MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 251 of 1164

E

BP DOHC

-a TO HEATER

&$ No.1 RELAY

COOLANT ~~ESERVOI~~

@ ENGINE COOLANT

TOTAL CAPACITY

MTX: 5.0

liters (5.3 US qt, 4.4 Imp qt)

ATX: 6.0 liters (6.3 US qt, 5.3 Imp qt)

23UOEX-00

1. Engine coolant

6. Electric cooling fan system

Inspection ...................................

page E- 5 System circuit

.............................

page E-l 3

Replacement ...............................

page E-

6 System inspection

....................... page E-14

2. Radiator cap

7. Fan motor

Inspection ................................... page E- 7

Inspection ...................................

page E-14

3. Radiator

Replacement..

............................. page E-i 5

Removal / Installation..

................

page E-

8 8. Water thermoswitch

Inspection

.................. ................................... page E- 9 Removal / Installation

page E-16

4. Thermostat

Inspection ...................................

page E-l 6

Removal I Installation

.................. page E- 9 9. Radiator thermoswitch (ATX)

Inspection

.................. ...................................

page E- 9 Removal I Installation

page E-l 7

5. Water pump

Inspection

...................................

page E-l 7

Removal / Installation ..................

page E-i 1 10. Fan relay

Inspection ...................................

