wiring MAZDA MX-5 1994 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 329 of 1708

G STARTING SYSTEM Check 1 Check 3 Check 2 STARTER Caution Obtain the code number and deactivate the audio anti-theft system before disconnecting the bat- tery. (Refer to section T.) Removal / Installation 1. Disconnect the negative battery cable. 2. Disconnect the wiring from the starter. 3. Remove the starter bracket. (MT only) 4. Raise the front of the vehicle and support it with safety stands. 5. Remove the bolts and the starter. 6. Install in the reverse order of removal. Tightening torque Nut O: 10-11 N.m (100-120 kgfam, 87-100 in4bf) Bolt, Nut O: 38-51 N.m (3.8-53 kgf-m, 28-38 ft4bf) Bolt 0: 16-22 N.m (1.6-2.3 kgf.m, 12-16 ft-lbf) Bolt 0: 38-51 N.m (3.8-5.3 kgf-m, 28-38 ft-lbf) Gartner Banana

Page 334 of 1708

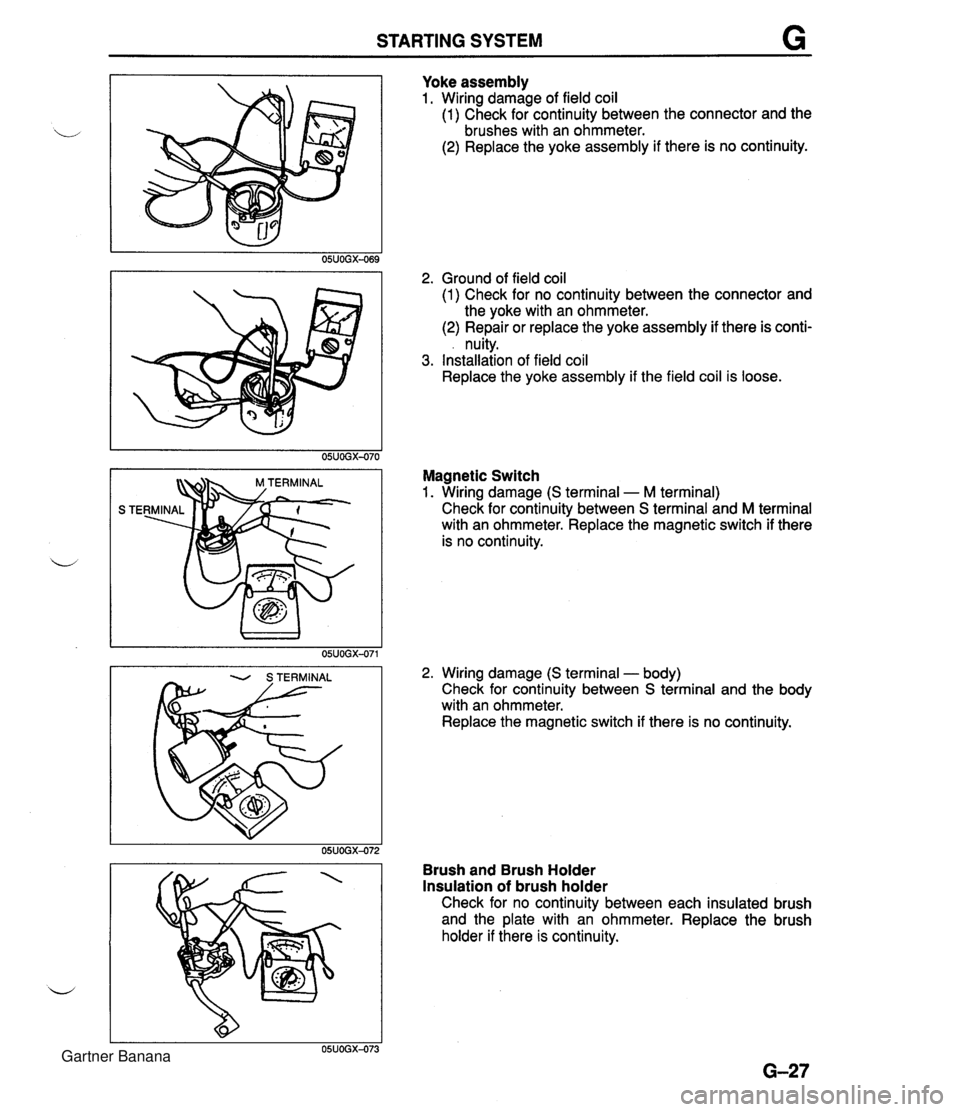

STARTING SYSTEM Yoke assembly 1. Wiring damage of field coil (1) Check for continuity between the connector and the brushes with an ohmmeter. (2) Replace the yoke assembly if there is no continuity. 2. Ground of field coil (1) Check for no continuity between the connector and the yoke with an ohmmeter. (2) Repair or replace the yoke assembly if there is conti- . nuity. 3. Installation of field coil Replace the yoke assembly if the field coil is loose. Magnetic Switch 1. Wiring damage (S terminal - M terminal) Check for continuity between S terminal and M terminal with an ohmmeter. Replace the magnetic switch if there is no continuity. 2. Wiring damage (S terminal - body) Check for continuity between S terminal and the body with an ohmmeter. Replace the magnetic switch if there is no continuity. Brush and Brush Holder Insulation of brush holder Check for no continuity between each insulated brush and the plate with an ohmmeter. Replace the brush holder if there is continuity. Gartner Banana

