MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 1111 of 1232

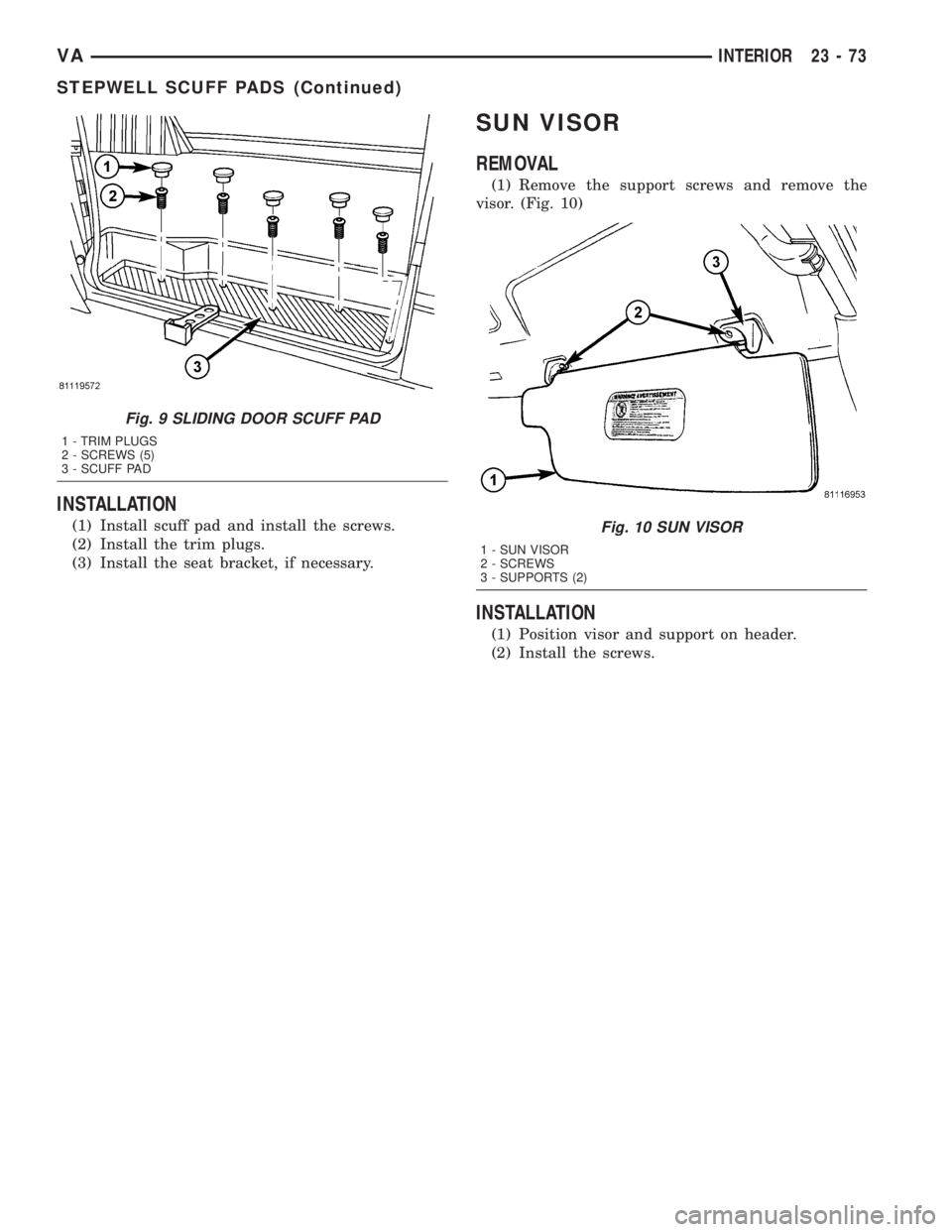

INSTALLATION

(1) Install scuff pad and install the screws.

(2) Install the trim plugs.

(3) Install the seat bracket, if necessary.

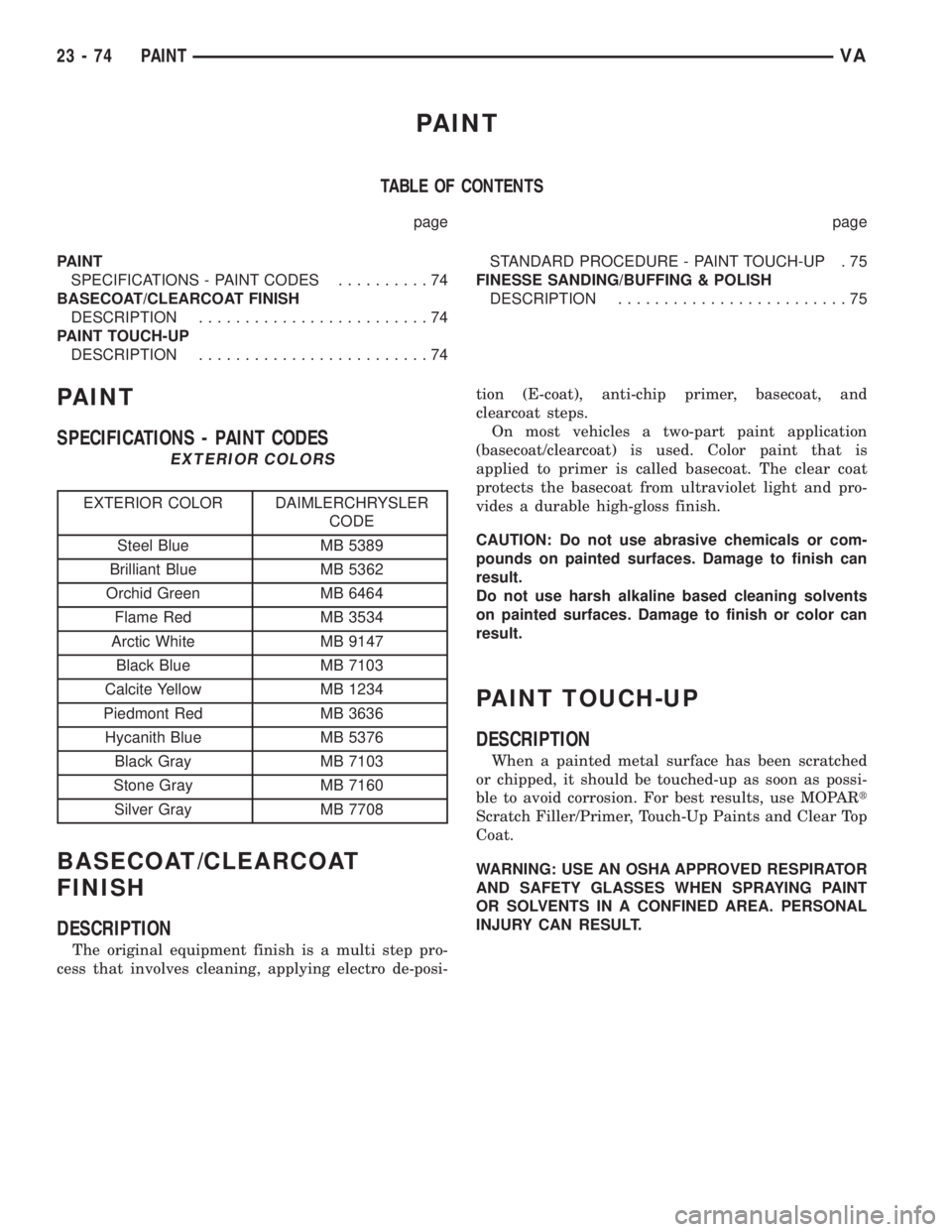

SUN VISOR

REMOVAL

(1) Remove the support screws and remove the

visor. (Fig. 10)

INSTALLATION

(1) Position visor and support on header.

