MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 241 of 1164

ENGINE OIL, OIL FILTER D

b

I

03UODX-00

ONODX-01

r

03UODX-011

ENGINE OIL

INSPECTION

1. Be sure the vehicle is on level ground.

2. Warm up the engine to normal operating temperature and

stop it.

3. Wait for five minutes.

4. Remove the oil level gauge and check the oil level and con-

dition.

5. Add or replace oil as necessary.

Note

l The distance between the L and F marks on the level

gauge represents 0.8 liter (0.85 US qt, 0.70 Imp qt).

REPLACEMENT

Warning

l Be careful when draining; the oil is hot.

1. Warm up the engine to normal operating temperature and

stop it.

2. Remove the oil filler cap and the oil pan drain plug.

3. Drain the oil into a suitable container.

4. Install a new gasket and the drain plug.

Tightening torque:

29-41 N,m (3.0-4.2 m-kg, 22-30 ft-lb)

5. Refill the engine with the specified type and amount of en-

gine oil.

6. Refit the oil filler cap.

7. Run the engine and check for leaks.

8. Check the oil level and add oil if necessary.

Oil pan capacity

B6 SOHC

BP SOHC and DOHC

liters (US qt, Imp qt)

3.0 (3.2, 2.6)

3.6G.843.2)

w

03UODX-011

D-7

Page 242 of 1164

D OIL FILTER, OIL COOLER

r

\/

OSUODX-0

‘I . 03UODX-01

OIL FILTER

REPLACEMENT

1. Remove the oil filter with a suitable wrench.

2. Use a clean rag to wipe off the mounting surface on the

engine.

3. Apply a small amount of clean engine oil to the rubber seal

of the new filter.

4. Install the oil filter and tighten it by hand until the rubber

seal contacts the base.

5. Tighten the filter 1 and 116 turns with a filter wrench.

6. Start the engine and check for leaks.

7. Check the oil level and add oil if necessary.

Oil filter capacity: 0.17 liter (0.18 US qt, 0.15 Imp qt)

OIL COOLER (BP DOHC)

REMOVAL

1. Drain the engine oil.

2. Remove the oil filter with an oil filter wrench.

3. Disconnect the water hoses.

4. Remove the oil cooler.

INSTALLATION

1. Install the oil cooler.

Tightening torque:

29-39 Nnrn (3.0-4.0 m-kg, 22-29 ft-lb)

2. Install the oil filter. (Refer to page D-8.)

3. Add engine oil to the correct level.

4. After installing the filter, check that there is no oil leakage

while the engine is running.

5. Recheck the oil level using the dipstick.

(Refer to page D-7.)

Page 243 of 1164

OIL PAN

OIL PAN

REMOVAL / INSTALLATION

1. Disconnect the negative battery cable.

2. Drain the engine oil.

3. Remove the under cover and side cover.

4. Remove in the order shown in the figure, referring to

Removal Note.

5. Install in the reverse order of removal, referring to Installation Note.

B6 SOHC

37-52 (3.8-5.3, 27-38)

I

GASKET,

REPLACE

9-94 (7.0-9.6, 51-69)

-52 ,a m-c .a .Y’)-*II

29-41 (3.0--/.2, 22-30)

_- ,r.rr--r-u, -.--““I ‘.8 11 Nm 4,

#O-r 10 cm-k% 69-96 in-lb) ,a&

7.8-l 1 N.m (SO-1 10 cm-kg, 69-96 in-lb)

1. Front exhaust pipe and bracket

2. Integrated stiffener

3. Oil pan

Removal Note ,...*..,,..*..,..*.......... page D-10

Inspect for cracks, deformation or damage

installation Note .,,.,..,,,.,.,......,.... Page D-l 1 4. Oil strainer

5. Main bearing support plate (MBSP)

Removal Note ,..,..I.,.......,........... page D-l 1

Installation Note .,..,,.,.....,,.....,..,.. page D-l 1

D-9

Page 244 of 1164

D OIL PAN

BPSOHCANDDOHC 37-52 (3.8-5.3, 27-38)

I -

16-21 (1.8-2.1, 12-15)

