check engine MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 471 of 1164

STARTING SYSTEM G

STARTER INTERLOCK SWITCH (MTX)

CONTACT

IGNITION SWITCH

IG2 ROD

p IG1 ‘NTERlfM$TCH

i BATTERY

I

STARTER

For operator safety, if the clutch pedal is not depressed during starting, battery power will not be supplied

to the starter and the engine will not crank.

Interlock Switch

Inspection

1. Disconnect the interlock switch connector.

2. Connect an ohmmeter to the switch.

3. Check the continuity.

Clutch pedal

----- I_

Depressed

Released 4.

Replace the switch if necessary.

Continuity

--

Yes

No

G-31

Page 650 of 1164

ENGINE SPEED SENSING POWER STEERING

23UONX-03

03UONX-032

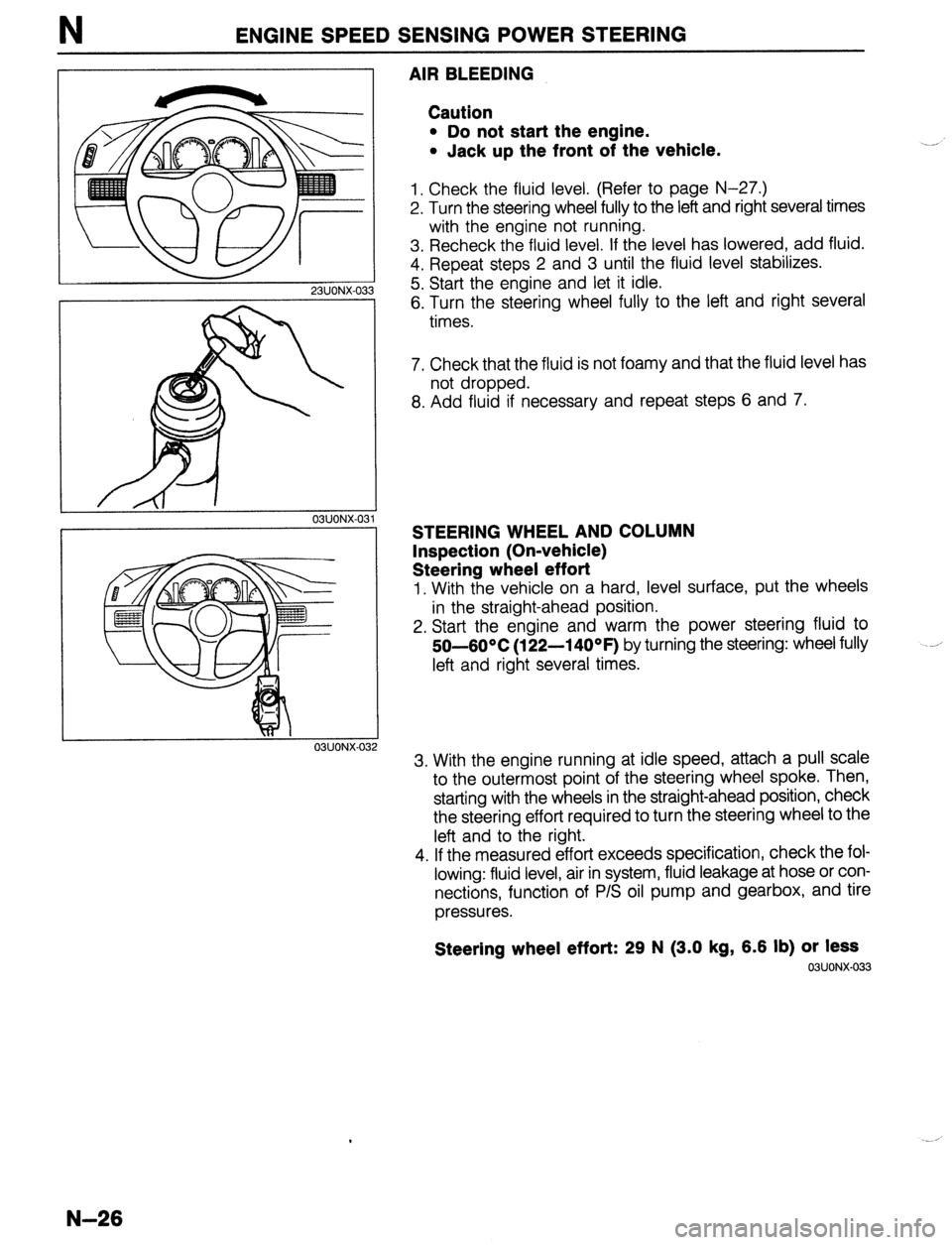

AIR BLEEDING

Caution

l Do not start the engine.

l Jack up the front of the vehicle.