(2) Install the screws.

Fig. 9 SLIDING DOOR SCUFF PAD

1 - TRIM PLUGS

2 - SCREWS (5)

3 - SCUFF PAD

Fig. 10 SUN VISOR

1 - SUN VISOR

2 - SCREWS

3 - SUPPORTS (2)

VAINTERIOR 23 - 73

STEPWELL SCUFF PADS (Continued)

Page 1112 of 1232

PAINT

TABLE OF CONTENTS

page page

PAINT

SPECIFICATIONS - PAINT CODES..........74

BASECOAT/CLEARCOAT FINISH

DESCRIPTION.........................74

PAINT TOUCH-UP

DESCRIPTION.........................74STANDARD PROCEDURE - PAINT TOUCH-UP . 75

FINESSE SANDING/BUFFING & POLISH

DESCRIPTION.........................75

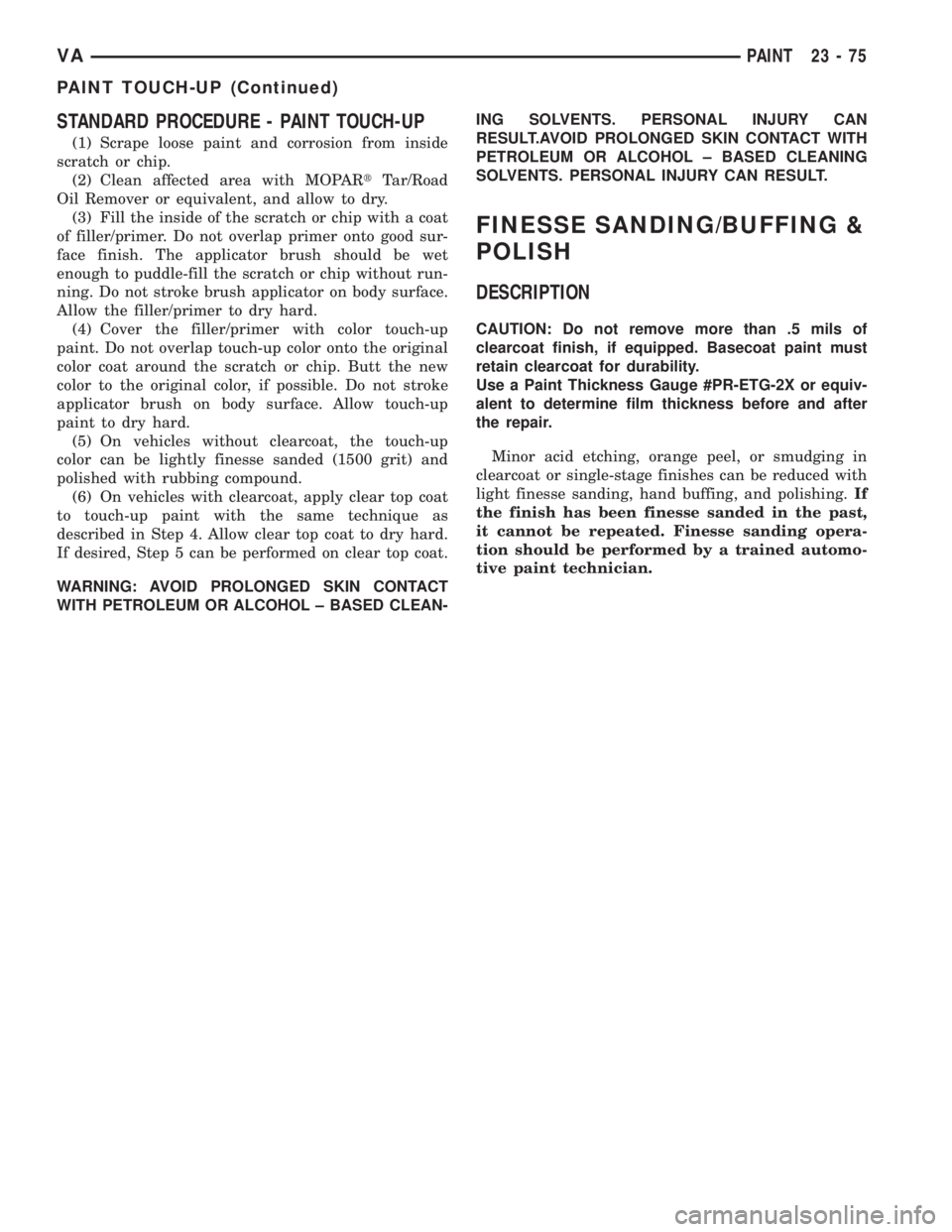

PAINT

SPECIFICATIONS - PAINT CODES

EXTERIOR COLORS

EXTERIOR COLOR DAIMLERCHRYSLER

CODE

Steel Blue MB 5389

Brilliant Blue MB 5362

Orchid Green MB 6464

Flame Red MB 3534

Arctic White MB 9147

Black Blue MB 7103

Calcite Yellow MB 1234

Piedmont Red MB 3636

Hycanith Blue MB 5376

Black Gray MB 7103

Stone Gray MB 7160

Silver Gray MB 7708

BASECOAT/CLEARCOAT

FINISH

DESCRIPTION

The original equipment finish is a multi step pro-

cess that involves cleaning, applying electro de-posi-tion (E-coat), anti-chip primer, basecoat, and

clearcoat steps.

On most vehicles a two-part paint application

(basecoat/clearcoat) is used. Color paint that is

applied to primer is called basecoat. The clear coat

protects the basecoat from ultraviolet light and pro-

vides a durable high-gloss finish.

CAUTION: Do not use abrasive chemicals or com-

pounds on painted surfaces. Damage to finish can

result.

Do not use harsh alkaline based cleaning solvents

on painted surfaces. Damage to finish or color can

result.

PAINT TOUCH-UP

DESCRIPTION

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-

ble to avoid corrosion. For best results, use MOPARt

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat.

WARNING: USE AN OSHA APPROVED RESPIRATOR

AND SAFETY GLASSES WHEN SPRAYING PAINT

OR SOLVENTS IN A CONFINED AREA. PERSONAL

INJURY CAN RESULT.

23 - 74 PAINTVA

Page 1113 of 1232

STANDARD PROCEDURE - PAINT TOUCH-UP

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with MOPARtTar/Road

Oil Remover or equivalent, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

face finish. The applicator brush should be wet

enough to puddle-fill the scratch or chip without run-

ning. Do not stroke brush applicator on body surface.

