-28 T-36 T-37 T-37 Gartner Banana

Page 879 of 1708

T WARNING LIGHT AND SENDER UNIT WARNING LIGHT AND SENDER UNlT STRUCTURAL VIEW 1. Brake system warning light 2. Seat belt warning light 3. Air bag system warning light 4. Retractor indicator light 5. Alternator warning light 6. MIL (malfunction indicator light) 7. O/D OFF indicator light 8. Antilock brake system warning light 9. Washer level indicator light 10. Rear window defroster indicator light Reference Table Warning indicator light SRS air bag system Retractor indicator light Alternator MIL (malfunction indicator light) O/D OFF Antilock brake system Washer level 45UOTX-062 T-34 Reference page or section T-154 T- 48 section G section F section K section P T- 39 J Gartner Banana

Page 883 of 1708

T WARNING LIGHT AND SENDER UNIT Remedy 1. Disconnect the timer and buzzer unit connector. 2. Turn the ignition switch ON, and verify that the seat belt warning light illuminates. I Warning light illuminates I Action Seat Belt Warning Light The seat belt warning light is controlled by the timer and buzzer unit. 1 Reolace timer and buzzer unit I Symptom: Seat belt warning light remains on six seconds after ignition switch is turned on. (Timer function does not operate.) I Yes Repair wiring harness (Instrument cluster - Timer and buzzer unit) I d 1 Symptom: Seat belt warning light does not illuminate when ignition switch is first turned on. I 45UOTX-070 Step 1 1. Ground terminal J of the timer and buzzer unit connector. 2. Turn the ignition switch ON, and verify that the seat belt warning light illuminates. 1 Warning light illuminates I Action I Step 2 1. Ground terminal D of the timer and buzzer unit connec- tor. 2. Turn the ianition switch ON. and verifv that the seat belt No Yes warning light illuminates. . Go to Step 2 Repair wiring harness (Timer and buzzer unit - GND) Warning light Illuminates Action Replace timer and buzzer unit Check bulb of seat belt warning light If bulb is OK, repair wiring harness (Instrument cluster - Timer and buzzer unit) Gartner Banana

Page 884 of 1708

WARNING LIGHT AND SENDER UNIT T OHMMETER Washer Level Indicator lnspection 1. Disconnect the connector from the washer level sensor. 2. Jump terminal-wire L (harness side) to a body ground. 3. Start the engine and check that the WASHER indicator illuminates. 4. If there is no illumination, check the bulb, wiring harness, and sensor. Replace or repair as necessary. Washer Level Sensor lnspection 1. Connect the sensor connector (sensor side) to an ohm- meter. 2. Move the sensor float up and down. 3. Verify that there is continuity when the float is at the low- est point. BRAKE FLUID LEVEL SENSOR lnspection 1. Check for continuity of the sensor. 2. If continuity is not as specified, replace the level sensor. Float level Below MIN Above MIN BUCKLE SWITCt Continuity Yes No OHMMETER -1 PARKING BRAKE SWITCH lnspection 1. Disconnect the parking brake switch connector. 2. Check for continuity between the switch connector and ground. I Lever I Continuity I 3. If continuity is not as specified, adjust or replace the parking brake switch. (Refer to section P.) Pulled one notch Released BUCKLE SWITCH lnspection 1. Disconnect the buckle switch connector 2. Check for continuity of the switch. Yes No Seat belt I Continuity Seat belt buckled Seat belt unbuckled No Yes 3. If continuity is not as specified, replace the buckle switch. Gartner Banana