1. Check the fluid level. (Refer to page N-27.)

2. Turn the steering wheel fully to the left and right several times

with the engine not running.

3. Recheck the fluid level. If the level has lowered, add fluid.

4. Repeat steps 2 and 3 until the fluid level stabilizes.

5. Start the engine and let it idle.

6. Turn the steering wheel fully to the left and right several

times.

7. Check that the fluid is not foamy and that the fluid level has

not dropped.

8. Add fluid if necessary and repeat steps 6 and 7.

STEERING WHEEL AND COLUMN

Inspection (On-vehicle)

Steering wheel effort

1. With the vehicle on a hard, level surface, put the wheels

in the straight-ahead position.

2. Start the engine and warm the power steering fluid to

50-60°C

(122-14OOF) by turning the steering: wheel fully

left and right several times.

3. With the engine running at idle speed, attach a pull scale

to the outermost point of the steering wheel spoke. Then,

starting with the wheels in the straight-ahead position, check

the steering effort required to turn the steering wheel to the

left and to the right.

4. If the measured effort exceeds specification, check the fol-

lowing: fluid level, air in system, fluid leakage at hose or con-

nections, function of P/S oil pump and gearbox, and tire

pressures.

Steering wheel effort: 29 N (3.0 kg, 6.6 lb) or less 03UONX-033

N-26

Page 651 of 1164

ENGINE SPEED SENSING POWER STEERING N

r-

-l

03UONX-034

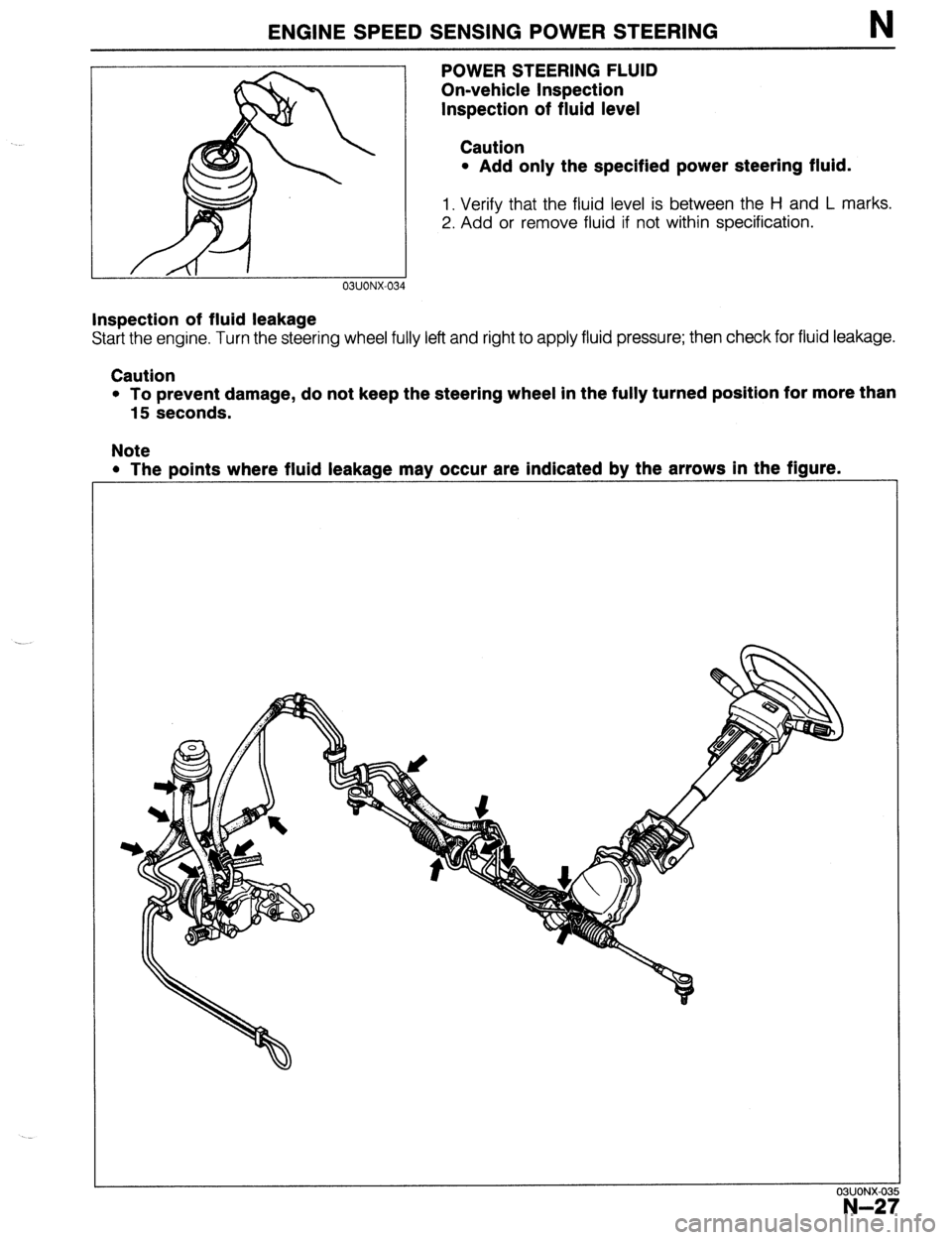

POWER STEERING FLUID

On-vehicle Inspection

Inspection of fluid level

Caution

l Add only the specified power steering fluid.

1. Verify that the fluid level is between the H and L marks.

2. Add or remove fluid if not within specification.

Inspection of fluid leakage

Start the engine. Turn the steering wheel fully left and right to apply fluid pressure; then check for fluid leakage.

Caution

+ To prevent damage, do not keep the steering wheel in the fully turned position for more than

15 seconds.

Note

l The points where fluid leakage may occur are indicated by the arrows in the figure.

03UONX-035

N-27

Page 657 of 1164

ENGINE SPEED SENSING POWER STEERING N

I I

-.

* :I

-3==T

I

, 93GONX-031

93GONX-03 2

I

93GONX-03 3

I

03UONX-822

t

~ t

93WJNX-03

Oil seal and bearing

1. Use the SST to remove the bearing and the oil seal from

the plug.

Caution

l The oil seal can not be reused.

Outer box assembly

1. Use the SST to remove the outer box.

Oil seal and inner guide

1, Use the SST to remove the oil seal and inner guide toward

the cylinder side.

Caution

l The oil seal can not be reused.

