ignition MAZDA MX-5 1994 Manual PDF

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 217 of 1708

TROUBLESHOOTING GUIDE INSPECTION Check for correct fuel line pressure at idle Section B ACTION Go to next step - Yes High compression Check engine condition Carbon deposits Engine compression: 1,255-883 kPa 112.8-9.0 kgf/cm2, 182-128 psi)-300 rpm Section B Check for correct fuel line pressure at idle page F-110 Yes - No Check if fuel line pressure decreases when accelerating quickly Fuel line pressure: 265-314 kPa (2.7-43.2 kgf/cm2, 38-46 psi) (Vacuum hose to pressure regulator discon- nected) 0 If decreases, check for clogging between fuel pump and pressure regulator 0 If no decrease, go to next step Low pressure Check fuel line pressure while pinching fuel return hose 0 If fuel line pressure quickly increases, check pressure regulator page F-118 0 If fuel line pressure gradually increases, check for clog- ging between fuel pump and pressure regulator If not clogged, check fuel pump maximum pressure w page F-115 INSTALL CLAPS Check for correct ignition timing at idle IJ&T page F-76 Yes Check if ignition timing advances when accelerating o If advances, go to next step o If no advance, replace PCME LW page F-143 Ignition timing: 10" + lo BTDC No - Yes Adjust page F-76 Check for EGR system malfunction page F-124 Repair or replace Go to next step Go to next step Check if cooling system is OK Section E Yes No - Yes Repair or replace Thermostat Electric cooling fan Radiator ~3 Section E Section B Section E Try known good PCME and check if condition im- proves IJ&T page F-144 Replace PCME page F-143 Change fuel to another brand or use higher octane fuel Gartner Banana

Page 218 of 1708

![MAZDA MX-5 1994 Manual PDF TROUBLESHOOTING GUIDE rROUBLESHOOTlNG HINTS] > Poor connection or damaged fuel system or fuel evaporative system 3 Charcoal canister overflow due to fuel evaporative system malfunction 28 INSPECTION C MAZDA MX-5 1994 Manual PDF TROUBLESHOOTING GUIDE rROUBLESHOOTlNG HINTS] > Poor connection or damaged fuel system or fuel evaporative system 3 Charcoal canister overflow due to fuel evaporative system malfunction 28 INSPECTION C](/img/28/57072/w960_57072-217.png)

TROUBLESHOOTING GUIDE rROUBLESHOOTlNG HINTS] > Poor connection or damaged fuel system or fuel evaporative system 3 Charcoal canister overflow due to fuel evaporative system malfunction 28 INSPECTION Check if fuel leak or damage are visible at fuel sys- tem and fuel evaporative system FUEL ODOR ACTION IESCRIPTION I Gasoline odor in cabin Yes Repair or replace page F-107 30 to next step Check if "00" is displayed on Self-Diagnosis Check- er with ignition switch ON page F-79 SELECT SW A SYSTEM SELECT 1 I Yes - No - Yes So to next step Diagnostic Trouble Code No. displayed Check for cause (Refer to specified check sequence) page F-81 "88" flashes Check PCME terminal 1 E voltage page F-145 Specification: Battery positive voltage (Ignition switch ON) o If OK, replace PCME page F-143 o If not OK, check wiring between PCME and Self-Diagno- sis Checker page F-7 Check if vacuum is felt at purge solenoid valve with engine running and throttle valve opened (Neutral switch connector disconnected) Go to Step 5 Check for purge solenoid valve operating sound in this condition o If OK, check vacuum hoses for clogging page F-6 o If not OK, go to next step Apply battery positive voltage and ground to purge solenoid valve and check if air flows through valve Yes Check PCME terminal 2X voltage page F-146 Replace purge solenoid valve @S page F-132 Try known good PCME Daae F-144 Gartner Banana

Page 220 of 1708

![MAZDA MX-5 1994 Manual PDF TROUBLESHOOTING GUIDE F POOR FUEL ECONOMY I [TROUBLESHOOTING HINTS] Nhile fuel consumption is drastically increased during city driving, short-run operation, stop and go driving, extended winterwarm- MAZDA MX-5 1994 Manual PDF TROUBLESHOOTING GUIDE F POOR FUEL ECONOMY I [TROUBLESHOOTING HINTS] Nhile fuel consumption is drastically increased during city driving, short-run operation, stop and go driving, extended winterwarm-](/img/28/57072/w960_57072-219.png)

