wiring MAZDA MX-5 1994 Manual PDF

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 421 of 1708

K ON-BOARD DIAGNOSIS SYSTEM DIAGNOSTIC TROUBLE CODE N0.64 3-2 CONTROL SOLENOID VALVE ACTION STEP I INSPECTION Yes 1 3epair or replace connector Are there any poor connections at sole- noid valve and powertrain control module (transmission) connectors? 30 to next step shown Is output voltage of 3-2 control solenoid valve at powertrain control module (trans- mission) OK? Yes ;heck wiring and go to step 5 page K-45 B4 (-) term, Battery positive voltage Voltage (V) Condition downshift Other condition (+) term. 2M 30 to next step Grounc I I I I I 3 1 Disconnect 20-pin powertrain control Yes 30 to step 5 module (transmission) connector Is resistance between terminal 2M and ground Resistance: 13-2752 30 to next step Disconnect solenoid connector Is resistance between ground and termi- nal A of 3-2 control solenoid valve OK? page K-42 Yes ;heck wiring and connectors form powertrain control module transmission) to 3-2 control solenoid valve If OK, go to next step If not OK, repair wiring and/or connector Resistance: 13-2752 qeplace 3-2 control solenoid valve Disconnect the negative battery cable for at least 20 seconds and depress the brake pedal Connect the battery cable and recheck for code Is diagnostic trouble code displayed? page K-21 Yes 3eplace powertrain control module (transmission) page K-45 ntermittent poor connection :heck for cause Gartner Banana

