ignition MAZDA PROTEGE 1992 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 45 of 1164

ON-VEHICLE MAINTENANCE Bl

Steps After Installation

1. Connect the negative battery cable.

2. Start the engine and check as follows:

l Ignition timing. (Refer to page 91-8.)

03UOBl-026

. .

81-15

Page 49 of 1164

.

ON-VEHICLE MAINTENANCE

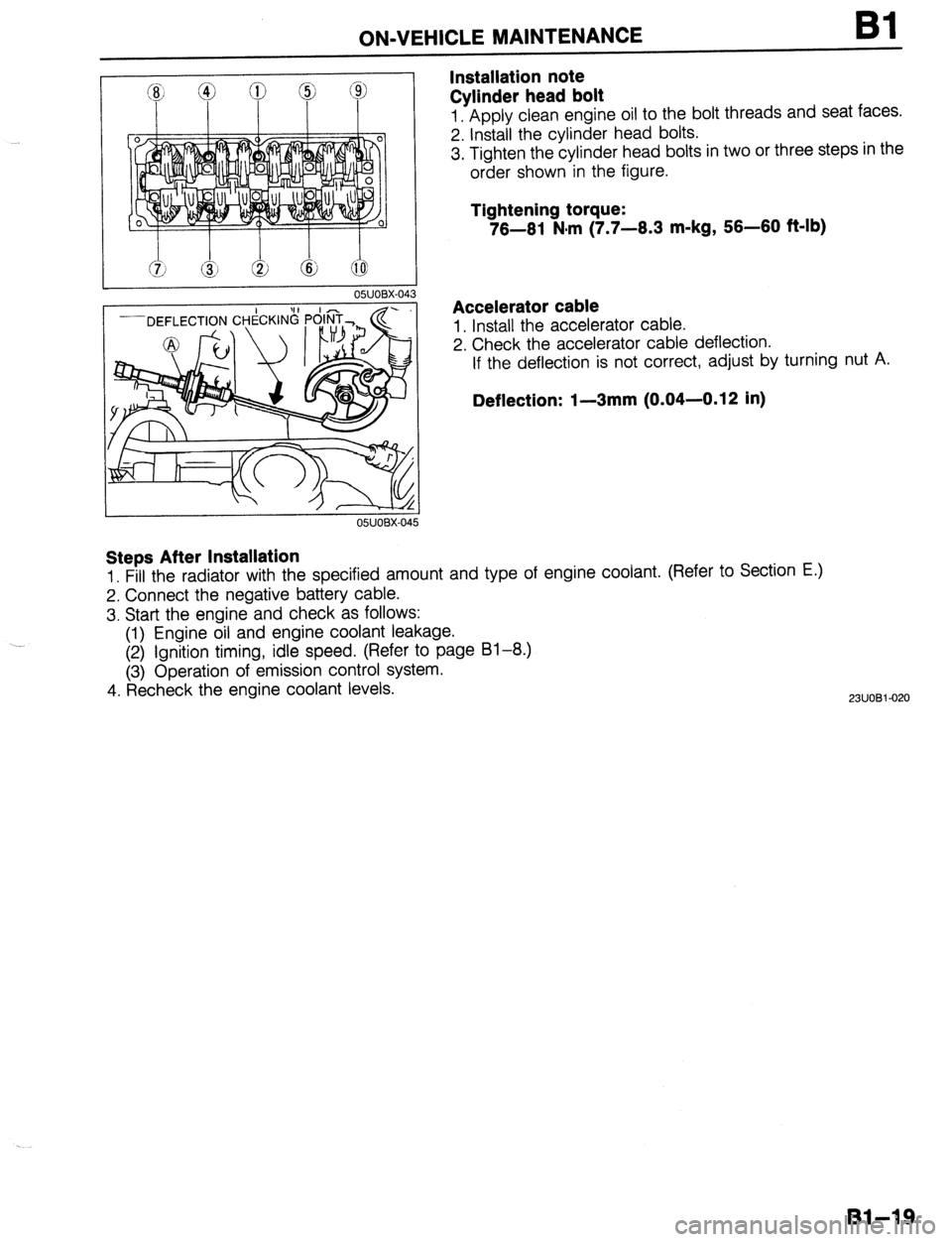

Installation note

Cylinder head bolt Bl

1. Apply clean engine oil to the bolt threads and seat faces.

2. Install the cylinder head bolts.

3. Tighten the cylinder head bolts in two or three steps in the

order shown in the figure.