TROUBLESHOOTING GUIDE F POOR FUEL ECONOMY I [TROUBLESHOOTING HINTS] Nhile fuel consumption is drastically increased during city driving, short-run operation, stop and go driving, extended winterwarm- ~p periods, etc., as opposed to "trip" mileage, an attempt should be made to determine these factors when confronted with "poor mileage" conditions. However, since the operator is not always at fault, the following is offered. 3 Operator depressing accelerator more than usual due to O Alcohol blended fuel used low engine power @ High vehicle load Poor ignition Low tire pressure Low intake air amount Unrecommended tire used Electric spark advance control malfunction Brake dragging Clutch slipping @ Fuel cut control malfunction Exhaust component restricted @ High idle speed AirIFuel mixture too rich High fuel line pressure INSPECTION Check factors other than engine Low tire pressure Section Q Unrecommended tire used @zT Section Q Clutch slipping Section H Brake dragging Section P Exhaust component restricted @zT page F-128 ACTION - Yes Go to next step Repair Check if air hoses are connected correctly @zT page F-99 Yes - No Go to next step Repair @zT page F-99 Check if air cleaner element is clean page F-76 Yes - No Go to next step Replace page 699 Check if "00" is displayed on Self-Diagnosis Check- er with ignition switch ON @zT page F-79 Yes Go to next step SELECT SW A SYSTEM SELECT 1 Diagnostic Trouble Code No. displayed Check for cause (Refer to specified check sequence) page F-81 "88" flashes Check PCME terminal 1 E voltage US page F-145 Specification: Battery positive voltage (Ignition switch ON) 6 If OK, replace PCME page F-143 6 If not OK, check wiring between PCME and Self-Diagno- sis Checker page F-7 Check switches for correct operation with Self- Diagnosis Checker Monitor Lamp and ignition switch ON page F-95 SELECT SW A Yes Go to next step ~~p Lamp not ONIOFF with specified switch Check for cause (Refer to specified check sequence) @zT page F-96 Lamp always ON Check wiring between PCME terminal 1 F and Self-Diag- nosis Checker us page F-7 Gartner Banana

Page 221 of 1708

TROUBLESHOOTING GUIDE INSPECTION Check if PCME terminal voltages are OK (20,2N, 20,2P, 2Q, 2R, 2U and 2V) page F-146 Check if fuel cut operation is OK during decelera- tion Fuel cut: Above 1,900 rpm after warm-up Check for correct ignition timing at idle page F-76 Ignition timing: 10" 2 lo BTDC Check for correct fuel line pressure at idle page 6118 Fuel line pressure: 216-264 kPa i2.2-2.7 kgf/cm2, 32-48 psi) INSTALL CLAPS ' Run engine at idle and check if fuel line pressure is held after ignition switch turned OFF page F-109 Fuel line pressure: More than 147 kPa {I .5 kgf/cm2, 21 psi) for 5 mln. PRESSURE IGNITION 5 MIN. TIME SWITCH OFF Yes - No Yes No Yes No Yes No - Yes No ACTION Go to next step Check for cause (Refer to "Check Point for Each Terrni- nal") paae F-148 Go to next step Try known good PCME @ page F-144 Go to next step Adjust page M6 Go to next step High pressure Check if vacuum hose to pressure regulator is damaged or poorly connected o If OK, replace pressure regulator * page F-119 O If not OK, repair or replace hose So to next step Check fuel injector for fuel leakage page F-120 Change fuel to another brand Gartner Banana

Page 223 of 1708

![MAZDA MX-5 1994 Manual PDF F TROUBLESHOOTING GUIDE DESCRIPTION I Blower fan operates but cool air not expelled ITROUBLESHOOTING HINTS] Open or short circuit in wiring harness NC relay malfunction 34 Air conditioning sensor malf MAZDA MX-5 1994 Manual PDF F TROUBLESHOOTING GUIDE DESCRIPTION I Blower fan operates but cool air not expelled ITROUBLESHOOTING HINTS] Open or short circuit in wiring harness NC relay malfunction 34 Air conditioning sensor malf](/img/28/57072/w960_57072-222.png)

