fuse MAZDA PROTEGE 1992 Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 918 of 1164

T

I WARNING SYSTEM

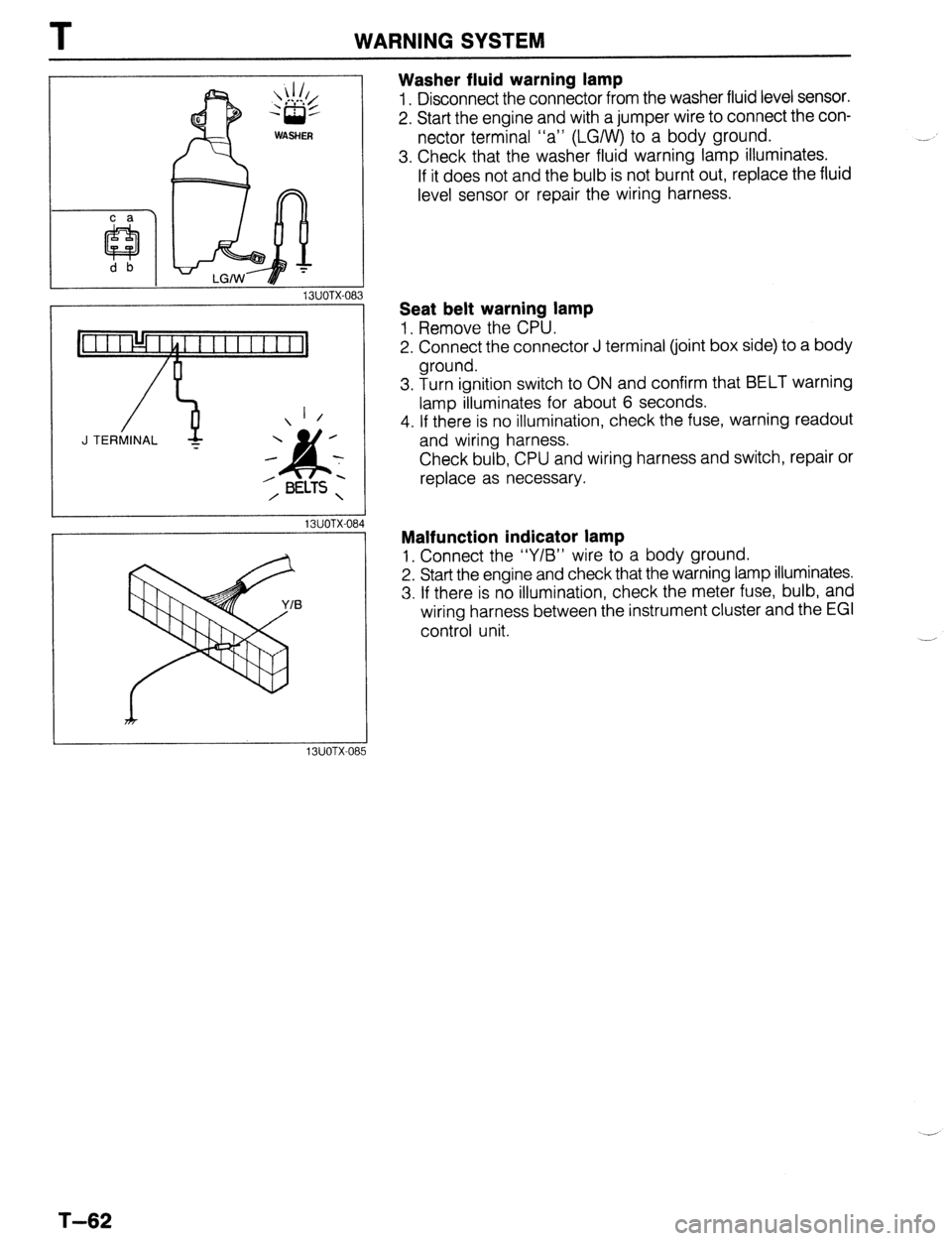

Washer fluid warning lamp

1. Disconnect the connector from the washer fluid level sensor.

2. Start the engine and with a jumper wire to connect the con-

nector terminal “a” (LGIW) to a body ground.

3. Check that the washer fluid warning lamp illuminates.

If it does not and the bulb is not burnt out, replace the fluid

level sensor or repair the wiring harness.

13UOTX-08

_-

1 /

J TERMINAL -

13UOTX-08

13UOTX-08

Seat belt warning lamp

1, Remove the CPU.

2. Connect the connector J terminal (joint box side) to a body

ground.