---P 31-46 (3.2-4.7, 23-3’

37-52 (3.8-5.3, 27-36

Ax. GASKET. 1

REPLACE,

cd h 37-52 (3.8-5.3, 27-38) GiSKET,

REPLACE

/ 29-41 (3.0-4.2, 22-30)

-v

44

7.6-l 1 N.m (80-l 10 cm-kg, 69-95 in-lb) N.m (m-kg, ft-It

1 SUODX-0

1. Front exhaust pipe and bracket 3. Oil strainer

2. Oil pan 4. Main bearing support plate (MBSP)

Removal Note . . . . . . . . . . . below Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . page D-l I

. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspect for cracks, deformation and

damage

Installation Note *............,....,......* page D-l 1 Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . . page D-l 1

Removal Note

Oil pan

B6 SOHC

1. Remove the oil pan mounting bolt.

2. Insert a screwdriver or a suitable tool between the MBSP

and oil pan, and pry them.

Caution

l Do not insert the prying tool between the MBSP and

cylinder block.

l Do not damage or scratch the contact surfaces.

3. Remove the oil pan.

D-IO

Page 245 of 1164

OIL PAN

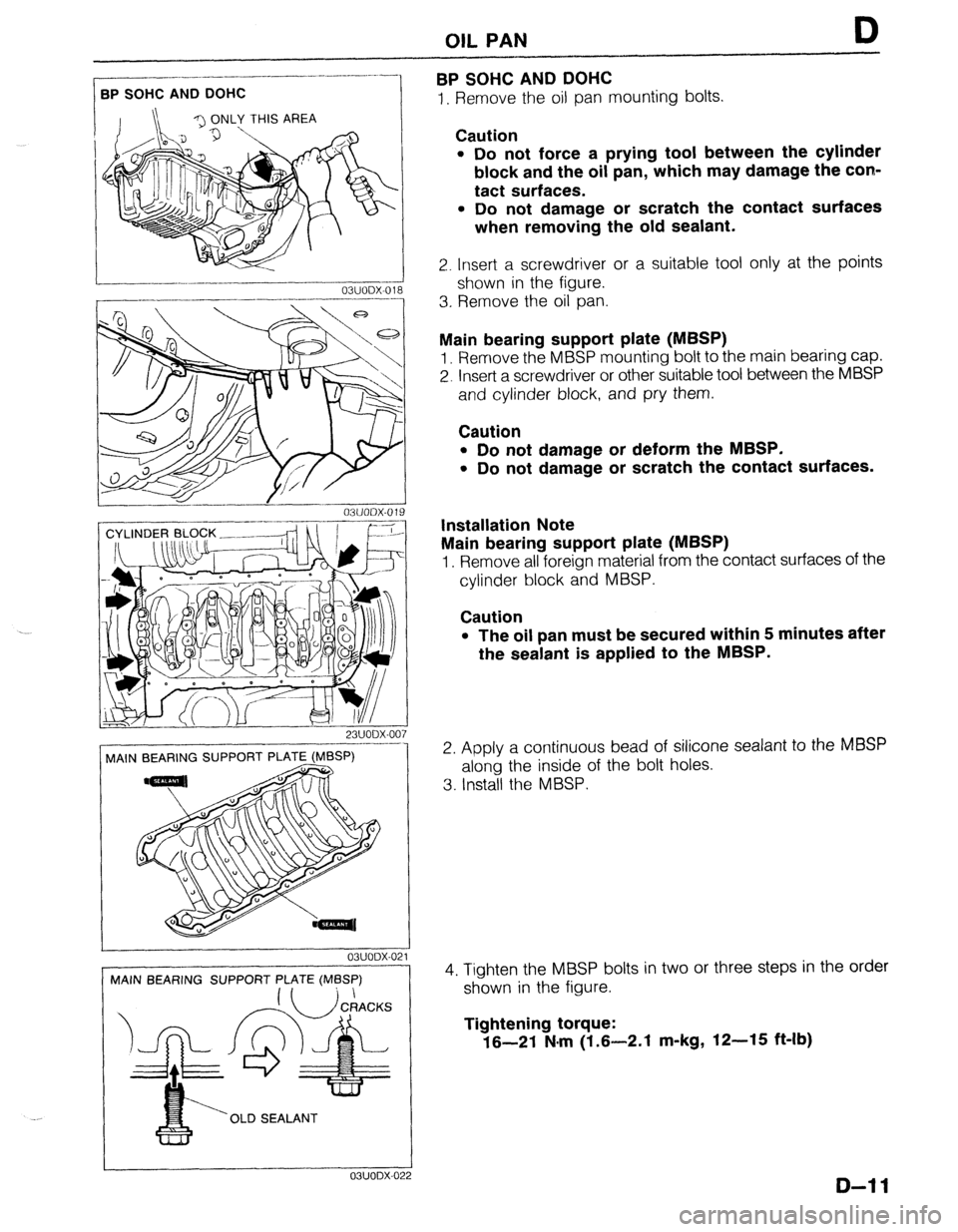

BPSOHCANDDOHC

D

I. Remove the oil pan mounting bolts. .-_-__------- BPSOHCANDDOHC

23UODX-007

MAIN BEARING SUPPORT PLATE (MBSP)

! 03UODX-021

MAIN BEARING SUPPORT PLATE (MBSP)

‘OLD SEALANT ---1_1

