lock MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 676 of 1164

P CONVENTIONAL BRAKE SYSTEM

Removal / Inspection / Installation

1. Remove in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary.

3. install in the reverse order of removal.

4. After installation, check and adjust the pedal height and free play if necessary.

r

20-34 (2.0-3.5, 14-25)

N-m (m-kg, ft-lb)

23UOPX-01

1. Cotter pin

2. Clevis pin

3. Nut

4. Lock washer

5. Bolt 6. Return spring 9. Bushing

Inspect for wear and damage Inspect for wear

7. Pedal 10. Bushing

Inspect for bending and Inspect for wear

damage 11. Pad

8, Pedal pipe Inspect for wear

MASTER CYLINDER

Removal / Installation

1. Remove in the order shown in the figure, referring to Removal Note.

2. Install in the reverse order of removal, referring to Installation Note.

3. After installation. add brake fluid. bleed air, and check for fluid leakage.

1.3-2.2, 9.4-16)

9.6-16 (1.0-1.6, 7.2-12)

13-22 (1.3-2.2, 9.4-l

N.m (m-kg, ft-lb)

23UOPX-01

1. Connector 4. Nut and washer

2. Brake pipe 5. Master cylinder

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page P-i 1 Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . . page P-l 1

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . . page P-l 1 Disassembly / Assembly /

3. Hose (MTX) Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page P-l 2

P-l 0

Page 677 of 1164

CONVENTIONAL BRAKE SYSTEM P

03UOPX-02,

4

ADJUSTING BOLT

‘ ’

I ’ “-

03UOPX-025

r

03UOPX-02

6

ir

23UOPX.OC

OWOPX-028

Removal note

Brake pipe

Disconnect the brake pipe from the master cylinder with the

SST.

Caution

l Do not allow the brake fluid to get on painted sur-

faces. If it does, wlpe it off immediately.

Installation note

Master cylinder

Piston to push rod clearance

Before installing the master cylinder, check the clearance be-

tween the piston of the master cylinder and the push rod of

the power brake unit as follows.

1. Place the

SST atop top of the master cylinder. Turn the ad-

justing bolt until it bottoms in the push rod hole in the piston.

2. Apply 500

mmHg (19.7 in-Hg) vacuum to the power brake

unit with a vacuum pump.

3. Invert the adjustment gauge used in Step 1 and place it on

the power brake unit.

4. Measure the clearance between the end of the gauge and

the push rod of the power brake unit. If it is not

Omm (0

in),

loosen the push rod locknut and turn the push rod to

make the adjustment.

Note

l By making the above adjustment, the clearance be-

tween the push rod and piston (after Installation of

the brake master cylinder and the power brake unit)

will be as shown in the table below.

Push rod-to-piston clearance

When vacuum applied to unit is

0 mmHg (0 inHg) 0.4-0.6mm (0.016-0.024 in)

I

When vacuum applied to unit is

approx. 500 mmHg (19.7 inHg)

I O.l-0.4mm (0.004-0.016 in)

Brake pipe

1. Tighten the brake pipe flare nut with the SST.

Tightening torque:

13-22 N,m (1.3-2.2 m-kg, 9.4-16 ft-lb)

P-l 1

Page 689 of 1164

CONVENTIONAL BRAKE SYSTEM

REAR BRAKE (DISC)

Quick Inspection, On-vehicle

Disc pad

1. Jack up the rear of the vehicle and support it with safety

stands.

2. Remove the wheels.

3. Verify that the remaining thickness of the pads.

Thickness: l.Omm (0.04 in) min.

1 SUOPX-011

Replacement

Disc pad

1. Remove in the order shown in the figure, referring to Removal Note.

2. Install in the reverse order of removal, referring to Installation Note.

12-16 (1.2-l .6, 6.7-l 2

N.m (m-kg, &lb)

,,?I lftPY.rl17

1. Screw plug

2. Manual adjustment gear

Removal Note, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Below

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . . page P-24 _.,--. ,. ., . .