3. Turn ignition switch to ON and confirm that BELT warning

lamp illuminates for about 6 seconds.

4. If there is no illumination, check the fuse, warning readout

and wiring harness.

Check bulb, CPU and wiring harness and switch, repair or

replace as necessary.

Malfunction indicator lamp

1, Connect the “Y/B” wire to a body ground.

2. Start the engine and check that the warning lamp illuminates.

3. If there is no illumination, check the meter fuse, bulb, and

wiring harness between the instrument cluster and the EGI

control unit.

T-62

Page 932 of 1164

REAR WINDOW DEFROSTER

Defroster does not operate

1

Check defog 20A fuse Short circuit (Broken wire)

0 OK

Turn Ign switch to ON

Confirm battery voltage on B/W wire of rear window

defroster switch Repair harness (Fuse - Rear window defroster switch)

0 1 OK

Confirm battery voltage on B/L wire of rear window

defroster switch with the switch ON

I NG

) Check rear window defroster switch

(Refer to page T-77)

0 OK

With the switch ON, confirm battery voltage on B/L wire NG ) Repair harness (Rear window defroster switch -

of the defroster filament Filament)

I

0 1 OK -1 NG

Confirm OV on B wire of the defroster filament - Faulty grounding

Check filament (Refer to page T-77)

23UOTX-047

T-76

Page 937 of 1164

CRUISE CONTROL SYSTEM T

L 23UOTX-05

Condition Code Numbers

Self-diagnosis of malfunction

The test light will flash if a malfunction is present.

Inspection Procedure

Self-diagnosis of malfunction

1. Locate the cruise control connector.

2. Connect a 1.4W test light between terminals f and d, with

connector attached to control unit.

Note

l There is no wire in terminal d of the connector. Push

the test light through the connector and touch the

corresponding pin on the control unit.

3. Turn the ignition switch to ON.

4. Turn the cruise control on by pressing the MAIN switch. (The

MAIN indicator lamp will come ON.)

5. Press and hold the RESUMElACCEL switch for more than

three second.

6. The test light will illuminate for 3 seconds and go out for

2 seconds.

7. The self-diagnostic system is activated and the test light will

flash if a problem is present.

8. Make note of the condition code number(s).

(Refer to the chart at the bottom of the page).

9. After retrieving the code(s), drive the vehicle at more than

16 km/h (lOmph), or press the MAIN switch to deactivate

self-diagnosis. (The MAIN indicator lamp will go OFF.)

Note

l The cruise control system will not operate when in

the self-diagnosis mode.

Pattern of output signal

(Test light)

ON

OFF ON

GFF

,“r,- ON

OFF Note

23UOTX-05

l

If there is more than one malfunction, the code numbers will be indicated in numerical order.

T-81 Code

No.

01

05 Possible Cause Action

Defective wiring (Actuator-Cruise control

unit, Stoplight switch-Cruise control unit)

Defective actuator

Defective stoplight switch (For cruise)

STOP fuse blown

Defective wiring (Fuse - Cruise control

unit)

Both stoplight switches (for vehicle and

cruise) are ON simultaneously

Defective SET/COAST. or RESUME/ Inspect cruise control switch

ACCEL switch (Refer to page T-21)

Defective cruise control unit Repair harness

Inspect actuator

(Refer to page T-87)

Inspect stoplight switch

(Refer to page T-87)

Replace fuse

Repair harness

Inspect stoplight switches

(Refer to pages T-47 and

T-87)

Go to troubleshooting

(Refer to page T-83)

