check engine MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 439 of 1164

CONTROL SYSTEM F

23UOFX-151

WASHER,

REPLACE

9MUOF2-24

05UOFX-25

9MUOF2-24

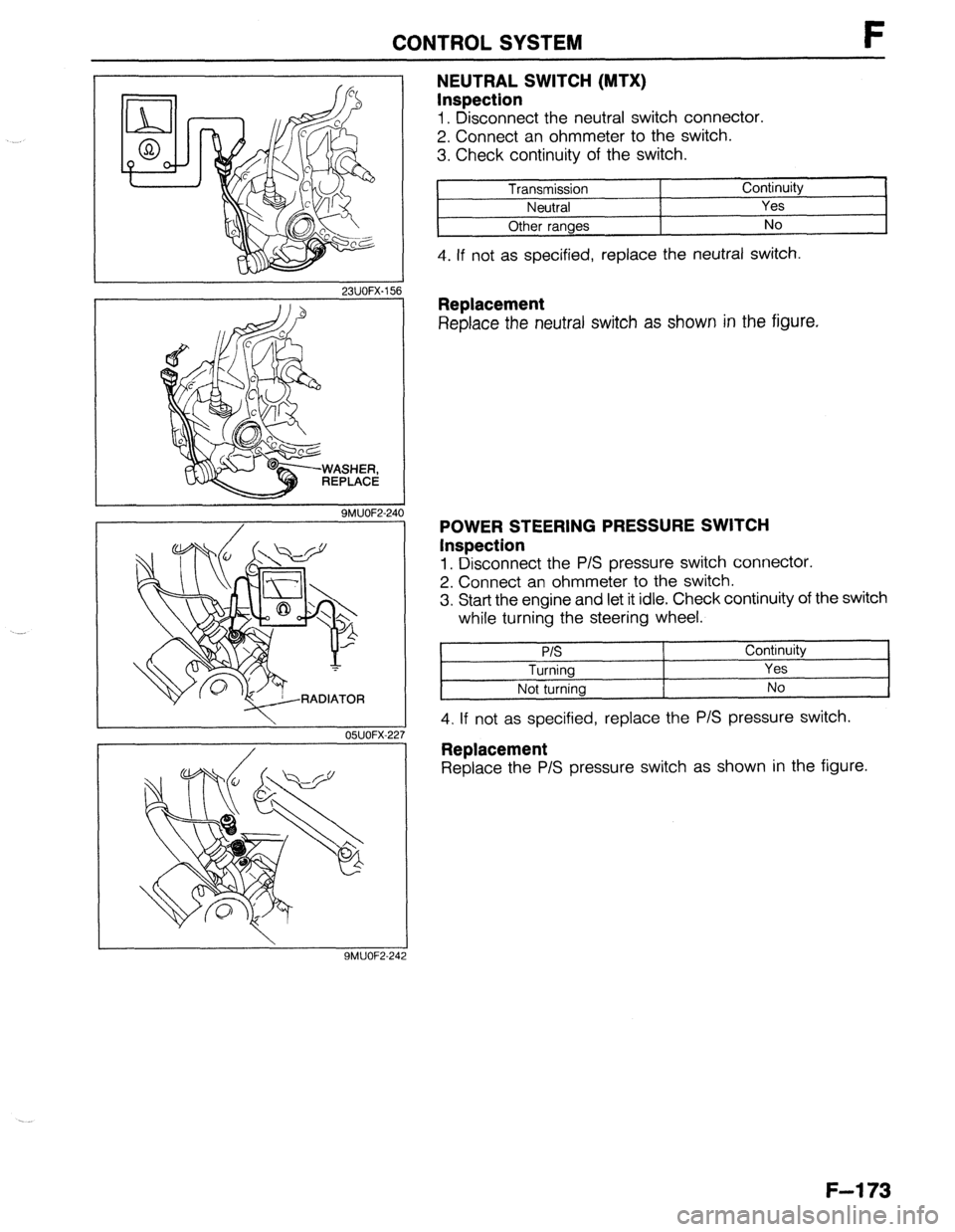

NEUTRAL SWITCH (MTX)

Inspection

1. Disconnect the neutral switch connector.

2. Connect an ohmmeter to the switch.

3. Check continuity of the switch.

Transmission Continuity

Neutral Yes

Other ranges No

4. If not as specified, replace the neutral switch.

Replacement

Replace the neutral switch as shown in the figure.

POWER STEERING PRESSURE SWITCH

Inspection

1. Disconnect the P/S pressure switch connector.

2. Connect an ohmmeter to the switch.

3. Start the engine and let it idle. Check continuity of the switch

while turning the steering wheel.

