MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 281 of 1164

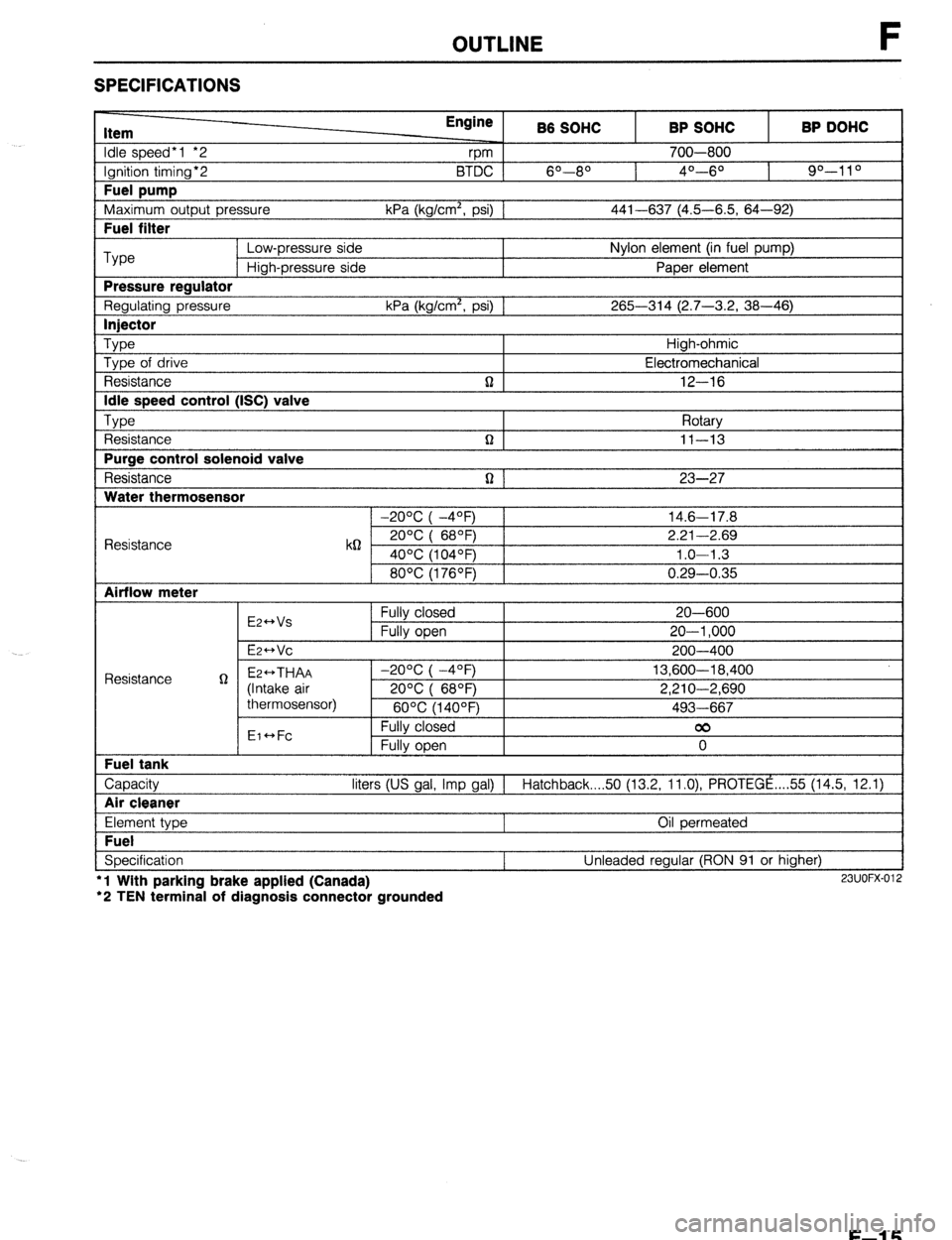

OUTLINE F

SPECIFICATIONS

Item

Idle speed*1 *2

Ignition timing*2

Fuel pump

Maximum outout Dressure Engine

rpm B6 SOHC

6O--80 BTDC 1

kPa (ka/cm’. osi1 1 BP SOHC

700-800

4O---6O BP DOHC

90-l 1 O

441-637 (4.5-6.5. 64-92) I

I Fuel filter I

Type Low-pressure side Nylon element (in fuel pump)