Page 949 of 1164

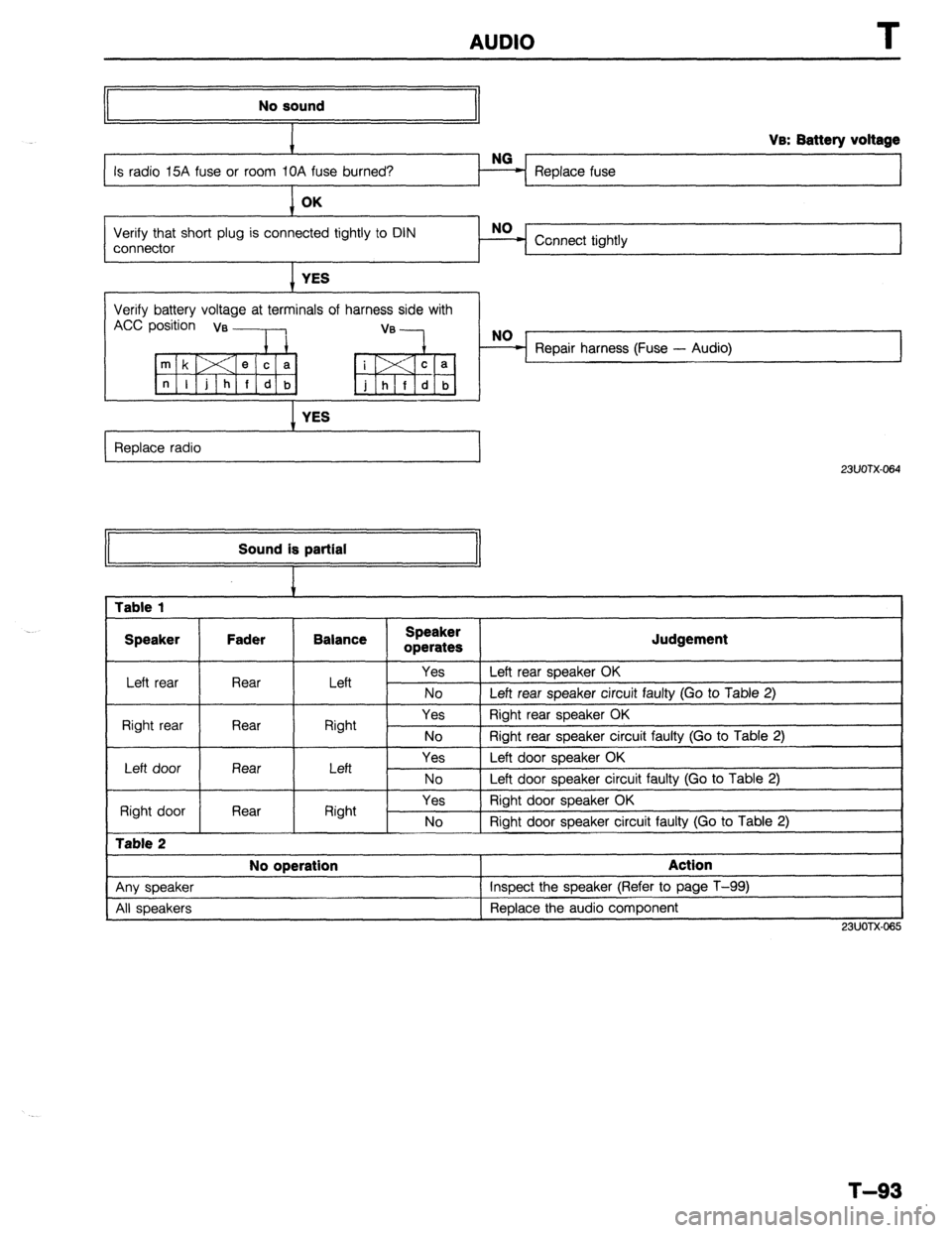

AUDIO

No sound

Replace fuse Va: Battery voltage

Verify that short plug is connected tightly to DIN

connector Connect tightly

I YES

Verify battery voltage at terminals of harness side with

Accp;;;ia, ,:---lb, “‘-k,

I YES

Replace radio

I

23UOTX-064 Sound is partial

1 Table 1

I Speaker Fader Balance

I Speaker

operates

I Judgement

Left rear Rear I Left Yes 1 Left rear speaker OK

No 1 Left rear soeaker circuit faulty (Go to Table 2)

Right rear Rear

I Right Yes Right rear speaker OK

No 1 Riaht rear sneaker circuit fauftv (Go to Table 2)

I

Left door

Right door

Table 2

Rear

Rear Left

Right Yes

No

Yes

No Left door speaker OK

Left door speaker circuit faulty (Go to Table 2)

Right door speaker OK

Right door speaker circuit faulty (Go to Table 2)

