check engine MAZDA PROTEGE 1992 Manual Online

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 350 of 1164

F SELF-DIAGNOSIS FUNCTION

Troubleshooting

If a service code number is shown on the SST, check for the cause by using the chart related to the code

number shown.

Service code number

CODE LOCATION OF

NO.

MALFUNCTION OUTPUT SIGNAL PATTERN

SELF-DIAGNOSIS FAIL-SAFE

02

Ne-signal

:E nl-u No Ne-signal

-

03 G-signal

(DOHC) No G-signal Cancels 2-group

injection

06* Vehicle speed

sensor ON

OFF No input signal from Shifting performed

vehicle speed normally

sensor

08 Airflow meter ON

OFF Open or short circuit Basic fuel injection

amount fixed as for two

driving modes

(1) Idle switch ON

(2) Idle switch OFF

09 Water

thermosensor ON

OFF Maintains constant 20%

(68OF) command

10 Intake air

thermosensor Maintains constant 20°C

(68OF) command

12

Throttle sensor

“,E l--uL-l Throttle opening judged

as full stroke lockup not

provided

Atmospheric ON Maintains constant

14 pressure sensor command of sea level

(in ECU)

OFF pressure

15 Oxygen sensor

(inactivation) ON

OFF Sensor output

continues less than

0.55V 95 sec. after

engine starts

(1500 rpm) Cancels engine feedback

operation

Oxygen sensor ON Sensor output Cancels engine feedback

17

(Inversion) continues uncharged operatron

OFF 50 sec. after engine

exceeds 1500 rpm

Solenoid valve ON

25 (pressure

regulator)

OFF u 1 nnluln Open or short crrcurt

“If the marked code numbers appeor, refer to Section K

F-84

Page 366 of 1164

SELF-DIAGNOSIS FUNCTION

:ODE No. 17 (Oxygen sensor-lnvarsion)

r t

INSPECTION

Check if same Code No. is present after per-

forming after-repair procedure CT- page F-704

Check monitor lamp of Self-Diagnosis Checker il-

luminate at idle after warming-up engine and

running it at 2,500-3,000 rpm

for 3 minutes

Check for correct fuel line pressure at idle CT page F-129

Fuel line pressure;

265-314 kPa (2.7-3.2 kg/cm2, 38-46 psi)

{Vacuum hose to pressure regulator

disconnected)

4 Check injectors for fuel teakage c3 page F-132

5

Disconnect each high-tension lead at idle and

check if engine speed decreases equally at each

cylinder

Circuit Oiagram

MTX

I ACTION

Yes 1 Go to next step NO

Check oxygen sensor circuit for poor

connection

r3 If OK, perform troubleshooting

Code No.15

a

If not OK, repair or replace con-

nector u page F-98

Yes Go to next step Note

l A/F mixture rich

No

I Go to Step 5 Note

l A/F mixture is lean or misfire

occurring

Yes

I Go to next step No High pressure

Check if fuel return hose is ciogged or

restricted

+ If OK, replace pressure regulator CT page F-130

c3 If not OK, repair or replace

Yes Replace injector

No Check if water thermosensor is OK

ti if OK, Go to Step 11

c3 If not OK, replace water thermo-

sensor c7 page F-168

CT page F-168

Yes

Go to next step No

Go to Step 8

23UOFX-07

OXYGEN SENSOR

I

R/L

ECU

----------h--M

23UOFX-074

F-l 00

Page 368 of 1164

SELF-DIAGNOSIS FUNCTION

:ODE No. 1 25 (SOLENOID VALVE - PRESSUREREGULATORCONTROL)-BPENGINE

r (

TEP

1

-

2

-

3 I

INSPECTION

Disconnect connector from ECU and check if

battery voltage exists at ECU terminal 2T (MTX)

3M (ATX) wire (G/O) with ignition switch ON

In same condition as Step 1, check if battery

voltage exists at solenoid valve connector

terminal-wire (G/O) ACTION

Yes Check ECU terminal connector for poor -

connection

* If OK, replace ECU CT page F-149

+

If not OK, repair or replace connector

No Go to next step

Yes Repair or replace wire (G/O)