High-pressure side Paper element

Pressure reaulator

Regulating pressure kPa (kg/cm’, psi) 1 265-314 (2.7-3.2, 38-46)

I lniector I

Type Type of drive

Resistance

Idle speed control (ISC) valve

TvDe , ,

t Resistance

Purge control solenoid valve

Resistance

Water thermosensor n High-ohmic

Electromechanical

12-16

Rotarv

n I II-13 I

n 1 23-27

1 -20% I -4OFj 1 14.6-17.8

Resistance k62 2ooc i 68OF) 2.21-2.69

40°C (104OF) 1.0-l .3

80°C (176OF) 0.29-0.35

Airflow meter

E2++Vs

E2-Vc Fully closed

Fully open 20-600

20-l ,000

200-400

Capacity liters (US gal, Imp gal) 1 Hatchback 50 (13.2, ll.O), PROTEGE ,... 55 (14.5, 12.1)

I Air cleaner I

Element type

Fuel

Specification l

l Wlth parking brake applied (Canada)

‘2 TEN terminal of diagnosis connector grounded Oil permeated

Unleaded regular (RON 91 or higher) 23UOFX-012

F-l 5

Page 282 of 1164

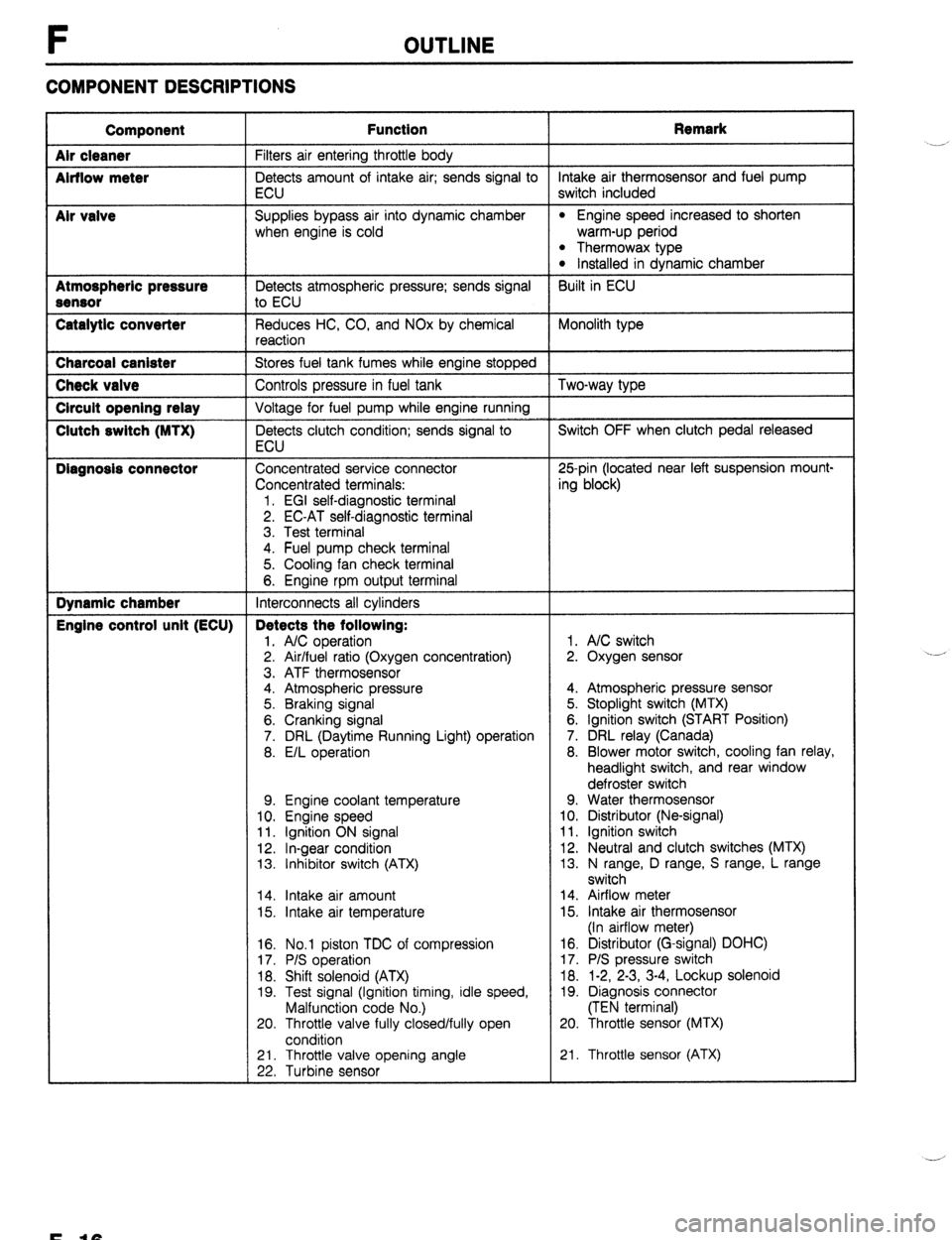

F OUTLINE

COMPONENT DESCRIPTIONS

Component

Air cleaner

Airflow meter

Mr valve

Atmospheric pressure

Sensor

Catalytic converter Function Remark

Filters air entering throttle body

Detects amount of intake air; sends signal to intake air thermosensor and fuel pump

ECU switch included

Supplies bypass air into dynamic chamber

l Engine speed increased to shorten

when engine is cold warm-up period

l Thermowax type l Installed in dynamic chamber

Detects atmospheric pressure; sends signal Built in ECU

to ECU

Reduces HC, CO, and NOx by chemical Monolith type

reaction Charcoal canister

Stores fuel tank fumes while engine stopped Check valve

Controls pressure in fuel tank Two-way type Circuit opening relay

Voltage for fuel pump while engine running Clutch switch (MTX)

Detects clutch condition; sends signal to Switch OFF when clutch pedal released

ECU Diagnosis connector

Concentrated service connector 25pin (located near left suspension mount-

Concentrated terminals: ing block)

1. EGI self-diagnostic terminal

2. EC-AT self-diagnostic terminal

3. Test terminal

4. Fuel pump check terminal

5. Cooling fan check terminal

6. Engine rpm output terminal Dynamic chamber

