MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 261 of 1164

ELECTRIC COOLING FAN SYSTEM E

ELECTRIC COOLING FAN SYSTEM

SYSTEM CIRCUIT

I

SINGLE-SPEED TYPE

WITH A/C

r __________ -------- ------..---- i

I

I

I -

I

I

r,

, II

I 1

P ’

iI

:”

IGZ

b CONNECTOR

WATER

THERMOSWITCH

ABOVE 97% (207OF): ON WO-SPEED TYPE

WITH AK

r--------

l

I

I

I

I

I

I I

I

I

I

L-

No.2

FAN

RELAY

ADDITIONAL

FAN

MOTOR - -_-_---

A-- 1- A/C SWITCH

_________ - -.--- -- _ .- .- - LDIAGNOSIS

CONNECTOR

WATER

THERMOSWITCH

ELAY ABOVE 97% (207“F): ON

RADIATOR SWITCH

ABOVE 105-Z (221°F): ON

03UOEX-019

E-13

Page 262 of 1164

E ELECTRIC COOLING FAN SYSTEM, FAN MOTOR

03UOEX-02

I

1

I

‘4

.

2

.:

)

SYSTEM INSPECTION

1. Jump across the fan test (TFA) terminal and the ground

(GND) terminal of the diagnosis connector.

2. Turn the ignition switch ON and verify that the fan operates.

If the fan does not operate, inspect the cooling fan system

components and wire harness. -.-

3. Remove the radiator cap and place a thermometer in the

radiator filler neck.

4. Start the engine.

5. Verify that the fan operates when the coolant temperature

reaches approx. 97OC (207OF).

If it does, check the water thermoswitch.

(Refer to page E-16.)

FAN MOTOR

INSPECTION

Single-Speed Type

1. Check that the battery is fully charged.

2. Disconnect the fan motor connector.

3. Connect the battery and an ammeter to the fan motor con-

nectar.

4. Verify that current is as specified.

Current (A)

B6 SOHC

BP SOHC

BP DOHC MTX ATX

6.6 f 1 6.6 f 1

6.6 f 1 -

6.6 f 1 -

5. If current is not within specification and/or the fan does not

turn smoothly, replace the fan motor.

Two-Speed Type

1. Check that the battery is fully charged.

2. Disconnect the fan motor connector.

3. Connect the battery and an ammeter to the fan motor con-

nectors for low-speed inspection. 4. Verify that the fan motor operates smoothly at the standard

current.

Current (A): 8.8 + 10% MAX

I

03UOEX-022

E-14

Page 263 of 1164

FAN MOTOR E

I-

i.- 5. Connect the battery, an ammeter, and switch to the fan mo-

tor connectors for high-speed inspection.

6. Verify that the fan motor operates smoothly at the standard

current or less with the switch ON.

Current (A): 13.3 + 10% MAX

7. If the fan motor is faulty, replace it.

---“-. --

REPLACEMENT

Caution

l Position the hose clamp in the original location on the hose, and squeeze the clamp lightly

with large pliers to ensure a good fit.

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the order shown in the figure.

4. Install in the reverse order of removal.

7.8-11 N.m

7.8-11 N.m

(80-110 cm-kg,

1. Resonance chamber

4. Radiator cowling

2. Cooling fan connector

5.