F TROUBLESHOOTING GUIDE DESCRIPTION I Blower fan operates but cool air not expelled ITROUBLESHOOTING HINTS] Open or short circuit in wiring harness NC relay malfunction 34 Air conditioning sensor malfunction Magnetic clutch malfunction PCME malfunction AIC DOES NOT WORK INSPECTION ;round terminal B at NC relay with jumper wire Yes tnd check if condenser fan operates when ignition ;witch is turned ON #C RELAY I ;round terminal B at PCME 1 J terminal with jump- Yes ,r wire and check if condenser fan operates when gnition switch is turned ON - No :heck if Air conditioning sensor is OK Yes Section U ACTION 30 to next step 30 to A/C system Troubleshooting Section U 30 to next step qepair wire between PCME and A/C relay page F-7 Try known good PCME page F-144 ;heck Air conditioning sensor and wiring Section U Gartner Banana

Page 224 of 1708

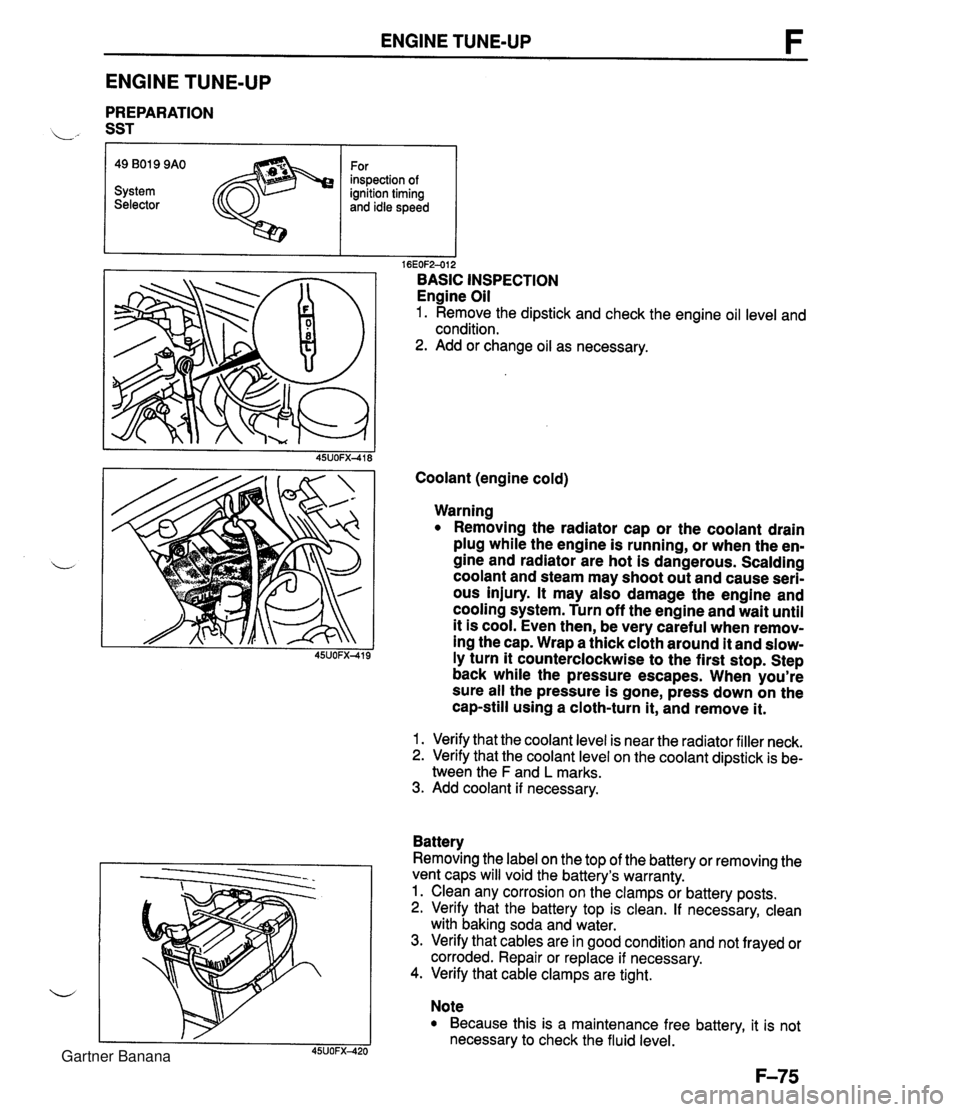

ENGINE TUNE-UP ENGINE TUNE-UP PREPARATION L" SST r I I 16EOF2-012 BASIC INSPECTION Engine Oil 1. Remove the dipstick and check the engine oil level and condition. 2. Add or change oil as necessary. 49 B019 9AO System Selector Coolant (engine cold) For inspection of ignition timing and idle speed Warning Removing the radiator cap or the coolant drain plug while the engine is running, or when the en- gine and radiator are hot is dangerous. Scalding coolant and steam may shoot out and cause seri- ous injury. It may also damage the engine and cooling system. Turn off the engine and wait until it is cool. Even then, be very careful when remov- ing the cap. Wrap a thick cloth around it and slow- ly turn it counterclockwise to the first stop. Step back while the pressure escapes. When you're sure all the pressure is gone, press down on the cap-still using a cloth-turn it, and remove it. 1. Verify that the coolant level is near the radiator filler neck. 2. Verify that the coolant level on the coolant dipstick is be- tween the F and L marks. 3. Add coolant if necessary. Battery Removing the label on the top of the battery or removing the vent caps will void the battery's warranty. 1. Clean any corrosion on the clamps or battery posts. 2. Verify that the battery top is clean. If necessary, clean with baking soda and water. 3. Verify that cables are in good condition and not frayed or corroded. Repair or replace if necessary. 4. Verify that cable clamps are tight. Note Because this is a maintenance free battery, it is not necessary to check the fluid level. Gartner Banana