Interconnects all cylinders Engine control unit (ECU) Detects the following:

1. A/C operation 1. A/C switch

2. Air/fuel ratio (Oxygen concentration) 2. Oxygen sensor

3. ATF thermosensor

4. Atmospheric pressure 4. Atmospheric pressure sensor

5. Braking signal 5. Stoplight switch (MTX)

6. Cranking signal 6. Ignition switch (START Position)

7. DRL (Daytime Running Light) operation 7. DRL relay (Canada)

8. E/L operation 8. Blower motor switch, cooling fan relay,

headlight switch, and rear window

defroster switch

9. Engine coolant temperature 9. Water thermosensor

10. Engine speed 10. Distributor (Ne-signal)

11. Ignition ON signal 11. Ignition switch

12. In-gear condition 12. Neutral and clutch switches (MTX)

13. Inhibitor switch (ATX) 13. N range, D range, S range, L range

switch

14. Intake air amount 14. Airflow meter

15. Intake air temperature 15. Intake air thermosensor

(In airflow meter)

16. No.1 piston TDC of compression

17. P/S operation

18. Shift solenoid (ATX)

19. Test signal (Ignition timing, idle speed,

Malfunction code No.)

20. Throttle valve fully closed/fully open

condition 16. Distributor (G-signal) DOHC)

17. P/S pressure switch

18. 1-2, 2-3, 3-4, Lockup solenoid

19. Diagnosis connector

(TEN terminal)

20. Throttle sensor (MTX)

21. Throttle valve opening angle

22. Turbine sensor 21. Throttle sensor (ATX) .__r

F-10

Page 283 of 1164

OUTLINE

Component Function Remark

Engine control unit (ECU) Controls operation of the following:

(Cont’d)

1. A/C (Cut-off) 1. A/C relay

2. Fail-safe function 2. Self-Diagnosis Checker and MIL

3. Fuel injection system 3. Injector

4. idle speed control 4. Idle speed control (ISC) valve

5. Ignition timing control system 5. Igniter

6. Monitor function 6. Monitor lamp (Self-Diagnosis Checker)

7. Pressure regulator control system 7. Solenoid valve

(Pressure regulator control) (BP)

8. Purge control system 8. Purge control solenoid valve

9. VICS 9. Solenoid valve (WCS) (DOHC) Fuel filter

Filters particles from fuel Fuel pump

Provides fuel to injectors l Operates while engine running l Installed in fuel tank Igniter