Page 440 of 1708

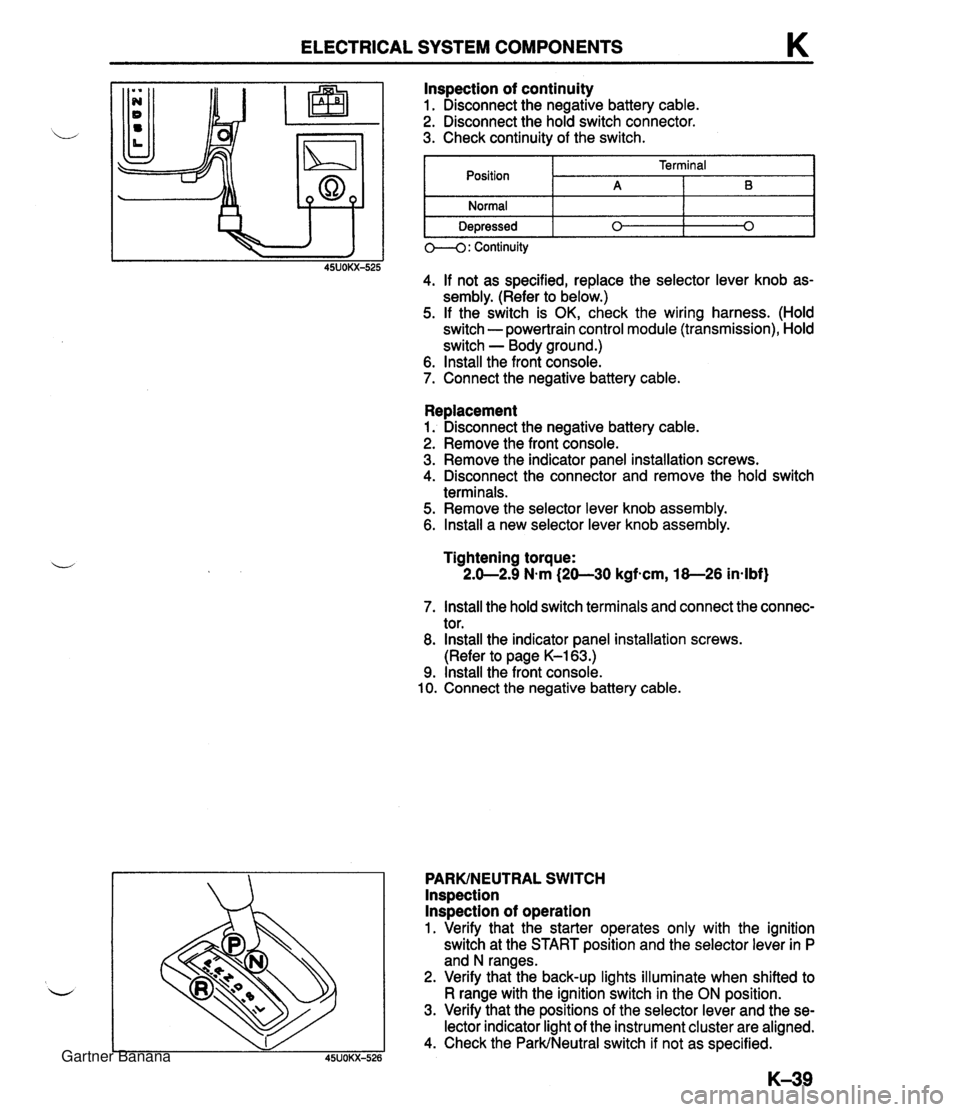

ELECTRICAL SYSTEM COMPONENTS K Replacement 1. Disconnect the negative battery cable. 2. Remove the front console. 3. Remove the indicator panel installation screws. 4. Disconnect the connector and remove the hold switch terminals. 5. Remove the selector lever knob assembly. 6. lnstall a new selector lever knob assembly. lnspection of continuity 1. Disconnect the negative battery cable. 2. Disconnect the hold switch connector. 3. Check continuity of the switch. Tightening torque: 2.0-2.9 N.m (20-30 kgfscm, 18-26 in-lbf) Position Normal Depressed 7. lnstall the hold switch terminals and connect the connec- tor. 8. lnstall the indicator panel installation screws. (Refer to page K-163.) 9. lnstall the front console. 10. Connect the negative battery cable. PARKINEUTRAL SWITCH lnspection lnspection of operation 1. Verify that the starter operates only with the ignition switch at the START position and the selector lever in P and N ranges. 2. Verify that the back-up lights illuminate when shifted to R range with the ignition switch in the ON position. 3. Verify that the positions of the selector lever and the se- lector indicator light of the instrument cluster are aligned. 4. Check the ParkINeutral switch if not as specified. 0--4: Continuity 45UOKX-525 4. If not as specified, replace the selector lever knob as- sembly. (Refer to below.) 5. If the switch is OK, check the wiring harness. (Hold switch - powertrain control module (transmission), Hold switch - Body ground.) 6. lnstall the front console. 7. Connect the negative battery cable. Terminal A 0 B 0 Gartner Banana

Page 443 of 1708

K ELECTRICAL SYSTEM COMPONENTS Replacement 1. Disconnect the negative battery cable. 2. On level ground, jack up the vehicle and support it evenly on safety stands. 4 3. Disconnect the vehicle speed pulse generator connec- tor. 4. Remove the vehicle speed pulse generator. 5. Install the new vehicle speed pulse generator. Tightening torque: 7.9--10.7 N-m (80-110 kgfecm, 70-95.4 in-lbf) 6. Connect the vehicle speed pulse generator connector. 7. Connect the negative battery cable. 1-2 SHIFT, 2-3 SHIFT, 3-4 SHIFT, 3-2 CONTROL SOLENOID VALVE Inspection 1. On level ground, jack up the vehicle and support it evenly on safety stands. 2. Disconnect the solenoid valve connector. d 3. Measure resistance between each terminal and ground. Resistance: l3-27a 4. If not correct, check the wiring harness for an open or short circuit. Replace the solenoid valve. Solenoid valve 1-2 shift 2-3 shift 3-4 shift 3-2 control LOCKUP CONTROL SOLENOID VALVE lnspection 1. Disconnect the solenoid valve connector. 2. Measure the resistance between the terminals. Terminal C D - A B Resistance: l3-2Sil 3. If not correct, replace the solenoid valve. Gartner Banana

Page 444 of 1708

ELECTRICAL SYSTEM COMPONENTS K I POWERTRAIN CONTROL POWERTRAIN CONTROL MODULE (TRANSMISSION) lns~ection 1. kemove the powertrain control module (Transmission). (Refer to page K-45.) 2. Disconnect the control module connectors. 3. Connect the SSTs (Engine Signal Monitor and Adapt- er Harness) to the powertrain control module (Transmis- sion) as shown. 4. Place the SST (sheet) on the Engine Signal Monitor. 5. Turn the ignition switch ON. 6. Measure the terminal voltage at each terminal. 7. If any control module terminal voltage is incorrect, check the related input of output devices and wiring. If no prob- lem is found, replace the powertrain control module (Transmission). Caution Applying voltage to terminals A and B of this SST will damage the SST. Gartner Banana