lnspectlon

Steerlng rack

1. Check the rack for cracking or other damage or for abnor-

mal wear of the teeth; replace it if necessary.

2. Check the seal ring installation part of the rack for abnor-

mal wear or damage; replace it if necessary.

3. Use V blocks to support both ends of the large-diameter

part of the rack; check for excessive bending; replace it if

necessary.

Bending limit: 0.15mm (0.006 In) (near rack center)

Plug

1. Check for scratches or other damage at the oil seal instal-

lation inner diameter; replace it if necessary.

Page 658 of 1164

N ENGINE SPEED SENSING POWER STEERING

23UOiX-055

23UONX-057

23UONX-05s

23UONX-05

Assembly

1. Mounting bracket and mounting rubber (gear housing

side)

(1) install the mounting bracket and mounting rubber (gear

housing side) to the gear box. ,

2. Steering rack

(1) Install a new O-ring and new seal ring to the rack’s

piston.

(2) After installing the seal ring, seat it properly at the pis-

ton circumference.

(3) Install the oil seal and inner guide to the

SST.

(4) Using the SST, place the oil seal and inner guide at the

edge of the steering rack’s pinion.

(5) After mounting the steering rack to the gear box, use

a press to install the oil seal and inner guide to the cor-

rect position.

Caution

l When pressing in, do not apply a load pressure of

more than 29,430 kPa (300 kg/cm2, 4,266 psi), be-

cause to do so will damage the oil seal and inner

guide.

l Apply grease to the seal ring, O-ring oil seal and in-

ner guide.

23UONX-056

3. Outer box assembly

(1) Install a new U-gasket and O-ring to the outer box.

(2) After installing the SST to the rack, install the outer box,

and use the

SST to tighten.

Tightening torque:

39-49 N-m (4-S m-kg, 29-36 ft-lb)

4. Cylinder air-tightness check

(1) Install the SST to the cylinder part of the gear housing.

(2) Using a vacuum pump, apply a vacuum of 400 mmHg

and check to be sure that the vacuum is maintained for

30 seconds.

(3) If there is any leakage, replace the oil seal.

5. Oil seal

(1) Use the SST to install a new oil seal to the gear housing.

Note

l Apply grease to the oil seal.

N-34

Page 663 of 1164

ENGINE SPEED SENSING POWER STEERING

93GONX-05:

93GONX-056

93GONX-O!

93GONX-05

Disassembly note

Oil pump

Note

l As shown in the figure, when securing the oil pump

in a vise, be sure to use the SST so that force is not

applied to the pulley or shaft.

Assembly note

Rotor

1. Install the rotor to the shaft with the rotor’s identification mark

facing upward.

Cam ring

1. Install the cam ring so that its identification mark is facing

downward.