Receives spark signal from ECU and gener-

ates high voltage in ignition coil Ignition switch

Engine cranking signal sent to ECU (START position)

Inhibitor switch (ATX)

Detects in-gear condition; sends signal to Switch ON in N or P range

ECU Injector

Intake air thermosensor

Idle speed control (ISC)

valve

Main relay

(FUEL INJ relay)

MIL (Malfunction

indicator lamp)

Neutral switch (MTX)

Oxygen sensor

PCV valve

P/S pressure switch

Pressure regulator

Resonance chamber

Resonance duct

Separator

Stoplight switch

Solenoid valve

(Purge control)

Shutter valve actuator

(DOHC)

Throttle body

Throttle sensor

Injects fuel into intake port l Controlled by signals from ECU

l High-ohmic injector

Detects intake air temperature; sends signal Installed on dynamic chamber

to ECU

Controls bypass air amount Controlled by duty signal from ECU

Supplies electric current to injectors, ECU,

etc.

Lamp flashes to indicate malfunction code

number of input and output devices

Detects in-gear condition; sends signal to

ECU

Detects oxygen concentration; sends signal

to ECU

Controls blowby gas introduced into engine

Detects P/S operation; sends signal to ECU

Adjusts fuel pressure supplied to injectors

Reduces intake air noise

Reduces intake air noise

Prevents fuel from flowing into charcoal

canister

Detects braking operation (deceleration),

sends signal to ECU

Controls evaporative fumes from canister to

intake manifold

Closes/opens shutter valve to improve

torque characteristics

Controls intake air quantity

l Detects throttle valve fully closed/fully

opened condition (MTX) TEN terminal grounded

Switch ON in neutral

Zirconia ceramic and platinum coating

P/S: ON when steering wheel turned right or

left

Controlled by duty signal from ECU

For Variable inertia charging system (VICS*)

Integrated throttle sensor, dashpot, and ISC

valve

l Detects throttle valve opening angle

(A-W

l Sends signals to ECU

F-l 7

Page 284 of 1164

F OUTLINE

I Component

I Function

I Remark

I

Three-way

solenoid

valve vIcs*

Pressure

regulator

control

Controls vacuum to shutter valve actuator

Controls vacuum to pressure regulator Cuts vacuum when engine speed above

5.000 ram

Cuts vacuum just after starting when engine

hot starting Vacuum chamber

(DOHC)