Page 559 of 1708

SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) Replacement 1. Disconnect the negative battery cable. 2. Remove the column cover. 3. Disconnect the key interlock solenoid connector. 4. Remove the screws and the key interlock solenoid. 5. Install the key interlock solenoid and tighten the screws. Tightening torque: 6.S-13 N-m (70-1 30 kgf-m, 61-11 3 ft-lbf} I I I 6. Verify that the key interlock solenoid operates. (Refer to 45UOKX-576 "Inspection" above.) 7. Connect the key interlock solenoid connector. 8. Install the column cover. 9. Connect the negative battery cable. KEY INTERLOCK UNIT Inspection 1. Remove the column cover. 2. Turn the ignition switch ON, and check terminal volt- ages, referring to the chart below. 3. If not as specified, repair the wiring harness andlor key -, interlock unit. B+: Battery positive voltage - - - Within 2 seconds of twning the P-range switch ON, and either the ACC or IG ON. Except above conditions Correct measurement valve 0 B+ E Condition Terminal I I I I terminal connected to I Ground 1 Constant M 0 Ignition switch ON Ignition switch OFF P-range switch and ACC are ON, or IG is ON Except above condition I B+ 0 S 0 B+ P-range switch ON P-range switch OFF I 0 B+ - ACC switch ON ACC switch OFF B+ 0 Gartner Banana

Page 561 of 1708

K SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) CONNECTOR B CONNECTOR A 3. Lift up slightly on the selector lever, selector sleeve, and indicator panel, and disconnect the hold switch connec- tor. 4. Disconnect the HOLD switch connector. .--' 5. Shift the selector lever to P range. 6. Turn the ignition switch ON, and check terminal voltages and continuity, referring to the chart below. Disconnect the shift-lock actuator connector to check continuity be- tween terminal c (harness side) and ground. 7. If not as specified, repair the wiring harness and/or shift- lock actuator. I ~~UOKX-477 B+: Battery positive voltage I Connector I Terminal connectd to l terminal I Condition I Correct measurement vaive I I 1 I I A a B-C I P range, selector lever release button not depressed I OR I lBl e I B I P ranae, selector lever release button not depressed I OV I A B B B B 8. Grasp the HOLD switch wiring harness and pull it while pushing the selector knob down fully onto the selector le- ver. 9. Connect the HOLD switch connector. 10. Adjust the indicator panel. (Refer to page K-161.) Install the screws in the order shown in the figure. 11. Apply locking compound to the selector knob screw threads after the threads have been cleaned. Tighten the screws. Tightening torque: 2.0-2.9 N-m (20-30 kgf-cm, 18-26 in-lbf) b a b C (harness side) d 12. Install the rear console. 13. Connect the negative battery cable. 14. Verify correct operation of the shift-lock system. B-C B-C B-C Body B-C Constant Ignition switch OFF Ignition switch ON Constant Brake pedal released -t depressed OR B+ El+ on OV -+ B+ -1 Gartner Banana

Page 565 of 1708

K SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) I O.%1 .Omm 0.6-0.7mm (0.035-0.039 in} (0.024-0.028 in) I 0.5-0.6mm (0.02-4.024 in) FRONT OF VEHICLE SHIFT ROD ' SPRING PIN FRONT OF VEHICLE - ADJUSTMENT LEVER I SHIFT ROD ' SPRING PIN I SLIDER '2EEi Removal note Selector knob Refer to shift-lock actuator inspection; page K-159, Steps 2-43. i/ Spring pin 1. On level ground, jack up the vehicle and support it evenly on safety stands. 2. Remove the spring pin. Installation note Spring pin 1. On level ground, jack up the vehicle and support it evenly on safety stands. 2. Install a new spring pin forward as shown in the figure. 3. Adjust the selector lever position. (Refer to page K-161.) -, Indicator panel 1. Set the selector sleeve over the selector lever. 2. Grasp the HOLD switch wiring harness and pull it while pushing the selector knob down fully on the selector le- ver. 3. Connect the HOLD switch connector. 4. Shift the selector lever to P range. 5. Align the alignment hole in the slider with the hole in the indicator panel. Install suitable heavy-gauge wire to hold the slider. 6. Tighten the indicator mounting screws in the order shown in the figure. 7. Remove the wire from the slider. 8. Verify that the selector lever properly aligns with the indi- cator in each range. 9. Verify correct operation of the emergency override but- ton. Gartner Banana