No Go to next step

Check if solenoid valve is OK Yes Check for short or open circuit in wiring

w page F-135 from main relay (FUEL INJ relay) to

solenoid valve

No Replace solenoid valve

I I I

23UOFX-077

:ODE No. 26 (SOLENOID VALVE - PURGE CONTROL)

STEP INSPECTION

Disconnect connector from ECU and check if

battery voltage exists at ECU terminal 2X (MTX)

20 (ATX) wire harness (W/L) with ignition switch

ON Yes

No

In same condition as Step 1, check if battery

Yes

voltage exists at solenoid valve connector

terminal-wire (W/L)

No

Check if solenoid valve is OK

Yes

w page F-140

t- No

--

4 ACTION

Check ECU terminal connector for poor

connection

ti If OK, replace ECU c;p page F-149

e

If not OK, repair or replace connector

Go to next step

Repair or replace wire harness (W/L)

Go to next step

Check for short or open circuit in wiring

from main relay (FUEL INJ relay) to

Circuit Diagram

MTX

I-

FROM

BATTERY

FROM

23UOFX-07 9

F-l 02

Page 370 of 1164

F SELF-DIAGNOSIS FUNCTION

23UOFX-08: 3

03UOFX.086

i:a pj

MONITOR

SELECT El

03UOFX-:6

7

I

7

After-repair Procedure

1. Cancel the memory of malfunctions by disconnecting the

negative battery cable for

at least 20 seconds. Reconnect

the negative battery cable.

2. Connect the

SST (System Selector) to the diagnosis con-

nector.

3. Set the switch @to position 1.

4. Set TEST SW to SELF-TEST.

5. Connect the

SST (Self-Diagnosis Checker) to the System

Selector and a ground.

6. Set the select switch of the Self-Diagnosis Checker to posi-

tion A.

7. Turn the ignition switch ON.

8. Start and warm up the engine, then run it at

2,000 rpm for

three minutes.

9. Verity that no code numbers are displayed.

F-l 04

Page 371 of 1164

SELF-DIAGNOSIS FUNCTION F

SWITCH MONITOR FUNCTION

Individual switches can be inspected by the SST (Self-Diagnosis checker).

Note

l The TEN terminal of the diagnosis connector must be grounded and the ignition switch ON

(engine stopped).

l If either of the switches remain activated, the monitor lamp will be illuminated.

ECU

NEUTRAL SWITCH (MTX)

CLUTCH SWITCH (MTX)

=d-’ 1

BATTERY

INHIBITOR SWITCH (ATX)

STOPLIGHT SWITCH (MTX)

HEADLIGHT SWITCH MONITER LAMP

REAR WINDOW (SELF-DIAGNOSIS CHECKER)

DEFROSTER SWITCH

AIC SWITCH

BLOWER SWITCH

THROTTLE SENSOR asp-

- _

COOLING FAN SWITCH

03UOFX

Switch

Clutch switch

Neutral switch (MW

(M-W Self-Diagnosis Checker (Monitor lamp)