4. M-spring

5. Disc pad assembly

Inspection . , . , , . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . page P-25

6. Shim

3. Lock bolt 7. Guide plate

Removal note

Manual adjustment gear

Turn the manual adjustment gear counterclockwise with an

Allen wrench to pull the brake caliper piston inward. (Turn until

it stops)

03UOPX-062

P-23

Page 690 of 1164

CONVENTIONAL BRAKE SYSTEM

Installation note

Manual adjustment gear

1. Turn the manual adjustment gear clockwise until the brake

pads just touch the disc pIaTe.

2. Return the manual adjustment gear l/3-turn

Removal / Installation

Caliper

1. Jack up the rear of the vehicle and support it with safety stands.

2. Remove the wheels.

3. Remove in the order shown in the figure, referring to

Removal Note.

4. Install in the reverse order of removal, referring to Installation Note.

5. Tighten all nuts and bolts to the specified torques, referring to the figure.

@ 22-29 (2.2-3.0, 16-22)

23-30 (2.2-3.1, 16-

N.m (m-kg, R-lb)

23UOPX-00

1. Parking cable 7. Caliper

Removal I Inspection / Disassembly / Inspection /

Installation . . . . . . . . . . . . . . . . . . . . . . ,.,........ page P-32 Assembly ,.....*........................... page P-26

2. Connecting bolt 8. Disc pad assembly

3. Brake hose Replacement ,...,.,.,.,........*........... page P-23

4. Screw plug Inspection . . . . . . . ..*......................... page P-25

5. Manual adjustment gear 9. Bolt

Removal Note . . . . . . . . . . . . . . . ,,..,.,....... page P-23 10. Mounting support

Installation Note ,....,.,..,.,...,., ,...,., page P-24 11, Disc plate

6. Lock bolt Inspection .,...........*..................... page P-25

After installation:

(1) Add brake fluid and bleed air. (Refer to page P-6.)

(2) Adjust the parking brake lever stroke. (Refer to page P-31 .)

(3) Depress the brake pedal a few times and check that the rear brakes do not drag excessively while

rotating the wheel by hand.

P-24

Page 692 of 1164

P CONVENTIONAL BRAKE SYSTEM

CALIPER

Disassembly / Inspection / Assembly

Caution

l Replace the caliper assembly if a problem is found.

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

2. Inspect all parts and repair or replace as necessary.

3. Assemble in the reverse order of disassemblv, referrina to

Assembly Note.

(3.7-5.5, 27-40)

5.9~Sh N-m

REPLACE (60-90 cm-kg, 52-78 in-lb)

@ REPLACE

N-m (m-kg, Mb)

23UOPX-01

1. Dust seal 8. Piston seal

Inspect for damage and poor sealing Disassembly Note . . . . . . . . . . . . . . . . . . . . . . .

page P-22

2. Piston 9. Spring

Disassembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Below 10. Operating lever

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page P-27 11. Boot

Inspect for wear and rust

3. Manual adjustment gear

4. Snap ring

5. Adjusting bolt

6. O-ring

7. Connecting link 12. Rubber cup and bleeder screw

13. Boot

14. Boot

15. Caliper body

Inspect for damage and cracks

Dlsassembly note

Piston

1. Turn the adjustment gear clockwise with an Allen wrench

to remove the piston from the adjustment gear. (Turn the

adjustment gear until it becomes easy to turn.)

Page 693 of 1164

CONVENTIONAL BRAKE SYSTEM

03UOPX-07

Assembly note

Piston

Insert the piston into the caliper and turn the adjustment gear

counterclockwise with an Allen wrench to pull the piston in-

ward. (Turn until it stops.)

P-27

Page 694 of 1164

P CONVENTIONAL BRAKE SYSTEM

REAR BRAKE (DRUM)

Quick Inspection, On-vehicle

1. Jack up the rear of the vehicle and support it with safety

stands.

2. Remove the wheels.

3. Remove the brake drum. (See below)

4. Verify the remaining thickness of the lining.

Thickness: l.Omm (0.04 in) min.