page E-l 8

E-3

Page 252 of 1164

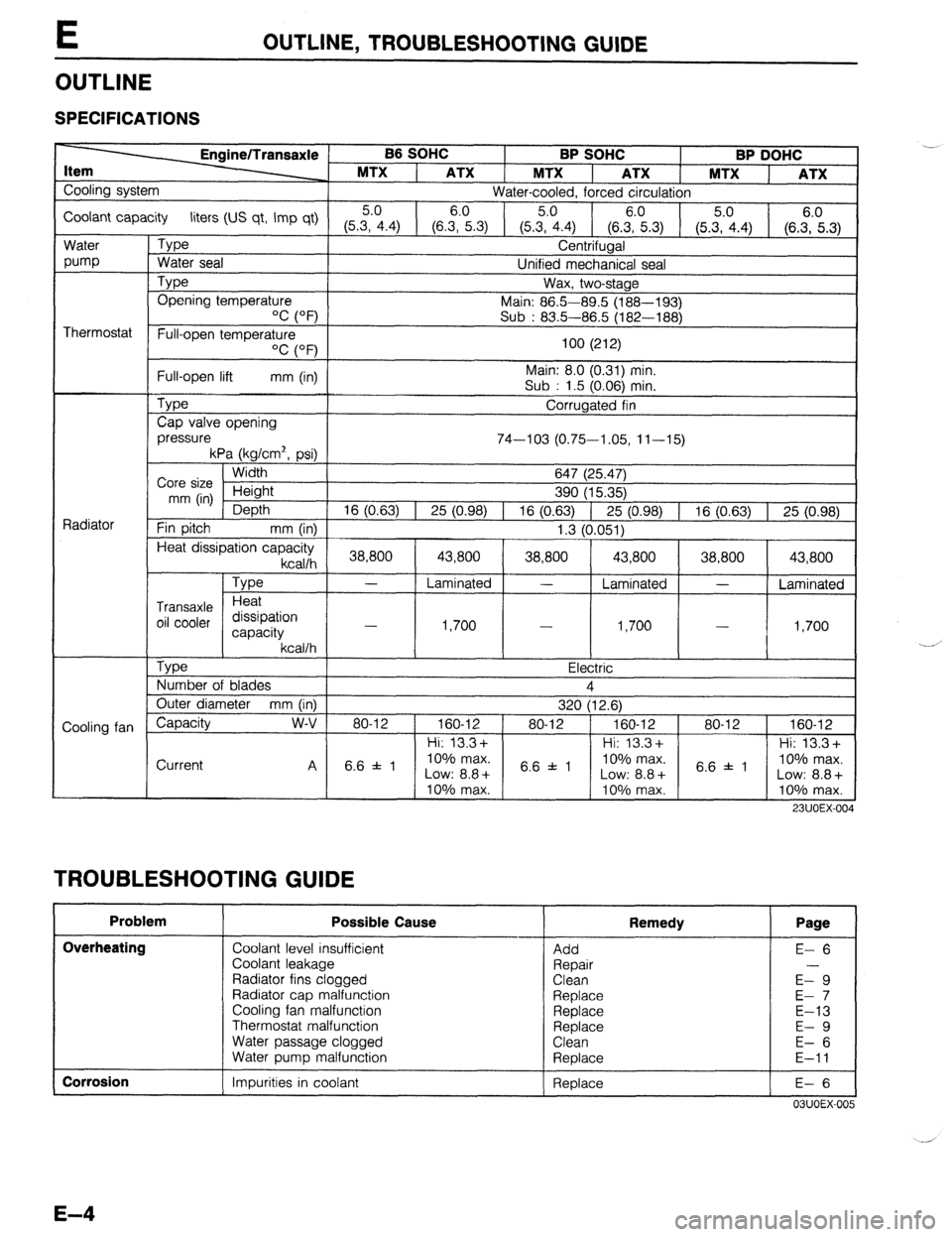

E OUTLINE, TROUBLESHOOTING GUIDE

OUTLINE

SPECIFICATIONS

B6 SOHC

BP SOHC BP DOHC

MTX

1 ATX 1 MTX ATX 1 MTX

ATX

Cooling system

Water-cooled, forced circulation

Coolant capacity liters (US qt, Imp qt) 5.0 6.0

5.0

(5.3, 4.4) (6.3, 5.3)

(5.35.04.4) (6.zi.3) (5.3, 4.4) (6.::.3)

Water

pump

Thermostat

Radiator

Cooling fan

L Type

Water seal Centrifugal

Unified mechanical seal

Type Opening temperature

‘C (OF’) Wax, two-stage

Main: 86.5-89.5 (188-193)

Sub : 83.5-86.5 (182-188)

Full-open temperature

OC (OF)

Full-open lift mm (in)

Type

Cap valve opening

pressure 100 (212)

Main: 8.0 (0.31) min.

Sub : 1.5 (0.06) min.

Corrugated fin

74-103 (0.75-1.05, 11-15)

kPa (kg/cm2, psi)

Width

Core size Height

mm (in)

Depth

Fin pitch

mm (in) 647 (25.47)

390 (15.35)

16 (0.63) 1 25 (0.98) 1 16 (0.63) 1 25 (0.98) 1 16 (0.63) 1 25 (0.98)

1.3 (0.051)

Heat dissipation capacity

kcallh 1 38,800 [ 43,800 ( 38,800 1 43,800 1 38,800 1 43,800 1

Type

Transaxle Heat

oil cooler dissipation

capacity

kcallh

Tvoe

- Laminated - Laminated -

Laminated

1,700

I .I -?nn

- -

I,,“”

I

I - I 4 Ye,-. I,IVV 1

, a-

- Electric

Number of blades 4

Outer diameter mm (in)

320 (12.6)

Capacity w-v 80-12 1 160-12 ) 80-12 ) 160-12 1 80-12 1 160-12

1 Hi: 13.3+ 1 1 Hi: 13.3+ 1 1 Hi: 13.3+

Current

TROUBLESHOOTING GUIDE I I I I

Problem Possible Cause

Overheating

Coolant level insufficient

Coolant leakage

Radiator fins clogged

Radiator cap malfunction

Cooling fan malfunction

Thermostat malfunction

Water passage clogged

Water puma malfunction .- Remedy Page

Add

Repair

Clean

Replace

Replace

Replace

Clean

Reolace E- 6

E-9

E- 7

E-13

E- 9

E- 6

E-11

I Corrosion

1 Impurities in coolant 1 Replace

I E-6 I

03UOEX-005

Page 253 of 1164

ENGINE COOLANT E

ENGINE COOLANT

PREPARATION

SST

49 9200 145

For 49 9200 146

For

inspection of inspection of

cooling system Adapter A cooling system

pressure (Part of pressure

49 9200 145)

05UOEX-00

INSPECTION

Warning

l Never remove the radiator cap while the engine is

hot.

l Wrap a thick cloth around the cap when removing it.

l When removing the radiator cap, loosen it slowly

to the first stop until the pressure in the radiator is

released, and then remove it.