Page 413 of 1708

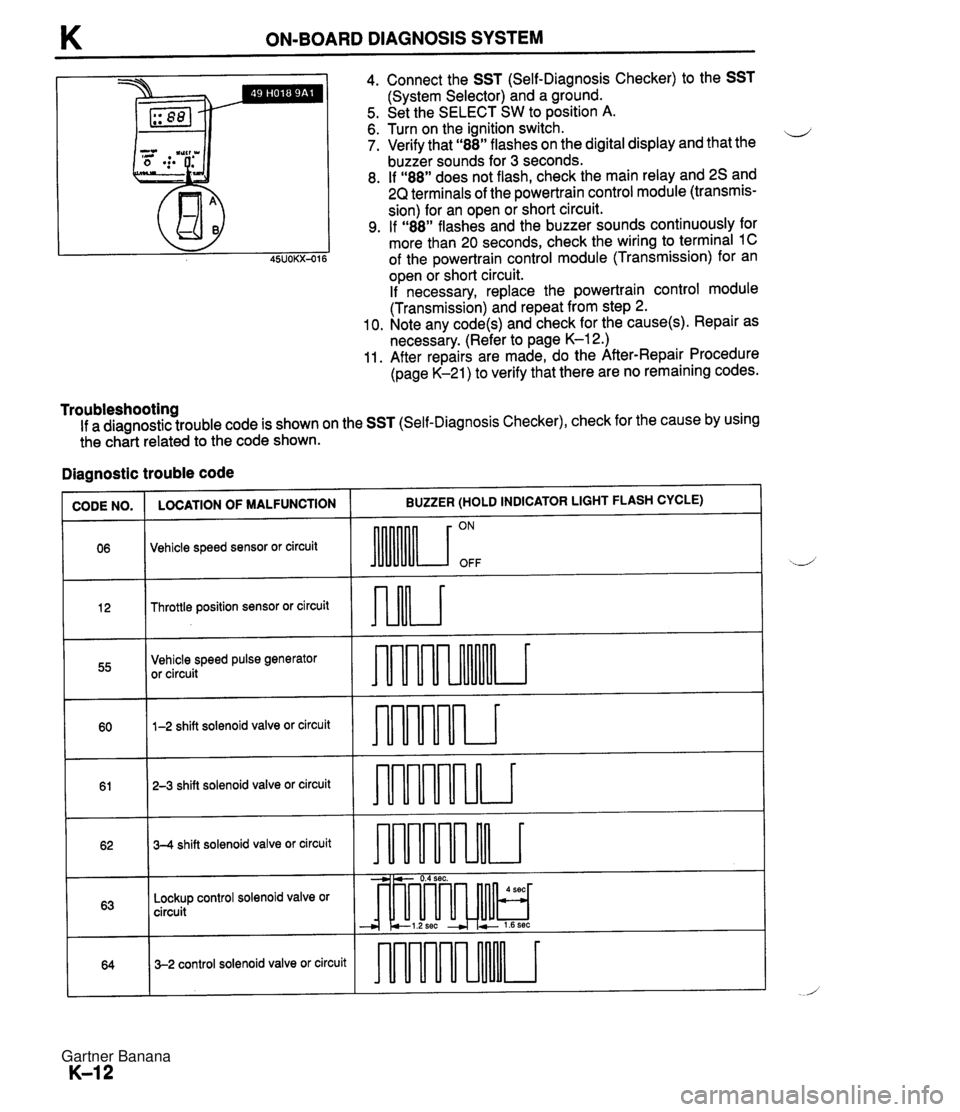

K ON-BOARD DIAGNOSIS SYSTEM Ill I 4. Connect the SST (Self-Diagnosis Checker) to the SST (System Selector) and a ground. 5. Set the SELECT SW to position A. 6. Turn on the ignition switch. ii 7. Verify that "88" flashes on the digital display and that the buzzer sounds for 3 seconds. 8. If "88" does not flash, check the main relay and 2s and 2Q terminals of the powertrain control module (transmis- sion) for an open or short circuit. 9. If "88" flashes and the buzzer sounds continuously for more than 20 seconds, check the wiring to terminal 1C of the powertrain control module (Transmission) for an open or short circuit. If necessary, replace the powertrain control module (Transmission) and repeat from step 2. 10. Note any code(s) and check for the cause(s). Repair as necessary. (Refer to page K-12.) 11. After repairs are made, do the After-Repair Procedure (page K-21) to verify that there are no remaining codes. Troubleshooting If a diagnostic trouble code is shown on the SST (Self-Diagnosis Checker), check for the cause by using the ch&t related to the code shown. Diagnostic trouble code ~U)DE NO. 1 LOCATION OF MALFUNCTION I BUZZER (HOLD INDICATOR LIGHT FLASH CYCLE) Throttle position sensor or circuit 06 Vehicle speed sensor or circuit 55 ON OFF Vehicle speed pulse generator or circuit 60 - 61 1-2 shift solenoid valve or circuit 62 - -- - 3-2 control solenoid valve or circuit 64 T 2-3 shift solenoid valve or circuit 63 - 3-4 shift solenoid valve or circuit -----a Lockup control solenoid valve or circuit -- --i---- - - - audrur - -, -. - 0.4 sec. - --I-& cl.2sec + 2 1.6sec * - 4 sec - - Gartner Banana