I No operation

I Action

I

1 Anv sneaker 1 Insoect the speaker (Refer to page T-99)

I

All speakers Replace the audio component

I

23UOTX.065

T-93

Page 962 of 1164

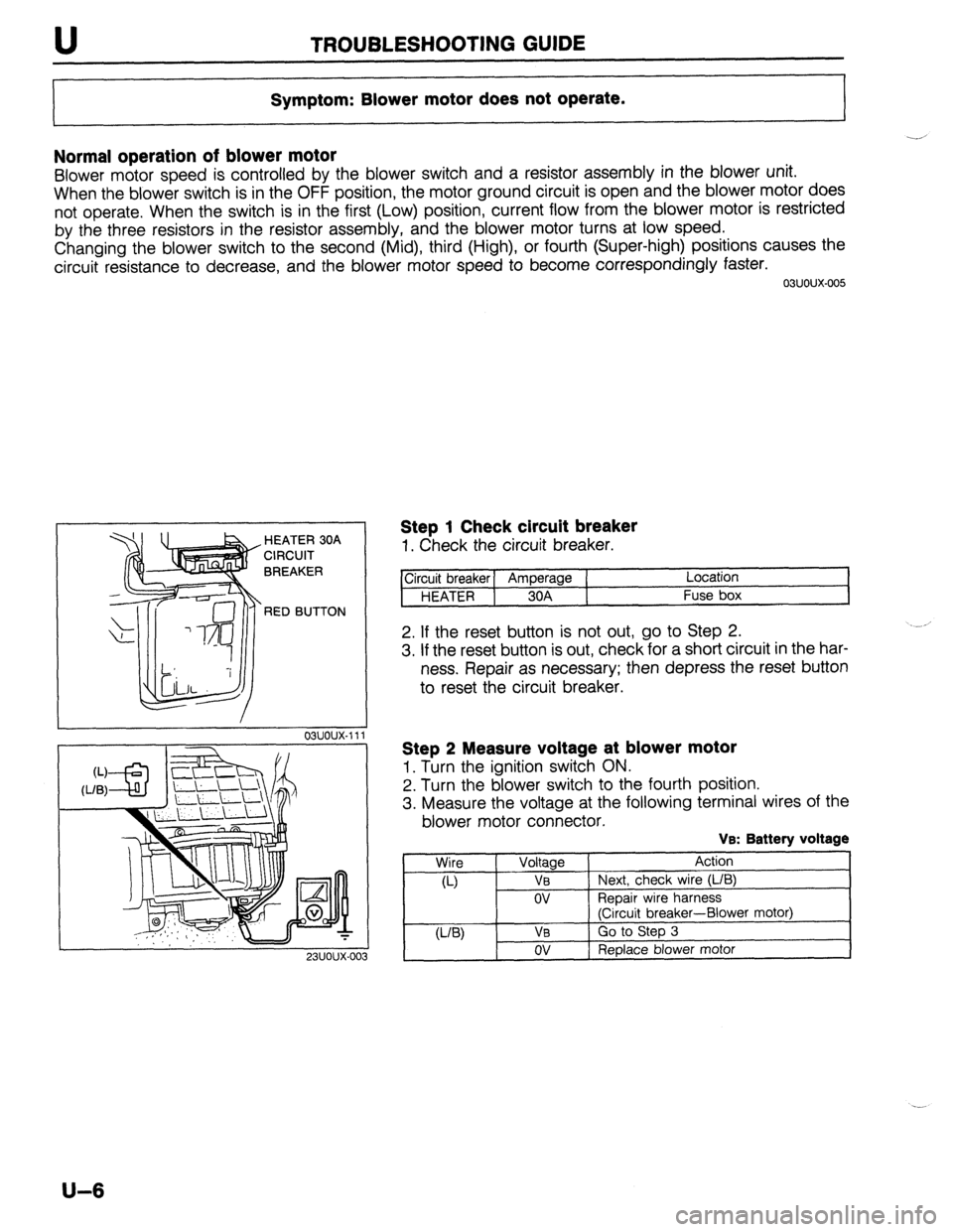

U TROUBLESHOOTING GUIDE

Symptom: Blower motor does not operate.

Normal operation of blower motor

Blower motor speed is controlled by the blower switch and a resistor assembly in the blower unit.

When the blower switch is in the OFF position, the motor ground circuit is open and the blower motor does

not operate. When the switch is in the first (Low) position, current flow from the blower motor is restricted

by the three resistors in the resistor assembly, and the blower motor turns at low speed.

Changing the blower switch to the second (Mid), third (High), or fourth (Super-high) positions causes the

circuit resistance to decrease, and the blower motor speed to become correspondingly faster.

03uoux-005

. HEATER 30A

CIRCUIT

BREAKER

RED BUTTON

23UOUX-01

Step 1 Check circuit breaker

1. Check the circuit breaker.

ircuit breaker] Amperage ( Location

HEATER 1 30A Fuse box

2. If the reset button is not out, go to Step 2.

3. If the reset button is out, check for a short circuit in the har-

ness. Repair as necessary; then depress the reset button

to reset the circuit breaker.

Step 2 Measure voltage at blower motor

1. Turn the ignition switch ON.

2. Turn the blower switch to the fourth position.

3. Measure the voltage at the following terminal wires of the

blower motor connector.