P/S

Turning

Not turning Continuity

Yes

No

4. If not as specified, replace the P/S pressure switch.

Replacement

Replace the P/S pressure switch as shown in the figure.

F-l 73

Page 444 of 1164

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

DIAGNOSTIC INDEX

No. Troubleshooting items

Page

1

Will not crank-starter motor does not operate G-4

2

Will not crank-starter motor spins G-4

3

Cranks slowly G-5 4

Alternator warning lamp illuminates when engine running

G-5

5 Discharged battery G-5

6

Misfire

G-5

03UOGX-004

SYMPTOM TROUBLESHOOTING -

1

iTEl

1

2

3 Will not crank-Starter motor does not operate

INSPECTION

T

Check if engine cranks with fully charged battery

Check if battery voltage is applied at B terminal

TERMINAL

battery voltaae is aoolied at S terminal

when clutch pedal depressed (MTX) and ignition

switch in START position

S TERMINAL

Yes

No

Yes ACTION Check charging system CT- page G-7

Go to next step

Go to next step

No Check wire harness

Yes

l Check magnetic switch l Check field coil l Check armature

No

l Check starter interlock switch (MTX) ccp: page G-31 l Check inhibitor switch (ATX) c=p Section K l Check ignition switch CI Section T l Check wire harness

1 L-T page G-28

CT- page G-29

CT- page G-29

23UOGX.001

03UOGX-006

G-4

Page 445 of 1164

TROUBLESHOOTING GUIDE G

3 Cranks slowly

STEP INSPECTION ACTION

1 Check if engine cranks normally with fully Yes Check charging system CT page G-7

charged battery

No Go to next step

2 Check starter cable connection for looseness Yes Repair or replace connection

and corrosion

OBUOGX-OC

I 1 4

.

Alternator warning lamp illuminates when engine running

STEP INSPECTION ACTION

1 Check for correct battery voltage at idle Yes Check wire harness between alternator L terminal and aI*

Specification: 14.1--14.7V ternator warning lamp

No Check charging system w page G-7

03UOGX-008

5 I Discharged battery I 1TEP INSPECTION

f Check charging system w page G-7 -

6

TEF

1

r

--

Yes

03UOGX-009

ACTION

Turn ignition switch ON and check dark current as shown

Dark current: Below 20mA

No Repair or replace parts as necessary 1

Misfire

INSPECTION

-

Disconnect high-tension lead from each spark

plug and check for strong blue spark while

cranking

, i

Yes

No T-

I

ACTION

- Check spark plug w page G-f8

~3 If OK, engine electrical system normal

~3 If not OK, clean or replace spark plug

Check ignition system ci’ page G-16

1 03UOGX-010

G-5

Page 447 of 1164

CHARGING SYSTEM G

TROUBLESHOOTING

INSPlhdN

ACTION

1

Check battery voltage Yes Go to next step Specification: Above 12.4V

No

Check battery ri-page G-8

2 Start engine and check if alternator warning

Yes Go to Step 4

lamp goes out

No Go to next step

3 Check if voltages at alternator terminals are Yes Check wire harness between battery and terminal B

3. Turn all electrical loads ON and depress

2,500-3,000 rpm

l Do not ground terminal B

G-7

Page 449 of 1164

CHARGING SYSTEM G

RUB

PRO

03UOGX-01

Terminal and cable

1. Check the tightness of the terminals to ensure good electri-

cal connections.

2. Check for corroded or frayed battery cables.

3. Check the rubber protector on the positive terminal for prop-

er coverage.

4. Clean the terminals if necessary, and coat them with grease.

Recharging

Battery

55D23L Slow charge Quick charge

(A) (4

Under 6 Max. 20

Slow charging

It is not necessary to remove the vent caps to perform a slow

charge.

Quick charging

Remove the battery from the vehicle and remove the vent caps

to perform a quick charge.

Warning

l Before performing maintenance or recharging the

battery, turn off all accessories and stop the engine.

l The negative cable must be removed first and in-

stalled last.

l Set the battery in water when quick charging to pre-

vent overheating the battery.