Page 414 of 1708

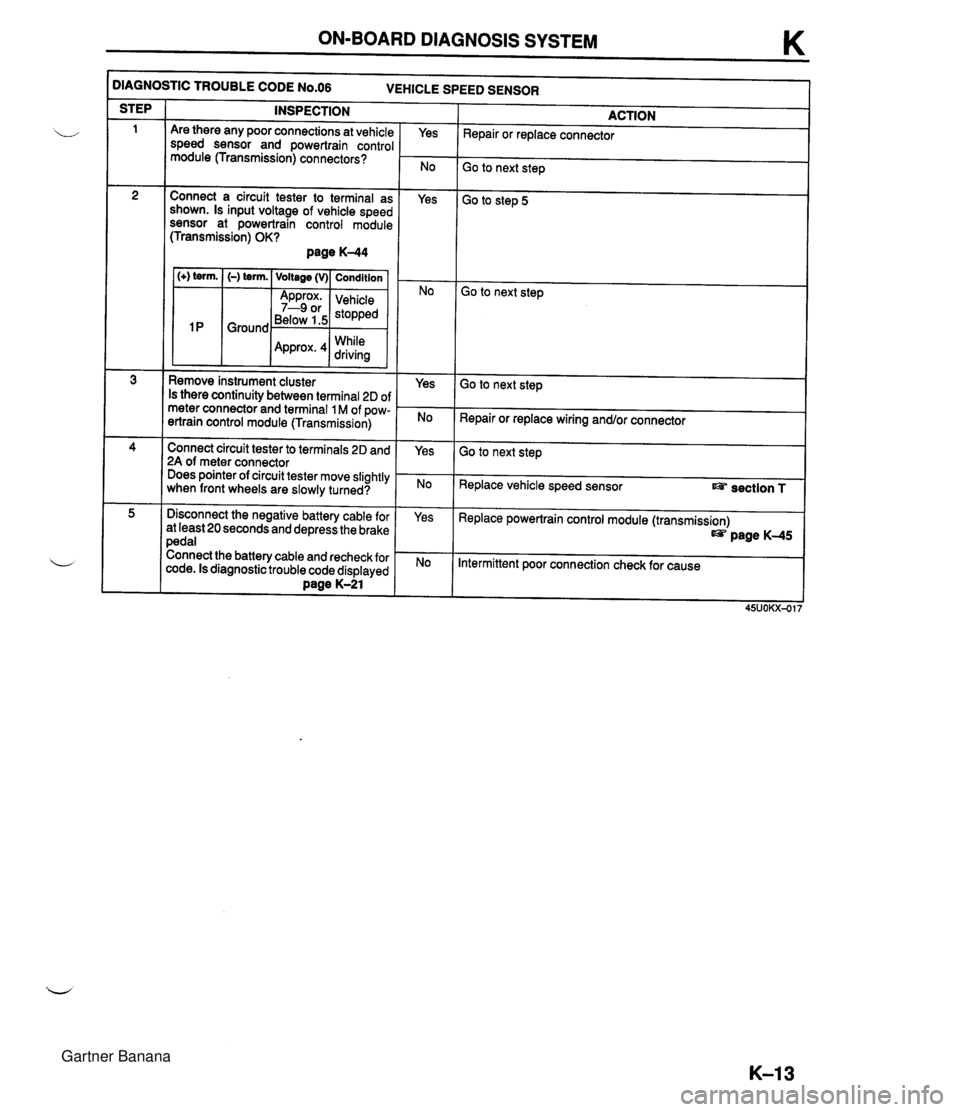

ON-BOARD DIAGNOSIS SYSTEM K )IAGNOSTIC TROUBLE CODE N0.06 VEHICLE SPEED SENSOR INSPECTION STEP ACTION Repair or replace connector Are there any poor connections at vehicle speed sensor and powertrain control module (Transmission) connectors? Yes Go to next step Connect a circuit tester to terminal as shown. Is input voltage of vehicle speed sensor at powertrain control module (Transmission) OK? page K-44 Yes Go to step 5 1 (+) term. I (-) term. ( Voltage (v)( Condition I Go to next step Below 1.5 While Remove instrument cluster Is there continuity between terminal 2D of meter connector and terminal 1 M of pow- ertrain control module (Transmission) Yes Go to next step Repair or replace wiring and/or connector Connect circuit tester to terminals 2D and 2A of meter connector Does pointer of circuit tester move slightly when front wheels are slowly turned? Yes Go to next step Replace vehicle speed sensor section T Disconnect the negative battery cable for at least 20 seconds and depress the brake pedal Connect the battery cable and recheck for code. Is diagnostic trouble code displayed Dane K-21 Yes Replace powertrain control module (transmission) page K-45 Intermittent poor connection check for cause Gartner Banana

