check engine MAZDA PROTEGE 1992 Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 397 of 1164

231JOFX-1

FUEL SYSTEM F

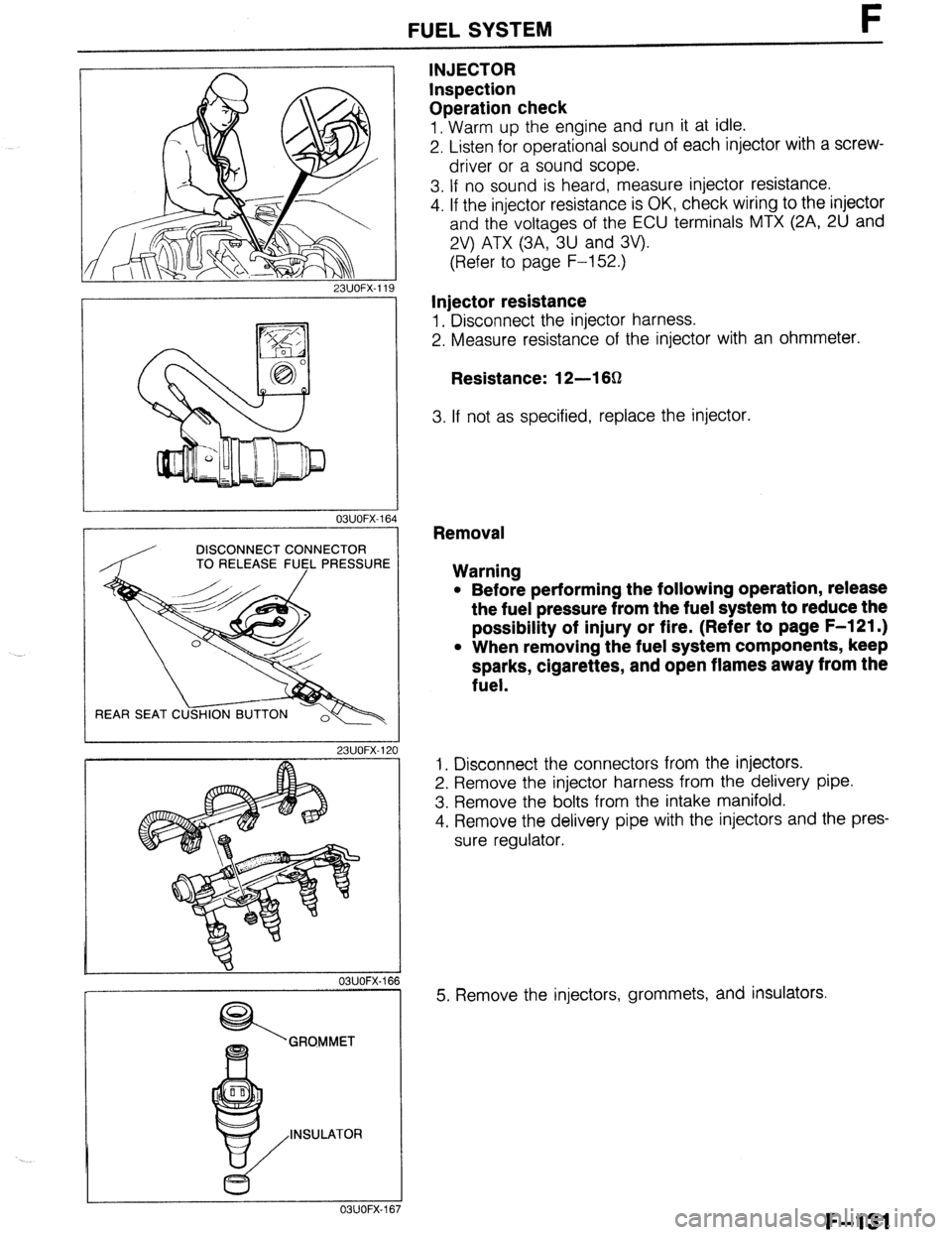

INJECTOR

Inspection

Operation check

1. Warm up the engine and run it at idle.

2. Listen for operational sound of each injector with a screw-

driver or a sound scope.