03UOEX~006

Coolant Level (Engine cold)

1. Verify that the coolant level is near the radiator filler neck.

2. Remove the coolant level gauge and check the coolant level.

Coolant Quality

1. Verify that there is no buildup of rust or scale around the

radiator cap or radiator filler neck.

2. Verify that coolant is free of oil. Replace the coolant if

necessary.

Coolant Leakage

1. Connect a radiator tester (commercially available) and the

SST to the radiator filler neck.

2. Apply

103 kPa (1.05 kg/cm2, 15 psi) pressure to the

system.

3. Verify that the pressure is held.

If not, check for coolant leakage.

E-5

Page 254 of 1164

E ENGINE COOLANT

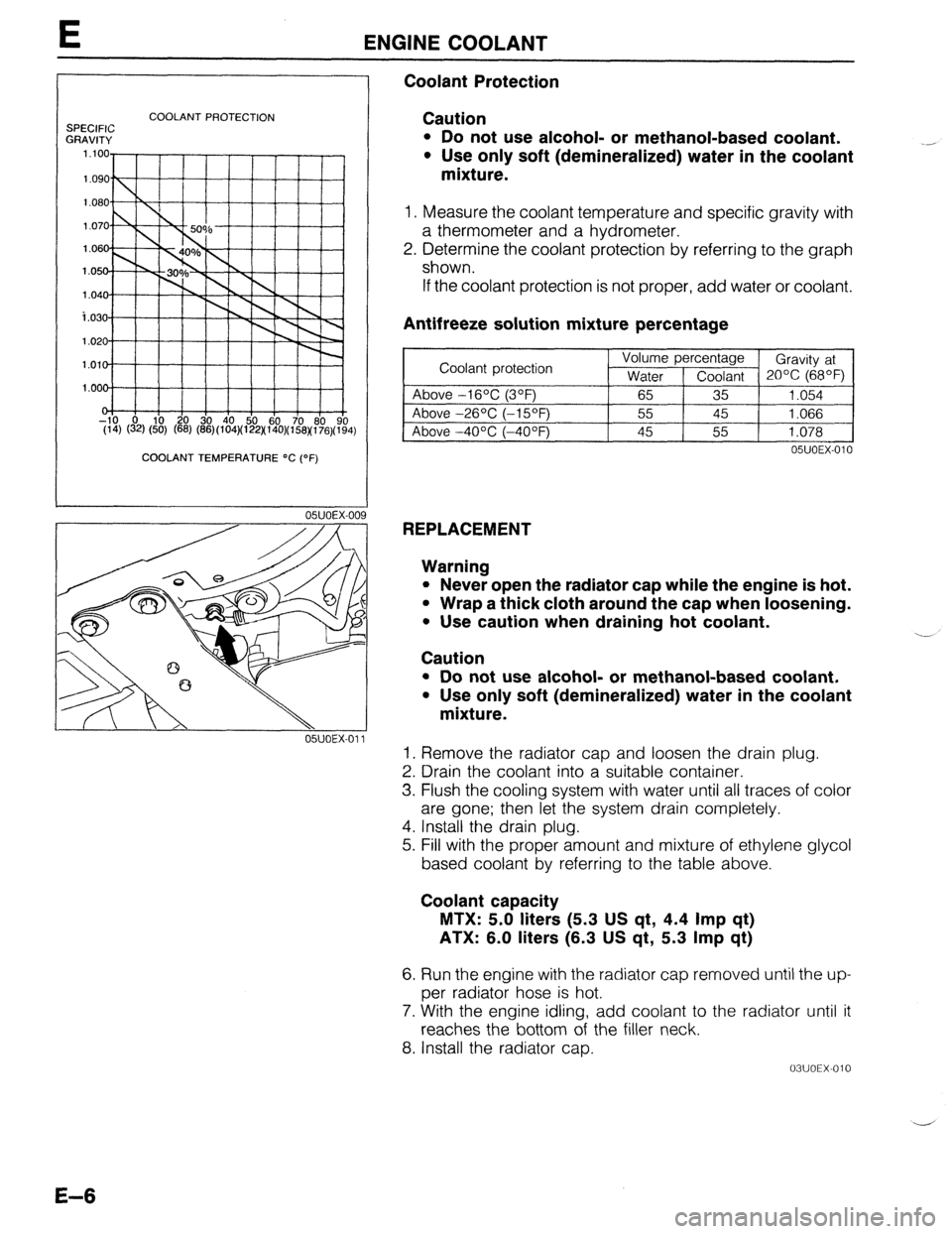

SPECIFIC

GRAVITY COOLANT PROTECTION

l.OOd ’ ’ I I I I I

0, I I

-10 0 i 10 20 30 40 50 60

70 60 90

(14) (32) (50) (66) (66)(104)(122)(140)(158~176)(194)

COOLANT TEMPERATURE OC (OF)

Coolant Protection

Caution

l Do not use alcohol- or methanol-based coolant.

l Use only soft (demineralized) water in the coolant

mixture.

1. Measure the coolant temperature and specific gravity with

a thermometer and a hydrometer.

2. Determine the coolant protection by referring to the graph

shown.

If the coolant protection is not proper, add water or coolant.

Antifreeze solution mixture percentage

~1

05UOEX-010

REPLACEMENT

Warning

l Never open the radiator cap while the engine is hot.

l Wrap a thick cloth around the cap when loosening.

. Use caution when draining hot coolant.

Caution ..-

l Do not use alcohol- or methanol-based coolant.

l Use only soft (demineralized) water in the coolant

mixture.

1. Remove the radiator cap and loosen the drain plug.