Water thermosensor

Stores vacuum for use during wide open For WCS*

throttle

Detects coolant temperature; sends signal to

ECU

l WCS: Variable Inertia Charging System 23UOFX-013

F-l 8

Page 285 of 1164

OUTLINE F

MEMO

F-19

Page 286 of 1164

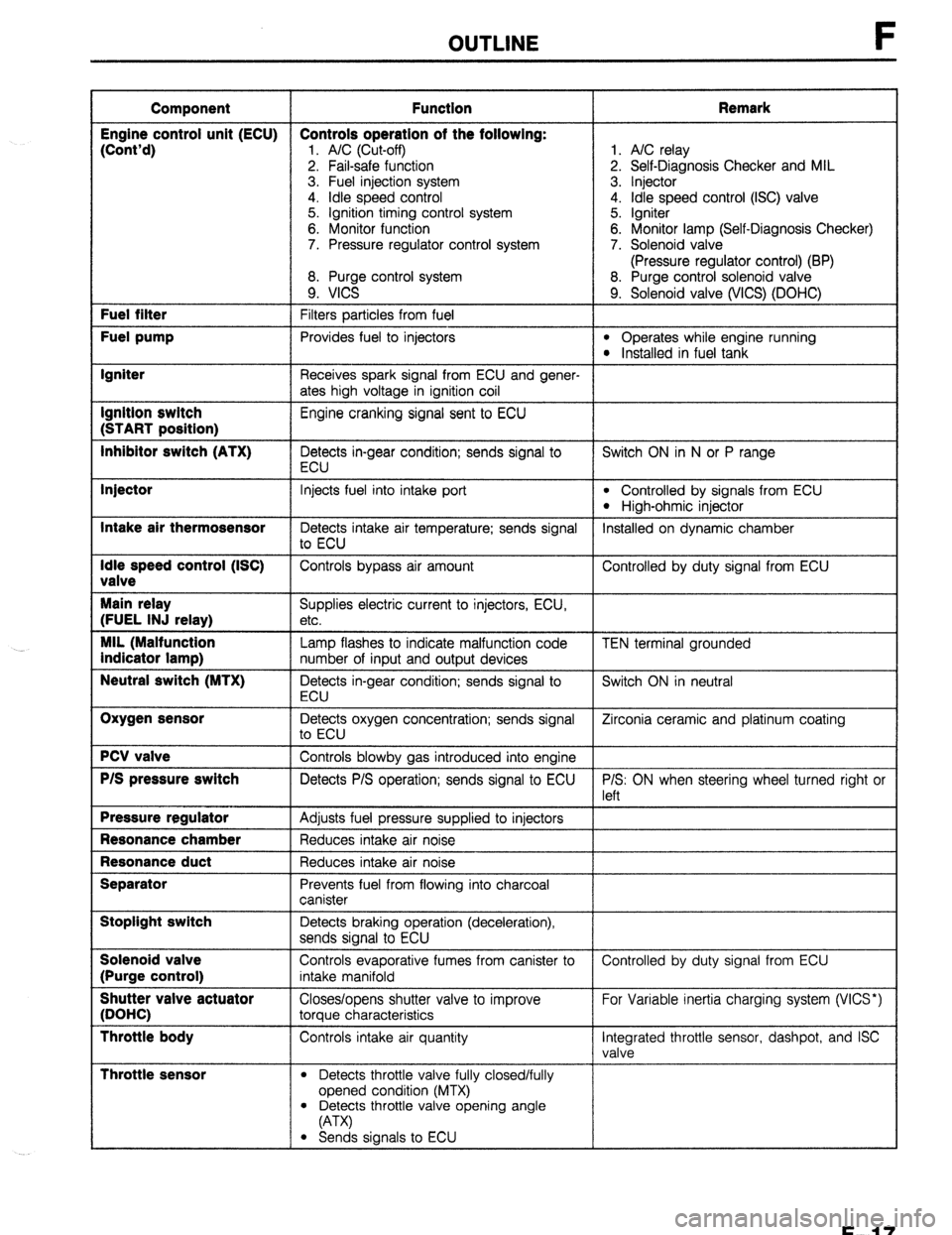

F TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

ENGINE CONTROL OPERATION CHART

Note

Input Device and Engine Conditions

l The data in this chart is for reference only.

INPUT DEVICES APPROX,- SENSORS

MATE TIME G& THROTTLE SENSOR

(BASED ON TRIBUTOR

WATER INTAKE

10-16°C, (G. OXYGEN AIRFLOW AIR

VT

POW

.50-6OOF

SIGNAL)” ;;;;;f- SENSOR METER

AMBIENT) (Ne-SIGNAL) THERMO- TERMINAL TERMINAL yE\MINAL

CONDITIONS SENSOR (ATX)

WX)

A

c

CRANKING

-COLD ENGINE Signal has Signal has Signal has Signal has Slgnal has Slgnal has

l COLD AIR zero no affect no effect no effect no effect no effect

no effect

. COLD COOLANT on ECU on ECU on ECU on ECU on ECU

on ECU

Cool to A A

COLD START

warm: Low volume Closed Closed

Closed

-FAST IDLE

One

Medium airflow: throttle: throttle:

l COLD AIR

minute

voltage High volt-

Low volt- Low volt- throttle.

Low volt-

* COLD COOLANT

(3.5” and :zo:o, ,,Pbove 1’,“,“$; a(ogi-O,8”) ;149&“) we W)

dropping) to high

(68OF)]:

COLD DRIVEAWAY voltage A

Above

-PART THROTTLE Two (O-0.9”) 2.3”

l COLD AIR minutes

l COLD COOLANT

v v ,,

Warm: Medi- Sensor Moderate II

WARM DRIVEAWAY

volume air-

-PART THROTTLE Three N&IGNAL um voitage hot:

flow: Low

l WARM AIR minutes Sends all Vvwrox switching l WARM COOLANT cylinders 0.7V and

from high to medium

Part Part

TDC signal dropping) voltage voltage

throttle: throttle.