Allow the filler/primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap touch-up color onto the original

color coat around the scratch or chip. Butt the new

color to the original color, if possible. Do not stroke

applicator brush on body surface. Allow touch-up

paint to dry hard.

(5) On vehicles without clearcoat, the touch-up

color can be lightly finesse sanded (1500 grit) and

polished with rubbing compound.

(6) On vehicles with clearcoat, apply clear top coat

to touch-up paint with the same technique as

described in Step 4. Allow clear top coat to dry hard.

If desired, Step 5 can be performed on clear top coat.

WARNING: AVOID PROLONGED SKIN CONTACT

WITH PETROLEUM OR ALCOHOL ± BASED CLEAN-ING SOLVENTS. PERSONAL INJURY CAN

RESULT.AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL ± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

FINESSE SANDING/BUFFING &

POLISH

DESCRIPTION

CAUTION: Do not remove more than .5 mils of

clearcoat finish, if equipped. Basecoat paint must

retain clearcoat for durability.

Use a Paint Thickness Gauge #PR-ETG-2X or equiv-

alent to determine film thickness before and after

the repair.

Minor acid etching, orange peel, or smudging in

clearcoat or single-stage finishes can be reduced with

light finesse sanding, hand buffing, and polishing.If

the finish has been finesse sanded in the past,

it cannot be repeated. Finesse sanding opera-

tion should be performed by a trained automo-

tive paint technician.

VAPAINT 23 - 75

PAINT TOUCH-UP (Continued)

Page 1114 of 1232

SEATS

TABLE OF CONTENTS

page page

ARMREST

REMOVAL.............................76

INSTALLATION.........................76

HEADREST

REMOVAL.............................76

INSTALLATION.........................76

SEAT - FRONT

REMOVAL.............................77

INSTALLATION.........................77

SEAT BACK - FRONT

REMOVAL.............................77

INSTALLATION.........................77

SEAT CUSHION - FRONT

REMOVAL.............................78

INSTALLATION.........................78SEAT ADJUSTERS - FRONT

REMOVAL.............................78

INSTALLATION.........................78

SEAT - REAR

REMOVAL.............................79

INSTALLATION.........................79

REAR SEAT BACK SHIELD

REMOVAL.............................79

INSTALLATION.........................79

SEAT BACK CUSHION/COVER - REAR

REMOVAL.............................80

INSTALLATION.........................80

SEAT CUSHION/COVER - REAR

REMOVAL.............................80

INSTALLATION.........................80

ARMREST

REMOVAL

(1) Remove the screws and remove the armrest

cover.

(2) Remove the three bolts and remove the arm-

rest from the seat back.

INSTALLATION

(1) Install the armrest and install the three bolts.

(2) Install the armrest cover and install the

screws.

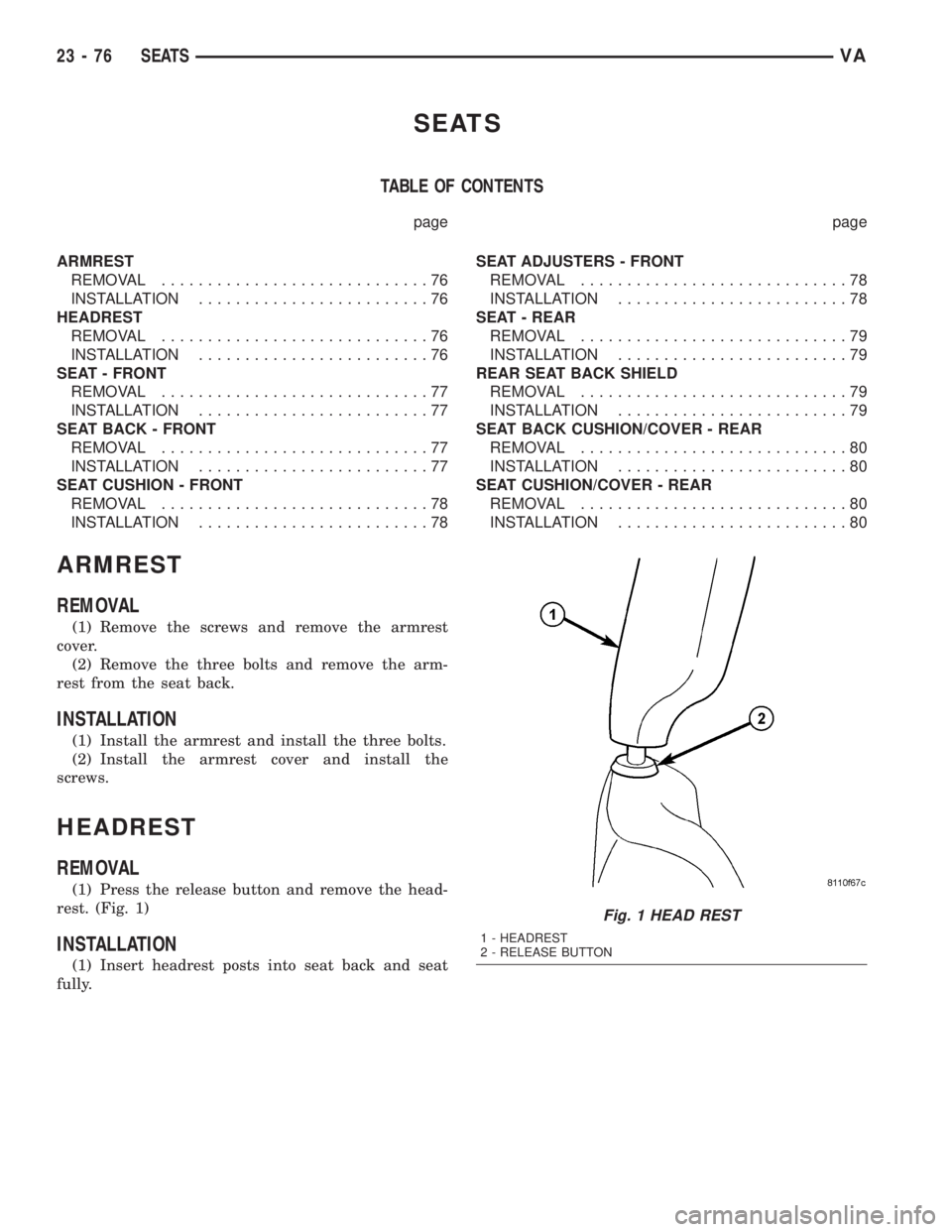

HEADREST

REMOVAL

(1) Press the release button and remove the head-

rest. (Fig. 1)

INSTALLATION

(1) Insert headrest posts into seat back and seat

fully.