3. If no sound is heard, measure injector resistance.

4. If the injector resistance is OK, check wiring to the injector

and the voltages of the ECU terminals MTX (2A, 2U and

2V) ATX (3A, 3U and 3V).

(Refer to page F-152.)

Injector resistance

1. Disconnect the injector harness.

2. Measure resistance of the injector with an ohmmeter.

Resistance: 12-l 6Q

3. If not as specified, replace the injector.

03UOFX-1

DISCONNECT CONNECTOR

TO RELEASE FU5L PRESSUR

REAR SEAT C

23UOFX-1

OBUOFX-

GRQMMET

INSULATOR

c5

OSUOFX-

Removal

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F-121 .)

l When removing the fuel system components, keep

sparks, cigarettes, and open flames away from the

fuel.

1. Disconnect the connectors from the injectors.

2. Remove the injector harness from the delivery pipe.

3. Remove the bolts from the intake manifold.

4. Remove the delivery pipe with the injectors and the pres-

sure regulator.

5. Remove the injectors, grommets, and insulators.

F-131

Page 401 of 1164

PRESSUREREGULATORCONTROLSYSTEM F

03UOFX-17

*

03UOFX-14!

OSUOFX-17

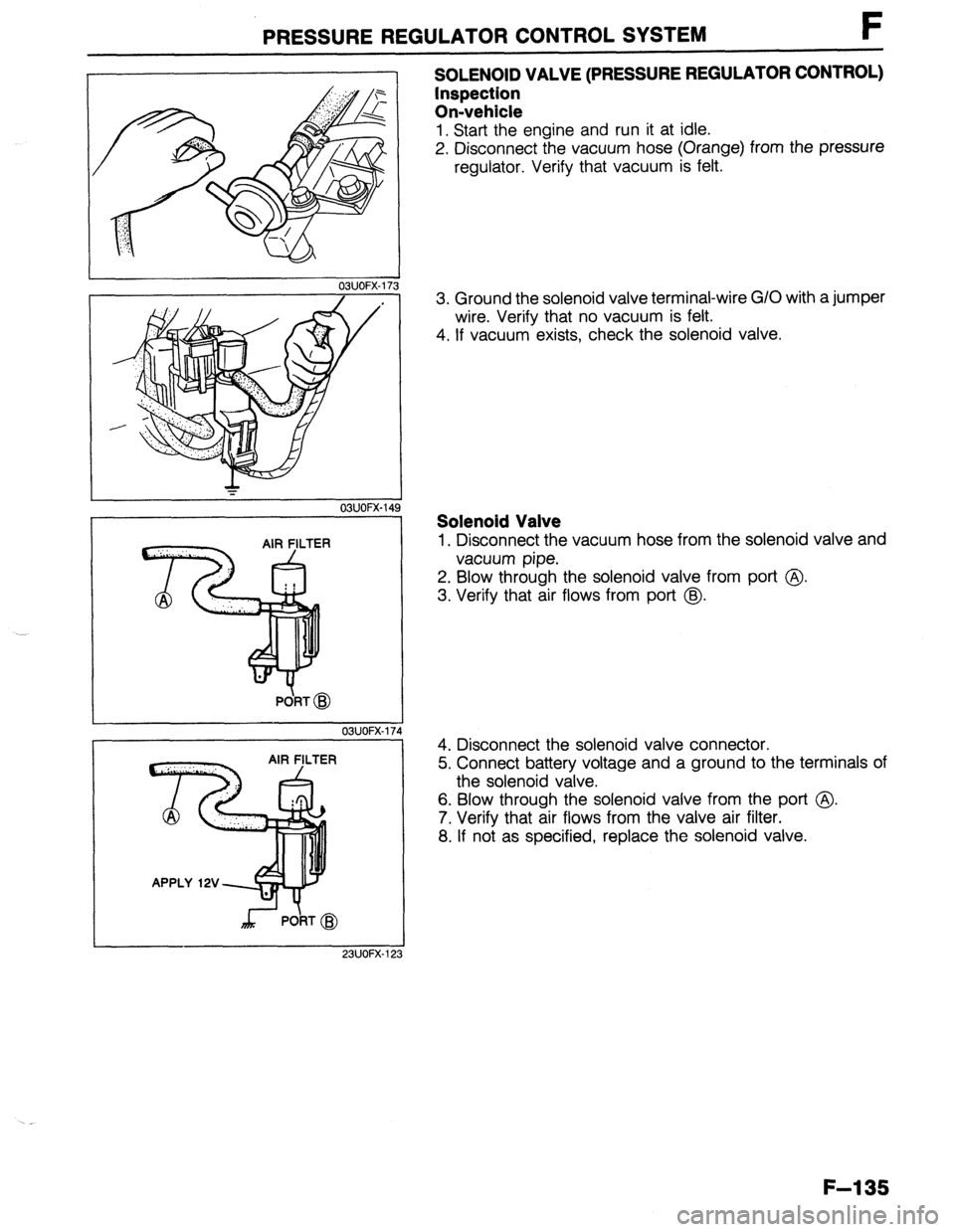

SOLENOID VALVE (PRESSURE REGULATOR CONTROL)

Inspection

On-vehicle

1. Start the engine and run it at idle.

2. Disconnect the vacuum hose (Orange) from the pressure

regulator. Verify that vacuum is felt.

3. Ground the solenoid valve terminal-wire G/O with a jumper

wire. Verify that no vacuum is felt.

4. If vacuum exists, check the solenoid valve.

Solenoid Valve

1. Disconnect the vacuum hose from the solenoid valve and

vacuum pipe.

2. Blow through the solenoid valve from port @

3. Verify that air flows from port @.

4. Disconnect the solenoid valve connector.

5. Connect battery voltage and a ground to the terminals of