Page 225 of 1708

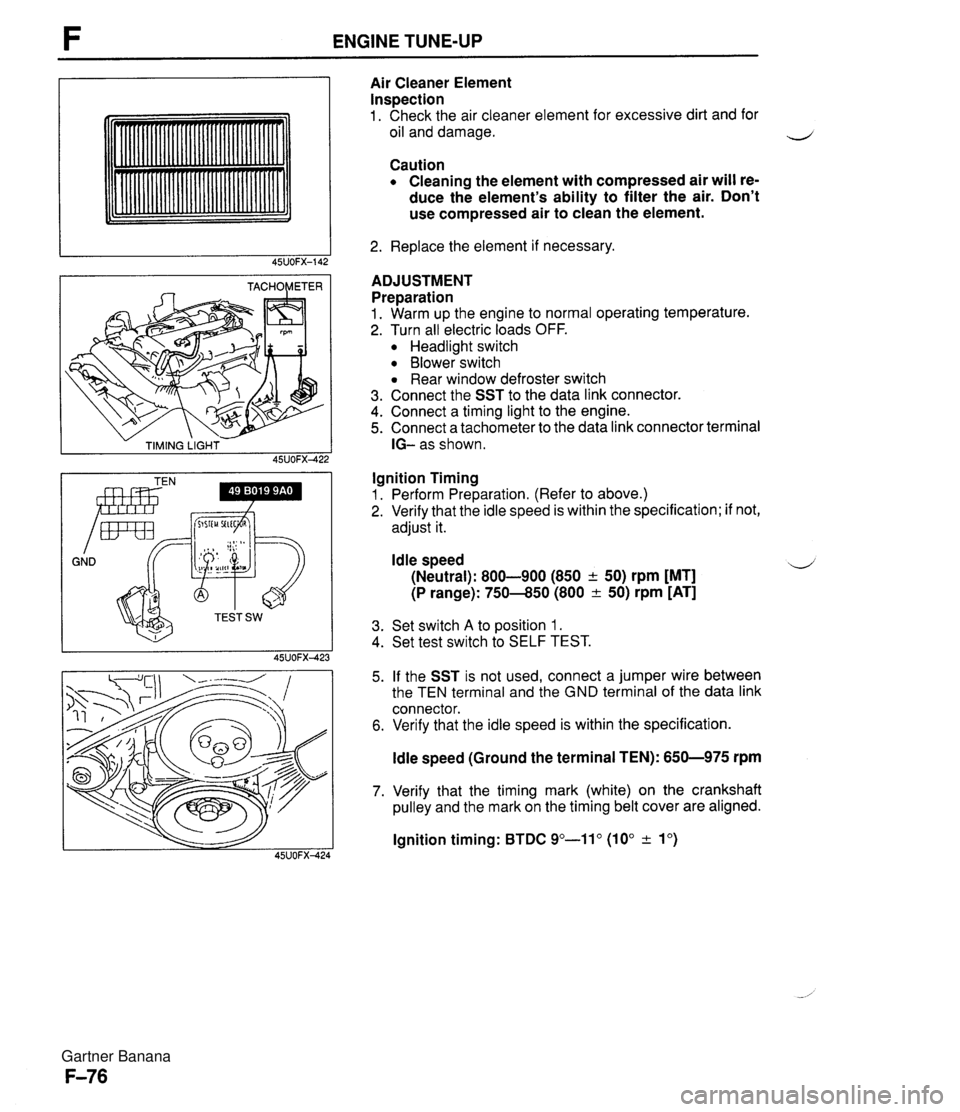

ENGINE TUNE-UP - TIMING LIGHT - 45UOFX422 GND Irnr Air Cleaner Element Inspection 1. Check the air cleaner element for excessive dirt and for oil and damage. Caution Cleaning the element with compressed air will re- duce the element's ability to filter the air. Don't use compressed air to clean the element. 2. Replace the element if necessary. ADJUSTMENT Preparation 1. Warm up the engine to normal operating temperature. 2. Turn all electric loads OFF. Headlight switch Blower switch Rear window defroster switch 3. Connect the SST to the data link connector. 4. Connect a timing light to the engine. 5. Connect a tachometer to the data link connector terminal IG- as shown. Ignition Timing 1. Perform Preparation. (Refer to above.) 2. Verify that the idle speed is within the specification; if not, adjust it. Idle speed 4 (Neutral): 800-900 (850 + 50) rpm [MT] (P range): 750-850 (800 & 50) rpm [AT] 3. Set switch A to position 1. 4. Set test switch to SELF TEST. 5. If the SST is not used, connect a jumper wire between the TEN terminal and the GND terminal of the data link connector. 6. Verify that the idle speed is within the specification. ldle speed (Ground the terminal TEN): 650-975 rpm 7. Verify that the timing mark (white) on the crankshaft pulley and the mark on the timing belt cover are aligned. lgnition timing: BTDC 9"-11" (10" & lo) Gartner Banana