Fig. 1 HEAD REST

1 - HEADREST

2 - RELEASE BUTTON

23 - 76 SEATSVA

Page 1115 of 1232

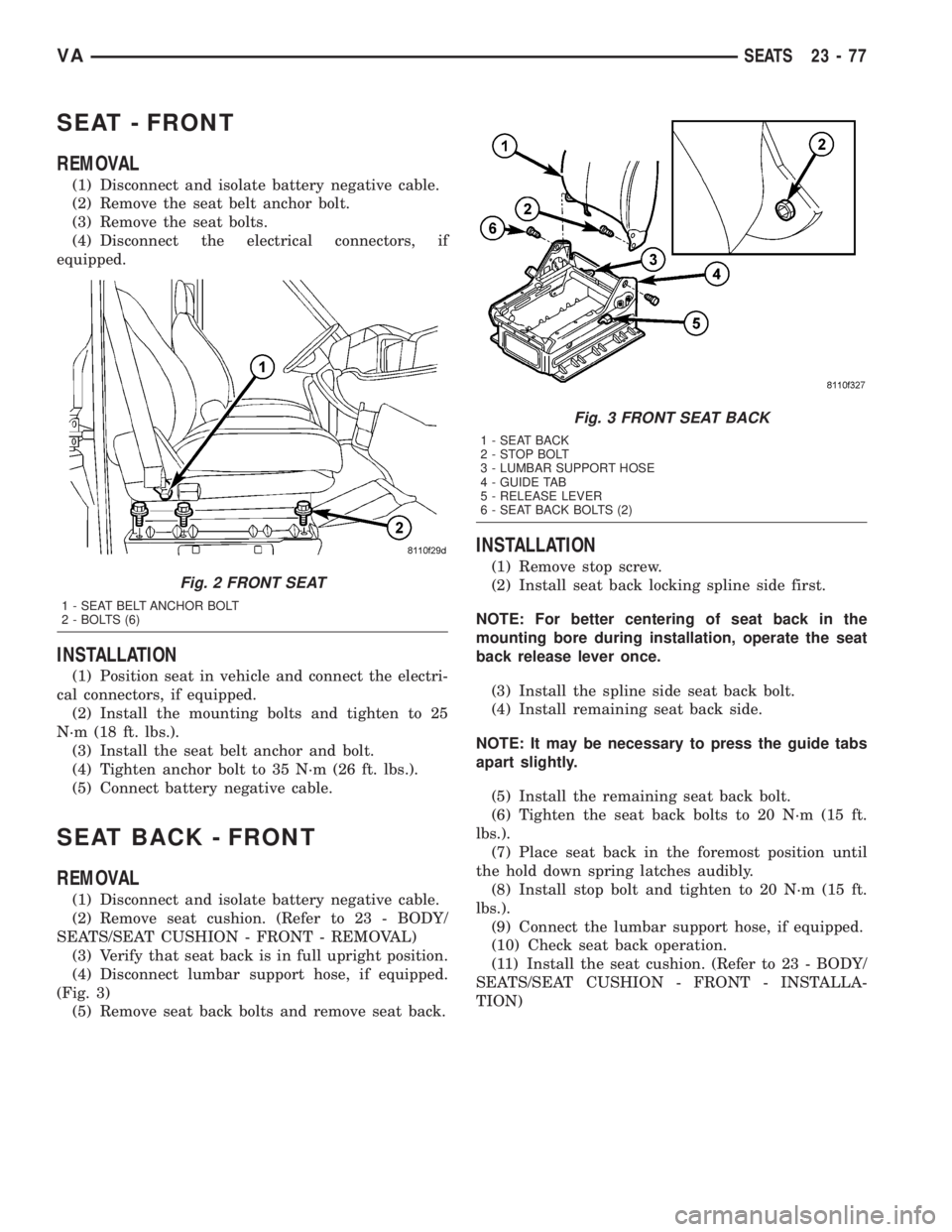

SEAT - FRONT

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove the seat belt anchor bolt.

(3) Remove the seat bolts.

(4) Disconnect the electrical connectors, if

equipped.

INSTALLATION

(1) Position seat in vehicle and connect the electri-

cal connectors, if equipped.

(2) Install the mounting bolts and tighten to 25

N´m (18 ft. lbs.).

(3) Install the seat belt anchor and bolt.

(4) Tighten anchor bolt to 35 N´m (26 ft. lbs.).

(5) Connect battery negative cable.

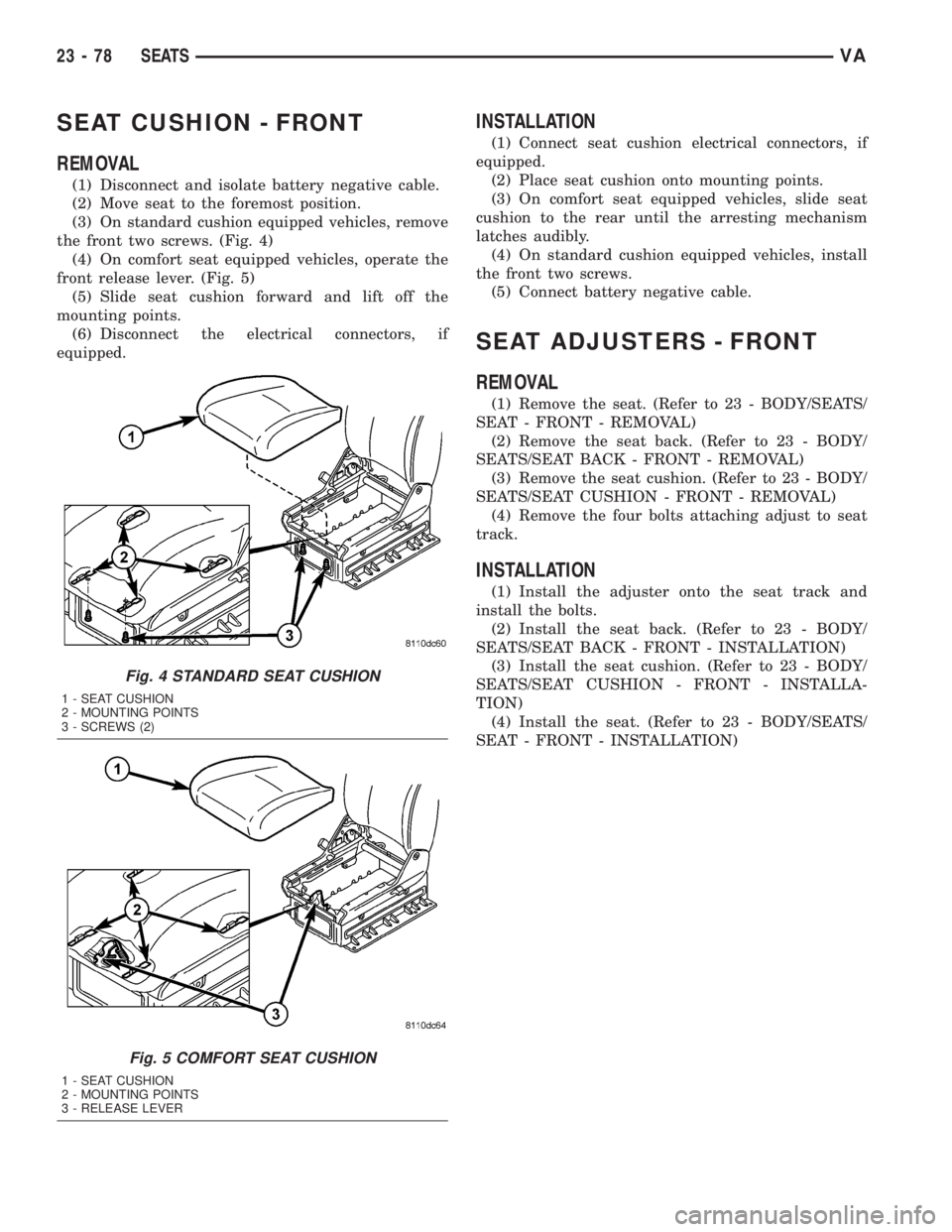

SEAT BACK - FRONT

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - FRONT - REMOVAL)

(3) Verify that seat back is in full upright position.