Light ON Light OFF Pedal released Pedal depressed

In gear Neutral Remark In gear

Clutch pedal released

Inhibitor switch

(ATX) L, S, D or R range

N or P range -

Throttle sensor Pedal depressed (Not fully) Pedal released/fully depressed -

Stoplight switch

Pedal depressed Pedal released -

Headlight switch

ON

OFF Headlights/parking lights: ON

Blower switch

ON

OFF Blower switch at 2nd or

above position

AIC switch

ON OFF Fan speed control at 1st po-

sition

Rear window defroster

switch ON

OFF -

Water thermoswitch Fan operating Fan not operating -

23UOFX-084

F-l 05

Page 372 of 1164

SELF-DIAGNOSIS FUNCTION

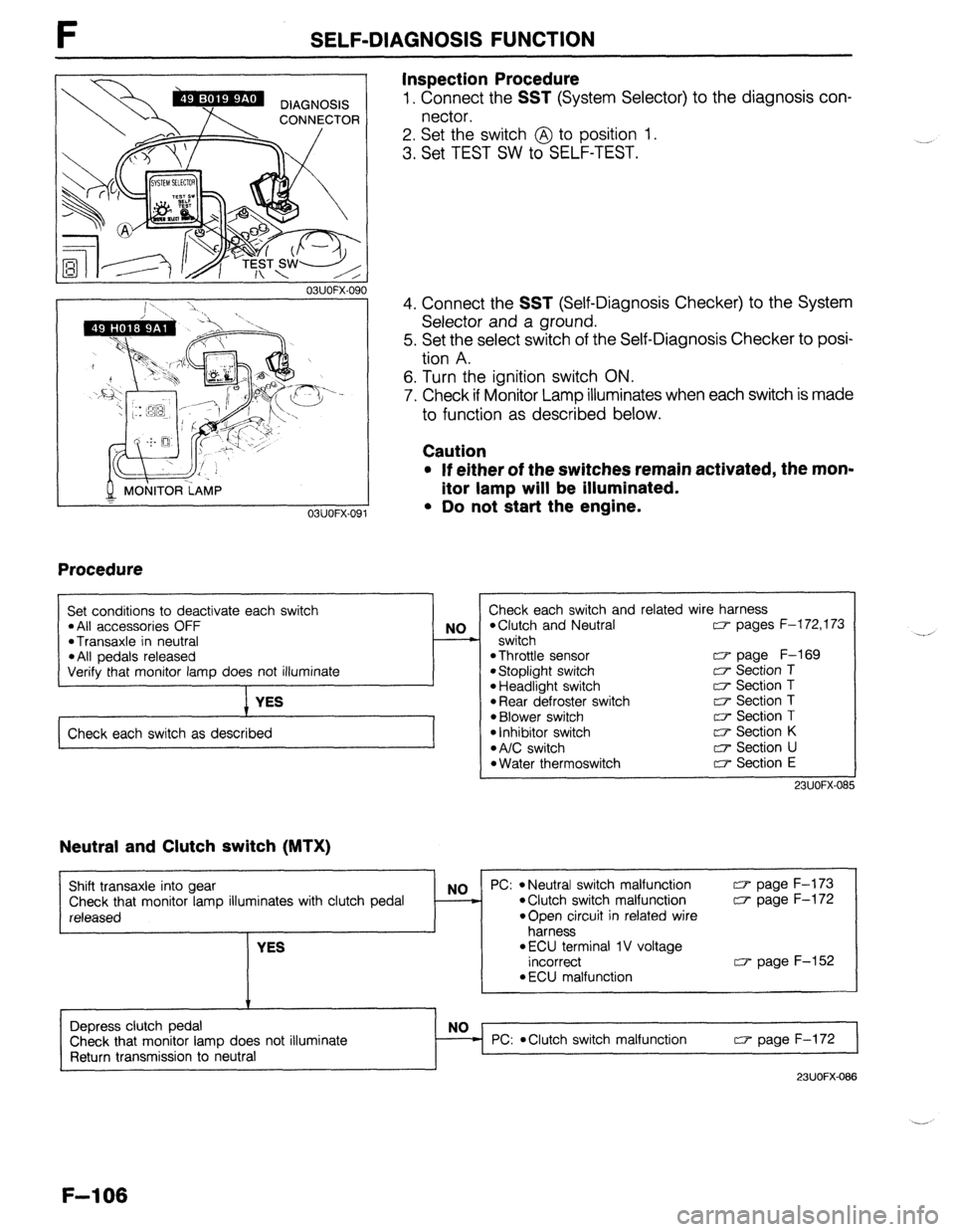

Inspection Procedure

1. Connect the SST (System Selector) to the diagnosis con-

nector.

2. Set the switch @ to position 1.

3. Set TEST SW to SELF-TEST.

03UOFX.090

MONITOR LAMP

T

03UOFX-091

Procedure

4. Connect the SST (Self-Diagnosis Checker) to the System

Selector and a ground.

5. Set the select switch of the Self-Diagnosis Checker to posi-

tion A.

6. Turn the ignition switch ON.

7. Check if Monitor Lamp illuminates when each switch is made

to function as described below.

Caution

* If either of the switches remain activated, the mon-

itor lamp will be illuminated.

l Do not start the engine.