Cooling fan

3. Radiator hose upper

6. Fan motor

E-l 5

Page 264 of 1164

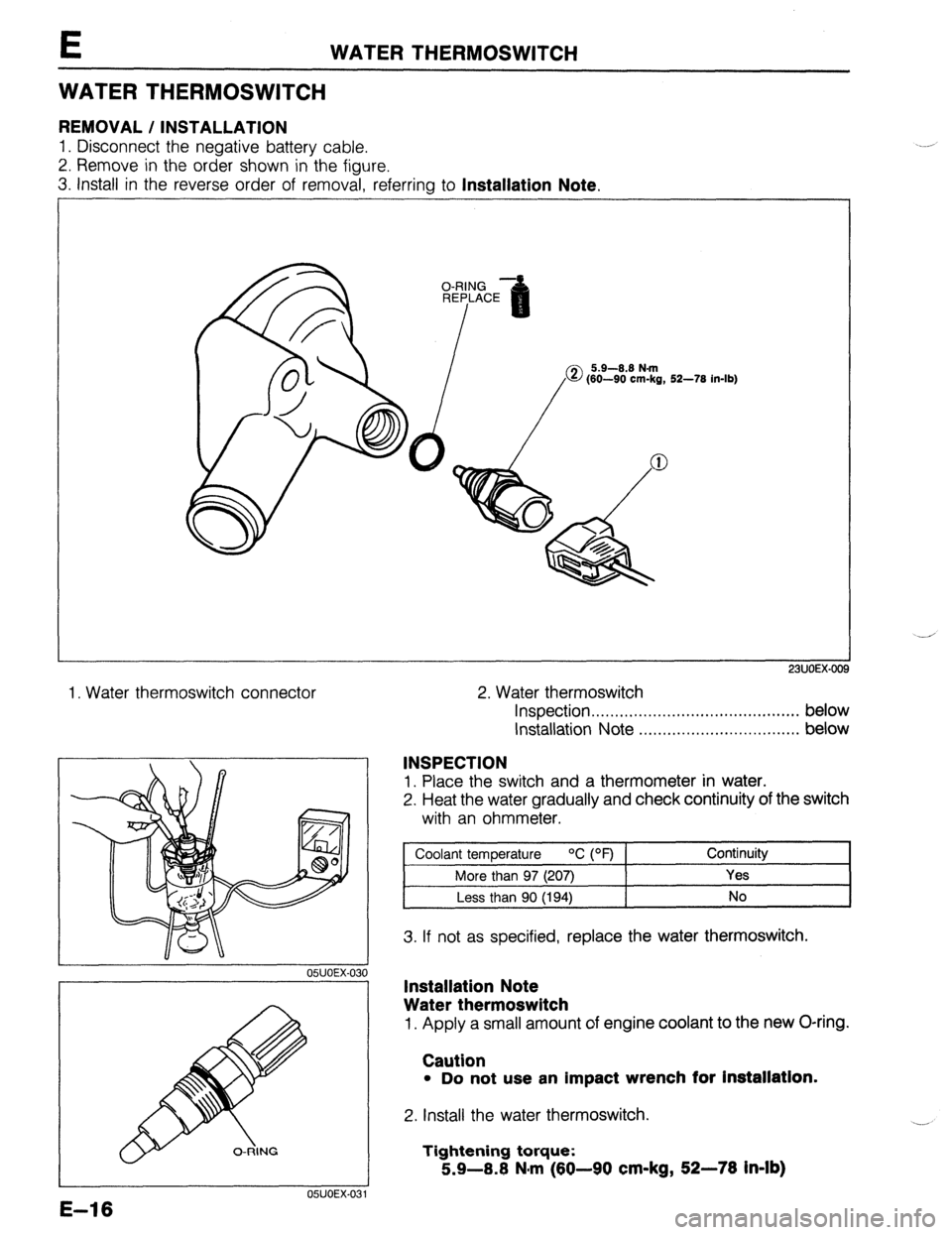

E WATER THERMOSWITCH

WATER THERMOSWITCH

REMOVAL / INSTALLATION

1. Disconnect the negative battery cable.

2. Remove in the order shown in the figure.

3. Install in the reverse order of removal, referring to

Installation Note.

2. Water thermoswitch

23UOEX-OO!

1. Water thermoswitch connector

05UOEX-031

05UOEX.03

E-16

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . below

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . below

INSPECTION

1. Place the switch and a thermometer in water.

2. Heat the water gradually and check continuity of the switch

with an ohmmeter.

I Coolant temDerature

OC PF) 1 Continuity

I

More than 97 (207) Yes

Less than 90 (194) No

3. If not as specified, replace the water thermoswitch.

Installation Note

Water thermoswitch

1. Apply a small amount of engine coolant to the new O-ring.

Caution

l Do not use an impact wrench for Installation.

2. Install the water thermoswitch.

Tightening torque:

5.9-8.8 N#m (69-90 cm-kg, 52-78 in-lb)