Tightening torque:

76-61 N#m (7.7-6.3 m-kg, 56-60 f&lb)

Accelerator cable

1. Install the accelerator cable.

2. Check the accelerator cable deflection.

If the deflection is not correct, adjust by turning nut A.

Deflection: I-3mm (0.04-0.12 in)

Steps After Installation

1. Fill the radiator with the specified amount and type of engine coolant. (Refer to Section E.)

2. Connect the negative battery cable.

3. Start the engine and check as follows:

(1) Engine oil and engine coolant leakage.

(2) Ignition timing, idle speed. (Refer to page 81-8.)

(3) Operation of emission control system.

4. Recheck the engine coolant levels.

2311081-020

Bl-19

Page 54 of 1164

Bl ON-VEHICLE MAINTENANCE

01 EOBX-056

23UOBi -0:

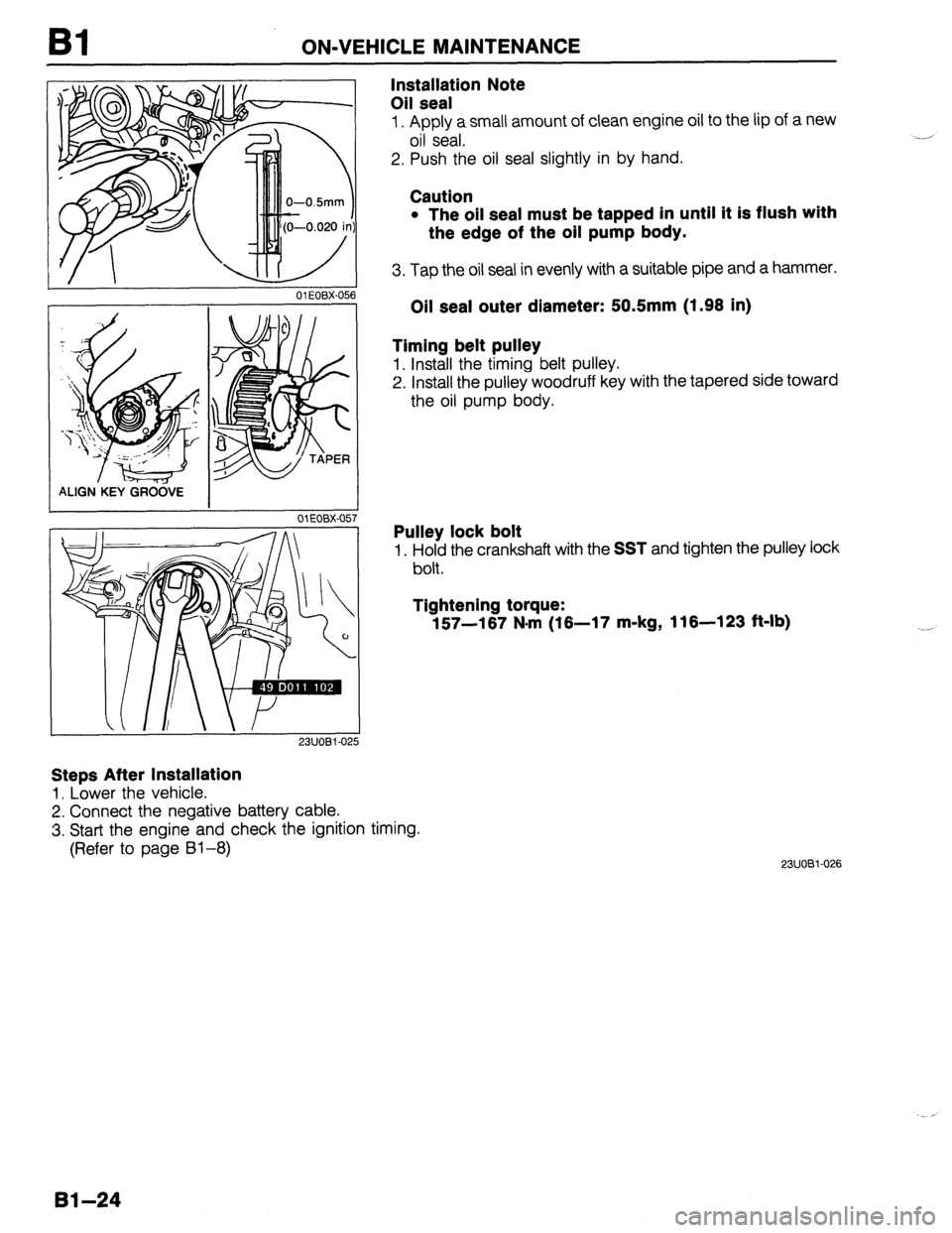

Steps After Installation

1. Lower the vehicle.

2. Connect the negative battery cable.

3. Start the engine and check the ignition timing.

(Refer to page 61-8)

Installation Note

Oil seal

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

Caution

l The oil seal must be tapped in until it is flush with

the edge of the oil pump body.

3. Tap the oil seal in evenly with a suitable pipe and a hammer.

Oil seal outer diameter: 50.5mm (1.98 in)

Timing belt pulley

1. Install the timing belt pulley.

2. Install the pulley woodruff key with the tapered side toward

the oil pump body.

Pulley lock bolt

1. Hold the crankshaft with the SST and tighten the pulley lock

bolt.

Tightening torque:

157-167 N*rn (16-17 m-kg, 116-123 ft-lb)

23UOBi-026

Bl-24

Page 121 of 1164

ASSEMBLY Bl

03UOBl-16

03UOB1.21 38

Injector and Distribution Pipe Assembly (BP SOHC)

1. Install the injector and distribution pipe assembly with new

insulators.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

Intake Manifold Assembly

1, Remove all foreign material from the intake manifold con-

tact surface.

2. Install a new gasket and the intake manifold assembly.

Tightening torque:

19-25 N*m (1.9-2.6 m-kg, 14-19 ft-lb)

Distributor and High-tension Lead

1. Apply engine oil to the O-ring, and position it on the dis-

tributor.

2. Apply engine oil to the blade.

3. Install the distributor with the blade fit into the camshaft

groove.

4. Temporarily, loosely tighten the distributor installing bolt.

5. Adjust the ignition timing after engine installation.

(Refer to Section G.)

6. Connect the high-tension leads.

81-91

Page 130 of 1164

Bl INSTALLATION

Step 5

1. Connect the harness connectors shown in the figure.

GROUND ALTERNATOR

OIL PRESSURE SWITCH

I- THFOTTLE SENSOR

NEUTRAL SWITCH (MTX)

IGNITION COIL

$A_c_K;u_p LIGHT SWITCH

____------- ;

Step 6

Torque Specifications

7.8-11 N.m (80-110 cm-kg, 89-95 in-lb)

19-25 (1.9-2.6, 14-19)

2.9-5.9 N.m

(30-60 cm-kg, 26-52 in-lb)

7.8-11 N.m

(80-l 10 cm-kg,

6.4-9.3 N.m 37-52

(3.8-5.3, 27-38)

24-35

(2.4-3.6, 17-26)

7.8-11 N.m 160-110 cmika, 69-95 in-lb) ‘-- -- -..’ ‘-=’ -’ / 166-96 r?m.ka.

66-82 in-lb) 69-95 in-lb)