I

I Set conditions to deactivate each switch l All accessories OFF l Transaxle in neutral l All pedals released NO

-

Verify that monitor lamp does not illuminate

YES

Check each switch as described Check each switch and related wire harness

*Clutch and Neutral CT- pages F-l 72,173

switch

*Throttle sensor w page F-169 l Stoplight switch c7 Section T l Headlight switch c7 Section T l Rear defroster switch T;P Section T l Blower switch [r+ Section T

l Inhibitor switch a Section K l A/C switch 0 Section U l Water thermoswitch c7 Section E

23UOFX-OS!

Neutral and Clutch switch (MTX)

Shift transaxle into gear

Check that monitor lamp illuminates with clutch pedal

released

YES NO PC: l Neutral switch malfunction a page F-173 l Clutch switch malfunction w page F-172

*Open circuit in related wire

harness

l ECU terminal 1 V voltage

incorrect w page F-152

l ECU malfunction

Depress clutch pedal

Check that monitor lamp does not illuminate

Return transmission to neutral PC:

*Clutch switch malfunction w page F-172

23UOFX-088

F-l 06

Page 379 of 1164

INTAKE AIR SYSTEM F

I 23UOFX-096

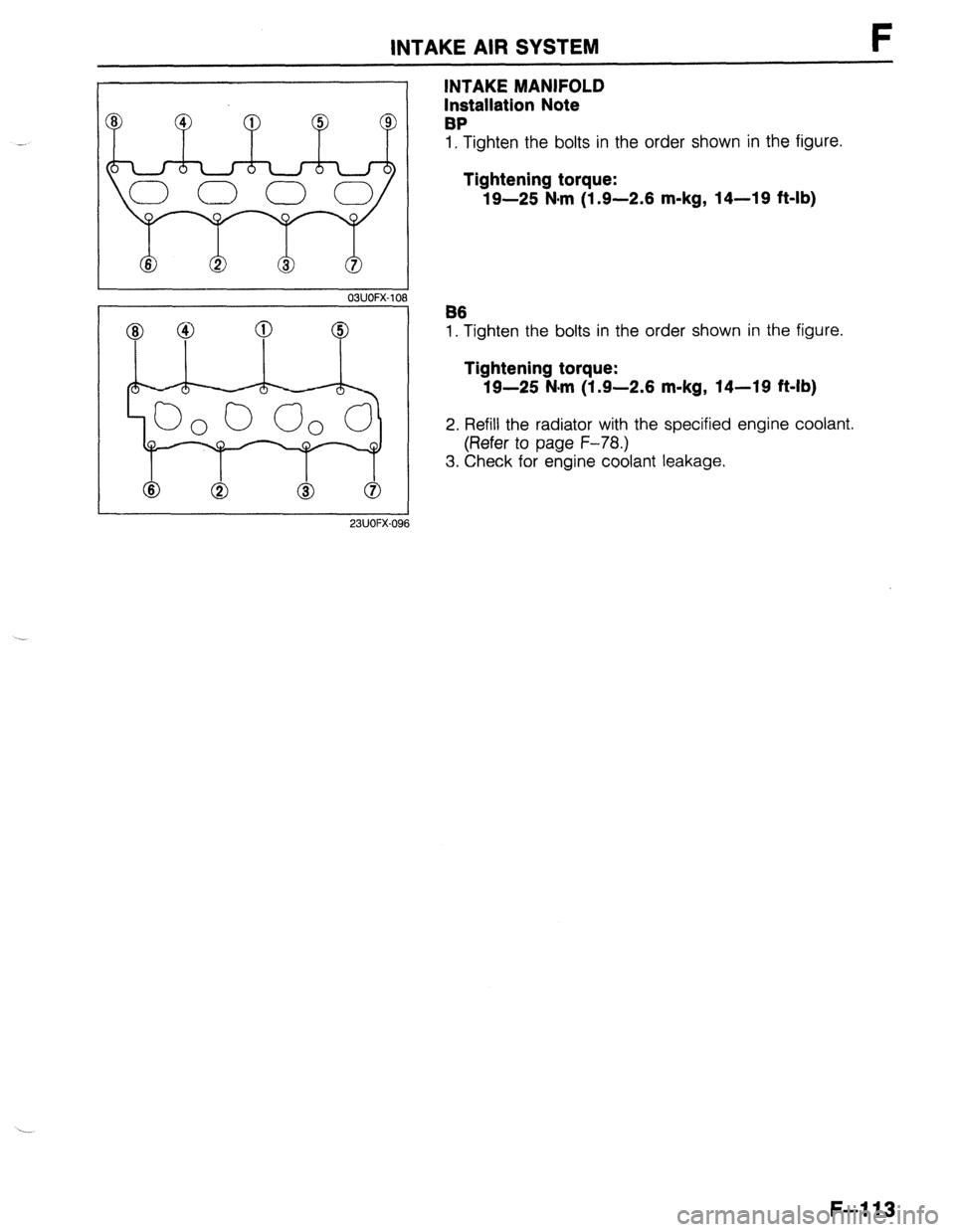

INTAKE MANIFOLD

Installation Note

BP

1, Tighten the bolts in the order shown in the figure.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

B6

1. Tighten the bolts in the order shown in the figure.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

2. Refill the radiator with the specified engine coolant.

(Refer to page F-78.)