Page 265 of 1164

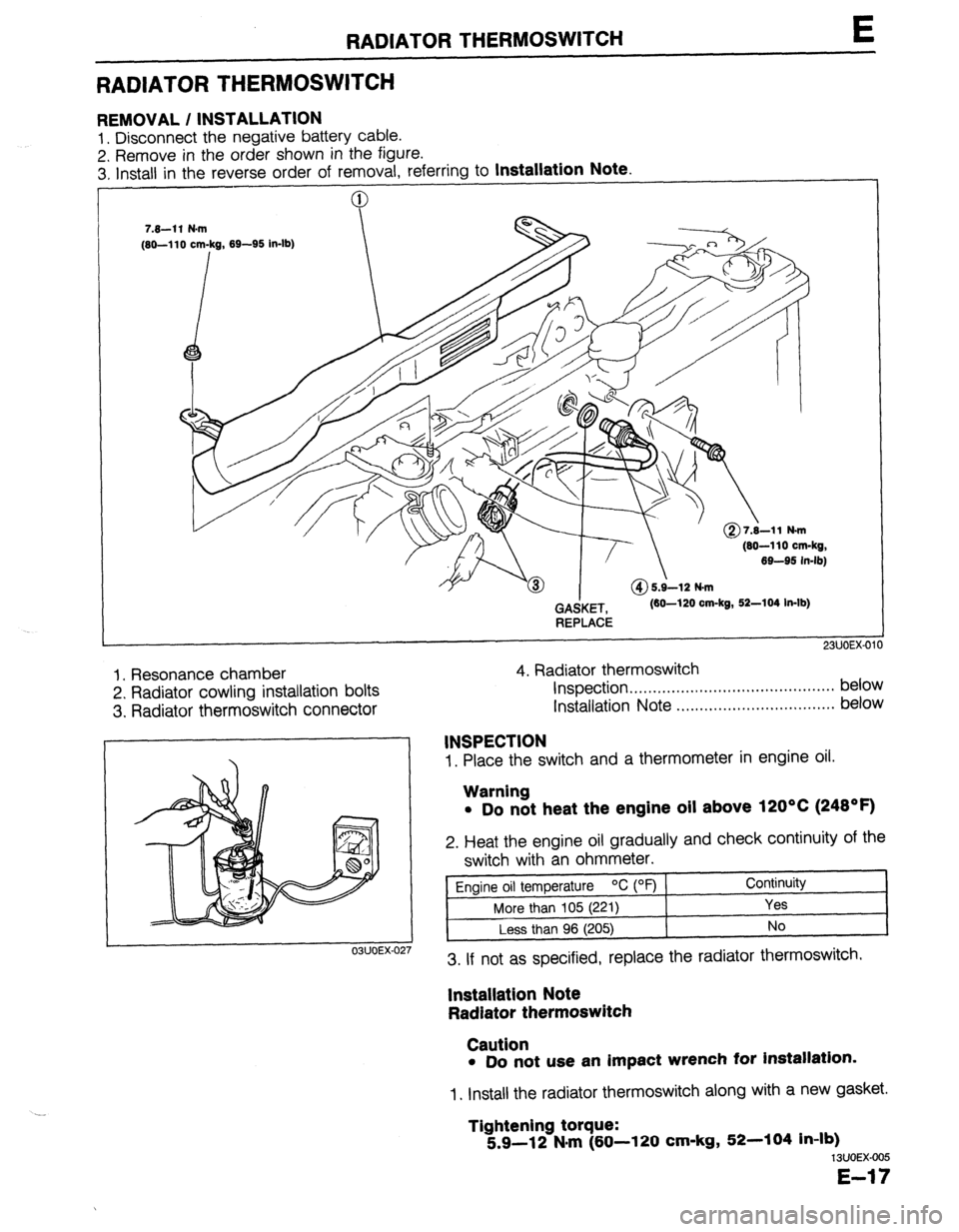

RADIATOR THERMOSWITCH E

RADIATOR THERMOSWITCH

REMOVAL / INSTALLATION

1. Disconnect the negative battery cable.

2. Remove in the order shown in the figure.

3. Install in the reverse order of removal. referrina to

Installation Note.

(80-110 cm-kg,

69-95 in-lb)

GAdKET,

REPLACE (60-120 cm-kg, 52-104 In-lb)

1. Resonance chamber

2. Radiator cowling installation bolts

3. Radiator thermoswitch connector 4. Radiator thermoswitch

Inspection . . . . . . . . . . . . . . . ..*...,..,..................* below

Installation Note ..,.,........,.......,........,... below

1. Place the switch and a thermometer in engine oil.

03UOEX-02

INSPECTION

Warning

l Do not heat the engine oil above 120°C (248OF)

2. Heat the engine oil gradually and check continuity of the

switch with an ohmmeter.

Engine oil temperature OC (OF) Continuity

More than 105 (221)

Yes

Less than 96 (205) No

3. If not as specified, replace the radiator thermoswitch.

lnstallatlon Note

Radiator thermoswitch

Caution

l Do not use an impact wrench for installation.