N.m (m-kg, ft-lb -- OBUOBl-1E

Bl-100

Page 132 of 1164

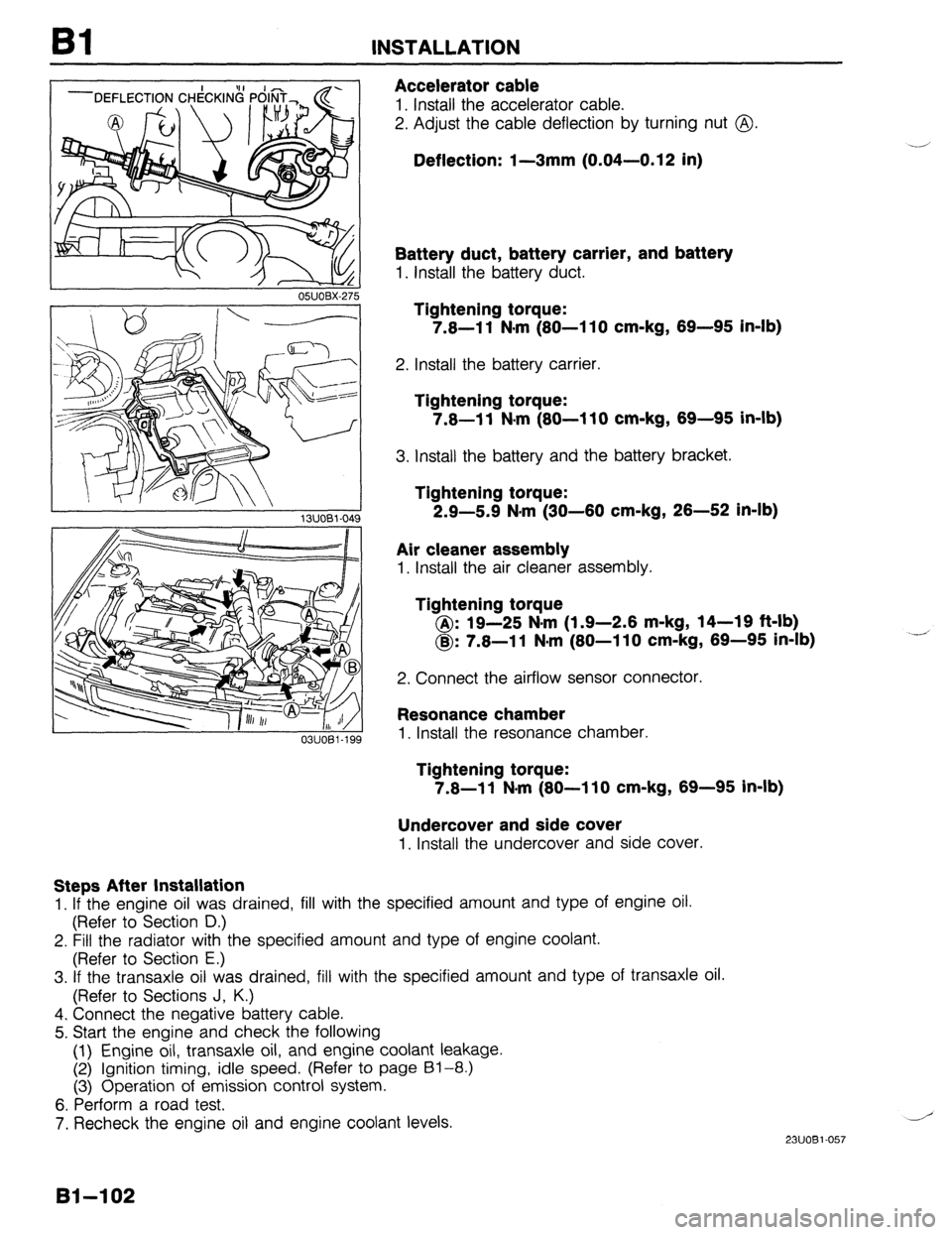

INSTALLATION

OWOBX-27!

Resonance chamber

1. Install the resonance chamber.

Tightening torque:

7.8-l 1 N-m (80-I 10 cm-kg, 69-95 in-lb)

Undercover and side cover

1. Install the undercover and side cover.

Steps After Installation

1. If the engine oil was drained, fill with the specified amount and type of engine oil.

(Refer to Section D.)

Accelerator cable

1. Install the accelerator cable.

2. Adjust the cable deflection by turning nut @.

Deflection: I-3mm (0.04-0.12 in)

Battery duct, battery carrier, and battery

1. Install the battery duct.

Tightening torque:

7.8-l 1 N-m (80-l 10 cm-kg, 69-95 in-lb)

2. Install the battery carrier.

Tightening torque:

7.8-11 N.m (80-110 cm-kg, 69-95 in-lb)

3. Install the battery and the battery bracket.

Tightening torque:

2.9-5.9 N*m (30-60 cm-kg, 26-52 in-lb)

Air cleaner assembly

1. Install the air cleaner assembly.

lightening torque

@: 19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

@: 7.8-l 1 N-m (80-I 10 cm-kg, 69-95 in-lb)

2. Connect the airflow sensor connector.

2. Fill the radiator with the specified amount and type of engine coolant.

(Refer to Section E.)