Page 703 of 1708

P ANTILOCK BRAKE SYSTEM (ABS) TROUBLESHOOTING GUIDE Troubleshooting Guide with ABS Tester ABS tester ADAPTER PART No.0000-42-0010 HYDRAULIC UNIT CONNECTOR POSSlTlVE BATTERY 97UOPX469 Connecting ABS tester 1. Turn the ignition switch OFF. 2. Connect the SST harness to an extension harness, and wrap the connection with electrical tape to prevent short- ing. 3. Connect the SST between the hydraulic unit wiring har- ness connectors and to the positive battery terminal. 4. Roll back the carpet and remove the protecter. 5. Connect the ABS tester to the control unit connector at harness side .using the adaptor. Warning Driving the vehicle while the tester is connected to the ABS control unit is extremely dangerous. The brakes could fail, resulting in death or seri- / -1 ous injury. Disconnect the tester from the ABS control unit before driving the vehicle. Gartner Banana

Page 714 of 1708

ANTILOCK BRAKE SYSTEM (ABS) P Inspection of ABS system Check system ground Caution To prevent damage to the terminals, create a probe by wrapping a thin wire around the tester lead before inserting. Check for an open circuit in (B) wire from terminals 1 Dl 1 S, and 2F of the control unit connector and ground. Check antilock warning light 1. Remove the instrument cluster. 2. Connect 12V to terminal 2K (C-Ol), and ground to termi- nal 1 K ((2-01). 3. Verify that the ABS warning light illuminates. 4. If there is no illumination, check the meter fuse, bulb, and wiring harness. 5. If OK, check the wiring harness (Warning light - Control unit - Hydraulic unit) and repair or replace as necessary. Check ABS diode 1. Check the meter fuse, bulb, and wiring harness. 2. Check the wiring harness (Warning light - Control unit - Hydraulic unit). 3. Disconnect the hydraulic unit 12-pin connector. 4. Using an ohmmeter, check for continuity of the terminals. 5. If continuity is not as specified, replace the hydraulic unit. Check front and rear valves 1. Disconnect the hydraulic unit 12-pin connector. 2. Using an ohmmeter, check for resistance of the termi- nals. -- 3. If resistance is not as specified, replace the hydraulic unit. 4. If resistance is as spe'cified, check the wiring harness (Hydraulic unit - ABS control unit). E (YIG) - H (B) (Rear Valve) C (BR) - H (B) (Right Front Valve) A (B/W) - H (B) (Left Front Valve) Check brake light switch 1. Disconnect the brake light switch connector. 2. Check for continuity between the terminals of the switch. Resistance (n) Approx. 1 .O-1.2 Approx. 1.0-1.2 Approx. 1 .+I .2 M : Indicates continuity Depressed brake pedal 3. If the continuity is not as specified, check the STOP fuse and wiring harness (Brake light switch - Control unit). 0 I 0 Released brake pedal Gartner Banana

Page 715 of 1708

P ANTILOCK BRAKE SYSTEM (ABS) MOTOR RELAY I I VALVE RELAY / I Check motor relay 1. Disconnect the negative battery cable. 2. Remove the motor relay. 3. Connect an ohmmeter and check for continuity at the .,i relay terminals. 4. If continuity is not as specified, replace the motor relay. 5. If OK, check the wiring harness (Motor relay - Control unit main fuse [ABS 60A1). Check pump motor Disconnect the control unit 2-pin connector and check for continuity between terminal a (FIN) wire and ground. If there is no continuity, replace the hydraulic unit. d 0 Check valve relay 1. Disconnect the negative battery cable. 2. Release the valve relay locks from the hydraulic unit and remove the valve relay. 3. Using an ohmmeter, check continuity of the relay termi- nals. M: Indicates continuity Connect to a 0 12V - c I b d 0 I I C++3: lndicates continuity Ground - b 4. If continuity is not as specified, replace the valve relay. b 0 e Connect to 12V I Ground c 0 a b c d Gartner Banana