1. Install the radiator thermoswitch along with a new gasket.

Tightening torque:

5.9-12 N#m (60-l 20 cm-kg, 52-104 in-lb)

13UOEX-005

E-17

Page 266 of 1164

t FAN RELAY

FAN RELAY

REMOVAL / INSPECTION

1. Disconnect the negative battery cable.

2. Remove the fan relay in a place shown in the figure.

FAN RELAY

BP ATX)

l o... . ,. . . . . . . . . . TYPE 1 @ No.2 FAN RELAY

(FOR !3P ATX)

@AND @ . . . ..TYPE 2

03UOEX-029

[TYPE l] [TYPE 21

INSPECTION

1. Check continuity as shown with an ohmmeter.

Contir

No

Yes Terminal

m-0

OS-@

2. Apply 12V between terminals @ and @.

Check for continuity between terminals @ and 0.

3. If not as specified, replace the fan relay. .-

._/ ’

Page 267 of 1164

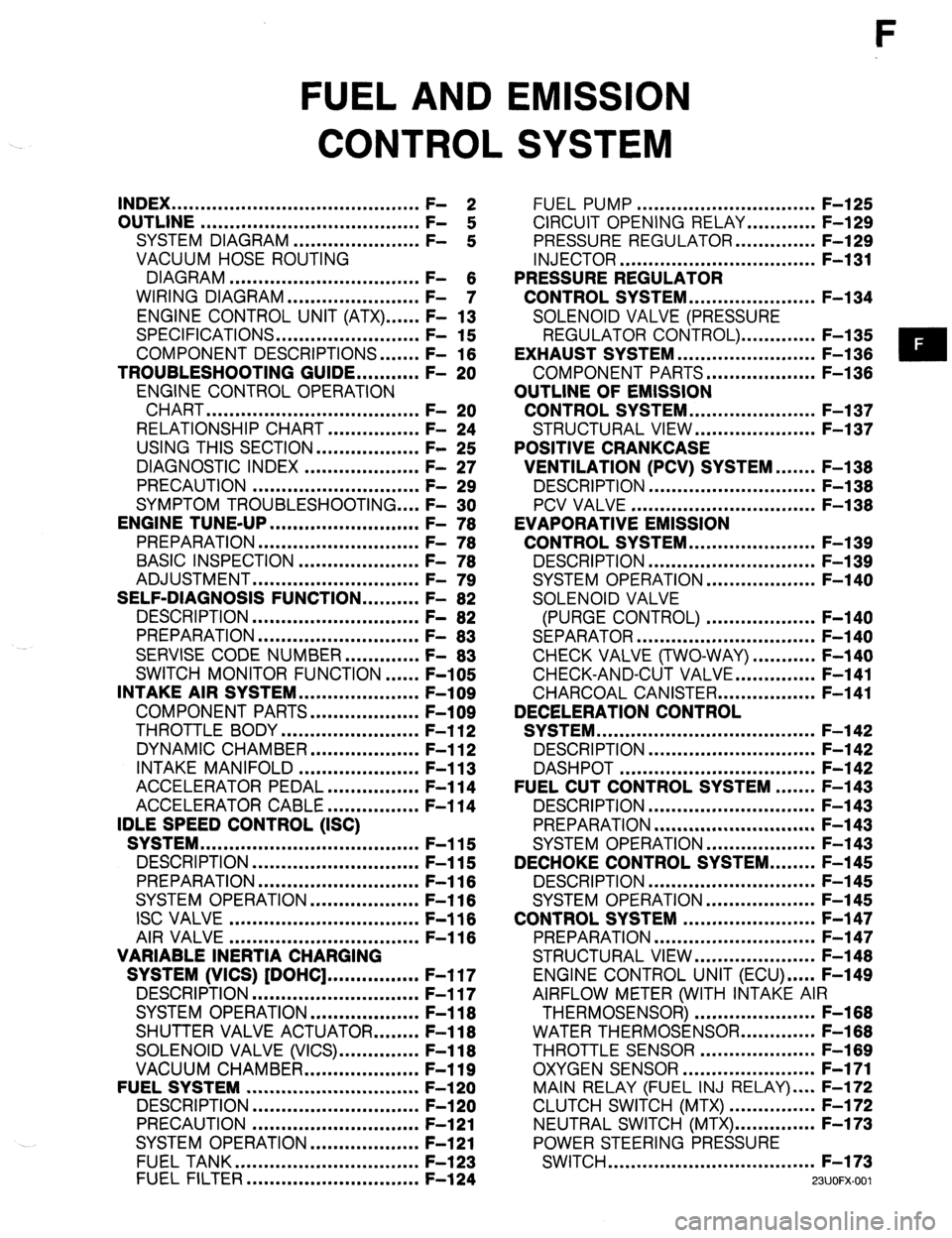

F

FUEL AND EMISSION

CONTROL SYSTEM

INDEX ...........................................