VB: Battery voltage

Wire

Voltage Action

a-) VB Next, check wire (L/B)

ov ReDair wire harness

(Ciicuit breaker-Blower motor)

U-W VB Go to Step 3

ov Replace blower motor

U-6

Page 968 of 1164

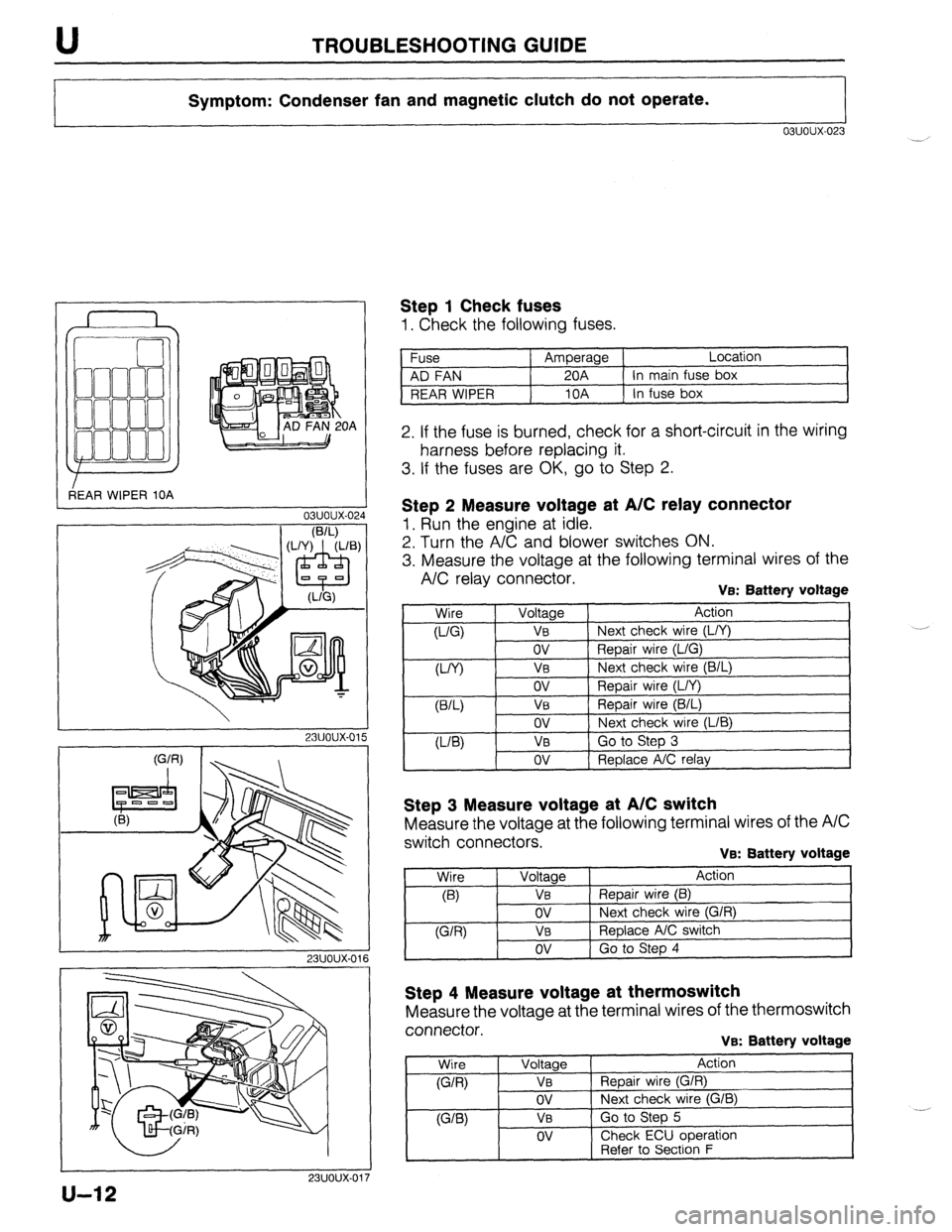

TROUBLESHOOTING GUIDE

Symptom: Condenser fan and magnetic clutch do not operate.

03uoux-023

r

3EAR WIPER 10A OA

L

03uoux-02.

I

1 Step 1 Check fuses

1. Check the following fuses.

Fuse Amperage Location

AD FAN 20A In main fuse box

REAR WIPER 10A In fuse box

2. If the fuse is burned, check for a short-circuit in the wiring

harness before replacing it.