2. Drain the coolant into a suitable container.

3. Flush the cooling system with water until all traces of color

are gone; then let the system drain completely.

4. Install the drain plug.

5. Fill with the proper amount and mixture of ethylene glycol

based coolant by referring to the table above.

Coolant capacity

MTX: 5.0 liters (5.3 US qt, 4.4 Imp qt)

ATX: 6.0 liters (6.3 US qt, 5.3 Imp qt)

6. Run the engine with the radiator cap removed until the up-

per radiator hose is hot.

7. With the engine idling, add coolant to the radiator until it

reaches the bottom of the filler neck.

8. Install the radiator cap.

03UOEX-010 -

E-6

Page 255 of 1164

RADIATOR CAP E

RADIATOR CAP

PREPARATION

I I 05UOEX-014

INSPECTION

Radiator Cap Valve

1. Remove foreign material (such as water residue) from be-

tween the radiator cap valve and the valve seat.

2. Attach the radiator cap to a radiator cap tester (commer-

cially available) with the

SST. Apply pressure gradually to

74-103 kPa (0.75-l .05 kg/cm , 11-15 PSI).

3. Wait about 10 seconds. Verify that the pressure has not

decreased.

Negative Pressure Valve

1. Pull the negative pressure valve to open it. Verify that it

closes completely when released.

2. Check for damage on the contact surfaces and for cracked

or deformed seal packing.

3. Replace the radiator cap if necessary.

E-7

Page 256 of 1164

E RADIATOR

RADIATOR

REMOVAL / INSTALLATION

Caution

l Position the hose clamp in the original location on the hose, and squeeze the clamp lightly

with large pliers to ensure a good fit.

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the order shown in the figure.