OUTLINE ...................................... ;: 2

SYSTEM DIAGRAM ...................... F-

:

VACUUM HOSE ROUTING

DIAGRAM .................................

WIRING DIAGRAM ....................... F- 6

- 7

ENGINE CONTROL UNIT (ATX) ...... F- 13

SPECIFICATIONS.. ....................... F- 15

COMPONENT DESCRIPTIONS.

...... F- 16

TROUBLESHOOTING GUIDE.. ......... F- 20

ENGINE CONTROL OPERATION

CHART

..................................... F- 20

RELATIONSHIP CHART.. .............. F- 24

USING THIS SECTION .................. F- 25

DIAGNOSTIC INDEX .................... F- 27

PRECAUTION ............................. F- 29

SYMPTOM TROUBLESHOOTING .... F- 30

ENGINE TUNE-UP

.......................... F- 76

PREPARATION ............................

F- 76

BASIC INSPECTION ..................... F- 78

ADJUSTMENT .............................

F- 79

SELF-DIAGNOSIS FUNCTION .......... F- 82

DESCRIPTION .............................

F- 82

PREPARATION

............................

F- 83

SERVISE CODE NUMBER.. ........... F- 83

SWITCH MONITOR FUNCTION ...... F-105

INTAKE AIR SYSTEM.. ................... F-109

COMPONENT PARTS.. ................. F-109

THROTTLE BODY ........................ F-l 12

DYNAMIC CHAMBER ................... F-l 12

INTAKE MANIFOLD ..................... F-l 13

ACCELERATOR PEDAL ................ F-l 14

ACCELERATOR CABLE ................ F-l 14

IDLE SPEED CONTROL (ISC)

SYSTEM ......................................

F-115

DESCRIPTION ............................. F-115

PREPARATION

............................ F-116

SYSTEM OPERATION.. ................. F-l 16

ISC VALVE ................................. F-116

AIR VALVE

................................. F-116

VARIABLE INERTIA CHARGING

SYSTEM (VICS) [DOHC] ................ F-l 17

DESCRIPTION ............................. F-117

SYSTEM OPERATION ................... F-l 18

SHUTTER VALVE ACTUATOR.. ...... F-l 18

SOLENOID VALVE (VICS). ............. F-118

VACUUM CHAMBER.. .................. F-119

FUELSYSTEM .............................. F-l 20

DESCRIPTION

............................. F-l 20

PRECAUTION ............................. F-121

SYSTEM OPERATION.. ................. F-121

FUEL TANK ................................

F-l 23

FUEL FILTER .............................. F-l 24 FUEL PUMP ............................... F-l 25

CIRCUIT OPENING RELAY.. .......... F-129

PRESSURE REGULATOR.. ............ F-129

INJECTOR .................................. F-l 31

PRESSURE REGULATOR

CONTROL SYSTEM.. .................... F-l 34

SOLENOID VALVE (PRESSURE

REGULATOR CONTROL). ............ F-l 35

EXHAUST SYSTEM ........................ F-l 36

COMPONENT PARTS.. ................. F-136

OUTLINE OF EMISSION

CONTROL SYSTEM.. .................... F-l 37

STRUCTURAL VIEW.. ................... F-l 37

POSITIVE CRANKCASE

VENTILATION (PCV) SYSTEM.. ..... F-138

DESCRIPTION .............................