3. If the fuses are OK, go to Step 2.

I

23uoux-011

Step 2 Measure voltage at A/C relay connector

1. Run the engine at idle.

2. Turn the A/C and blower switches ON.

3. Measure the voltage at the following terminal wires of the

A/C relay connector. VEX Battery voltage

,

Wire

0-Q

W) Voltage Action

VB Next check wire (L/Y)

ov Repair wire (L/G)

V0 Next check wire (B/L)

ov

VB

ov

VB

ov Repair wire (L/Y)

Repair wire (B/L)

Next check wire (LIB)

Go to Step 3

Replace A/C relay

Step 3 Measure voltage at A/C switch

Measure the voltage at the following terminal wires of the A/C

switch connectors.

VB: Battery voltage

Step 4 Measure voltage at thermoswitch

Measure the voltage at the terminal wires of the thermoswitch

connector.

VB: Battery voltage

Wire

(G/R)

WB)

Voltage

VB

ov

VB

OV

Action

Repair wire (G/R)

Next check wire (G/B)

Go to Step 5

Check ECU ooeration

1 -. [ Refer to Secti6n F

u-12

Page 1050 of 1164

PARTS INDEX

I

CRANKSHAFT.. ....................................

I31 -64

CYLINDER BLOCK .............................. 61-60

CYLINDER HEAD..

............................... 81-54

CYLINDER HEAD GASKET .................

Bl-16

DRIVE BELT(S). ...................................... 81-5

FRONT OIL SEAL ................................ 81-23

HLA .............................................. Bl-7,20,60

OIL JET ................................................ 81-61

PISTON.. ...............................................

Bl-62

PISTON PIN..

........................................ 81-62

PISTON RING

....................................... 81-62

REAR

OIL SEAL..

................................. 81-25

TENSIONER, IDLER ............................. Bl-65

TENSIONER

SPRING ...........................

Bl-65

TIMING BELT ..................................

Bl-12,65

TIMING BELT PULLEY ........................

Bl-65

VALVE MECHANISM ........................... Bl-55

ENGINE

(BP DOHC) .................................... B2-2

CAMSHAFT ..........................................

82-58

CAMSHAFT PULLEY ...........................

B2-65

CONNECTING ROD..

........................... 82-63

CRANKSHAFT ......................................

B2-64

CYLINDER BLOCK ..............................

82-60

CYLINDER

HEAD.. ............................... B2-54

CYLINDER HEAD GASKET .................

82-16

DRIVE

BELTS.. .......................................

B2-5

FRONT

OIL SEAL ................................

82-26

H LA ..............................................

OIL JET .......................... B2-7iyL;;

......................

PISTON .................................................

B2-62

PISTON PIN ..........................................

82-62

PISTON RING..

..................................... 82-62

REAR OIL SEAL ................................... B2-28

TENSIONER, IDLER ............................. B2-65

TENSIONER SPRING ........................... B2-65

TIMING

BELT.. ................................

B2-12,65

TIMING BELT PULLEY ........................ 82-65

VALVE MECHANISM ........................... 82-55

ENGINE CONTROL UNIT (ECU) ............... F-149

ENGINE COOLANT

........................................ E-5

ENGINE OIL.. .................................................

D-7

ENGINE OIL FILTER.. .................................... D-8

’ EXHAUST SYSTEM. ...................................

F-136

EXTRACTOR CHAMBER .............................. S-53

F

FAN MOTOR (COOLING FAN). ................... E-14

FAN RELAY (COOLING FAN). ..................... E-18

FLASHER UNIT ............................................

T-17

FLOORMAT ..................................................

S-99

FLYWHEEL ..................................................

H-18

FRONT AXLE .................................................

M-4

FRONT BRAKE ............................................

P-l 8

FRONT BUMPER ......................................... S-39

FRONT DOOR ................................................

S-8

FRONT DOOR LOCK AND OPENER ..........

S-13

PI-2

FRONT FENDER PANEL ............................... S-7

FRONT LOWER ARM .................................. R-16

FRONT SHOCK ABSORBER AND SPRING R-11

FRONT SIDE WINDOW REGULATOR AND

GLASS ........................................................ S-10

FRONT STABILIZER..

................................... R-l 8

FRONT SUSPENSION .................................. R-l 0

FUEL FILLER LID AND OPENER..

.............. S-37

FUEL FILTER .............................................. F-l 24

FUEL GAUGE SENDER UNIT ..................... T-73

FUEL PUMP ............................................... F-125

FUEL TANK

................................................ F-123

FUSE AND JOINT BOX.. .............................. T-12

H

HEADLIGHT AND

FRONT COMBINATION LIGHT..