G-9

Page 456 of 1164

G IGNITION SYSTEM

TROUBLESHOOTING

iTEP

INSPECTION

ACTION

1

Check if MIL illuminates when engine is running Yes Check for malfunction code number

and perform troubleshooting (TEN ter-

minal grounded) c7 Section F

No Go to next step

2 Drsconnect high-tension lead from distributor and

Yes

check for strong blue spark while cranking en-

l Check distributor cap and rotor v page G-22

gine * Check high-tension lead

KP page G-19 c7 page G-17

+ Ignition system normal

No

Go to next step

3 Check if resistance of ignition coil is OK

Yes

Go to next step ~7

page G-19

Specification (at 20°C [66”9):

Primary coil winding: 0.81-0.99Q No

Replace ignition coil

Secondary coil winding: IO-16 kQ

-i

Check if resistance of high-tension leads is OK Yes Go to next step

D= page G-17

Specification: 16 kQ per 1 m (3.28 ft)

No Replace high-tension lead

5 Check if igniter is OK

m- page G-23 Yes

Replace ECU

No

Replace igniter

03UOGX-03

G-16

Page 457 of 1164

IGNITION SYSTEM G

r

03UOGX-03

SOHC

LOCK BOLTS

DOHC

A LOCK BOLTS I 03UOGX-0’

03UOGX-C

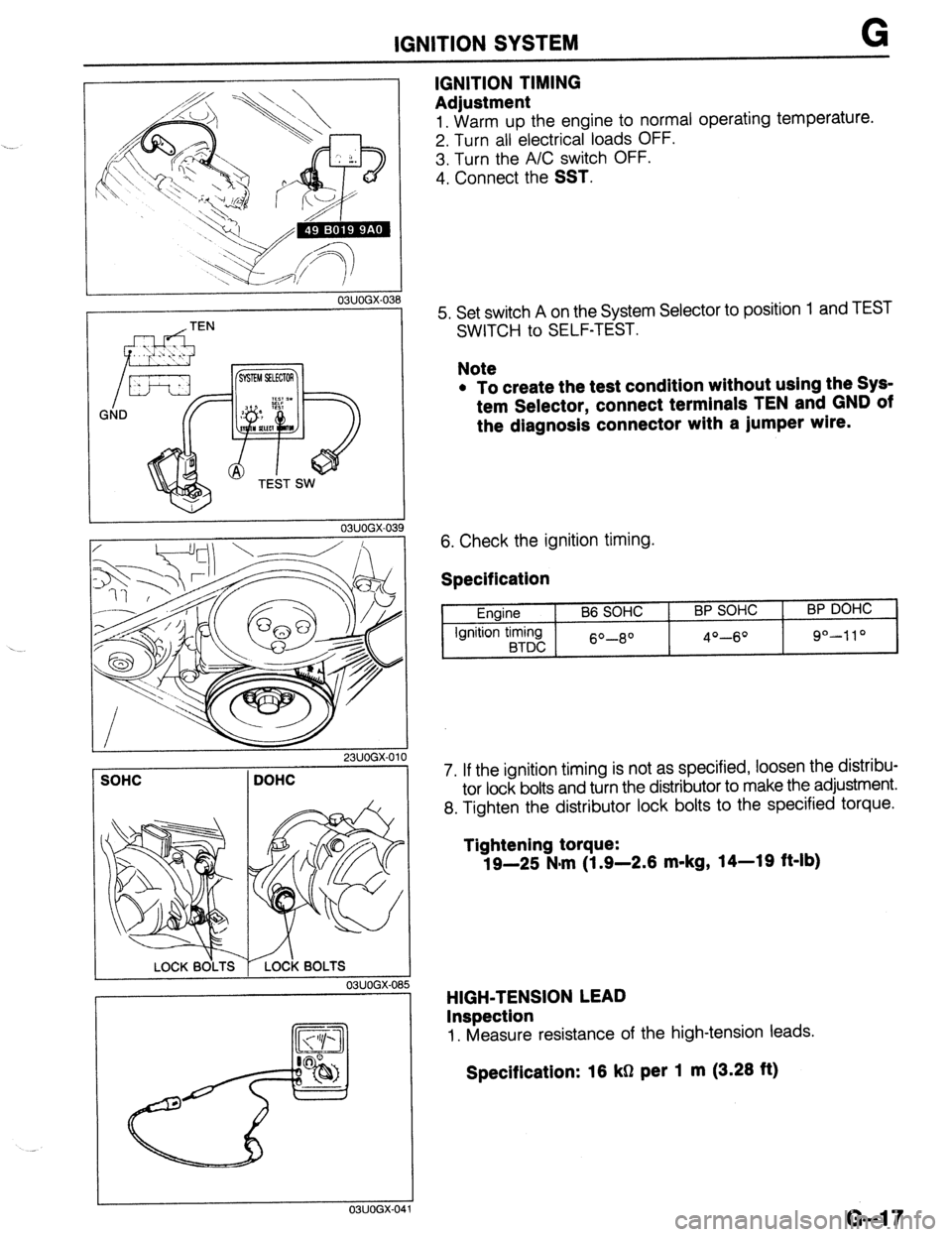

IGNITION TIMING

Adjustment

1. Warm UD the enaine to normal operating temperature.

2. Turn all ‘electricarloads OFF.

3. Turn the A/C switch OFF.

4. Connect the

SST.