Page 226 of 1708

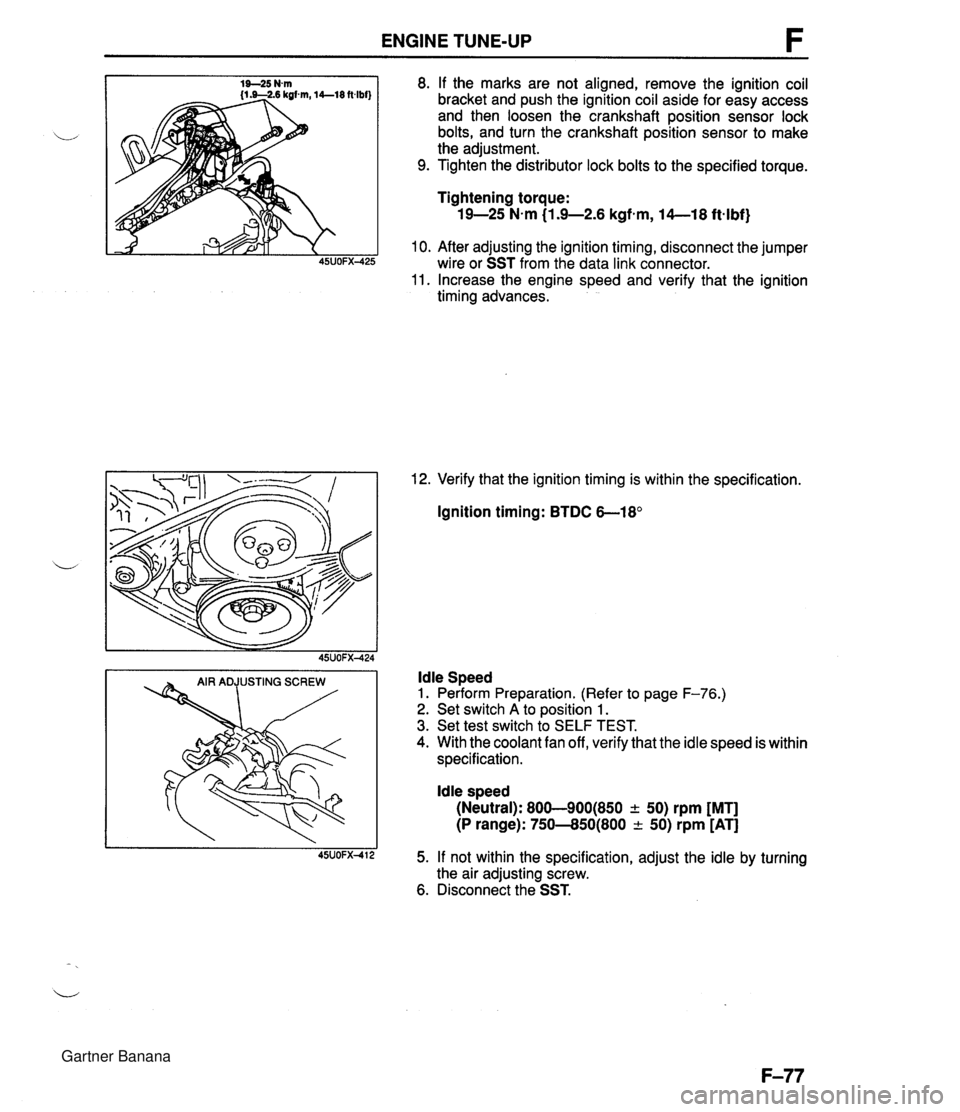

ENGINE TUNE-UP 8. If the marks are not aligned, remove the ignition coil bracket and push the ignition coil aside for easy access and then loosen the crankshaft position sensor lock bolts, and turn the crankshaft position sensor to make the adjustment. 9. Tighten the distributor lock bolts to the specified torque. Tightening torque: 19-25 N-m (1.9-2.6 kgfem, 14--18 ftqlbf) 10. After adjusting the ignition timing, disconnect the jumper wire or SST from the data link connector. 11. Increase the engine speed and verify that the ignition timing advances. 12. Verify that the ignition timing is within the specification. Ignition timing: BTDC 6-18' ldle Speed 1. Perform Preparation. (Refer to page F-76.) 2. Set switch A to position 1. 3. Set test switch to SELF TEST. 4. With the coolant fan off, verify that the idle speed is within specification. ldle speed (Neutral): 800-900(850 + 50) rpm [MT] (P range): 750--850(800 -c 50) rpm [AT] 5. If not within the specification, adjust the idle by turning the air adjusting screw. 6. Disconnect the SST. Gartner Banana

Page 227 of 1708

ON-BOARD DIAGNOSIS SYSTEM ON-BOARD DIAGNOSIS SYSTEM DESCRIPTION When troubles occur in the main input devices or output devices, check for the cause using the SST. Q Failures of each input and output device are indicated and retrieved from the powertrain control module (engine) as diagnosis trouble code numbers. Note For input devices, the PCME continuously checks for malfunctions. For output devices, it checks for malfunctions only in a