3. If the transaxle oil was drained, fill with the specified amount and type of transaxle oil.

(Refer to Sections J, K.)

4. Connect the negative battery cable.

5. Start the engine and check the following

(1) Engine oil, transaxle oil, and engine coolant leakage.

(2) Ignition timing, idle speed. (Refer to page 61-8.)

(3) Operation of emission control system.

6. Perform a road test,

7. Recheck the engine oil and engine coolant levels.

.-’

23UOBl-057

81-102

Page 133 of 1164

82

ENGINE

m :

(DOHC)

INDEX .......................................... B2- 2

OUTLINE ...................................... B2- 3

SPECIFICATIONS ........................ B2- 3

TROUBLESHOOTING GUIDE .......... B2- 3

ENGINE TUNE-UP PROCEDURE ......

B2- 5

PREPARATION ............................

B2- 5

ENGINE OIL ............................... B2- 5

ENGINE COOLANT.. ....................

B2- 5

DRIVE BELT ............................... B2- 5

HLA .......................................... B2- 7

IGNITION TIMING, IDLE SPEED ..... B2- 8

COMPRESSION ............................. 82-l 0

INSPECTION ...............................

82-l 0

ON-VEHICLE MAINTENANCE.. ........ 82-l 1

PREPARATION ............................

B2-11

TIMING BELT .............................. 82-l 2

CYLINDER HEAD GASKET ...........

82-16

HLA .......................................... 82-22

FRONT OIL SEAL.. ......................

62-26

REAR OIL SEAL .......................... 82-28

REMOVAL ..................................... 82-31

PROCEDURE .............................. 82-31

ENGINE STAND MOUNTING.. .........

82-38

PREPARATION ............................ 82-38

PROCEDURE ..............................

82-39

DISASSEMBLY .............................. 82-41

PREPARATION ............................ B2-41

AUXILIARY PARTS.. ..................... 82-42

TIMING BELT ..............................

82-43

CYLINDER HEAD.. ...................... 82-45

CYLINDER BLOCK

(EXTERNAL PARTS) ...................

B2-48

CYLINDER BLOCK

(INTERNAL PARTS). ................... 82-51 INSPECTION / REPAIR.. ................. 82-54

PREPARATION ............................ 82-54

CYLINDER HEAD.. ...................... B2-54

VALVE MECHANISM.. .................. 82-55

CAMSHAFT ................................ B2-58

HLA .......................................... 82-80

CYLINDER BLOCK ...................... 82-60

OIL JET ..................................... B2-61

PISTON, PISTON RING, AND

PISTON PIN .............................. 82-62

CONNECTING ROD.. ...................

82-63

CRANKSHAFT ............................ B2-64

BEARING ................................... 82-64

TIMING BELT ..............................

82-65

TENSIONER, IDLER.. ................... 82-65

TENSIONER SPRING ................... 82-65

PULLEY ..................................... 82-65

ASSEMBLY ................................... B2-66

PREPARATION ............................ B2-66

CYLINDER BLOCK

(INTERNAL PARTS). ................... 82-68

CYLINDER BLOCK

(EXTERNAL PARTS) ................... 82-73

CYLINDER HEAD.. ...................... 82-79

TIMING BELT .............................. 82-84

AUXILIARY PARTS.. .....................

B2-87

ENGINE STAND DISMOUNTING ..a” . . 82-91

PROCEDURE ..............................

82-91

INSTALLATION ............................. 82-93

PROCEDURE .............................. 82-93

23UOB2-001

Page 135 of 1164

OUTLINE, TROUBLESHOOTING GUIDE

OUTLINE

SPECIFICATIONS

ItC- Engine

BP DOHC

Type Gasoline, 4-cycle

Cylinder arrangement and number In-line, 4 cylinders

Combustion chamber Pentroof

Valve svstem DOHC, belt-driven 16 valves

Displacement

Bore and stroke cc (cu in) 1,839 (112.2)

mm (in) I 83.0 x 85.0 (3.27 x 3.35)

Compression ratio

Compression pressure

IN

Valve timing

EX kPa (kg/cm*, psi)-rpm

BTDC Open

Close ABDC

Open BBDC

Close ATDC 9.0

1,256 (12.8, 182)300

!zJ”