3. Check for engine coolant leakage.

F-113

Page 382 of 1164

F IDLE SPEED CONTROL (ISC) SYSTEM

PREPARATION

SST

OBUOFX-113

OSUOFX-I 14

I

23UOFX-095

J 03UOFX-1 lf

23UOFX-101

F-116

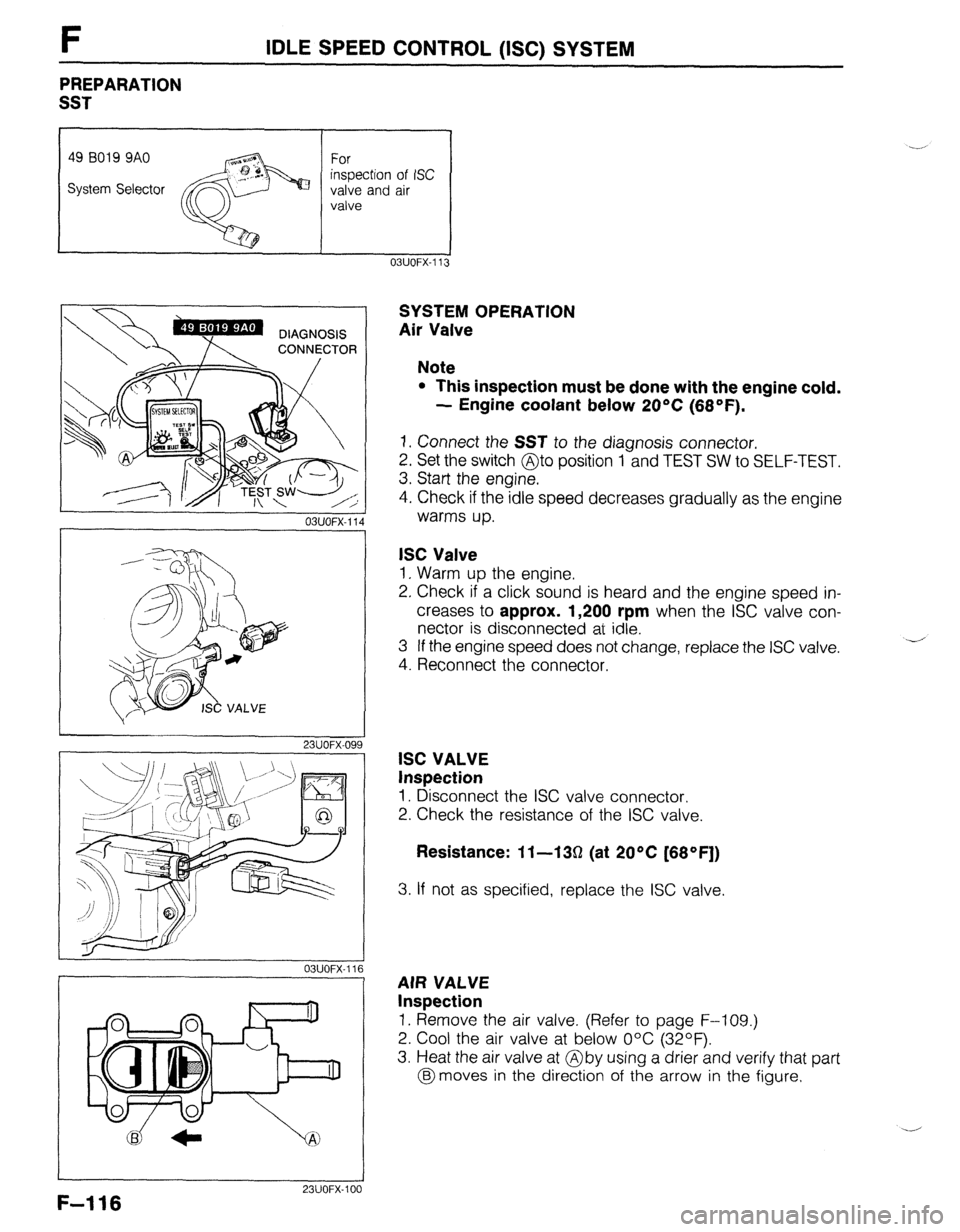

SYSTEM OPERATION

Air Valve

Note

l This inspection must be done with the engine cold.

- Engine coolant below 20°C (68°F).

1. Connect the SST to the diagnosis connector.

2. Set the switch @to position 1 and TEST SW to SELF-TEST.

3. Start the engine.

4. Check if the idle speed decreases gradually as the engine

warms up.

ISC Valve

1. Warm up the engine.

2. Check if a click sound is heard and the engine speed in-

creases to approx. 1,200 rpm when the ISC valve con-

nector is disconnected at idle.

3 If the engine speed does not change, replace the ISC valve.

4. Reconnect the connector.

ISC VALVE

Inspection

1. Disconnect the ISC valve connector.

2. Check the resistance of the ISC valve.

Resistance: 11-130 (at 20°C [68*F])

3. If not as specified, replace the ISC valve.

AIR VALVE

Inspection

1. Remove the air valve. (Refer to page F-109.)

2. Cool the air valve at below O°C (32OF).

3. Heat the air valve at @by using a drier and verify that part

@moves in the direction of the arrow in the figure.