Vane

1. Install the vanes (10 pieces) to the rotor, with the R part of

the vanes facing outward.

Inspection

Note

l Replace the pump assembly if necessary.

Pump body

1. Check the front and rear pump bodies for cracking or oth-

er damage and for abnormal wear of the moving surface

of the rotor.

N-39

Page 664 of 1164

N ENGINE SPEED SENSING POWER STEERING

93GONX-05

I 93GONX-05!

Cam ring, rotor, vanes, side plate

1. Check the moving surface of the cam ring’s vanes for ab-

normal wear.

2. Check the moving surface of the side plate and the pump

bodies for abnormal wear.

3. Check the moving surface of the vane cam ring for abnor-

mal wear.

4. Check the clearance of the rotor and vanes.

4

Control valve and spring

1. Check the control valve for cracking and other damage, for

clogging, and for abnormal wear of the moving part.

2. Check the spring for damage.

Page 665 of 1164

ENGINE SPEED SENSING POWER STEERING N

P/S

23UONX-04!

PULLEY

P/S AND A/C

23UONX-04

DRIVE BELT

Inspection

1. Check the drive belts for wear, cracks, and fraying. Replace

as necessary.

2. Verify that the drive belts are correctly mounted on the

pulleys.

3. Check the drive belt deflection by applying moderate pres-

sure (98 N,

10 kg, 22 lb) midway between the pulleys.

Note

l Measure the belt deflection between the specified

pulleys.

0 A belt is considered “New” if it has been used on

a running engine for less than five minutes.

Set the deflection specification below accordingly.

* Check the belt deflection when the engine is cold,

or at least 30 minutes after the engine has stopped.

Deflection

mm (in)

New Used Limit

8-9.0 (0.31-0.35) 9.0-10.0 (0.35-0.39) 11.5 (0.45)

4. If the deflection is not within specification, adjust it.

23UONX-047

Drive belt tension check

WHEN SET

I

23UONX-048

Note

l Belt tension can be checked in place of belt

deflection.

aBelt tension can be measured between any two

pulleys.

Using the SST check the belt tension.

Tension

N (kg, lb)

New

491-589

(50-60, 11 O-l 32) Used

422-491

(43-50, 95-l 10) Limit

245

(25, 55)