(4) Disconnect lumbar support hose, if equipped.

(Fig. 3)

(5) Remove seat back bolts and remove seat back.

INSTALLATION

(1) Remove stop screw.

(2) Install seat back locking spline side first.

NOTE: For better centering of seat back in the

mounting bore during installation, operate the seat

back release lever once.

(3) Install the spline side seat back bolt.

(4) Install remaining seat back side.

NOTE: It may be necessary to press the guide tabs

apart slightly.

(5) Install the remaining seat back bolt.

(6) Tighten the seat back bolts to 20 N´m (15 ft.

lbs.).

(7) Place seat back in the foremost position until

the hold down spring latches audibly.

(8) Install stop bolt and tighten to 20 N´m (15 ft.

lbs.).

(9) Connect the lumbar support hose, if equipped.

(10) Check seat back operation.

(11) Install the seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - FRONT - INSTALLA-

TION)

Fig. 2 FRONT SEAT

1 - SEAT BELT ANCHOR BOLT

2 - BOLTS (6)

Fig. 3 FRONT SEAT BACK

1 - SEAT BACK

2 - STOP BOLT

3 - LUMBAR SUPPORT HOSE

4 - GUIDE TAB

5 - RELEASE LEVER

6 - SEAT BACK BOLTS (2)

VASEATS 23 - 77

Page 1116 of 1232

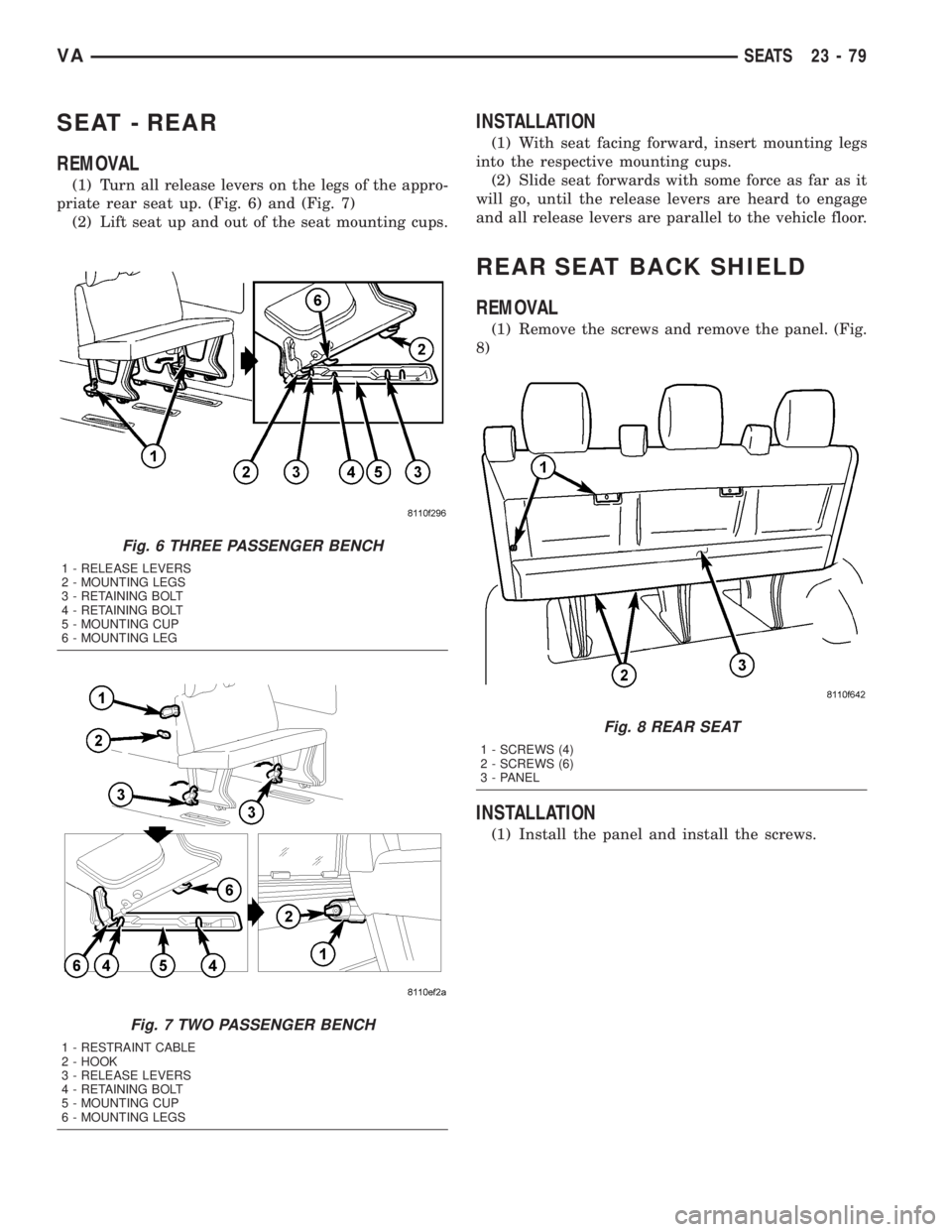

SEAT CUSHION - FRONT

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Move seat to the foremost position.

(3) On standard cushion equipped vehicles, remove

the front two screws. (Fig. 4)

(4) On comfort seat equipped vehicles, operate the

front release lever. (Fig. 5)

(5) Slide seat cushion forward and lift off the

mounting points.

(6) Disconnect the electrical connectors, if

equipped.

INSTALLATION

(1) Connect seat cushion electrical connectors, if

equipped.

(2) Place seat cushion onto mounting points.

(3) On comfort seat equipped vehicles, slide seat

cushion to the rear until the arresting mechanism

latches audibly.

(4) On standard cushion equipped vehicles, install

the front two screws.

(5) Connect battery negative cable.

SEAT ADJUSTERS - FRONT

REMOVAL

(1) Remove the seat. (Refer to 23 - BODY/SEATS/

SEAT - FRONT - REMOVAL)

(2) Remove the seat back. (Refer to 23 - BODY/

SEATS/SEAT BACK - FRONT - REMOVAL)

(3) Remove the seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - FRONT - REMOVAL)

(4) Remove the four bolts attaching adjust to seat

track.

INSTALLATION

(1) Install the adjuster onto the seat track and

install the bolts.