48O

56O

140

Valve clearance IN 0: Maintenance-free

mm (in)

EX 0: Marntenance-free

Idle speed *’ *’ MTX

rpm

ATX

Ignition timing*2

Firing order

::...With parking brake applied. (Canada)

. ..TEN terminal of diagnosis connector grounded BTDC 700-800

700-800 (P range)

90-l 1 O

l-3-4-2

P3UOBZ003

TROUBLESHOOTING GUIDE

Problem

Difficult starting

Poor idling

Excessive oil

consumption Possible Cause

Malfunction of engine-related components

Burned valve

Worn piston, piston ring, or cylinder

Failed cylinder head gasket

Malfunction of fuel system

Malfunction of ignition system

Malfunction of engine-related components

Malfunction of HLA*

Poor valve-to-valve seat contact

Failed cylinder head gasket

Malfunction of fuel system

Malfunction of ignition system

Oil working up

Worn piston ring groove or sticking piston ring

Worn oiston or cvlinder

Oil working down

Worn valve seal

Worn valve stem or auide

Oil leakaae i

Replace 82-55

Replace or repair 92-60, 62

Reolace B2-16

Refer to Section F

I

Replace 82-47, 79

Replace 82-55

Refer to Section 0 I

82-3

Page 136 of 1164

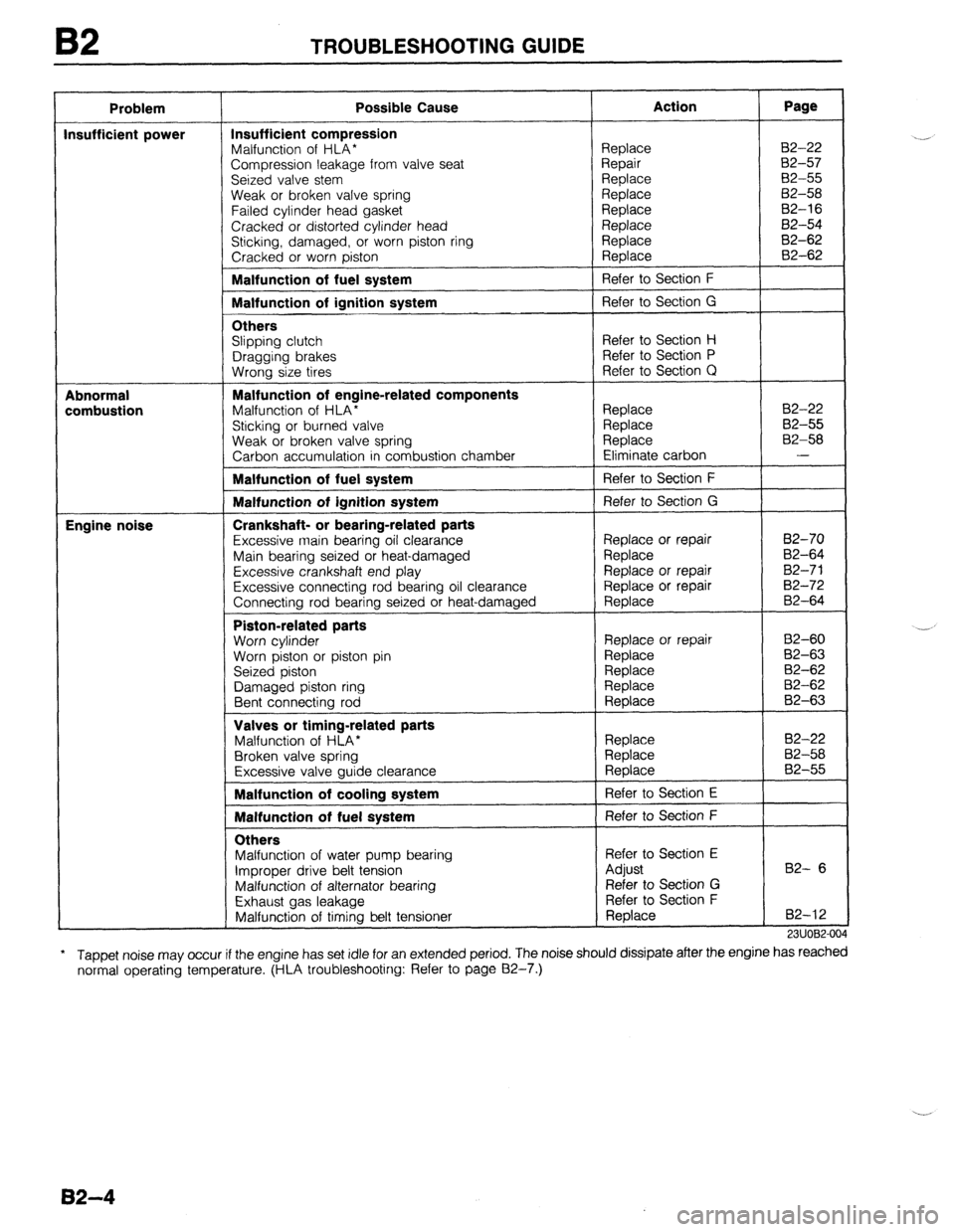

B2 TROUBLESHOOTING GUIDE

Problem

Insufficient power

Abnormal

combustion

Engine noise -

I

I

f

,

I

I

,

I

I Possible Cause Action Page

Insufficient compression

Malfunction of HLA*

Compression leakage from valve seat

Seized valve stem

Ueak or broken valve spring

Failed cylinder head

gasket Cracked or distorted cylinder head

Sticking, damaged, or worn piston ring

Cracked or worn piston Replace

Repair

Replace

Replace

Replace

Replace

Replace

Replace

Refer to Section F 82-22

82-57

02-55

B2-58

82-16

82-54

82-62

82-62 Malfunction of fuel system

Malfunction of ianition svstem