OBUODX-0: !2

Caution

l Do not force a prying tool between the cylinder

block and the oil pan, which may damage the con-

tact surfaces.

l Do not damage or scratch the contact surfaces

when removing the old sealant.

2. Insert a screwdriver or a suitable tool only at the points

shown in the figure.

3. Rernove the oil pan.

Main bearing support plate (MBSP)

1. Remove the MBSP mounting bolt to the main bearing cap.

2. Insert a screwdriver or other suitable tool between the MBSP

and cylinder block, and pry them.

Caution

l Do not damage or deform the MBSP.

l Do not damage or scratch the contact surfaces.

Installation Note

Main bearing support plate (MBSP)

1. Remove all foreign material from the contact surfaces of the

cylinder block and MBSP.

Caution

l The oil pan must be secured within 5 minutes after

the sealant is applied to the MBSP.

2. Apply a continuous bead of silicone sealant to the MBSP

along the inside of the bolt holes.

3. Install the MBSP.

4. Tighten the MBSP bolts in two or three steps in the order

shown in the figure.

Tightening torque:

16-21 N.m (1.6-2.1 m-kg, 12-15 ft-lb)

D-l 1

Page 246 of 1164

OIL PAN

I 03UODX.02

05UOBX.20

1

05UODX-021

56 SOHC

03UODX-02

3P s

03UODX-02!