I

1 BUOPX-017

Removal / Inspection / Installation

1. Remove the lining in the order shown in the figure, referring to Removal Note.

2. Install in the reverse order of removal, referring to Installation Note.

(18.0-24.0, 130-l 74)

N-m (m-kg, R-lb)

371 InPx-fll’

--_-. ,. -. 9

1. Screw

2. Brake drum

Inspection.. . . . . . . . page P-29

Installation Note

. . . . . . . . . . . . . . . . . . . . . . . page P-29

3. Return spring

4. Hold pin and spring

5. Anti-rattle spring

6. Brake shoe (leading side)

Inspection . . . . . . . . . . . . . . Above 7. Brake shoe (trailing side)

Inspection . . . . . . . . . . . . . . . . Above

8. Stopper spring and clip

9. Return spring

10. Parking brake cable

11. Operating lever assembly

12. Brake pipe

Removal Note . . page P-29 13. Bolt

14. Wheel cylinder

Disassembly I Inspection /

Assembly . . . . . . . page P-30

15. Wheel cylinder gasket

16. Hub cap

17. Locknut

18. Wheel hub

19. Backing plate

P-28

Page 699 of 1164

PARKING BRAKE SYSTEM

PARKING BRAKE LEVER

Removal / Inspection / Installation

Caution

l Install the parking brake switch so that it contacts the parking brake lever when the lever is

fully released.

l Turn the ignition switch ON, and check that the parking brake warning lamp illuminates with

the lever pulled one notch.

1. Block the wheels firmly.

2. Release the parking brake.

3. Remove in the order shown in the figure.

4. Inspect all components and parts, Replace parts if necessary.

5. Install in the reverse order of removal.

6. After installation: Adiust the parking lever stroke. (Refer to paae P-31 .)

N.m (m-kg, R-lb)