N-41

Page 679 of 1164

CONVENTIONALBRAKESYSTEM P

1 SUOPX-001

03UOPX-03

0

o3uoPx-os

0

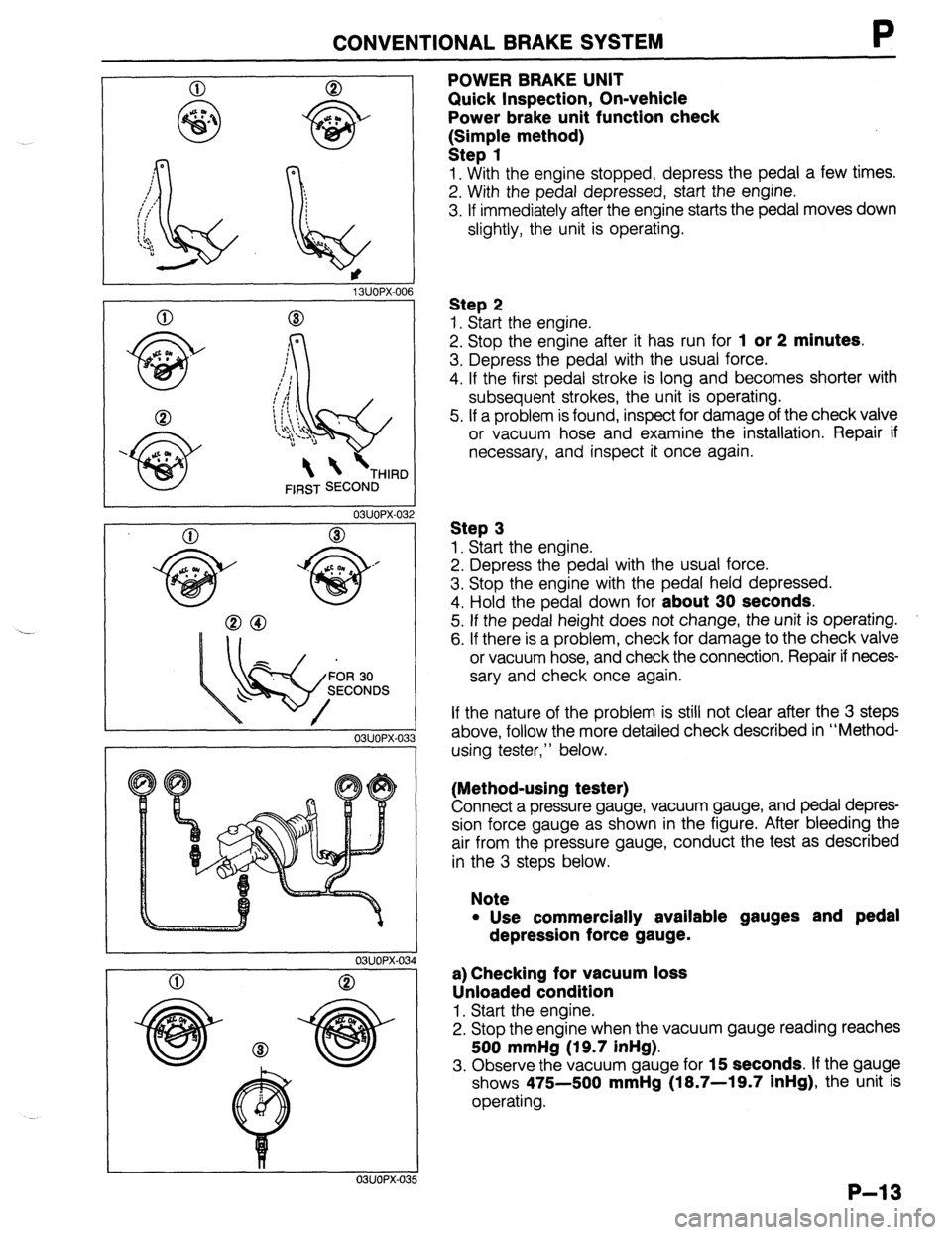

POWER BRAKE UNIT

Quick Inspection, On-vehicle

Power brake unit function check

k:;;p{e method)

1. With the engine stopped, depress the pedal a few times.

2. With the pedal depressed, start the engine.

3. If immediately after the engine starts the pedal moves down

slightly, the unit is operating.

Step 2

1. Start the engine.

2. Stop the engine after it has run for

1 or 2 minutes.

3. Depress the pedal with the usual force.

4. If the first pedal stroke is long and becomes shorter with

subsequent strokes, the unit is operating.

5. If a problem is found, inspect for damage of the check valve

or vacuum hose and examine the installation. Repair if

necessary, and inspect it once again.

Step 3

1. Start the engine.

2. Depress the pedal with the usual force.

3. Stop the engine with the pedal held depressed.

4. Hold the pedal down for

about 30 seconds.

5. If the pedal height does not change, the unit is operating.

6. If there is a problem, check for damage to the check valve

or vacuum hose, and check the connection. Repair if neces-

sary and check once again.

If the nature of the problem is still not clear after the 3 steps

above, follow the more detailed check described in “Method-

using tester,” below.

(Method-using tester)

Connect a pressure gauge, vacuum gauge, and pedal depres-

sion force gauge as shown in the figure. After bleeding the

air from the pressure gauge, conduct the test as described

in the 3 steps below.

Note

l Use commercially available gauges and pedal

depression force gauge.

a) Checking for vacuum loss

Unloaded condition

1. Start the engine.

2. Stop the engine when the vacuum gauge reading reaches

500 mmHg (19.7 inHg).

3. Observe the vacuum gauge for 15 seconds. If the gauge

shows 475-500

mmHg (18.7-19.7 inHg), the unit is

operating.

P-13

Page 680 of 1164

P CONVENTIONAL BRAKE SYSTEM

0 8

500 mmHg

(19.7 inHg)

96 N (20 kg, 44 lb)

03UOPX-03

03UOPX-03

03UOPX-031

Loaded condition

1. Start the engine.

2. Depress the brake pedal with a force of 196 N (20 kg, 44

lb).

3. With the brake pedal depressed, stop the engine when the

vacuum gauge reading reaches 500 mmHg (19.7 inHg).

4. Observe the vacuum gauge for 15 seconds. If the gauge

shows 475-500 mmHg (18.7-19.7 inHg), the unit is

operating.

b) Checking for hydraulic pressure

1. If with the engine stopped (vacuum 0 mmHg) the fluid pres-

sure is within specification, the unit is operating.

Pedal force Fluid pressure

196 N (20 kg, 44 lb) 1 1,177 kPa (12 kg/cm2, 171 psi) min

2. Start the engine. Depress the brake pedal when the vacu-

um reaches 500 mmHg (19.7 inHg). If the fluid pressure

is within specification, the unit is operating.

Pedal force Fluid pressure

196 N (20 kg, 44 lb) 7,063 kPa (72 kg/cm’, 1,024 psi)

P-14