4. Install in the reverse order of removal.

7.8-11 N.m (80-110 cm-kg, 69-95 in-lb)

-...__--- --- i

771 InFu.nnc; cvyILII ..,.,..

6. Oil cooler hose (ATX)

7. Radiator bracket

8. Radiator

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page E-9

9. Cooling fan and radiator cowling assembly 1. Resonance chamber

2. Cooling fan connector

3. Radiator thermoswitch connector (BP ATX)

4. Coolant reservoir hose

5. Radiator hose i

Y’

E-8

Page 257 of 1164

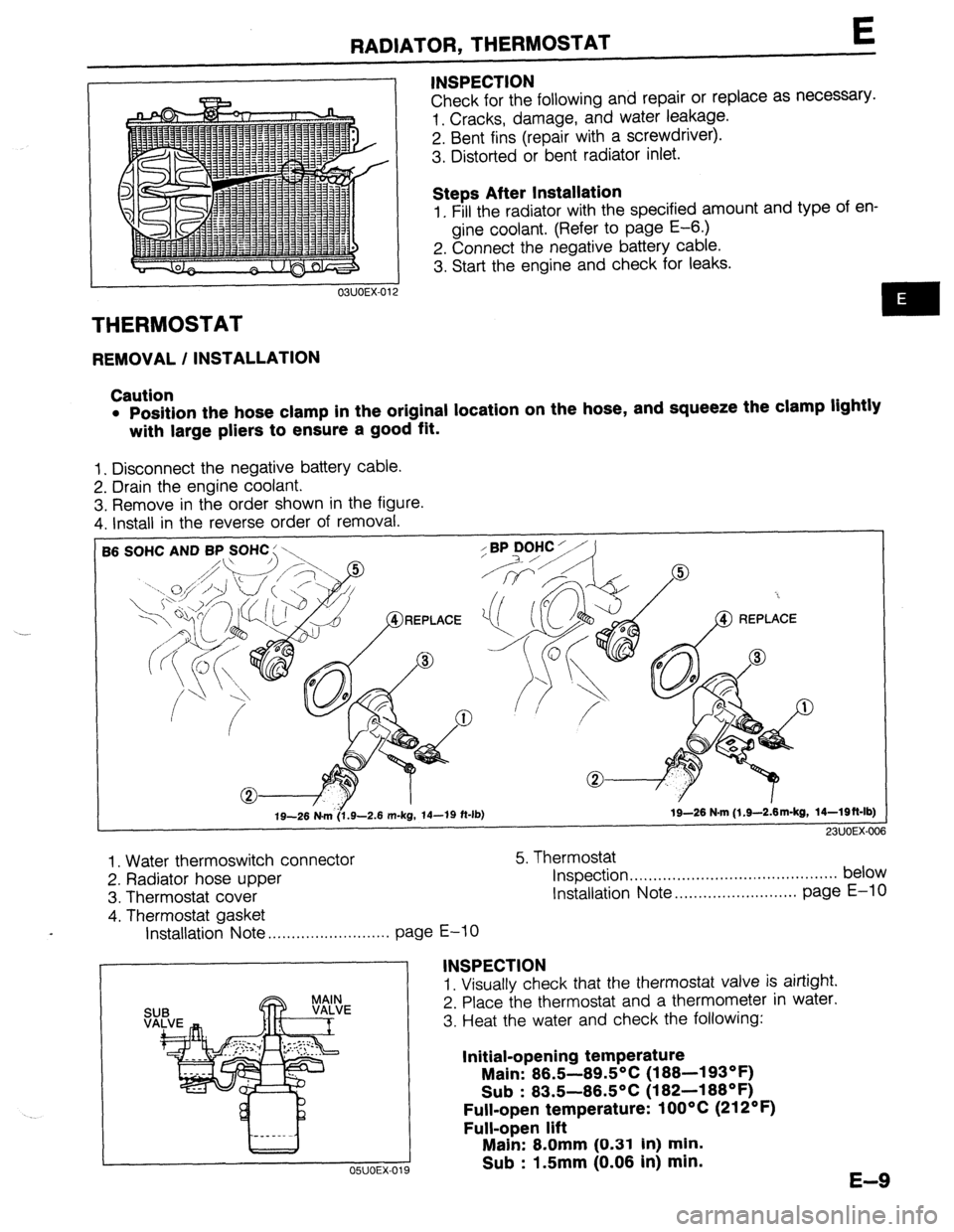

RADIATOR, THERMOSTAT t

THERMOSTAT

REMOVAL / INSTALLATION INSPECTION

Check for the following and repair or replace as necessary.