)

A (0.9V) (1 .o-3.5”)

to ECU

.“~ Medium Medium

HOT CRUISE

s voltage voltage

Open

l WARM AIR G-

SIGNAL”’ to low (0.8-3.0”) (4.5-5.5”) throttle:

l WARM COOLANT High

Sends No. voltage

1 cylinder (0.1”) voltage

1 (battery

TDC (com-

1 I voltage)

HOT ACCELERATION pression)

-60% THROTTLE signal to

Moderate

ECU

to strong

High Cool lo warm

voltage ;$,“,” Of j-20-4OT

f t

HOT ACCELERATION

More’ than Hot: Low (0.9”) Low (-4-‘04”F)l: W,ds open

voltage 1.5-4.3v

throttle: Wide open

-WIDE OPEN

four voltage

High volt- throttle

THROTTLE (0.5-1.5V)

minutes (Below High

0.5”) age (Above

voltage (OV)

t 1 3.OV)

I,

A 1. /I

DECELERATION

-CLOSED THROTTLE

HOT CURB IDLE

-EXTENDED

HOT ENGINE

SHUTDOWN Low

voltage

(0”) Low Closed Closed

Closed

volume throttle: throttle.

throttle.

of airflow:

~~~~!$$ (Above Low Low

Low

voltage voltage

voltage

to low 3.OV) (0.2-0.N) (4.5-5 5V) (OV)

voltage

(0.75%

t t 1 0.25”)

r v 1 I I

Sensor

hot: Low

OFF OFF voltage

-

(0.1”) until OFF OFF OFF OFF

OFF

sensw

COOIS

._-

Page 287 of 1164

![MAZDA PROTEGE 1992 Workshop Manual TROUBLESHOOTING GUIDE F

r

- SENSORS

z-----

‘RES-

‘URE

‘WITCH FRL (Dsy

ime Run-

ling

.ight)

:ONTROL

INIT

CANADA]

)FF

3attery

oltage)

T- IEUTRAL

rND

:LUTCH

iWITCHES

MTX) IIAGNO MAZDA PROTEGE 1992 Workshop Manual TROUBLESHOOTING GUIDE F

r

- SENSORS

z-----

‘RES-

‘URE

‘WITCH FRL (Dsy

ime Run-

ling

.ight)

:ONTROL

INIT

CANADA]

)FF

3attery

oltage)

T- IEUTRAL

rND

:LUTCH

iWITCHES

MTX) IIAGNO](/img/28/57077/w960_57077-286.png)

TROUBLESHOOTING GUIDE F

r

- SENSORS

z-----

‘RES-

‘URE

‘WITCH FRL (Dsy

ime Run-

ling

.ight)

:ONTROL

INIT

CANADA]

)FF

3attery

oltage)

T- IEUTRAL

rND

:LUTCH

iWITCHES

MTX) IIAGNOSIS

:ONNEC-

‘OR TEN

‘ERMINAL

rEST

‘ERMINAL) IGNITION SWITCH

s kgnal has

r IO effect

C In ECU

I neutral:

.ow volt-

rge signal

II ECU

w

-

f

I

Iriving in

iny gear:

iigh volt-

ige signal

o ECU

Battery TOP-

IGHT

WITCH UHIBITOR

iWITCH

4TX) L/C

;WITCH

5

IL

IGNAL

Sl ignal has

nl 3 effect

01 n ECU

H

0

F-f

S

C

VI

si

E

te

VI

C

VI

si

i

1 T

eadlight

r rear

‘indow

efroster

Nitch

IN: High

pltage

gnal to

CU (Bat-

try

sltage)

IFF: Low

altage

gnal to

cu

3elow

.5V)

B

S'

0

C,

C

L

E

E

II

(

\i

c

E

t’

I lower

Nitch**

r Electri-

al fan

IN: Low

foltage

signal to

iCU (Be-

3w 1.W)

IFF: High

loltage

rignal to

ICU (Bat-

ev

voltage)

I

OFF ITART

‘OSITION IN

OSITION

‘ends sig

al to

CU (Bat-

?ry

oltage) #ignal has

0 effect

#n ECU ignal has

0 effect

n ECU ignal has

0 effect

n ECU ;ignal has

IO effect

rn ECU ignal has

0 effect

n ECU

rake pedal Ggnal has

IQ effect

In ECU

1NorP

ange: No

ignal to

.cu

w

-

7D

ange: No

#ignal to

.cu

Battery

foltage)

- - - - -

ends sig-

31 to ECU

jattr ?ry

Atac

-2

/heel -

Jrned:

ow volt-