Page 415 of 1708

K ON-BOARD DIAGNOSIS SYSTEM - -- )IAGNOSTIC TROUBLE CODE N0.12 THROTTLE POSITION SENSOR ACTION I STEP INSPECTION Are there any poor connections at throttle position sensor and powertrain control module (transmission) connector or termi- nal? Yes Repair or replace connector I Go to next step Go to step 5 Connect a circuit tester to terminal as shown Is input voltage of throttle position sensor (TVO) at powertrain control module (transmission) OK? page K-45 1 (+) term. I (-) term. I Voltage (v)/ Condition 1 Yes No lgnition Go to next step ' 2T Ground valve Approx. closed I 0.8--4.3 position to wide open 1 throttle Go to next step Connect a circuit tester to terminals as shown Is input voltage of throttle position sensor (VREF) at powertrain control module (transmission) OK? page K-44 (+) term. (-) term. Voltage (V) Condition Approx. lgnition 4.55 ;p" 2A Ground Ignition 0 switch OFF Yes Check voltage at terminal 21 of powertrain control module (En- gine) Voltage: 4.5--5.5V (Ignition switch ON) If OK, go to next step If not OK, repair wiring andlor connector Check wiring and connectors form Powertrain control module (transmission) to throttle position sensor If OK, go to next step If not OK, repair wiring andlor connector Is throttle position sensor OK? Section F Yes No Yes Adjust or replace throttle position sensor t@? section F I Replace powertrain control module (transmission) t@? page K-45 is connect the negative battery cable for at least 20 seconds and depress the brake pedal Connect the battery cable and recheck for diagnostic trouble code Is diagnostic trouble code displayed? Daae K-21 Intermittent poor connection Check for cause Gartner Banana

Page 416 of 1708

ON-BOARD DIAGNOSIS SYSTEM K :TIC TROUBLE CODE No.55 VEHICLE SPEED PULSE GENERATOR ACTION Repair or replace connector INSPECTION control module (transmission) connector or terminal? I (+) term. 1 (-) term. I Voltage (v)( Condition I Are there any poor connections at vehicle speed pulse generator and powertrain No ' Go to next step Connect a circuit tester to terminal as shown Is input voltage of vehicle speed pulse generator at powertrain control module (transmission) OK? page K45 Engine Yes Engine I o ( stopped ( Yes Disconnect 20-pin powertrain control module (transmission) connector Is resistance between terminal 2J and ter- minal 2L OK? Go to step 5 I No I Go to next step Yes Go to step 5 Resistance: 200--400a Disconnect vehicle speed pulse genera- tor connector Is resistance between terminal E and ter- minal F OK? page K41 Resistance: 200--400n Disconnect the negative battery cable for at least 20 seconds and depress the brake mdal Sonnect the battery cable and recheck for jiagnostic trouble code Is diagnostic trouble code displayed? page K-21 45UOKX-019 Yes No Yes No Check wiring and connectors form powertrain control module (transmission) vehicle speed pules generator If OK, go to next step If not OK, repair wiring and/or connector Replace pulse generator Replace powertrain control module (transmission) us page K-45 Intermittent poor connection Check for cause Gartner Banana

Page 417 of 1708

K ON-BOARD DIAGNOSIS SYSTEM 1 KGNOSTIC TROUBLE CODE ~0.60 1-2 SHIFT SOLENOID VALVE INSPECTION Are there any poor connections at sole- noid valve and powertrain control module (transmission) connectors? shown Is output voltage of 1-2 shift solenoid valve at powertrain control module (trans- mission) OK? page K45 Bt: Battery positive voltage I (+) term. I (-) term. 1 voltage (v)I Condltlon 1 r B+ 1st gear 2E Ground o 2nd, 4GR Yes Disconnect 20-pin powertrain control module (transmission) connector Is resistance between terminal 2E and ground Resistance: 13-27Q Disconnect solenoid connector Is resistance between ground and termi- nal A of 1-2 shift solenoid valve OK? page K-42 Resistance: 13-278 Disconnect the negative battery cable for Yes at least 20 seconds and depress the brake pedal Connect the battery cable and recheck for code No Is diagnostic trouble code displayed? page K-21 ACTION Repair or replace connector GO to next step Check wiring and go to step 5 Go to next step Go to step 5 Go to next step Check wiring and connectors form powertrain control module (transmission) to 1-2 shift solenoid valve If OK, go to next step If not OK, repair wiring andlor connector Replace 1-2 shift solenoid valve Replace powertrain control module (transmission) page K-45 Intermittent poor connection Check for cause Gartner Banana