(2) Install the seat back. (Refer to 23 - BODY/

SEATS/SEAT BACK - FRONT - INSTALLATION)

(3) Install the seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - FRONT - INSTALLA-

TION)

(4) Install the seat. (Refer to 23 - BODY/SEATS/

SEAT - FRONT - INSTALLATION)

Fig. 4 STANDARD SEAT CUSHION

1 - SEAT CUSHION

2 - MOUNTING POINTS

3 - SCREWS (2)

Fig. 5 COMFORT SEAT CUSHION

1 - SEAT CUSHION

2 - MOUNTING POINTS

3 - RELEASE LEVER

23 - 78 SEATSVA

Page 1117 of 1232

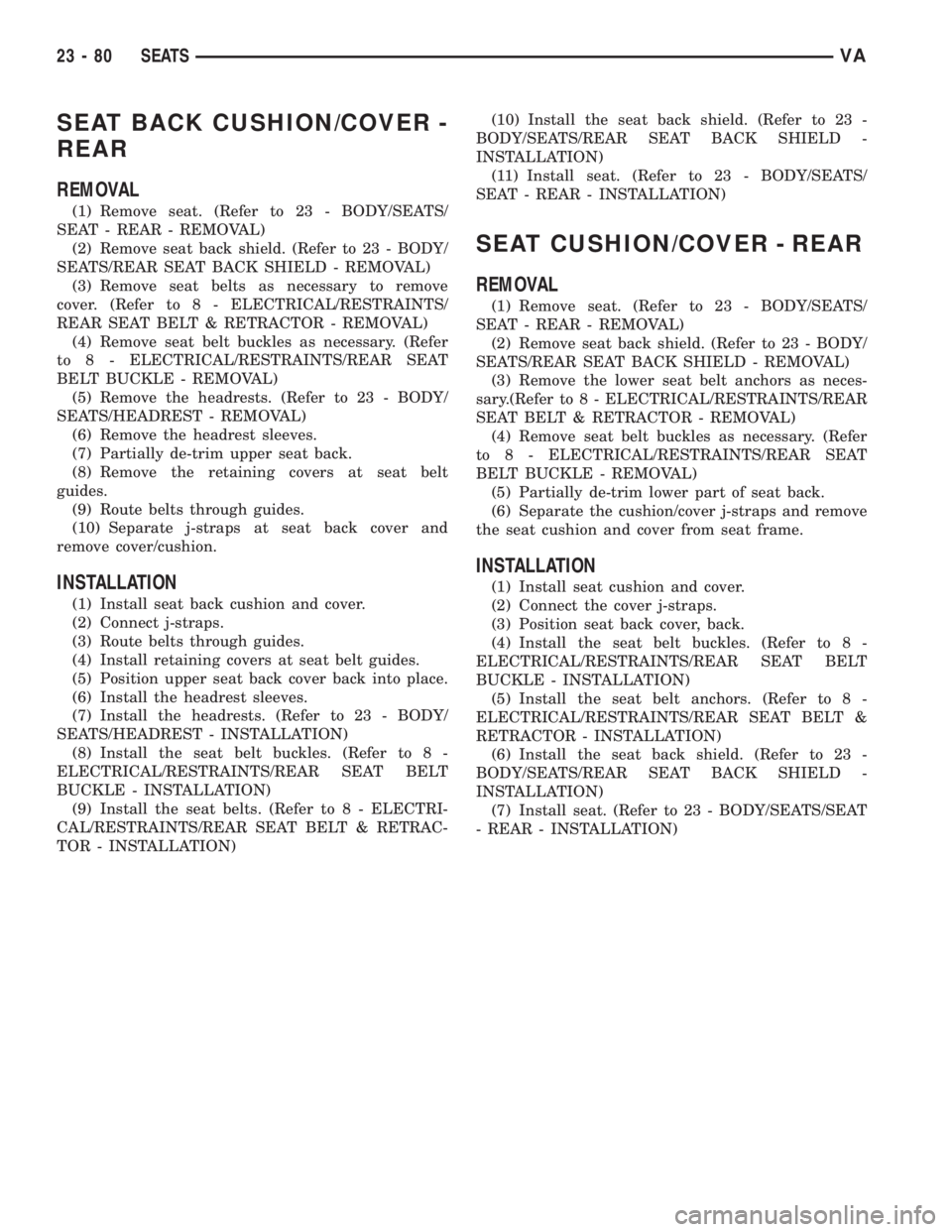

SEAT - REAR

REMOVAL

(1) Turn all release levers on the legs of the appro-

priate rear seat up. (Fig. 6) and (Fig. 7)

(2) Lift seat up and out of the seat mounting cups.

INSTALLATION

(1) With seat facing forward, insert mounting legs

into the respective mounting cups.

(2) Slide seat forwards with some force as far as it

will go, until the release levers are heard to engage

and all release levers are parallel to the vehicle floor.

REAR SEAT BACK SHIELD

REMOVAL

(1) Remove the screws and remove the panel. (Fig.

8)

INSTALLATION

(1) Install the panel and install the screws.

Fig. 6 THREE PASSENGER BENCH

1 - RELEASE LEVERS

2 - MOUNTING LEGS

3 - RETAINING BOLT

4 - RETAINING BOLT

5 - MOUNTING CUP

6 - MOUNTING LEG

Fig. 7 TWO PASSENGER BENCH

1 - RESTRAINT CABLE

2 - HOOK

3 - RELEASE LEVERS

4 - RETAINING BOLT

5 - MOUNTING CUP

6 - MOUNTING LEGS

Fig. 8 REAR SEAT

1 - SCREWS (4)

2 - SCREWS (6)

3 - PANEL

VASEATS 23 - 79

Page 1118 of 1232

SEAT BACK CUSHION/COVER -

REAR

REMOVAL

(1) Remove seat. (Refer to 23 - BODY/SEATS/

SEAT - REAR - REMOVAL)

(2) Remove seat back shield. (Refer to 23 - BODY/

SEATS/REAR SEAT BACK SHIELD - REMOVAL)

(3) Remove seat belts as necessary to remove

cover. (Refer to 8 - ELECTRICAL/RESTRAINTS/

REAR SEAT BELT & RETRACTOR - REMOVAL)

(4) Remove seat belt buckles as necessary. (Refer

to 8 - ELECTRICAL/RESTRAINTS/REAR SEAT

BELT BUCKLE - REMOVAL)

(5) Remove the headrests. (Refer to 23 - BODY/

SEATS/HEADREST - REMOVAL)

(6) Remove the headrest sleeves.

(7) Partially de-trim upper seat back.

(8) Remove the retaining covers at seat belt

guides.

(9) Route belts through guides.

(10) Separate j-straps at seat back cover and

remove cover/cushion.

INSTALLATION

(1) Install seat back cushion and cover.

(2) Connect j-straps.

(3) Route belts through guides.

(4) Install retaining covers at seat belt guides.

(5) Position upper seat back cover back into place.

(6) Install the headrest sleeves.