ge signal

I ECU

3elow

.5V)

teering

/heel

traight

head:

ligh volt-

ge signal

) ECU

dattery .erminal

lot

Irounded:

iigh volt-

tge Signal

3 ECU

Battery

roltage)

‘erminal

Irounded:

.ow volt-

rge signal

3 ECU

Below lo signal

ent to

cu

3elow

5V) r/C switch

IN:

iends sig-

ial to

CU (Be-

IW 1.5V)

r/C switch

IFF: No

ignal to

CU (Bat-

3ry

‘oltage) )RL ON:

w ends sig-

al to

CU (Bat-

2ry

oltage) lo signal

3 ECU

3elow

.5V) )RL OFF:

3attery

oltage)

I .5V’

medal

Sends

signal to

KU

Battery

voltage)

- -

In N or P

range:

Sends sig-

nal to ECU

PV In neutral:

Low volt-

age stgnal

to ECU

(W

I -

- - -

OFF OFF OFF OFF OFF OFF OFF

OFF OFF

23UOFX-0’

+’ Blower switch: 2nd position or more

F-21

Page 288 of 1164

F TROUBLESHOOTING GUIDE

Output Devices and Engine Conditions

Note

. The data in this chart is for reference only.

INJECTOR

CONDITIONS

CRANKING

-COLD ENGINE

l COLD AIR l COLD COOLANT

COLD START

-FAST IDLE

l COLD AIR l COLD COOLANT

COLD DRIVEAWAY

-PART THROTTLE

l COLD AIR l COLD COOLANT

WARM DRIVEAWAY

-PART THROTTLE

. WARM AIR

l WARM COOLANT

HOT CRUISE

l WARM AIR l WARM COOLANT Zero

One

mrnute

Two

minutes

Three

minutes

I AIR

INJECTION “AL”E

INJECTION TlMlNG

A

All A

cylinders

each

ignition

pulse

1

Rich Open:

coolant

tem-

perature:

Below

40%

(104OF)

,

I/

Rich and

2-group” 1’

lean l-group” /I

,

i

HOT ACCELERATION

-60% THROTTLE

-lOT ACCELERATION

-WIDE OPEN

THROTTLE

Closed ISC

VALVE

1, THREE-WAY

SOLENOID SOLENOID

VALVE VALVE

(PURGE

(PRESSURE

CONTROL) REGULATOR

CONTROL)‘3

c

OFF

(Purge

cut)

Large

1

, AK

RELAY

amount or

bypass air

OFF

(Vacuum

to

pressure

regulator)

After start-

rng: ON dur-

ing hot start

only (Vacu-

um cut)

OFF

l 2 SOHC, *’ BP

F-22

Page 289 of 1164

TROUBLESHOOTING GUIDE F

THREE-

WAY

SOLE-

NOID

VALVE

(WCS)”

ON

(Vacuum

to shutter

valve

actuator)

A

Engine

speed

below

5,000

rpm:

3FF

(Vacuum

wt)

I

3N

:Vacuum

:o shutter

Jalve

actuator)

OFF

23UOFX-01

F-23

Page 290 of 1164

F TROUBLESHOOTING GUIDE

RELATIONSHIP CHART

OUTPUT DEVICE

INPUT DEVICE

DIAGNOSIS CONNECTOR

[TEN TERMINAL) 0 0 0 0

IGNITION SWITCH (START POSITION) 0 0 0 0 0 0

E/L SIGNALg4 0

0

P/S PRESSURE SWITCH 0 0

B/C SWITCH 0 0 0

INHIBITOR SWITCH (ATX) 0 0 0 0 0 0 0

NEUTRALANDCLUTCH

SWITCHES (MTX) 0 0 0 0 0 0 0

STOPLIGHT SWITCH 0

0

&TMOSPHERIC PRESSURE SENSOR

[IN ECU) o 0 0 0 0

rHROTTLE SENSOR 0 0 0 0 0 0 0

INTAKE AIR THERMOSENSOR 0 0 0 0 0

MRFLOW METER 0 0 0 0 0

3XYGEN SENSOR 0 0 0 0

JVATERTHERMOSENSOR 0 0 0 0 0 0 0

G-SIGNAL*’ 0 0

3ISTRIBUTOR

Ne-SIGNAL 0 0 0 0 0 0 0 0

-- ,.-, ,--., ,.*

+z

*3 &HC

MIL: Malfunction Indicator Lamp

r.9u”rn-” I

*’ E/L SIGNAL: Blower fan control switch second position or higher, cooling fan operating, headlights ON, or rear win-

dow defroster switch ON

F-24