the solenoid valve.

6. Blow through the solenoid valve from the port @.

7. Verify that air flows from the valve air filter.

8. If not as specified, replace the solenoid valve.

F-l 35

Page 405 of 1164

EVAPORATIVE EMISSION CONTROL SYSTEM t

EVAPORATIVE EMISSION CONTROL SYSTEM

DESCRIPTION

/ /

ENGINE ENGINE

CONTROL CONTROL - INPUT - INPUT

UNIT UNIT

- -

SOLENOID VALVE SOLENOID VALVE k k / /

CHECK VALVE CHECK VALVE

(TWO-WAY) (TWO-WAY)

CHARCOAL CHARCOAL

CANISTER CANISTER

CHECK-AND-CUTC CHECK-AND-CUTC

VALVE VALVE

SEPARATOR SEPARATOR TO ENGINE TO ENGINE SIGNALS

The evaporative emission control system consists of the separator, the check-and-cut valve, the two-way

check valve, the charcoal canister, the purge control solenoid valve, the engine control unit (ECU), and the

input devices. The amount of evaporative fumes introduced into the engine and burned is controlled by the

solenoid valve to correspond to the engine’s operating conditions. To maintain best engine performance,

the solenoid valve is controlled by the ECU.

Operation

.._ The solenoid valve (purge control) is controlled by duty signals from the ECU to perform purging of the char-

coal canister. Purging is done when these conditions are met:

(1) After warm-up

(2) Driving in gear

(3) Accelerator pedal depressed (idle switch OFF)

(4) Oxygen sensor functioning normally

F-l 39

Page 406 of 1164

F EVAPORATIVE EMISSION CONTROL SYSTEM

03UOFX-17! 3

03UOFX-180

INSTALLATION DIRECTION

F-l 40

I

23UOFX-126

03UOFX-18

OSUOFX-l&

SYSTEM OPERATION

1 Warm up the engine to normal operating temperature and

run it at idle.

2. Disconnect the vacuum hose from the solenoid valve as

shown in the figure, and verify that no vacuum is felt at the

solenoid valve. -.