Page 387 of 1164

FUEL PUMP CONNECTOR

/

REAR SEAT C

FUEL SYSTEM F

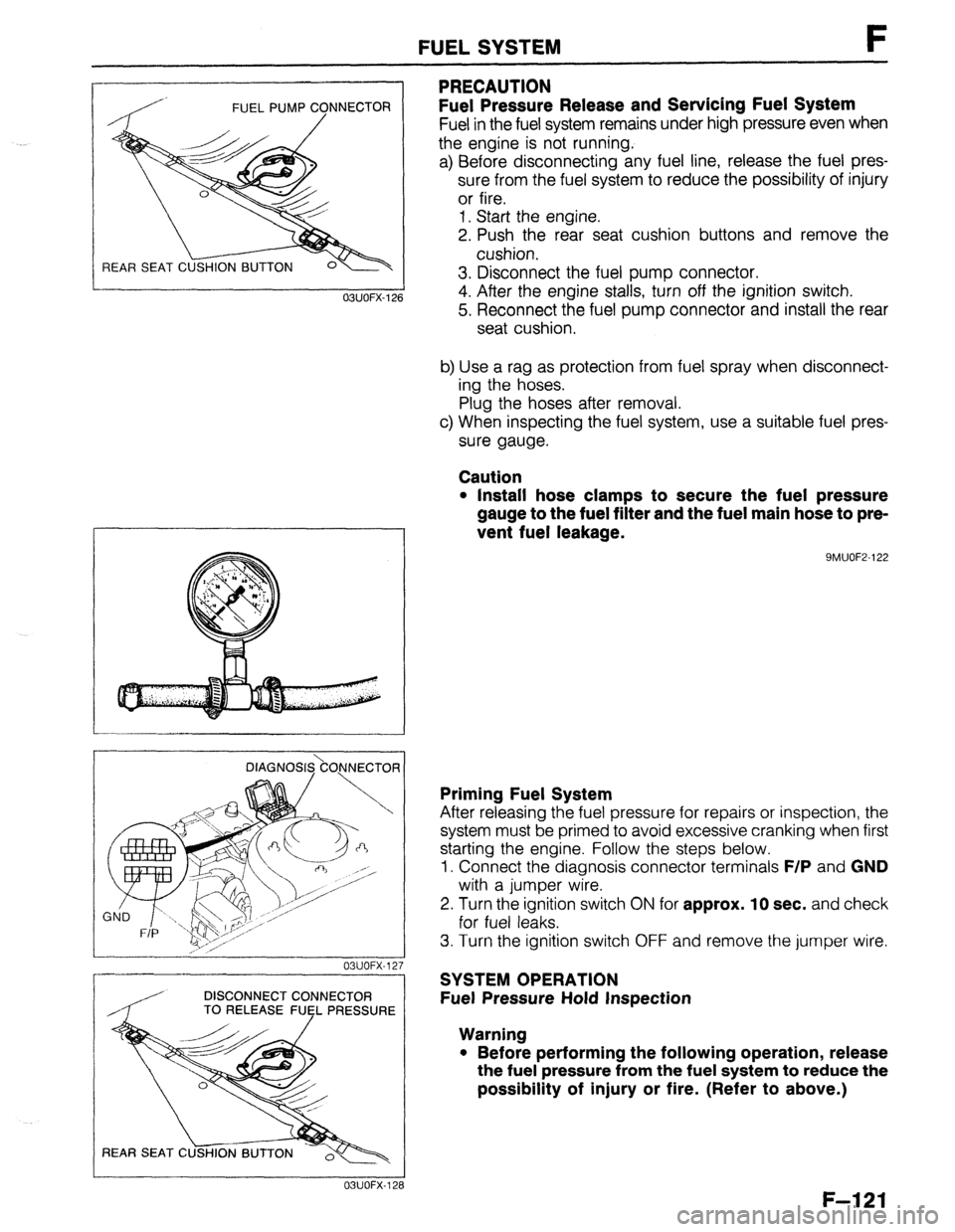

PRECAUTION

Fuel Pressure Release and Servicing Fuel System

Fuel in the fuel system remains under high pressure even when

the engine is not running.

a) Before disconnecting any fuel line, release the fuel pres-

sure from the fuel system to reduce the possibility of injury

or fire.

1. Start the engine.

2. Push the rear seat cushion buttons and remove the

cushion.

3. Disconnect the fuel pump connector.

4. After the engine stalls, turn off the ignition switch.

5. Reconnect the fuel pump connector and install the rear

seat cushion.

b) Use a rag as protection from fuel spray when disconnect-

ing the hoses.

Plug the hoses after removal.

c) When inspecting the fuel system, use a suitable fuel pres-

sure gauge.

Caution

l Install hose clamps to secure the fuel pressure

gauge to the fuel filter and the fuel main hose to pre-

vent fuel leakage.

9MUOF2-122 OBUOFX-126

DlAGNOS&O,NNECTOR

03UOFX-12.

-

DISCONNECT CONNECTOR

/ TO RELEASE FUEL PRESSURE

03UOFX-12;

Priming Fuel System

After releasing the fuel pressure for repairs or inspection, the

system must be primed to avoid excessive cranking when first

starting the engine. Follow the steps below.

1. Connect the diagnosis connector terminals

F/P and GND

with a jumper wire.

2. Turn the ignition switch

ON for approx. 10 sec. and check

for fuel leaks.

3. Turn the ignition switch OFF and remove the jumper wire.

SYSTEM OPERATION

Fuel Pressure Hold Inspection

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to above.)