................ T-41

HEADLIGHT RELAY ..................................... T-l 8

HEADLINER ................................................. S-89

HEATER CONTROL UNIT.. ......................... U-26

HEATER UNIT

.............................................. U-21

HIGH-MOUNT STOPLIGHT

.......................... T-45

HIGH-TENSION LEAD ................................. G-l 7

HOOD ............................................................. S-5

HORN T-88

...........................................................

HORN RELAY

.......................................... T-18,88

.__. ’

I I

IGNITER .......................................................

G-23

IGNITION COIL.. .......................................... G-19

INJECTOR .................................................. F-l 31

INSTRUMENT CLUSTER

AND SPEEDOMETER CABLE

.................... T-69

INTAKE MANIFOLD ................................... F-113

INTERIOR LAMP ..................................... T-52,53

ISC VALVE.. ................................................ F-l 16

J

JOINT SHAFT (FRONT AXLE) .................... M-18

L

LATERAL LINK AND TRAILING LINK.. ....... R-26

LICENSE PLATE LIGHT.. ............................. T-47

i

M

I

---

MAIN RELAY (FUEL INJ. RELAY). ............ F-172

MANUAL STEERING ..................................... N-4

MANUAL TRANSAXLE (F5M-R). .................. Jl-2

Page 1058 of 1164

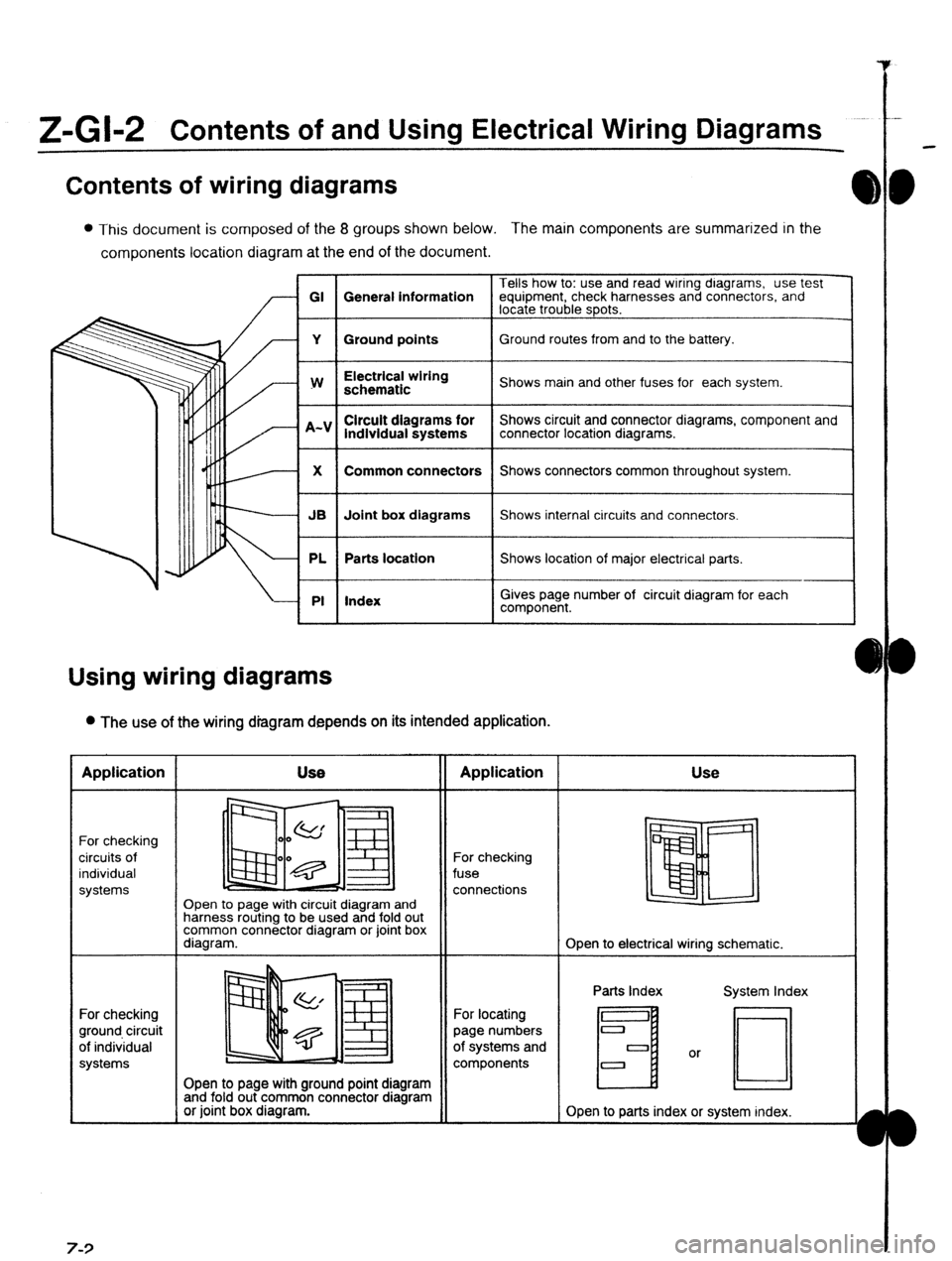

Z-Gl-2 Contents of and Using Electrical Wiring Diagrams

Contents of wiring diagrams

l This document is composed of the 8 groups shown below. The main components are summarized in the

components location diagram at the end of the document.

Tells how to: use and read wiring dragrams, use test

GI General information equipment, check harnesses and connectors, and

locate trouble spots.

Y Ground points Ground routes from and to the battery.

I

w

I Electrical wiring

schematic

I Shows main and other fuses for each system.

lndlvidual systems

I Shows circuit and connector diagrams, component and

connector location diagrams.

1

X

I Common connectors

I Shows connectors common throughout system.

I

JB Joint box diagrams Shows internal circuits and connectors.

PL Parts location Shows location of major electrical parts.

PI Index

I

I

Gives page number of circuit diagram for each

component.

Using wiring diagrams

l The use of the wiring diagram depends on its intended application. Application

For checking

circuits of

individual

systems

For checking

ground circuit

of individual

systems 7-3 Use

II Application

Open to page with circuit diagram and

harness routing to be used and fold out

common connector diagram or joint box

diagram. For checking

fuse

connections Use

Open to electrical wiring schematic.

Open to page with ground point diagram

and fold out common connector diagram

or joint box diagram. For locating

page numbers

of systems and