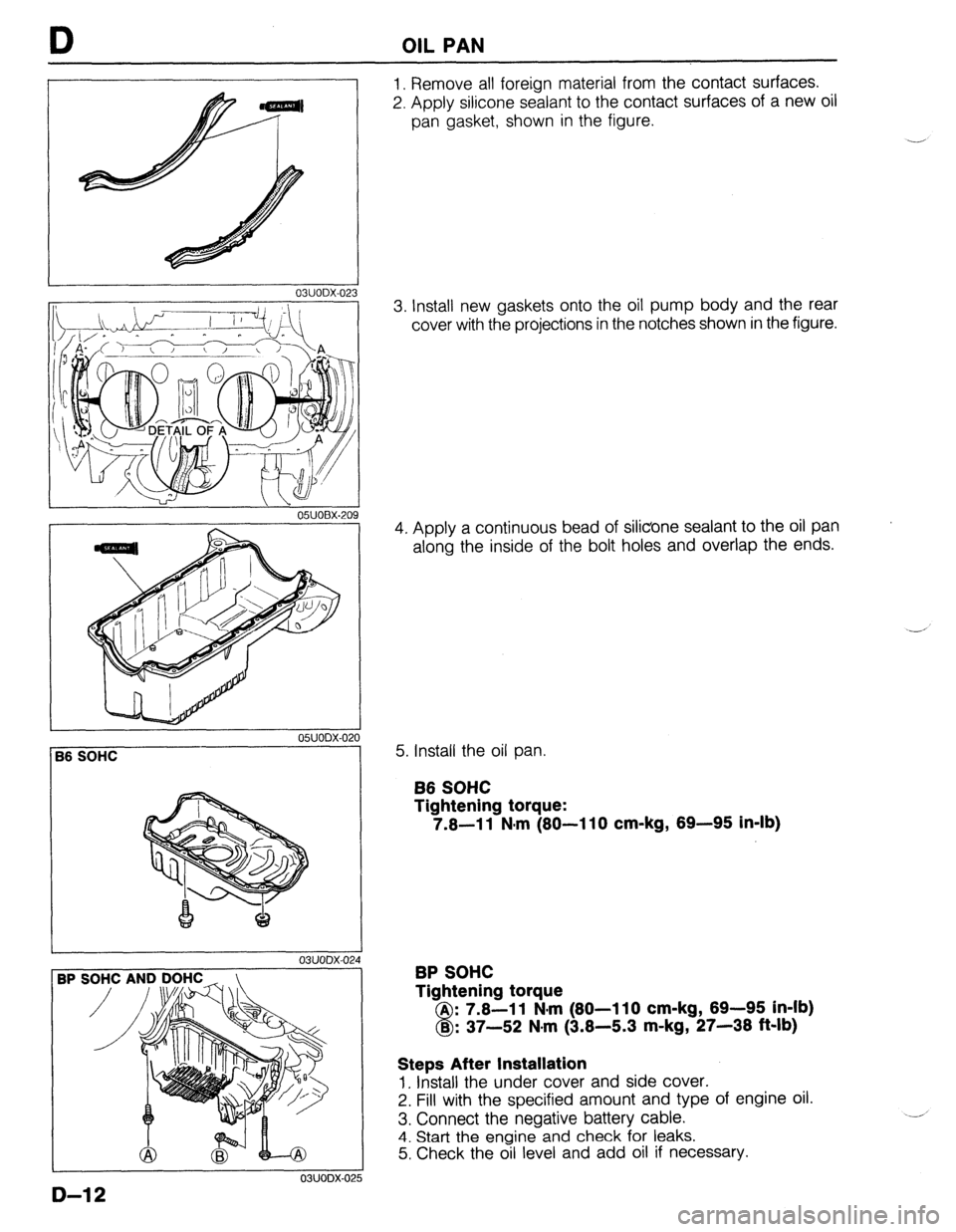

1. Remove all foreign material from the contact surfaces.

2. Apply silicone sealant to the contact surfaces of a new oil

pan gasket, shown in the figure.

3. Install new gaskets onto the oil pump body and the rear

cover with the projections in the notches shown in the figure.

4. Apply a continuous bead of silicone sealant to the oil pan

along the inside of the bolt holes and overlap the ends.

5. Install the oil pan.

B6 SOHC

Tightening torque:

7.6-11 N-m (80-110 cm-kg, 69-95 in-lb)

BP SOHC

Tightening torque

A : 7.8-l 1 N-m (80-l 10 cm-kg, 69-95 in-lb)