F-121

Page 395 of 1164

FUEL SYSTEM F

STA

OBUOFX- 15

03UOFX-15

DISCONNECT CONNECTOR

TO RELEASE FUfL PRESSURE

REAR SEAT C

23UOFX-11

INSTALL CLAMPS

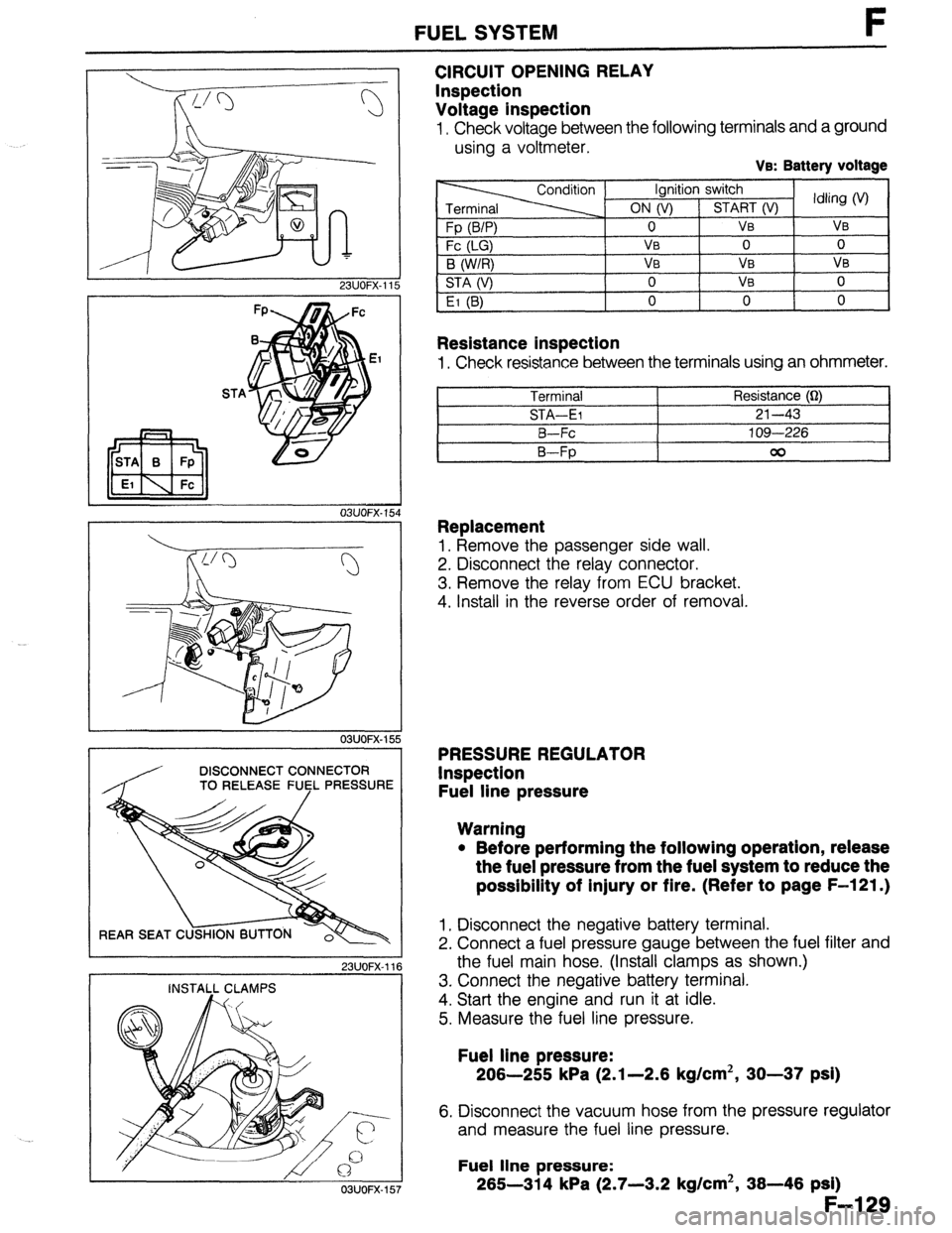

CIRCUIT OPENING RELAY

Inspection

Voltage inspection

I, Check voltage between the following terminals and a ground

using a voltmeter.

Ve: Battery voltage

Resistance inspection

1, Check resistance between the terminals using an ohmmeter.

Terminal Resistance (Q)

STA-El 21-43

B-Fc 109-226

B-Fp 00

Replacement

1, Remove the passenger side wall.

2. Disconnect the relay connector.

3. Remove the relay from ECU bracket.

4. Install in the reverse order of removal.

PRESSURE REGULATOR

Inspection

Fuel line pressure

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F-121.)

1, Disconnect the negative battery terminal.

2. Connect a fuel pressure gauge between the fuel filter and

the fuel main hose. (Install clamps as shown.)

3. Connect the negative battery terminal.

4. Start the engine and run it at idle.

5. Measure the fuel line pressure.

Fuel line pressure:

206-255 kPa (2.1-2.6 kg/cm2, 30-37 psi)

6. Disconnect the vacuum hose from the pressure regulator

and measure the fuel line pressure.

Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm2, 36-46 psi)

F-l 29

03UOFX-157