5. Set switch A on the System Selector to position

SWITCH to SELF-TEST. 1 and TEST

Note

l To create the test condition without using the Sys-

tem Selector, connect terminals TEN and GND of

the diagnosis connector with a jumper wlre.

6. Check the ignition timing.

Specification

Engine

Ignition timing

BTDC B6 SOHC BP SOHC

60-8O 4O-6O

BP DOHC

9°-110

7. If the ignition timing is not as specified, loosen the distribu-

tor lock bolts and turn the distributor to make the adjustment.

8. Tighten the distributor lock bolts to the specified torque.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

HIGH-TENSION LEAD

Inspection

1. Measure resistance of the high-tension leads.

Specification: 16 kg per 1 m (3.26 ft)

G-l 7

Page 458 of 1164

G IGNITION SYSTEM

-.-.. .----___ 03UOGX-042

03UOGX-04

--.---- J

03UOGX-044

WEAR AND CARBON

/

c- -BURNT

PLUG GAP

L--

c

DAMAGE AND

,llllll....*llll,lllf DETERIORATIOF

; -,DAMAGE

03UOGX.04

G-18

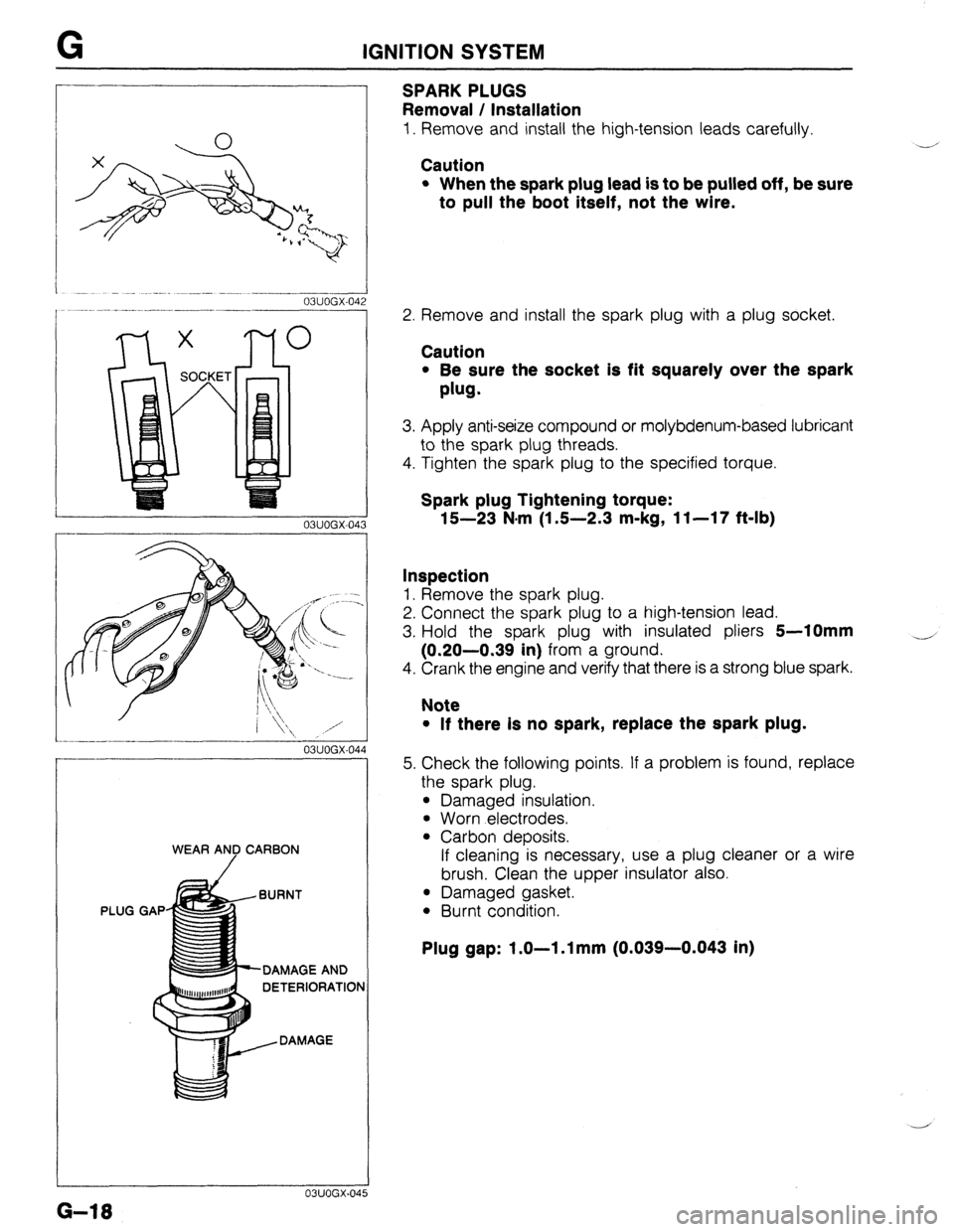

SPARKPLUGS

Removal / Installation

1. Remove and install the high-tension leads carefully.

Caution

l When the spark plug lead is to be pulled off, be sure

to pull the boot itself, not the wire.

Y’

2. Remove and install the spark plug with a plug socket.

Caution

l Be sure the socket is fit squarely over the spark

plug.

3. Apply anti-seize compound or molybdenum-based lubricant

to the spark plug threads.

4. Tighten the spark plug to the specified torque.

Spark plug Tightening torque:

15-23 N.m (1 S-2.3 m-kg, 11-17 f&lb)

Inspection

1. Remove the spark plug.

2. Connect the spark plug to a high-tension lead.

3. Hold the spark plug with insulated pliers

5-10mm

(0.20-0.39 in) from a ground.

4. Crank the engine and verify that there is a strong blue spark.

4

Note

l If there Is no spark, replace the spark plug.

5. Check the following points. If a problem is found, replace

the spark plug.

l Damaged insulation.

l Worn electrodes.

l Carbon deposits.

If cleaning is necessary, use a plug cleaner or a wire

brush. Clean the upper insulator also.

l Damaged gasket.

l Burnt condition.

Plug gap: 1.0-l .l mm (0.039-0.043 in)

Page 459 of 1164