Page 1100 of 1708

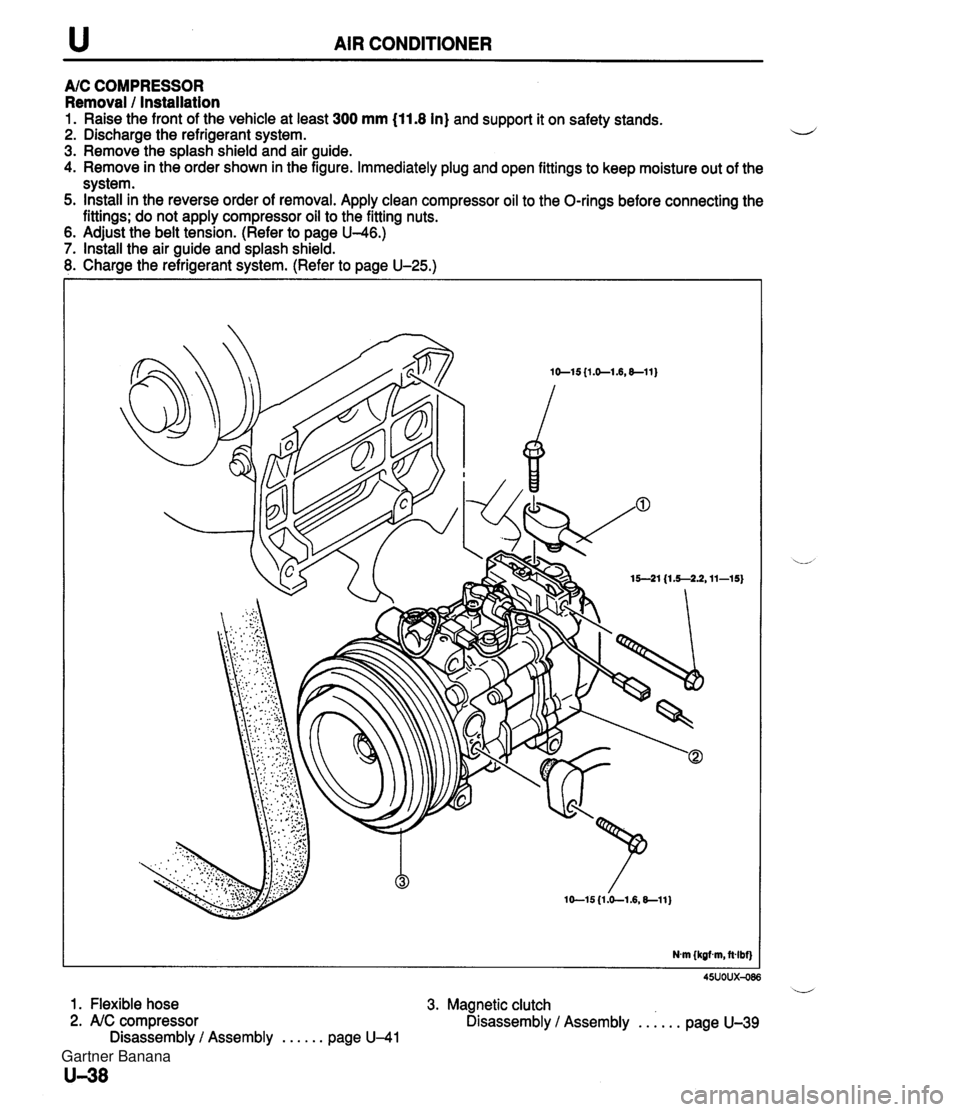

u AIR CONDITIONER A/C COMPRESSOR Removal / Installation 1. Raise the front of the vehicle at least 300 mm (11.8 In) and support it on safety stands. 2. Discharge the refrigerant system. i~ 3. Remove the splash shield and air guide. 4. Remove in the order shown in the figure. Immediately plug and open fittings to keep moisture out of the system. 5. Install in the reverse order of removal. Apply clean compressor oil to the O-rings before connecting the fittings; do not apply compressor oil to the fitting nuts. . 6. Adjust the belt tension. (Refer to page U-46.) 7. Install the air guide and splash shield. 8. Charge the refrigerant system. (Refer to page U-25.) 45uoux-086 i/ 1. Flexible hose 3. Magnetic clutch 2. AIC compressor Disassembly / Assembly . . . . . . page U-39 Disassembly / Assembly . . . . . . page U-41 Gartner Banana