3. If not as specified, check the solenoid valve.

SOLENOID VALVE (PURGE CONTROL)

Inspection

1. Disconnect the vacuum hoses from the solenoid valve.

2. Verify that no air flows through the valve.

3. Disconnect the solenoid valve connector and supply bat-

tery voltage as shown in the figure.

4. Verify that air flows through the valve.

5. If not as specified, replace the solenoid valve.

SEPARATOR

Inspection

1. Remove the left side trim.

2. Remove the separator.

3. Visually check the separator for damage. Replace it if

necessary.

CHECK VALVE (TWO-WAY)

Inspection

1. Remove the valve.

2. Check the operation of the valve with a vacuum pump.

Apply approx. 37 mmHg (1.46 inHg)

vacuum at port A Airflow

Apply approx. 44 mmHg (1.73 inHg)

vacuum at port B Airflow

Page 408 of 1164

F DECELERATION CONTROL SYSTEM

DECELERATION CONTROL SYSTEM

DESCRIPTION

The dashpot is used to prevent the throttle valve from suddenly closing

03UOFX-185

1

DASHPOT

Inspection

1. Open the throttle valve fully. Push the dashpot rod with a

finger and verify that it goes into the dashpot slowly.

2. Release the rod and check that it comes out quickly.

3. Replace the dashpot if not as specified.

,,

OBUOFX-18

4. Warm up the engine and run it at idle.

5. Connect a tachometer to the diagnosis connector IG-

terminal and increase engine speed to 4,000 rpm.

6. Slowly decrease the engine speed and check that the le-

ver touches the dashpot rod at the specified speed.

Specification:

l B6 ..**.............,....,.............. Approx. 3,000 rpm

l BP SOHC . ..*..................*.... Approx. 2,700 rpm

l BP DOHC . . . . . . . . . . . . . . . . . . . . ...“... Approx. 3,500 rpm

7. If not as specified, loosen the locknut and turn the dashpot

to adjust.

F-l 42

Page 411 of 1164

DECHOKE CONTROL SYSTEM t-

DECHOKE CONTROL SYSTEM

DESCRIPTION

To facilitate starting the engine when the spark plugs become fouled, such as when the engine is flooded,

fuel injection is cut if the throttle valve is held wide open while cranking and the engine coolant temperature

is O°C (32OF) or below. This allows the spark oluas to drv and purges excess fuel from the cylinders.

f-- ECU _

. IGNITION SWITCH (START)

l ENGINE SPEED BELOW 500 rpm ’

l THROTTLE VALVE FULLY OPEN

l ENGINE COOLANT TEMPERATURE ;

BELOW

0% (32°F) I FUEL CUT

OBUOFX-19

I / / ‘ I

SYSTEM OPERATION

1.

2. Check if the engine coolant temperature is below O°C

(32OF).

If the engine coolant temperature is above O°C (32OF), dis-

connect the water thermosensor connector and connect an

approx. 10 kB resistor to the connector.

03UOFX.198 3. Turn the ignition switch to START and verify that the injec-

OBUOFX-19! 3

tor operating sound is heard.

4. Depress the accelerator pedal fully and turn the ignition

switch START. Verify that no injector operating sound is

heard.

F-l 45

Page 413 of 1164

CONTROL SYSTEM F

CONTROLSYSTEM

PREPARATION

SST

49 9200 162

Engine Signal

Monitor

49 HO18 9Al

Self-Diagnosis

Checker

49 GO1 8 904

Sheet For

inspection of

ECU

For

inspection of

oxygen sensor

For

inspection of

ECU 49 GO18 903

Adapter

harness

49 BO19 9AO

System

Selector For

inspection of

ECU

For

inspection of

oxygen sensor

03UOFX-20

F-l 47

Page 415 of 1164

CONTROL SYSTEM F

SMALL TYPE

03UOFX.20:

03UOFX-20

23UOFX-13

TERMINALS

AANDB

c “.w a ,.1/M rrmrrm

_-

03UOFX-201

ENGINE CONTROL UNIT (ECU)

Removal / Installation

1. Remove the side walls (driver’s side and passenger’s side).

(Refer to page S-94.)