F-l 38

PCV VALVE ................................ F-l 38

EVAPORATIVE EMISSION

CONTROL SYSTEM.. .................... F-l 39

DESCRIPTION ............................. F-l 39

SYSTEM OPERATION.. ................. F-140

SOLENOID VALVE

(PURGE CONTROL) ................... F-140

SEPARATOR ............................... F-l 40

CHECK VALVE (TWO-WAY) ........... F-140

CHECK-AND-CUT VALVE.. ............ F-141

CHARCOAL CANISTER.. ............... F-141

DECELERATION CONTROL

SYSTEM ...................................... F-l 42

DESCRIPTION ............................. F-l 42

DASHPOT .................................. F-142

FUEL CUT CONTROL SYSTEM ....... F-143

DESCRIPTION ............................. F-l 43

PREPARATION ............................ F-l 43

SYSTEM OPERATION.. ................. F-143

DECHOKE CONTROL SYSTEM.. ...... F-145

DESCRIPTION ............................. F-l 45

SYSTEM OPERATION ................... F-l 45

CONTROL SYSTEM ....................... F-l 47

PREPARATION ............................ F-147

STRUCTURAL VIEW.. ................... F-l 48

ENGINE CONTROL UNIT (ECU) ..... F-149

AIRFLOW METER (WITH INTAKE AIR

THERMOSENSOR) ..................... F-168

WATER THERMOSENSOR.. ........... F-168

THROTTLE SENSOR .................... F-l 69

OXYGEN SENSOR.. ..................... F-171

MAIN RELAY (FUEL INJ RELAY) .... F-172

CLUTCH SWITCH (MTX) ............... F-172

NEUTRAL SWITCH (MTX). ............. F-173

POWER STEERING PRESSURE

SWITCH .................................... F-173

WJOFX-001

Page 268 of 1164

F INDEX

DlSTRhUTOR

SERVICE, SECTION G INHIBITOR SWITCH (ATX)

SERVICE, SECTION K

F-2

Page 269 of 1164

INDEX F

1. Resonance duct

Inspection / Replacement.. ........ page F-l 09

2. Air cleaner element

Inspection ................................. page F- 79

Replacement.. ........................... page F-l 09

3. Airflow meter

(With intake air thermosensor)

Inspection

................................. page F-l 68

Replacement.. ........................... page F-l 09

4. Resonance chamber

Inspection I Replacement.. ........ page F-l 09

5. Throttle body

Inspection .................................

page F-l 12

Replacement.. ...........................

page F-l 09

6. Throttle sensor

inspection ................................. page F-l 69

Adjustment..

.............................. page F-l 69

Replacement.. ........................... page F-l 71

7. ISC valve

Inspection ................................. page F-l 16

Replacement..

........................... page F-l 09

8. Dashpot

Inspection ................................. page F-l 42

9. Dynamic chamber

Removal / Installation ................

page F-109

Inspection [DOHC] ................... page F-l 12

10. Air valve

Inspection

................................. page F-l 16

Removal / Installation ................ page F-109

11. Shutter valve actuator

Inspection ................................. page F-l 18

12. Vacuum chamber [DOHC]

Inspection ................................. page F-l 19

13. Intake manifold

Removal / Installation ................ page F-l 09

14. Injector

Inspection .................................

page F-l 31

Removal .................................... page F-131

Installation.. ............................... page F-l 33 15. Pressure regulator