23UOPX.022

1. Rear console 5. Parking brake switch

Removal / Installation . . . . . . . . . . . . . . . . . . . . . Section

S 6. Parking brake cap

2. Adjusting nut 7. Release button

3. Bolt 8. Parking lever spring

4. Parking brake lever assembly 9. Parking brake lever

Inspect for damage and wear

P-33

Page 713 of 1164

WHEEL ALIGNMENT

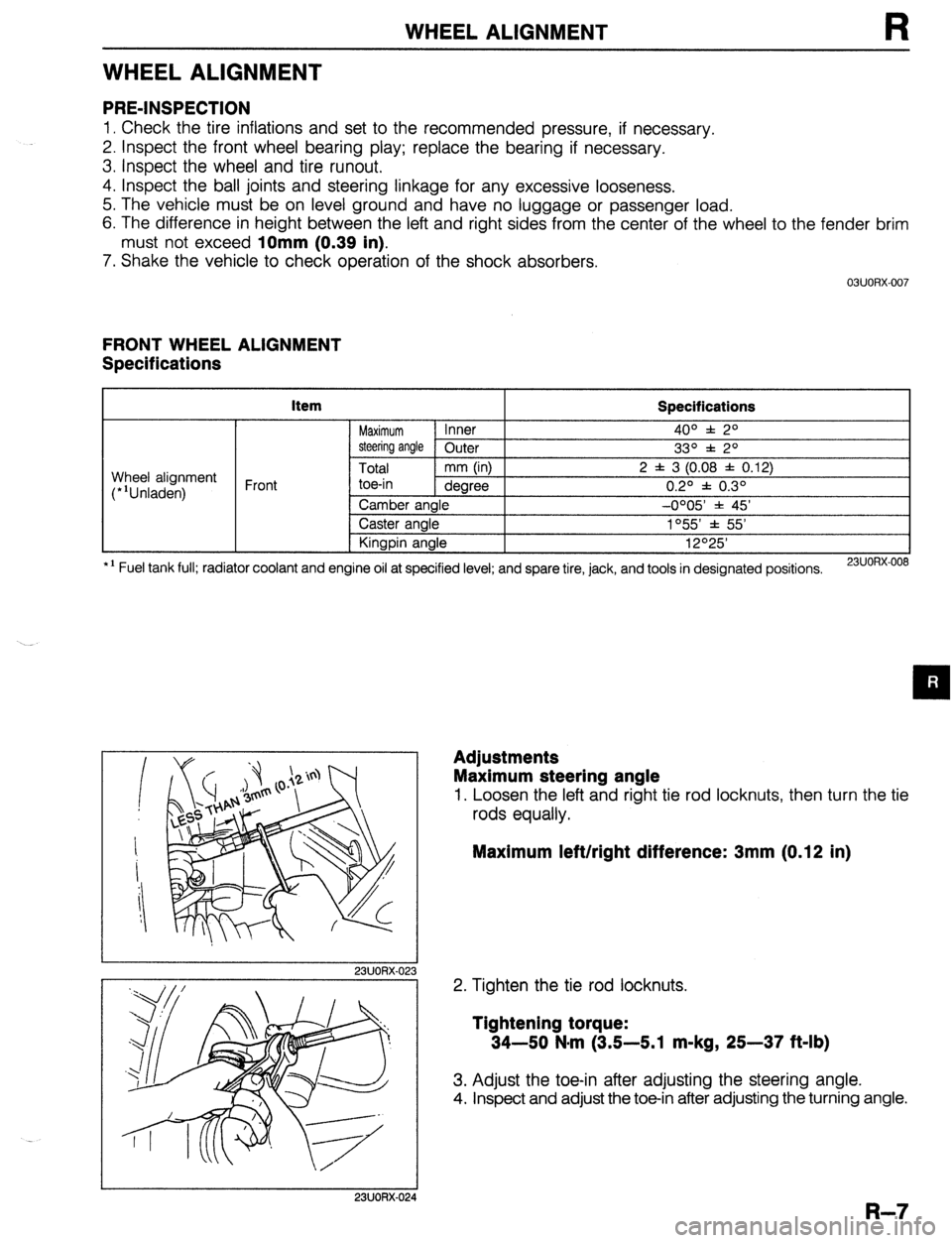

WHEEL ALIGNMENT

PRE-INSPECTION

1. Check the tire inflations and set to the recommended pressure, if necessary.

2. Inspect the front wheel bearing play; replace the bearing if necessary.

3. inspect the wheel and tire runout.

4. Inspect the ball joints and steering linkage for any excessive looseness.

5. The vehicle must be on level ground and have no luggage or passenger load.

6. The difference in height between the left and right sides from the center of the wheel to the fender brim

must not exceed

10mm (0.39 in).

7. Shake the vehicle to check operation of the shock absorbers.

03UORX.007

FRONT WHEEL ALIGNMENT

Specifications

item

Specifications

Maximum Inner 4o” f: 2O

steering angle Outer

33O f 2O

Total mm (in) 2 f 3 (0.08 f 0.12)

toe-in dearee 0.20 f 0.30 Wheel alignment

(*‘Unladen) Front

*I Fuel tank full; radiator coolant and Camber angle -0005 * 45’

Caster angle 1°55’ f 55’

Kingpin angle 12O25’

engine oil at specified level; and spare tire, jack, and tools in designated positions.

23UORX-008

I

I 23UORX-023

Adjustments

Maximum steering angle

1. Loosen the left and right tie rod locknuts, then turn the tie

rods equally.

Maximum left/right difference: 3mm (0.12 in)

2. Tighten the tie rod locknuts.

Tightening torque:

34-50 N-m (3.5-5.1 m-kg, 25-37 ft-lb)

3. Adjust the toe-in after adjusting the steering angle.

4. Inspect and adjust the toe-in after adjusting the turning angle.

I 23UORX-024

R-7

Page 714 of 1164

WHEEL ALIGNMENT

Camber and Caster

1, Jack up the front of the vehicle and support it with safety

stands.

2. Remove the mounting block nuts.

-

1 BUORX-01

23UORX-0;

3. Push the mounting block downward, and turn it to the

desired position.

Direction indicator

position

A

: Difference from standard position

Camber angle Caster angle

+14’ +14’

+29’ O0

+14’ -14’

4. Install and tighten the mounting nuts to the specified torque.

Tightening torque:

29-40 Nnrn (3.0-4.1 m-kg, 22-30 ft-lb)

Total toe-in

1. Loosen the left and right tie rod locknuts, then turn the tie

rods equally.

Caution

l The left and right tie rods are both right threaded,

so, to increase the toe-in, turn the right tie rod to-

ward the front of the vehicle and the left tie rod

equally toward the rear.

l One turn of the tie rod (both sides) changes the toe-

in by about 6mm (0.24 in).

2. Tighten the tie rod locknuts.

Tightening torque:

34-50 N-m (3.5-5.1 m-kg, 25-37 ft-lb)