Page 1108 of 1708

u AIR CONDITIONER I NC COMPRESSOR 45UOUX-119 Adjustment Drive belt (With PIS) 1. Loosen PIS oil pump bolts @ and @ and nut 0. ...-' 2. Adjust the belt tension and deflection to specification by turning adjusting bolt 0. 3. Tighten bolts @ and @J and nut 0. (Without PIS) 1. Loosen the locknut. 2. Adjust the belt tension and deflection to specification by Tightening torque: @I: 3246 N.m (3.2-4.7 kgf-m, 24-33 ftelbf) @I: 37-53 Nem (3.7-5.5 kgf-m, 27-39 ft-lbf) 0: 19-25 N.m (1 3-2.6 kgf-m, 14--18 ft-lbf) turning the adjusting bolt. 3. Tighten the locknut. 1 Tension t Deflection when applying moderate pressure 98 N {lo 1 kgf, 22 Ibf) Tightening torque: 38-51 N-m (3.8-5.3 kgf-m, 28-38 ft-lbf) Specification NC COMPRESSOR 45UOUX-121 New 490-588 N (50.0-60.0 kgf, 11 0-1 32 Ibf) 8.0-9.0 mm {0.31-0.35 in) Specification Used 422490 N (43.0-50.0 kgf, 9!5-110 Ibf) 9.0-1 0.0 mm I0.35--0.39 in) New Used Tension Deflection when applying moderate pressure 98 N (10 kgf, 22 Ibf) 490-588 N {50.0-60.0 kgf, 110-132 IbfJ 8.0-9.0 mm i0.31-0.35 in) 422490 N (43.0-50.0 kgf, 95-1 1 0 Ibf) 9.0-1 0.0 mm I0.35-0.39 in) Gartner Banana

Page 1110 of 1708

TD TECHNICAL DATA A. MEASUREMENTS I Item I Measurements I B. ENGINE Overall length mm {in) Overall width mm (in) Overall height mm {in) Wheelbase mm {in) 3,948 (1 55.4) 1,676 i65.9) 1,224 I48.2) 2,266 I89.2) 1,410 (55.5) 1,428 (56.2) Tread - ltem Tvoe u Front mm (in) Rear mm {in) BP DOHC Gasoline. 4-cvcle . In-line, 4-cylinders Pentroof DOHC, belt-driven 16 valves 83.0 x 85.0 {3.27 x 3.35) 1,840 (1,840, 11 2) 9.0 1,255 {I 2.8, 1823-300 883 (9.0, 1281-300 196 {2.0, 28) s. Cylinder arrangement and number Combustion chamber Valve system Bore x Stroke mm {in] Total piston displacement ml {cc, cu in) Compression ratio Valve timing Compression pressure kPa (kgflcm2. psil-r~m I Valve and valve auide I Standard Minimum Maximum difference between each cvlinder - - IN openz (BTDCO) Close (ABDCO) Open (BBDCO) EX close (ATDC") Valve clearance mm {in) Cylinder head 5 48 56 14 IN 133.8-1 34.0 i5.268-5.275) 0.1 0 {0.004) max. 0.10 {0.004) max. 0.02G0.066 {0.0010-0,0025) 0.18 {0.0071) Height mm (in) Distortion mm {in) Grinding mm {in) - 0: Maintenance-free Cylinder head-to-HLA clearance mm (in} Valve head diameter mm Iin) Valve head margin thickness mm {in} Valve face angle I Valve seat 1 u Standard Maximum Valve length mm {in) EX IN EX IN EX IN EX Standard Minimum Standard Minimum IN EX IN EX 5.99--6.03 iO.2359--0.2374) 0.005--0.060 (0.0002-0.0023) 0.01 b0.065 (0.0004-0,0025) 0.20 {0.008} 18.3-1 8.9 {0.7214.744) 18.3-1 8.9 (0.721-0.744) Guide inner diameter mm (in) 0: Maintenance-free 32.9-33.1 {I .296--1.303) 27.85-28.15 {I .097-1 .I 08) 0.9 {0.035) 1 .O (0.039) 45" 45" 101.89 {4.0114} 100.39 {3.9524) 101.99 (4.0153) 100.49 (3,9563) 5.970-5.985 {0.2351-0.2356) 5.96G5.980 l0.2349-0.2354) Valve stem diameter mm {in) Valve stem-to-guide clearance mm (in) Guide projection (Height "A) mm {in) Seat angle IN EX Maximum IN EX IN 45" EX 45" Gartner Banana