three-second period after the ignition switch is turned to ON, or the TEN termi- nal of the data link connector is grounded. - INPUT SIGNALS POWERTRAIN CONTROL MODULE (ENGINE) I- -t INPUT DEVICES FAIL-SAFE FUNCTION . ON-BOARD ,, DIAGNOSIS -+ SYSTEM - - 1 I I MALFUNCTIQN DISPLAY FUNCTION -t b P v C-- MONITOR FUNCTION u SYSTEM SELF-DIAGNOSIS SELECTOR CHECKER I CHECK Gartner Banana

Page 228 of 1708

ON-BOARD DIAGNOSIS SYSTEM PREPARATION SST 1 SELECT SW A STEM SELECT 1 * SYSTEM SEUC . TEST SW - SYSTEM SELECT i # SELF TEST DIAGNOSTIC TROUBLE CODE NUMBER Inspection procedure 1. Connect the SSTs to the data link connector and a ground. 2. Set the select switch to position A. 49 B019 9AO System Selector 3. Set the System Selector to position 1 and SELF TEST as shown. For diagnosis 4. Turn the ignition switch ON. 5. Verify that 88 flashes on the digital display and that the buzzer sounds for 3 sec. after turning the ignition switch ON. 6. If 88 does not flash, check the main relay (Refer to page F-156.), power supply circuit, and check connector wir- mg. 7. If 88 flashes and the buzzer continues for more than 20 sec., check for a short circuit between the powertrain control module (engine) terminal 1 E and the data link connector. Replace the powertrain control module (en- gine) if necessary and perform Steps 3 and 4 again. 8. Note any code numbers and check for the causes by re- ferring to the check sequences shown on pages F-83 to F-93. Repair as necessary. 9. After repairs, cancel the code numbers by performing the "After-repair procedure". (Refer to page F-94.) Gartner Banana