(7) Install the headrests. (Refer to 23 - BODY/

SEATS/HEADREST - INSTALLATION)

(8) Install the seat belt buckles. (Refer to 8 -

ELECTRICAL/RESTRAINTS/REAR SEAT BELT

BUCKLE - INSTALLATION)

(9) Install the seat belts. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/REAR SEAT BELT & RETRAC-

TOR - INSTALLATION)(10) Install the seat back shield. (Refer to 23 -

BODY/SEATS/REAR SEAT BACK SHIELD -

INSTALLATION)

(11) Install seat. (Refer to 23 - BODY/SEATS/

SEAT - REAR - INSTALLATION)

SEAT CUSHION/COVER - REAR

REMOVAL

(1) Remove seat. (Refer to 23 - BODY/SEATS/

SEAT - REAR - REMOVAL)

(2) Remove seat back shield. (Refer to 23 - BODY/

SEATS/REAR SEAT BACK SHIELD - REMOVAL)

(3) Remove the lower seat belt anchors as neces-

sary.(Refer to 8 - ELECTRICAL/RESTRAINTS/REAR

SEAT BELT & RETRACTOR - REMOVAL)

(4) Remove seat belt buckles as necessary. (Refer

to 8 - ELECTRICAL/RESTRAINTS/REAR SEAT

BELT BUCKLE - REMOVAL)

(5) Partially de-trim lower part of seat back.

(6) Separate the cushion/cover j-straps and remove

the seat cushion and cover from seat frame.

INSTALLATION

(1) Install seat cushion and cover.

(2) Connect the cover j-straps.

(3) Position seat back cover, back.

(4) Install the seat belt buckles. (Refer to 8 -

ELECTRICAL/RESTRAINTS/REAR SEAT BELT

BUCKLE - INSTALLATION)

(5) Install the seat belt anchors. (Refer to 8 -

ELECTRICAL/RESTRAINTS/REAR SEAT BELT &

RETRACTOR - INSTALLATION)

(6) Install the seat back shield. (Refer to 23 -

BODY/SEATS/REAR SEAT BACK SHIELD -

INSTALLATION)

(7) Install seat. (Refer to 23 - BODY/SEATS/SEAT

- REAR - INSTALLATION)

23 - 80 SEATSVA

Page 1119 of 1232

STATIONARY GLASS

TABLE OF CONTENTS

page page

BACKLITE - BULKHEAD TRIM PANEL

REMOVAL.............................81

INSTALLATION.........................81

QUARTER WINDOW

REMOVAL.............................81

INSTALLATION.........................81WINDSHIELD

WARNING

WINDSHIELD SAFETY PRECAUTIONS.....82

REMOVAL.............................82

INSTALLATION.........................83

BACKLITE - BULKHEAD TRIM

PANEL

REMOVAL

(1) Position an assistant opposite side of the bulk-

head trim panel to receive the glass and weatherstrip

seal.

(2) Start at an upper corner and separate the seal

from the window opening. Push the glass and seal

outward from the window opening. Remove the glass

and seal.

(3) Remove seal from glass if necessary.

(4) Clean the window opening.

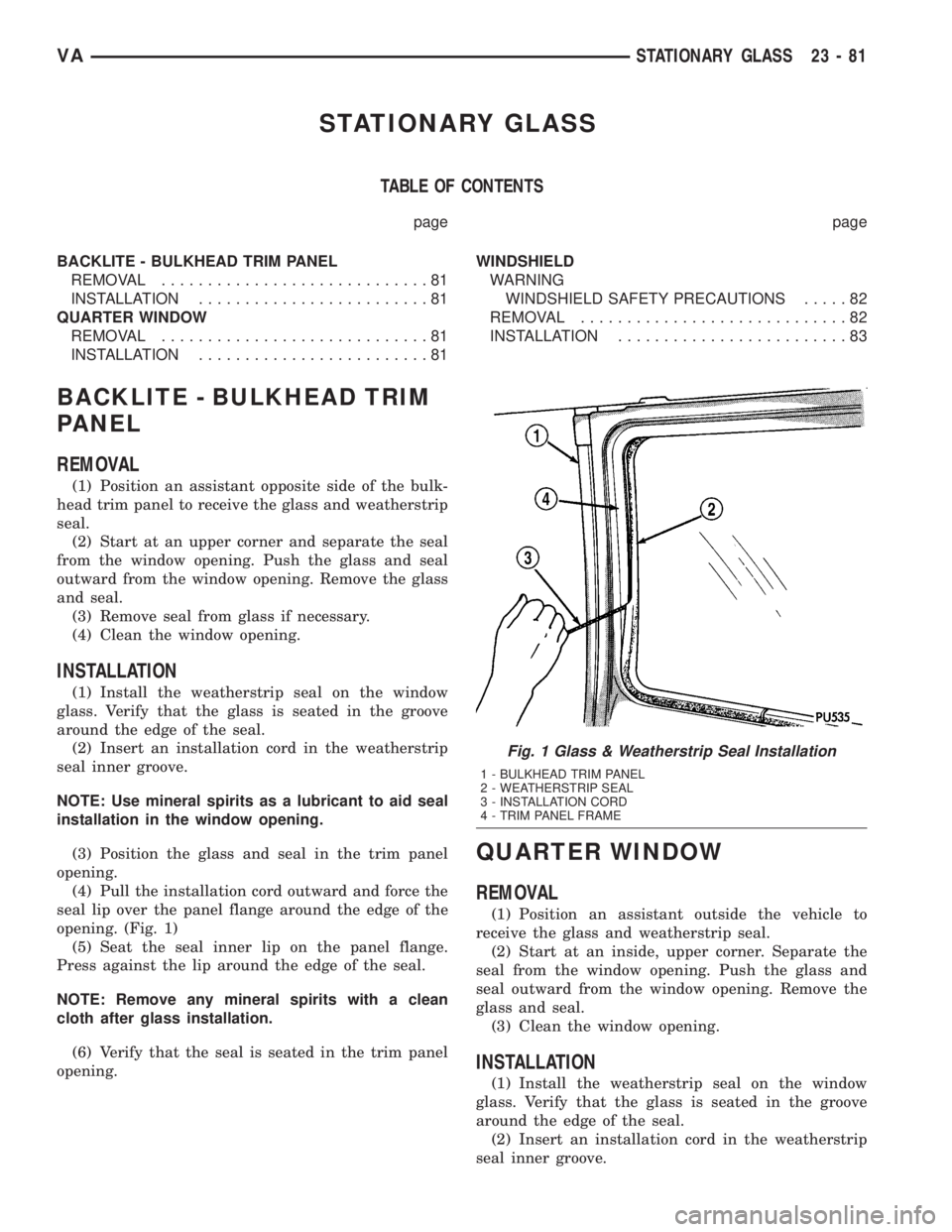

INSTALLATION

(1) Install the weatherstrip seal on the window

glass. Verify that the glass is seated in the groove

around the edge of the seal.

(2) Insert an installation cord in the weatherstrip

seal inner groove.

NOTE: Use mineral spirits as a lubricant to aid seal

installation in the window opening.

(3) Position the glass and seal in the trim panel

opening.

(4) Pull the installation cord outward and force the

seal lip over the panel flange around the edge of the

opening. (Fig. 1)

(5) Seat the seal inner lip on the panel flange.

Press against the lip around the edge of the seal.

NOTE: Remove any mineral spirits with a clean

cloth after glass installation.

(6) Verify that the seal is seated in the trim panel

opening.

QUARTER WINDOW

REMOVAL

(1) Position an assistant outside the vehicle to

receive the glass and weatherstrip seal.