8 B : 37-52 N.m (3.8-5.3 m-kg, 27-38 ft-lb)

Steps After Installation

1. Install the under cover and side cover.

2. Fill with the specified amount and type of engine oil.

3. Connect the negative battery cable.

4. Start the engine and check for leaks.

5. Check the oil level and add oil if necessary.

D-12

Page 247 of 1164

OIL PUMP D

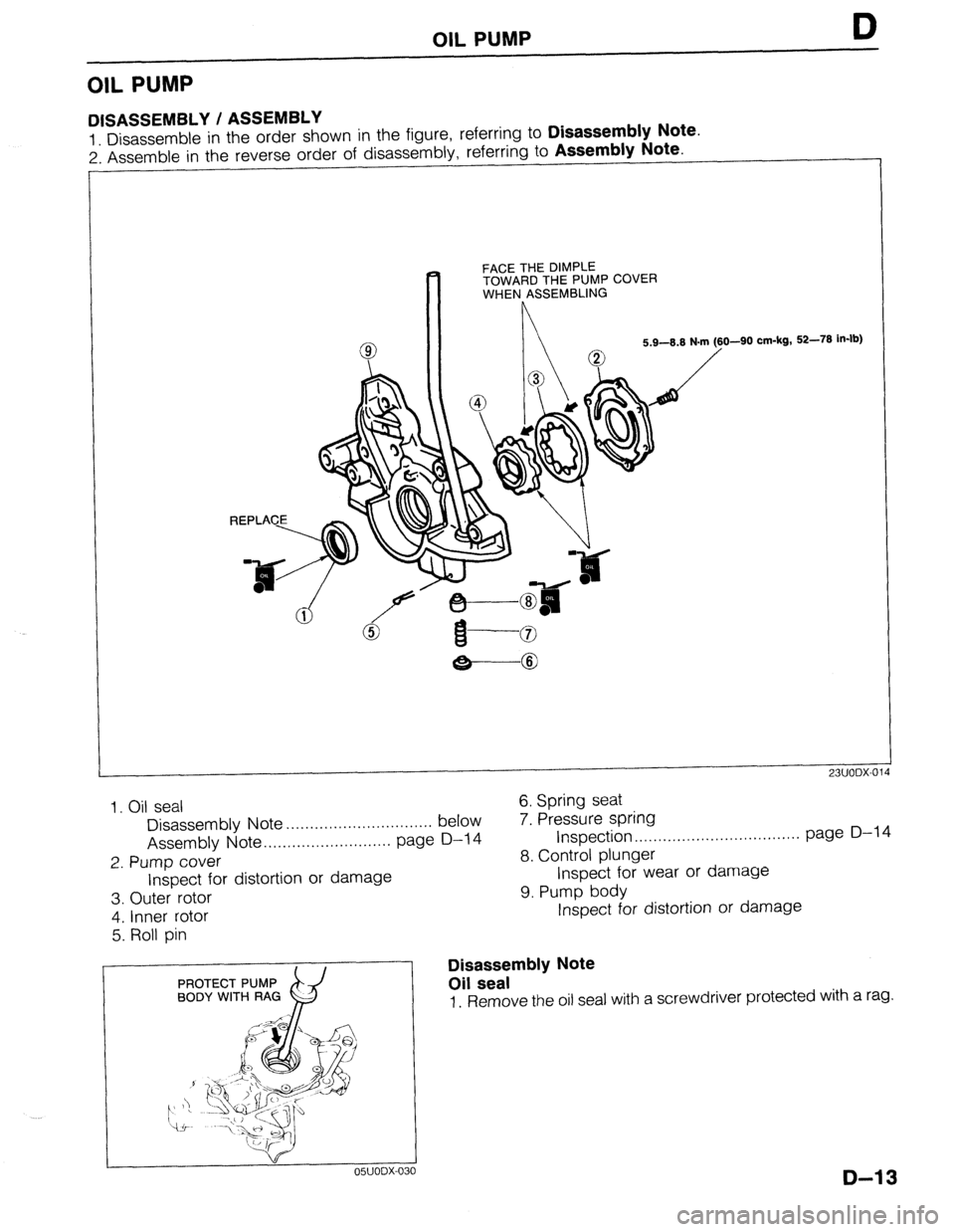

OIL PUMP

DISASSEMBLY / ASSEMBLY

1 Disassemble in the order shown in the figure, referring to Disassembly Note.

2: Assemble in the reverse order of disassembly, referring to Assembly Note.

FACE THE DIMPLE

TOWARD THE PUMP COVER

WHEN ASSEMBLING

O-90 cm-kg, 52-78 in-lb)