2. Remove the bolts and nuts.

3. Disconnect the ECU connectors.

4. Install a

new ECU in the reverse order of removal.

Inspection

1. Disconnect the ECU connectors.

2. Connect the

SSTs (Engine Signal Monitor and Adapt-

er)

to the ECU as shown,

3. Set the SST (Sheet) on the Engine Signal Monitor with

the specified side fancing up as shown.

Note

l MTX...48 PIN

l ATX...84 PIN

4. Measure the voltage at each terminal.

(Refer to pages F-150 to F-167.)

5. If any ECU terminal voltage is incorrect, check the related

input or output devices and wiring. If no problem is found,

replace the ECU. (Refer to above.)

Caution

l Never apply voltage to SST terminals A and B.

F-l 49

Page 434 of 1164

F CONTROL SYSTEM

23UOFX-l! 51

.

r---- - --------1

I

I

i I

I

:,

m7 I

- - -.-

Fc E, Vc Ez 23UOFX-158

WATER THER@OSENSOA

I

03UOFX-21

REPLACE WASHEF

f

OYJOFX-2’

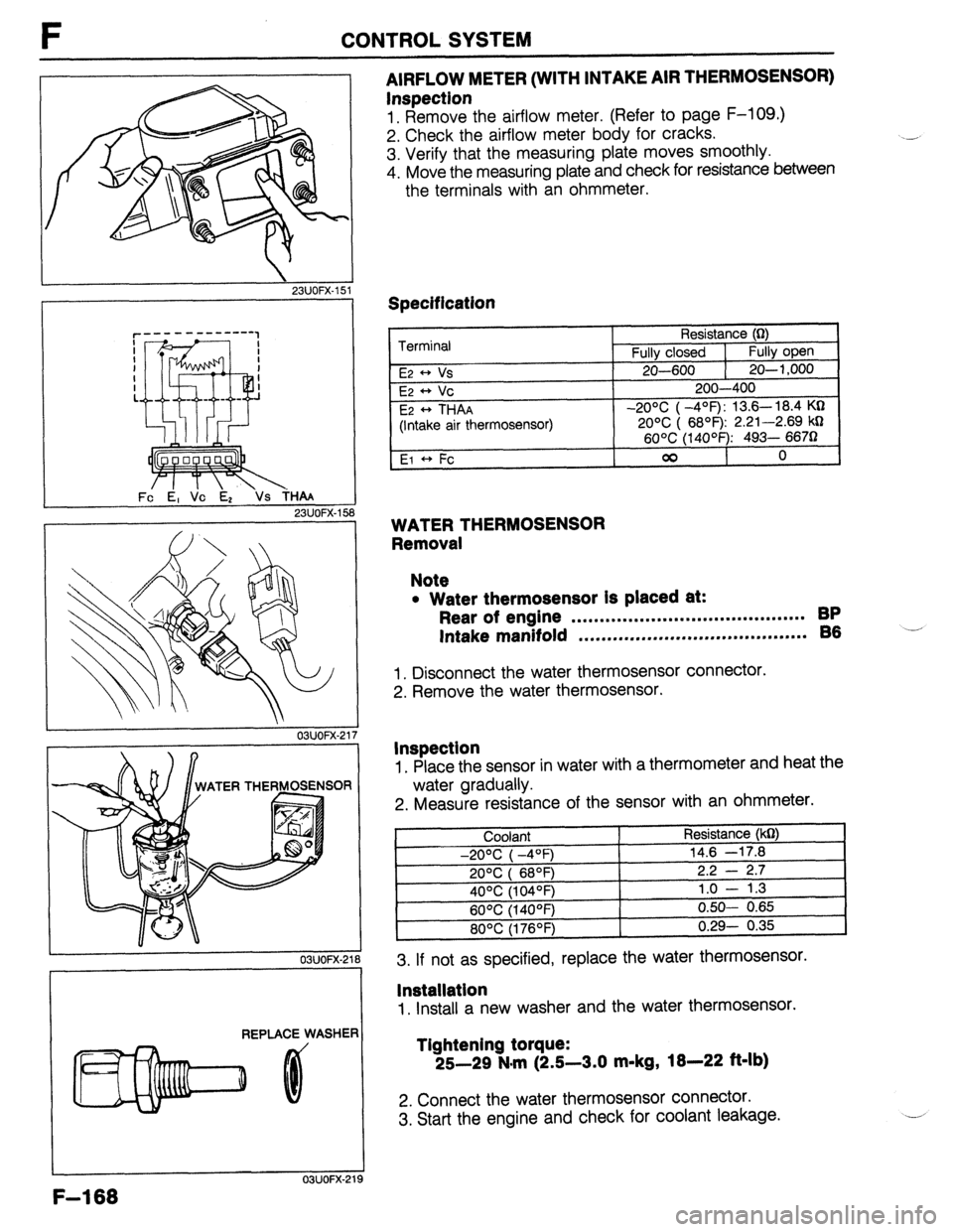

AIRFLOW METER (WITH INTAKE AIR THERMOSENSOR)

Inspection

1. Remove the airflow meter. (Refer to page F-109.)

2. Check the airflow meter body for cracks.

3. Verify that the measuring plate moves smoothly.