IGNITION SYSTEM . . . ._,

03UOGX-04

Lszl /

P

0 V

- 23UOGX-OC

03UOGX-048

03UOGX-04

03UOGX-0%

IGNITION COIL

Inspection

Spark test

1. Disconnect the high-tension lead from the distributor.

2. Hold it with insulated pliers 5-l

Omm (0.20-0.39 in) from

a ground.

3. Crank the engine and verify that a strong blue spark is

visible.

4. If there is no spark, disconnect the connector from the igni-

tion coil and check for voltage at the positive (+) terminal

of the connector with the ignition switch in the ON position.

Specification: Battery voltage

5. If there is no voltage, check the main fuse, ignition switch,

and wire harness.

Primary coil winding

1. Use an ohmmeter and measure resistance of the primary

coil winding. If not within specification, replace the coil.

Prlmary coil resistance: 0.81-0.99112 (at 2O*C [88*F])

Secondary coil winding

1. Use an ohmmeter and measure resistance of the secon-

dary coil winding. If not within specification replace the coil.

Secondary coil resistance: lo-18 kQ (at 20°C [68*F])

Insulation of case

1. Use a 500V megger tester to measure the insulation resis-

tance between each terminal and the case.

Speclficatlon: 10 MS1 min.

G-19

Page 470 of 1164

G STARTING SYSTEM

1 03lJOGX.079

23LJOGX-011

I I OBUOGX-081

3. Place the armature on V-blocks, and measure the runout

with a dial indicator.

If the runout is not within specification, repair it with a lathe

or replace the armature.

Runout: 0.05mm (0.002 in)

Maximum: O.lmm (0.004 in)

4. Replace the armature if the outer diameter of the commu-

tator is almost at or less than the grind limit.

5. If the commutator surface is dirty, wipe it with a cloth; if it

is rough, repair it with a lathe or fine sandpaper.

Engine

Grind limit mm (in) 1 B6 1 BP (MTX) 1 BP (ATX)

31.4 (1.24) 1 28.8 (1.13)

6. Segment groove depth

If the depth of the mold between segments is almost at or

less than the minimum, undercut the grooves to the stan-

dard depth.

Depth: OS-0.8mm (0.02-0.03 in)

Minimum: 0.2mm (0.008 in)

Bearing (if equipped)

1. Check for abnormal noise, looseness, or sticking.

2. Replace the bearing(s) if necessary.

I

03UOGX-082

G-30