Inspection ................................. page F-l 29

Replacement ............................. page F-l 30

16. Solenoid valve (Pressure regulator control)

[BP1

Inspection ................................. page F-l 35

17. Solenoid valve (VICS) [DOHC]

Inspection ................................. page F-l 18

18. Charcoal canister

Inspection ................................. page F-l 41

19. Solenoid valve (Purge control)

Inspection ................................. page F-l 40

20. Circuit opening relay

Inspection ................................. page F-l 29

Replacement ............................. page F-l 29

21. Engine control unit (ECU)

Removal / Installation ................ page F-l 49

Inspection ................................. page F-149

22. Clutch switch (MTX)

Inspection ................................. page F-l 72

Replacement.. ........................... page F-l 72

23. PCV valve

Inspection ................................. page F-l 38

24. Water thermosensor

Removal / Inspection /

Installation ............................... page F-l 68

25. Fuel filter (High-pressure side)

Replacement.. ........................... page F-l 24

26. Main relay (FUEL INJ relay)

Inspection ................................. page F-l 72

27. Neutral switch (MTX)

inspection ................................. page F-l 73

Replacement.. ........................... page F-l 73

28. Oxygen sensor

Inspection ................................. page F-l 71

Replacement ............................. page F-l 72

29. Power steering pressure switch

Inspection ................................. page F-l 73

Replacement.. ........................... page F-l 73

23UOFX-002

F-3

Page 270 of 1164

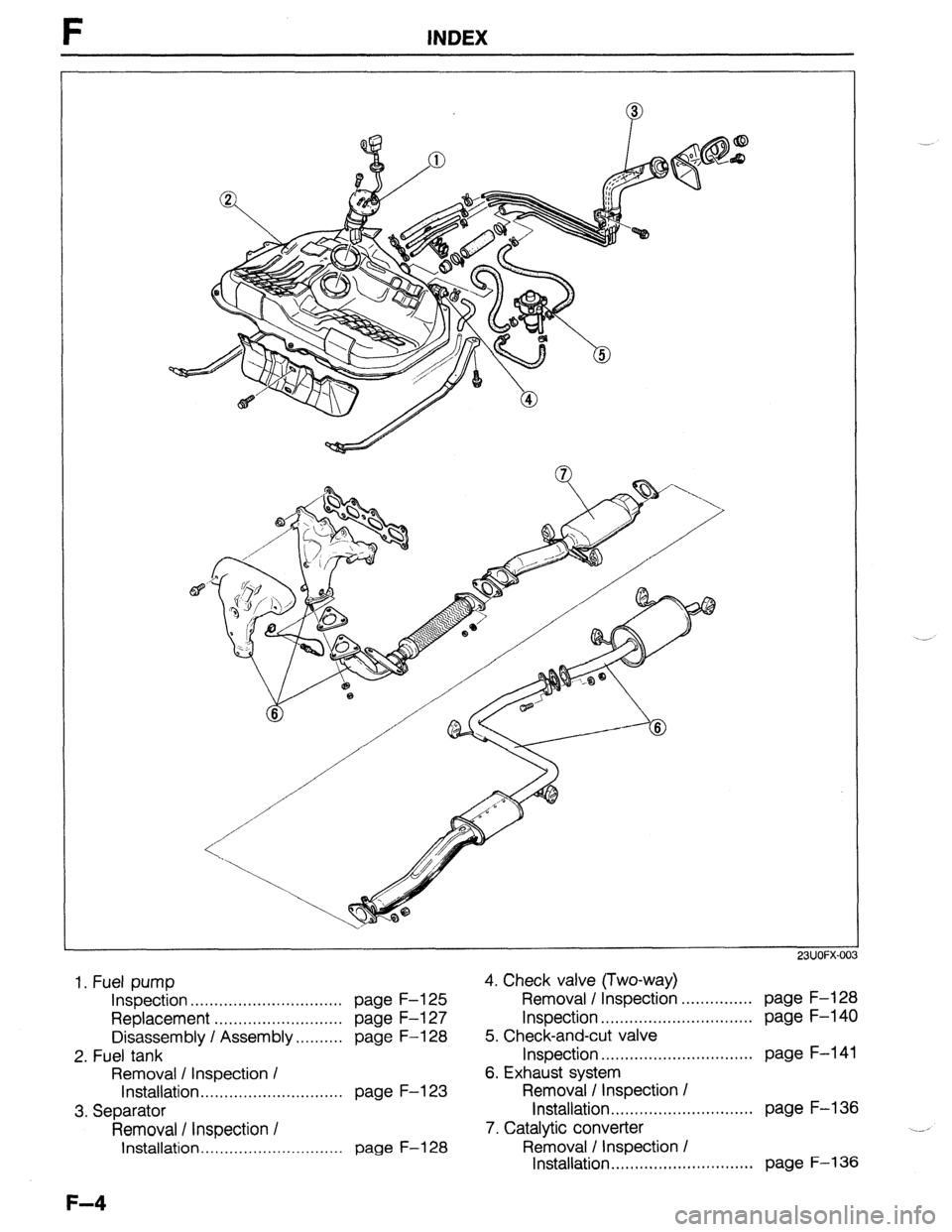

F INDEX

23UOFX-01

1. Fuel pump 4. Check valve (Two-way)

Inspection.. .............................. page F-l 25 Removal I Inspection ............... page F-128

Replacement ........................... page F-l 27 Inspection ................................ page F-140

Disassembly / Assembly.. ........ page F-l 28 5. Check-and-cut valve

2. Fuel tank Inspection ................................ page F-141

Removal I Inspection I 6. Exhaust system

Installation.. ............................ page F-l 23 Removal / Inspection /

3. Separator Installation.. ............................ page F-l 36

Removal I Inspection I 7. Catalytic converter

Installation.. ............................ page F-l 28 Removal / Inspection /

Installation .............................. page F-136

F-4