4. Move the measuring plate and check for resistance between

the terminals with an ohmmeter.

Specification

Terminal

E2 * Vs

E2 ++ Vc

E2

* THAA

(Intake air thermosensor)

El +, Fc Resistance (0)

Fully closed 1

Fully open

20-600 1 20-l ,000

200-400

-20% ( -4’=F): 13.6- 18.4 KQ

20% ( 6899 2.21-2.69 kD

60°C (14OOF): 493- 6670

00

0

WATER THERMOSENSOR

Removal

Note

l Water thermosensor Is placed at:

Rear of engine . . . . . . . . . . . . . . . . . . . . . . . . ..*.............. BP

Intake manifold ,.*......,..m...,..,.....*....*......... 86 -’

1. Disconnect the water thermosensor connector.

2. Remove the water thermosensor.

Inspection

1. Place the sensor in water with a thermometer and heat the

water gradually.

2. Measure resistance of the sensor with an ohmmeter.

3. If not as specified, replace the water thermosensor.

lnstallatlon

1. Install a new washer and the water thermosensor.

Tlghtening torque:

25-29 N.m (2.5-3.0 m-kg,

18-22 ft-lb)

2. Connect the water thermosensor connector.

3. Start the engine and check for coolant leakage.

F-l 68

Page 437 of 1164

CONTROL SYSTEM F

03UOFX-227

03UOFX-22:

03UOFX-22!