(2) Start at an inside, upper corner. Separate the

seal from the window opening. Push the glass and

seal outward from the window opening. Remove the

glass and seal.

(3) Clean the window opening.

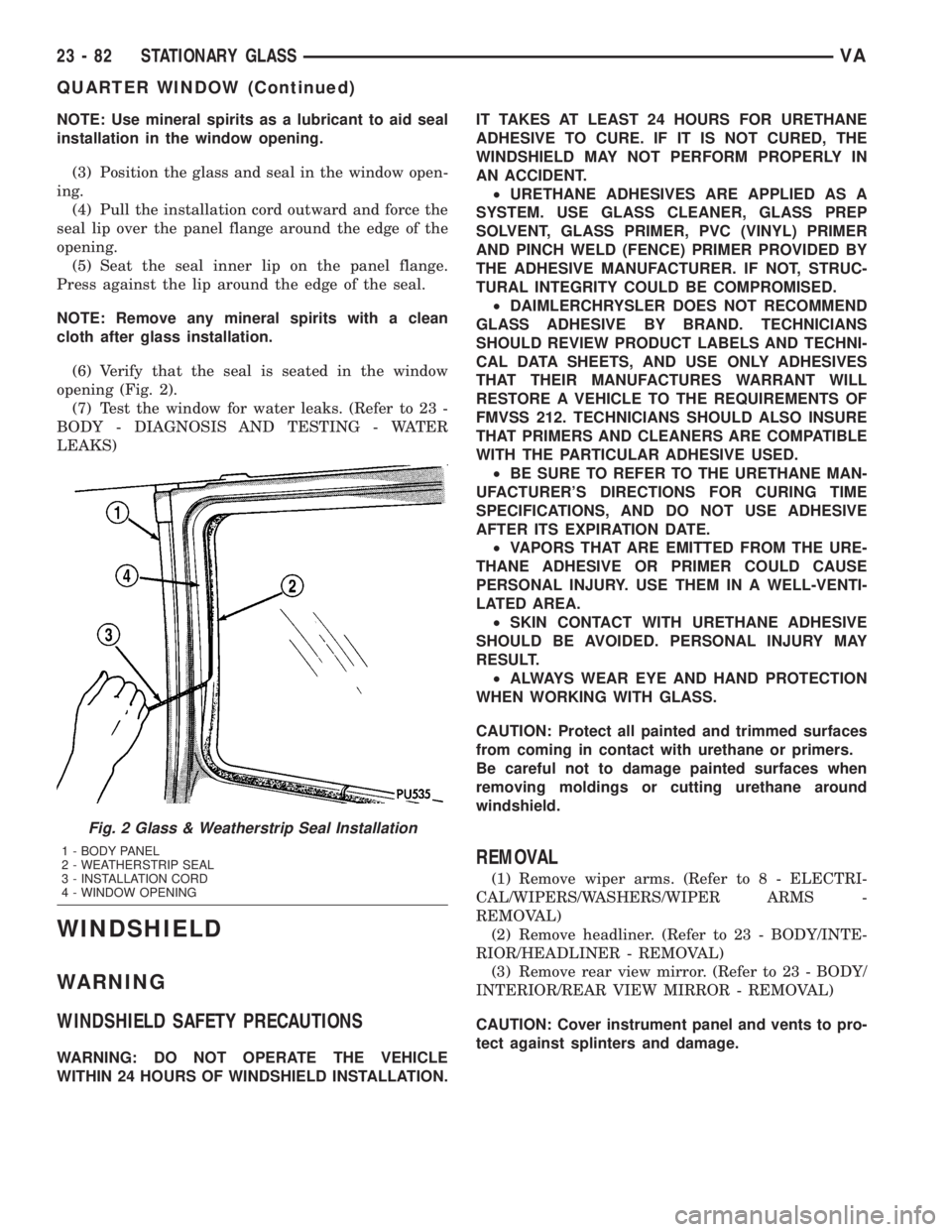

INSTALLATION

(1) Install the weatherstrip seal on the window

glass. Verify that the glass is seated in the groove

around the edge of the seal.

(2) Insert an installation cord in the weatherstrip

seal inner groove.

Fig. 1 Glass & Weatherstrip Seal Installation

1 - BULKHEAD TRIM PANEL

2 - WEATHERSTRIP SEAL

3 - INSTALLATION CORD

4 - TRIM PANEL FRAME

VASTATIONARY GLASS 23 - 81

Page 1120 of 1232

NOTE: Use mineral spirits as a lubricant to aid seal

installation in the window opening.

(3) Position the glass and seal in the window open-

ing.

(4) Pull the installation cord outward and force the

seal lip over the panel flange around the edge of the

opening.

(5) Seat the seal inner lip on the panel flange.

Press against the lip around the edge of the seal.

NOTE: Remove any mineral spirits with a clean

cloth after glass installation.

(6) Verify that the seal is seated in the window

opening (Fig. 2).

(7) Test the window for water leaks. (Refer to 23 -

BODY - DIAGNOSIS AND TESTING - WATER

LEAKS)

WINDSHIELD

WARNING

WINDSHIELD SAFETY PRECAUTIONS

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT.

²URETHANE ADHESIVES ARE APPLIED AS A

SYSTEM. USE GLASS CLEANER, GLASS PREP

SOLVENT, GLASS PRIMER, PVC (VINYL) PRIMER

AND PINCH WELD (FENCE) PRIMER PROVIDED BY

THE ADHESIVE MANUFACTURER. IF NOT, STRUC-

TURAL INTEGRITY COULD BE COMPROMISED.

²DAIMLERCHRYSLER DOES NOT RECOMMEND

GLASS ADHESIVE BY BRAND. TECHNICIANS

SHOULD REVIEW PRODUCT LABELS AND TECHNI-

CAL DATA SHEETS, AND USE ONLY ADHESIVES

THAT THEIR MANUFACTURES WARRANT WILL

RESTORE A VEHICLE TO THE REQUIREMENTS OF

FMVSS 212. TECHNICIANS SHOULD ALSO INSURE

THAT PRIMERS AND CLEANERS ARE COMPATIBLE

WITH THE PARTICULAR ADHESIVE USED.

²BE SURE TO REFER TO THE URETHANE MAN-

UFACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE

AFTER ITS EXPIRATION DATE.

²VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY. USE THEM IN A WELL-VENTI-

LATED AREA.

²SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED. PERSONAL INJURY MAY

RESULT.

²ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted and trimmed surfaces

from coming in contact with urethane or primers.

Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

REMOVAL

(1) Remove wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS -

REMOVAL)

(2) Remove headliner. (Refer to 23 - BODY/INTE-

RIOR/HEADLINER - REMOVAL)

(3) Remove rear view mirror. (Refer to 23 - BODY/

INTERIOR/REAR VIEW MIRROR - REMOVAL)

CAUTION: Cover instrument panel and vents to pro-

tect against splinters and damage.

Fig. 2 Glass & Weatherstrip Seal Installation

1 - BODY PANEL

2 - WEATHERSTRIP SEAL

3 - INSTALLATION CORD

4 - WINDOW OPENING

23 - 82 STATIONARY GLASSVA

QUARTER WINDOW (Continued)