-8

23UODX-014

1. Oil seal

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . below

Assembly Note .,,..,.....,..,............ page D-14

2. Pump cover

Inspect for distortion or damage 6. Spring seat

7. Pressure spring

Inspection ..,..,.....,..,..,..,.............. page D-l 4

8. Control plunger

Inspect for wear or damage

9. Pump body

3. Outer rotor

4. Inner rotor

5. Roll pin

PROTECT PUMP

BODY WITH RAG

x9 05UODX-OC IO

Inspect for distortion or damage

Disassembly Note

Oil seal

1. Remove the oil seal with a screwdriver protected with a rag.

D-13

Page 248 of 1164

OIL PUMP

OWODX-032

r----‘---I ----

L-

---- 05UODX-033

r- __I_.__^--

_- .-.. --.-.__-----^---

---7--l

L-.-.LlLd-..- ..-.---A OWODX-034

___ll_--_l___-----------

___I- 1

.i

5

INSPECTION

Pressure Spring

1 Inspect the spring for weakness or breakage.

2. Measure the free length. Replace the spring if necessary.

Free length: 45.5mm (1.791 in) -

Rotor Clearance

1. Measure the following clearances. Replace the rotor if

necessary.

Tooth tip clearance: 0.20mm (0.0079 in) max.

Outer rotor to pump body clearance:

0.22mm (0.0087 in) max.

Side clearance: 0.14mm (0.0055 in) max.

Assembly Note

Oil seal

1, Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand,

Caution

l The oil seal must be pressed in until it is flush with

the edge of the oil pump body.

-’

3. Press the oil seal in evenly with a suitable pipe.

Oil seal outer diameter: 44mm (1.73 in)

Page 249 of 1164

E

COOLING SYSTEM

INDEX ...................................................... E- 2

OUTLINE .................................................. E- 4

SPECIFICATIONS .................................... E- 4

TROUBLESHOOTING GUIDE ...................... E- 4

ENGINE COOLANT .................................... E- 5

PREPARATION ....................................... E- 5

INSPECTION ..........................................

REPLACEMENT ...................................... :z ;

RADIATOR CAP ........................................

PREPARATION ....................................... ;I ;

INSPECTION .......................................... E- 7

RADIATOR ............................................... E- 8

REMOVAL / INSTALLATION ...................... E- 8

INSPECTION .......................................... E- 9

THERMOSTAT .......................................... E- 9

REMOVAL / INSTALLATION ...................... E- 9

INSPECTION .......................................... E- 9

WATER PUMP .......................................... E-l 1

REMOVAL / INSTALLATION ...................... E-l 1

ELECTRIC COOLING FAN SYSTEM ............ E-13

SYSTEM CIRCUIT .................................... E-l 3

SYSTEM INSPECTION .............................. E-14

FAN MOTOR ............................................. E-14

INSPECTION .......................................... E-l 4

REPLACEMENT ...................................... E-l 5

WATER THERMOSWITCH .......................... E-l 8

REMOVAL / INSTALLATION ...................... E-18

INSPECTION .......................................... E-l 8

RADIATOR THERMOSWITCH ..................... E-l 7

REMOVAL I INSTALLATION ...................... E-17

INSPECTION .......................................... E-l 7

FAN RELAY .............................................. E-l 8

REMOVAL I INSPECTION .......................... E-l 8

INSPECTION .......................................... E-l 8

23UOEX-001

Page 250 of 1164

INDEX

B6 SOHC AND BP SOHC

COOLANT RESERVOIR

@ ENGINE COOLANT

TOTAL CAPACITY

MTX: 5.0 liters (5.3 US qt, 4.4 Imp qt)

ATX: 6.0 liters (6.3 US qt, 5.3 Imp qt)

1. Engine coolant 6. Electric cooling fan system

23UOEX-00

inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page E- 5

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page E-

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

page E- 2. Radiator cap

7

3. Radiator

Removal I Installation . . . . . . . ,.......... page E- 8

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page E- 9

4. Thermostat

Removal / Installation . . . . . . . . . . . . . . . . . . page E- 9

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page E- 9

5. Water pump

Removal / Installation ....t___.......... page E-i 1

System

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. Water thermoswitch

Removal / Installation . . . . . . . . . . . . . . . . .

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. Radiator thermoswitch (BP ATX) System

Removal I Installation . . . . . . . . . . . . . . . . . inspection . . . . . . . . . . . . . . . . . . . . . .

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IO. Fan relay

7. Fan motor

Removal / Inspection . . . . . . . . . . . . . . . . . page E-13

page E-14

page E-14

page E-15

page E-16

page E-16

page E-17

page E-l 7

page E-18 ..--’

E-2