Page 1112 of 1708

TD TECHNICAL DATA item Main journal diameter mm {in) BP DOHC Diameter mm {in) Piston-to-piston pin clearance mm {in) Connecting rod bush-to-piston pin clearance mm (in) Piston pin 19.987-1 9.993 {0.7869-0..7871) -0.00~0.013 {-0.0002-0.0005) 0.01 0-0.027 {0.0004--0.0010} I Main iournal out-of-round - . - . . - -. - size 0.25 {o.oi) undersize 0.50 (0.02) undersize 0.75 I0.03) undersize mm (in) I 0.05 10.0020) max. I Connectir~g rod and connecting rod bearing . L, . -- 2 - 1 Standard 1 Standard I 44.940-44.956 11.7693--1.7699) Minimum Standard ' Minimum Standard 'Minimum Standard Minimum 1 size 1 ~inimum I 44.908 11.76801 I 132.8S132.95 I5.231-5.234) 0.030 (0.001 2) max.1100 (3.94) 20.003--20.0 14 {0.78760.7879) 48.000-48.01 6 {I .8898-1.8903) 21.838-21.890 (0.8598-0.8618) 0.1 104.262 {0.0044-0.0103) 0.30 (0.01 2) Length (Center to center) mm {in) Bending mm (in) Small end bore (Bush inner diameter) mm {in) Big end bore mm {in) Big end width mm {in) 49.904 (1.9647) 49.704--49.708 {I $9569--1.9570) 49.652 {I .9548) 49.454--49.458 {I .947&1.9471) 49.402 (1.9450) 49.204--49.208 (1.9372-1.9373) 49.152 11.9351) Cranks haft Crankshaft runout mm (in) I 0.04 {0.0016) max. Standard 1 Standard I 49.938--49.956 (1.9661-1.9667) Connecting rod side clearance mm {in) . Standard Maximum Crankpin diameter mm (in) - -- s- - 8 undersize 0.50 10.02) undersize 44.1 90-44.206 {I .7398-1.7403) 44.158 {I .7385) 0.05 (0.00201 max. 0.75 {0.03) undersize " Main bearina Standard Minimum Main journal bearing oil clearance mm (in) - L~inimum Standard 'Minimum Crankpin out-of-round mm {in} Crankpin bearing oil clearance mm (in) Standard Maximum 44.658 (1.7582) 44.440-44.456 {I .7496-1,7502) 44.408 (1.74831 0.01 8-0.036 {0.0008--0.0014) 0.1 0 {0.004) Available undersize bearing mm (in) Standard Maximum - 0.25 {0.010), 0.50 {0.020), 0.75 (0.030) 0.020-0.044 {0.0008--0.0017) 0.10 {0.004} Available undersize bearing mm {in) Crankpin bearing 0.25 {0.010), 0.50 {0.020), 0.75 (0.030) Thrust bearing Crankshaft end play mm {in) Standard Maximum 0.080-0.282 (0.0032--0.0111) 0.30 (0.012) 2.500-2.550 {0.0985--0.1003) 2.625-2.675 (0.1 034-0.1 053) 2.750-2.800 {0.108H.1102) 2.875-2.925 {0.1132--0.1151) Bearing width mm {in) nming belt Belt deflection mm {in)/98 N (10 kgf, 22 Ibf) I 9.0-11.5 i0.360.45) ~U Standard size 0.25 (0.01) oversize 0.50 {0.02) oversize 0.75 (0.03) oversize Gartner Banana