Page 418 of 1708

ON-BOARD DIAGNOSIS SYSTEM K ,GNOSTIC TROUBLE CODE N0.61 2-3 SHIFT SOLENOID VALVE INSPECTION Are there any poor connections at sole- noid valve and powertrain control module (transmission) connectors? Connect a -circuit tester to terminal as shown Is output voltage of 2-3 shift solenoid valve at powertrain control module (trans- amission) page K-45 r B+: Battery posltive voltage (+)term. I (-)term. I Voltage (v)I Condition Disconnect 20-pin powertrain control module (transmission) connector Is resistance between terminal 2G and ground OK? Resistance: 13--27R Disconnect solenoid connector Is resistance between ground and termi- nal B of 2-3 shift solenoid valve OK? page K-42 Resistance: 13-2721 ACTION Yes No 5 Repair or replace connector Go to next step Disconnect the negative battery cable for at least 20 seconds and depress the brake pedal Connect the battery cable and recheck for code Is diagnostic trouble code displayed? page K-21 Check wiring and go to step 5 Yes No Go to next step Go to step 5 Go to next step Check wiring and connectors form powertrain control module (transmission) to 2-3 shift solenoid valve If OK, go to next step If not OK, repair wiring andlor connector - Replace 2-3 shift solenoid valve Replace powertrain control module (transmission) as page K-45 Intermittent poor connection Check for cause Gartner Banana

Page 419 of 1708

ON-BOARD DIAGNOSIS SYSTEM DIAGNOSTIC TROUBLE CODE No.62 3-4 SHIFT SOLENOID VALVE STEP 1 INSPECTION Are there anv Door connections at sole- noid valve a& 'powertrain control module (transmission) connectors? Connect a circuit tester to terminal as shown Is output voltage of 3-4 shift solenoid valve at ~owertrain control module (trans- mission) (+) term. If page K-45 B+: Battery posltive voltage -. - (-) term. I Voltage (v)I Condltlon I 1st 2nd, Ground Disconnect 20-pin powertrain control module (transmission) connector Is resistance between terminal 21 and ground OK? Resistance: 13-27R Disconnect solenoid connector Is resistance between ground and termi- nal B of 3-4 shift solenoid valve OK? page K-42 Resistance: 13-278 Disconnect the negative battery cable for at least 20 seconds and depress the brake pedal Connect the battery cable and recheck for code Is diagnostic trouble code displayed? page K-21 Yes ACTION Repair or replace connector No Go to next step No Go to next step Yes Check wiring and connectors form powertrain control module (transmission) to 3-4 shift solenoid valve If OK, go to next step If not OK, repair wiring and/or connector Replace 3-4 shift solenoid valve Go to step 5 No Go to next step Yes Replace powertrain control module (transmission) a page K45 No Intermittent poor connection Check for cause Gartner Banana

Page 420 of 1708

ON-BOARD DIAGNOSIS SYSTEM - DIAGNOSTIC TROUBLE CODE No.63 LOCKUP CONTROL SOLENOID VALVE STEP INSPECTION ACTION re there any poor connections at sole- id valve and powertrain control module ransmission) connectors? Yes Repair or replace connector Go to next step onnect a circuit tester to terminal as 10wn output voltage of lockup control sole- >id valve at powertrain control module ransmission) Yes Check wiring and go to step 5 page K-45 (+) term. 2K B+: Battery positive voltage Go to next step (-)term. Lockup Ground Solenoid - - isconnect 20-pin powertrain control ~odule (transmission) connector , resistance between terminal 2K and ,ound OK? Voltage (V) B+ Yes Condition Solenoid ON, Go to step 5 No Yes Go to next step Resistance: 13--2752 isconnect solenoid connector resistance between ground and termi- 31 B of lockup control solenoid valve OK? page K-42 Check wiring and connectors form powertrain control module (transmission) to lockup control solenoid valve If OK, go to next step If not OK, repair wiring and/or connector Resistance: 13--2752 No Yes No Replace lockup control solenoid valve isconnect the negative battery cable for :least 20 seconds and depress the brake sdal onnect the battery cable and recheck for ~de diagnostic trouble code displayed? page K-21 Replace powertrain control module (transmission) page K-45 Intermittent poor connection Check for cause Gartner Banana