*

03UOFX-231

I

SELF-W CtECXER

WOFX-15

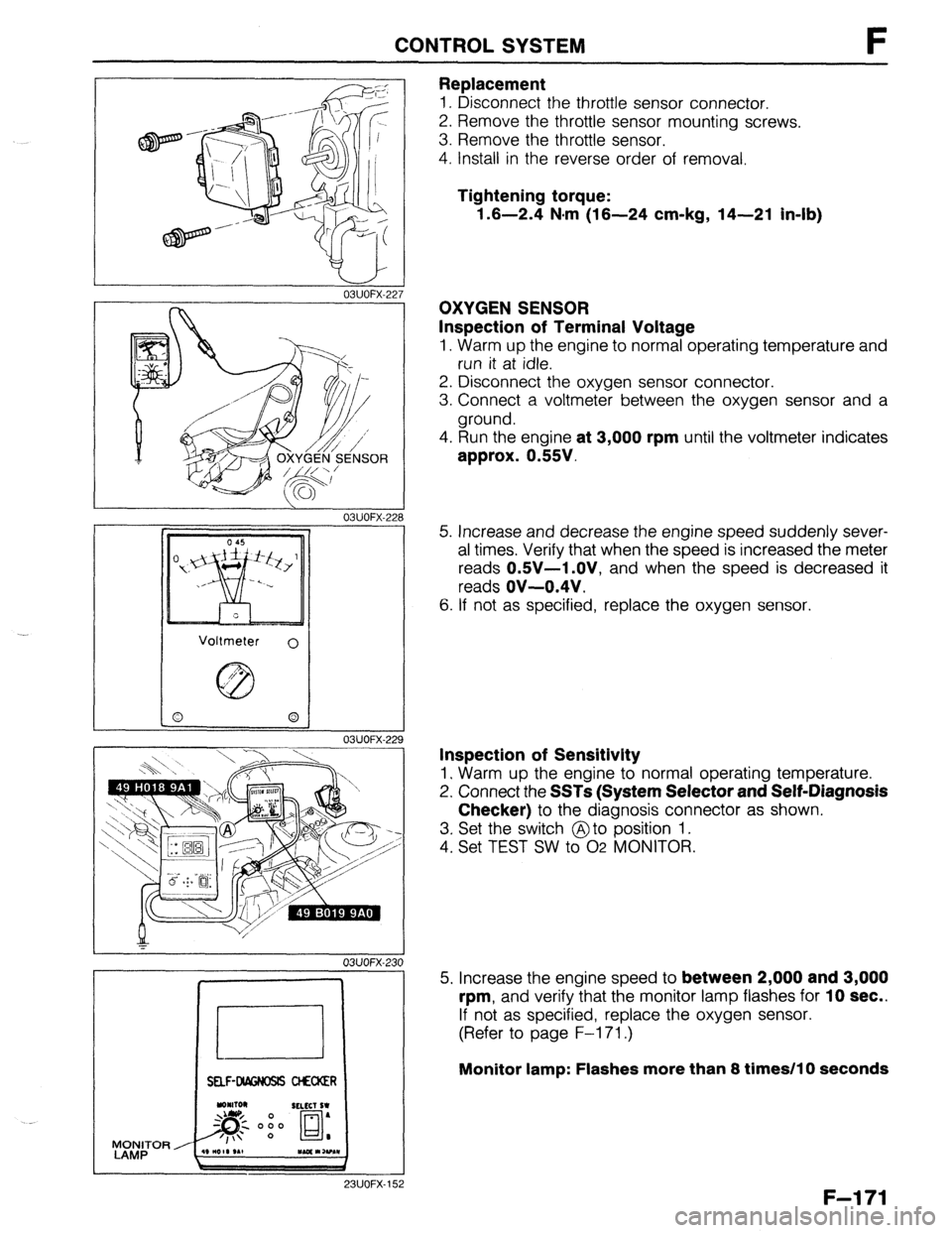

Replacement

1. Disconnect the throttle sensor connector.

2. Remove the throttle sensor mounting screws.

3. Remove the throttle sensor.

4. Install in the reverse order of removal.

Tightening torque:

1.6-2.4 N-m (16-24 cm-kg, 14-21 in-lb)

OXYGEN SENSOR

Inspection of Terminal Voltage

1. Warm up the engine to normal operating temperature and

run it at idle.

2. Disconnect the oxygen sensor connector.

3. Connect a voltmeter between the oxygen sensor and a

ground.

4. Run the engine

at 3,000 rpm until the voltmeter indicates

approx. 0.55V.

5. Increase and decrease the engine speed suddenly sever-

al times. Verify that when the speed is increased the meter

reads

OSV-1 .OV, and when the speed is decreased it

reads

OV-0.4V.

6. If not as specified, replace the oxygen sensor.

Inspection of Sensitivity

1. Warm up the engine to normal operating temperature.

2. Connect the

SSTs (System Selector and Self-Diagnosis

Checker)

to the diagnosis connector as shown.

3. Set the switch @to position 1.

4. Set TEST SW to 02 MONITOR.

5. Increase the engine speed to

between 2,000 and 3,000

rpm,

and verify that the monitor lamp flashes for 10 sec..

If not as specified, replace the oxygen sensor.

(Refer to page F-l 71.)

Monitor lamp: Flashes more than 8 times/l 0 seconds

F-l 71