components Parts Index

H

Open to parts index or system index.

Page 1064 of 1164

Z-Gl-8 Reading Wiring Diagrams

Svmbols I

Symbol Meaning Symbol Meaning

Battery (I, Generates electricity through Resistance l A resistor with a constant value

chemical reaction l Mainly used to protect electrical

l Supplies direct current to circuits components in circuits by maintaining

rated voltage

l Reading resistance values

Ground (1)

l Connecting point to vehicle body or No.1 Cobr band

-A- other ground wire where current flows -No.2 Cobr band

from positive to negative terminal of -No.3 Cobr band

battery No.4 Cobr band

1

l Ground (1) indicates a ground point to Flnt color. Rerkrancs

body through wire harness

Ground (2) l Gound (2) indicates point where

component is grounded directly to body

Remark

oCurrent wilt not flow through a circuit if

ground is faulty

Fuse (1)

(box)

Fuse (2)

l Melts when current flow exceeds that

specified for circuit, stopping current

flow

Precautions

o Do not replace with fuses exceeding

specified capacity

(Cartridge)

vlain fuse/Fusible

l Electrical switching component

a Turns on when voltage is applied to Motor

0 Converts electrical energy into

mechanical energy

Transistor (2)

coiibmr (Cl

l Reading code l Pulls in and expels gases and liquids

Lamp

Number of terminals O:Low- frequency NPN

l Emits light and generates heat when

Cigarette lighter

current flows through filament a Electrical coil that generates heat

Page 1067 of 1164

Troubleshootina Z-GM 1

Precautions when servicing electrical system

l Note the following items when servicing the electrical system.

l Do not alter the wiring or electrical equipment in any way as this may damage the vehicle or cause a fire

due to shorting or overcapacity of a circuit.

l Always disconnect the negative (- ) battery cable first and 0 Replace blown fuses with ones having the same designated

reconnect It last when disconnecting the battery. capacity.

1OA

15A

Zaution

l Be sure that the ignition and other switches are OFF

before disconnecting or connecting the battery

terminals.

Failure to do so may damage the semi-conductor

components. Caution l Replacing a fuse with one of a larger capacity than

designated may damage components or cause an electrical

fire.

l Secure harnesses with a clamp when provided to take Up l Tape areas of the

a Be sure that the harness

any slack. harness that may rub or

is not caught or damaged

bump against sharp

when mounting

edges to protect it from

components.

damage.

Caution

l Clamp all harnesses near vibrating components(e.g.

the engine) to remove any slack and prevent Contact

due to vibration.

l Do not handle roughly or drop electrical components.

l Disconnect heat sensitive

parts (e.g. relays, ECU)

when performing

maintenance where

temperatures may exceed l Make sure that the

connectors are securely

connected when

installed.

80°C (176°F) (i.e.welding).

oid