Others

Slipping clutch

Dragging brakes

Wrong size tires Malfunction of engine-related components

Malfunction of HLA*

Sticking or burned valve

Weak or broken valve spring

Carbon accumulation in combustion chamber Malfunction of fuel system

Malfunction of ignition system

Crankshaft- or bearing-related parts

Excessive main bearing oil clearance

Main bearing seized or heat-damaged

Excessive crankshaft end play

Excessive connecting rod bearing oil clearance

Connecting rod bearing seized or heat-damaged Piston-related parts

Worn cylinder

Worn piston or piston pin

Seized piston

Damaged piston ring

Bent connecting rod Valves or timing-related parts

Malfunction of HLA*

Broken valve spring

Excessive valve guide clearance Malfunction of cooling system

Malfunction of fuel svstem

Others

Malfunction of water pump bearing Refer to Section E

Improper drive belt tension Adjust

Malfunction of alternator bearing Refer to Section G

Exhaust gas leakage Refer to Section F

Malfunction of timing belt tensioner Replace Refer to Section G

Refer to Section H

Refer to Section P

Refer to Section C!

Replace B2-22

Replace 82-55

Replace 82-58

Eliminate carbon -

Refer to Section F

Refer to Section G

Replace or repair B2-70

Replace 82-64

Replace or repair 82-7 1

Replace or repair B2-72

Replace B2-64

Replace or repair

82-60

Replace 82-63

Replace 82-62

Replace 82-62

Replace 82-63

Replace

Replace

Replace

Refer to Section E

Refer to Section F 82-22

82-58

82-55

B2- 6

82-12

23UOB2-00,

..J

.-,

l

Tappet noise may occur if the engine has set idle for an extended period. The noise should dissipate after the engine has reached

normal operating temperature. (HLA troubleshooting: Refer to page 82-7.)