1. Cracks, damage, and water leakage.

2. Bent fins (repair with a screwdriver).

3. Distorted or bent radiator inlet.

Steps After Installation

1. Fill the radiator with the specified amount and type of en-

gine coolant. (Refer to page E-6.)

2. Connect the negative battery cable.

3. Start the engine and check for leaks.

Caution

l Position the hose clamp in the original location on the hose, and squeeze the clamp lightly

with large pliers to ensure a good fit.

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the order shown in the figure.

4. Install in the reverse order of removal.

SOHC AND BP SOHC : \,

19-26 N&6.9-2.6 m-kg, 14-19 ft-lb) 19-26 N-m (l.S--2&m-kg, 14-Wft-lb)

23UOEX-006

1. Water thermoswitch connector

2. Radiator hose upper

3. Thermostat cover

4. Thermostat gasket 5. Thermostat

Inspection . . . . .., .., ,.. ,.. . . . ,.. . . . . . . . . . . . . . . . . . . . . . . below

Installation Note ..,....................... page E-10

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . .

page E-10

INSPECTION

1. Visually check that the thermostat valve is airtight.

2. Place the thermostat and a thermometer in water.

3. Heat the water and check the following:

Initial-opening temperature

Main: 86.5-89.5°C (188-193OF)

Sub : 83.5-86.5OC (182-188OF)

Full-open temperature: 1 OOOC (212OF)

Full-open lift

OSUOEX-019

Main: 8.0mm (0.31 In) min.

Sub : 1.5mm (0.06 in) min.

E-9

Page 258 of 1164

E THERMOSTAT

Installation Note JIGGLE PIN Thermostat

6 8 8

1. Install the thermostat into the cylinder head with the jiggle

pin at the top. ..__

Thermostat gasket

1. Install a new gasket with the seal print side facing the cylin-

der head.

03UOEX-014

Steps After Installation

1. Fill the radiator with the specified amount and type of engine coolant. (Refer to page E-6.)

2. Connect the negative battery cable,

3. Start the engine and check for leaks.

03UOEX-015

.-

E-IO

Page 259 of 1164

WATER PUMP WATER PUMP

E

REMOVAL / INSTALLATION

Caution

l Do not disassemble the water pump. If a problem is found, replace the pump as a Unit.

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the order shown in the figure, referring to

Removal Note.

4. Install in the reverse order of removal.

B6 SOHC AND BP SOHC

83, t B6, BP SOHC

I

I

L-----------------_-- ------- -1

/ \/

19-26 (1.9-2.6, 14-19) LVVVLI. YY,

1. Timing belt 4. Water pump assembly

Service ., . . .., ,, ., . . . . . ,. ,.,. ., ,., . . ,,.... . . . . , Section Bl Inspect for cracks, damaged mounting

2. Water inlet pipe

and gasket surface, bearing condition, and leakage

3. Water bypass pipe and O-ring 5. Water pump gasket

E-l 1

Page 260 of 1164

BP DOHC

L 7.8-11 N-m (60-110 cm-kg, 69-95 in-lb)

E WATER PUMP

157-167

I

(W-17, 116-123) I

I

/

I

I

I

---N-w------

---------------

----_---_

-I

N.m (m-kg, ft-lb) 1

^^, *--., ^^^

1. Timing belt

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 5. Water pump assembly

B2

2. Water inlet pipe and gasket Inspect for cracks, damaged mounting

3. Water bypass pipe and O-ring surface, bearing condition, and leakage

4. Oil dip stick pipe bracket 6. Water pump gasket

Steps After Installation

1. Fill the radiator with the specified amount and type of engine coolant. (Refer to page E-6.)

2. Connect the negative battery cable,

3. Start the engine and check for leaks.

03UOEX-018

E-12