82-4

Page 140 of 1164

82 ENGINE TUNE-UP PROCEDURE

03UOB2-013

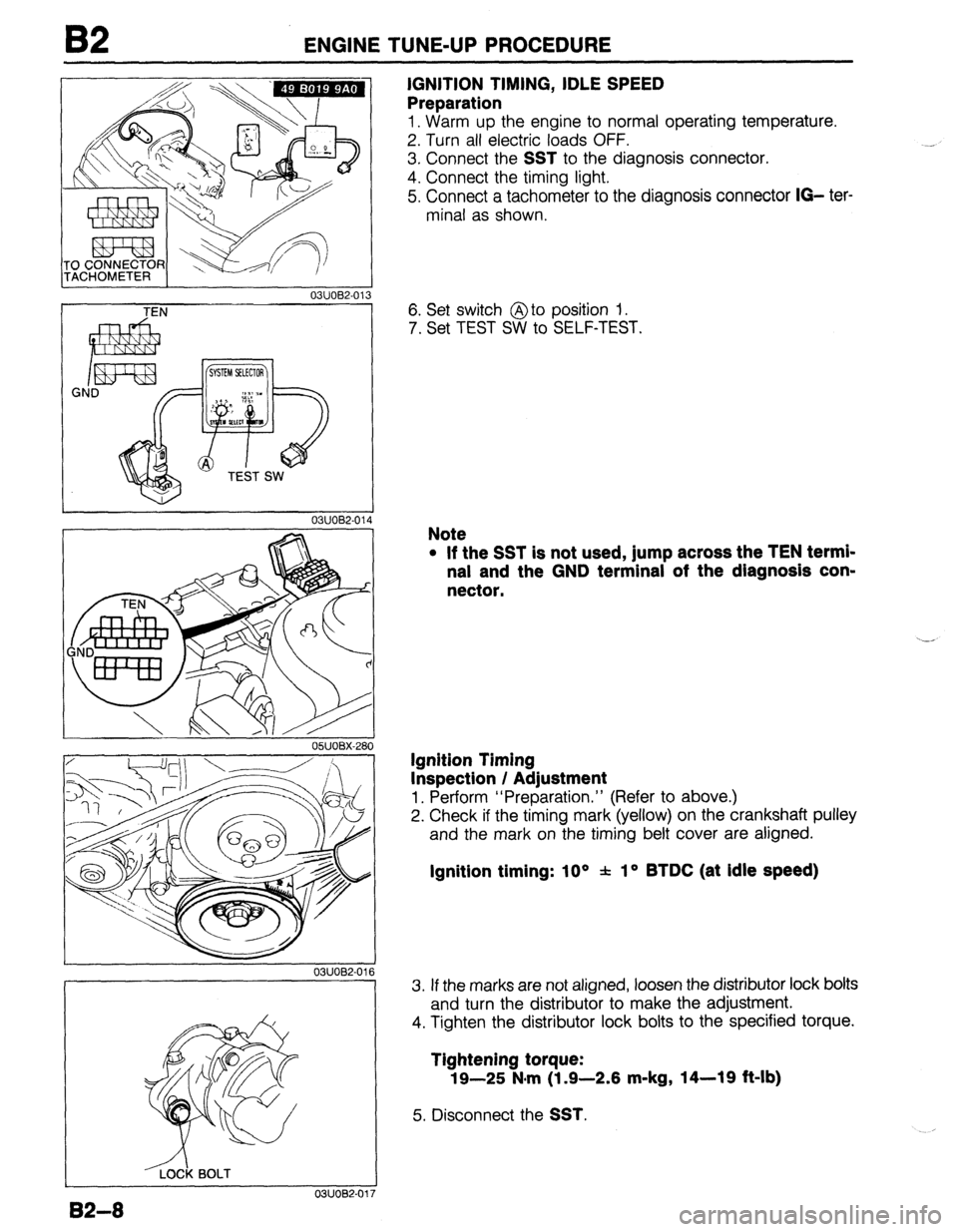

IGNITION TIMING, IDLE SPEED

Preparation

1. Warm up the engine to normal operating temperature.

2. Turn all electric loads OFF.

3. Connect the

SST to the diagnosis connector.

4. Connect the timing light.

5. Connect a tachometer to the diagnosis connector

IO- ter-

minal as shown.

TEN

03UOB2-01

I

-&k BOLT

0311082-01’

82-8

6. Set switch @to position 1.

7. Set TEST SW to SELF-TEST.

Note

l If the SST is not used, jump across the TEN termi-

nal and the GND terminal of the diagnosis con-

nector.

Ignition Timing

Inspection / Adjustment

1. Perform “Preparation.” (Refer to above.)

2. Check if the timing mark (yellow) on the crankshaft pulley

and the mark on the timing belt cover are aligned.

Ignition timing: 10 * f lo BTDC (at Idle speed)

3. If the marks are not aligned, loosen the distributor lock bolts

and turn the distributor to make the adjustment.

4. Tighten the distributor lock bolts to the specified torque.

Tightening torque:

19-25 N*m (1 .Q-2.6 m-kg, 14-19 ft-lb)

5. Disconnect the SST.